Intel

Latest about Intel

GPU price tracking 2026: Lowest price on every graphics card from Nvidia, AMD, and Intel today

By Stewart Bendle last updated

Check the best prices on Nvidia RTX and AMD Radeon graphics cards.

Intel clawed back CPU market share from AMD in the Steam Hardware survey for the first time in months

By Mark Tyson published

After months of consistent decline, Intel’s consumer CPUs have enjoyed a small but significant spell of market share growth, at least according to the latest Steam Hardware Survey.

RAM Price Index 2026: Lowest price on DDR5 and DDR4 memory of all capacities

By Zhiye Liu last updated

Check the best prices on DDR5 and DDR4 memory kits of different capacities.

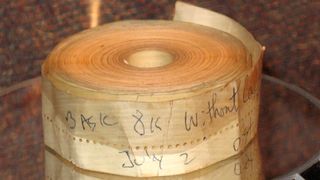

‘Most of you steal your software’ — Bill Gates complained about software piracy 50 years ago

By Mark Tyson published

50 years ago ‘An Open Letter to Hobbyists,’ typed by William Henry Gates III, bellyached about software piracy among the hobbyist community.

Intel returns to boxed workstation CPUs with Xeon 600 — Granite Rapids WS delivers up to 86 cores, 4TB of memory, and 128 PCIe 5 lanes

By Jake Roach published

Intel is returning to desktop workstations with Xeon 600. Granite Rapids WS CPUs deliver up to 61% better multi-threaded performance, according to Intel, sporting up to 86 cores and 4TB of memory.

AMD adopts FRED together with Intel for Zen 6 architecture

By Bruno Ferreira published

AMD adopts FRED together with Intel for Zen 6 architecture

The Intel 286 CPU was introduced on this day in 1982

By Mark Tyson published

44 years ago, this crafty collection of 134,000 transistors would mark a major inflection point in the PC industry.

Best SSDs 2026: From blazing-fast M.2 NVMe down to budget SATA

By Paul Alcorn last updated

We recommend the best SSDs for every need and budget based on our extensive lab tests.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.