HeyGears brings together precision and speed with the UltraCraft Reflex RS

3D printing has become cemented into multiple facets of manufacturing and creative processes. From the at-home enthusiast who uses 3D printing to create unique character models for tabletop games to the professional printer who creates customized prosthetics or dental implants, the only limit to our use of 3D printing is our own imaginations. HeyGears, an industry leader in professional-grade 3D printing equipment, is bringing precision and speed together with their newest 3D printer: the UltraCraft Reflex RS.

Built for precision and speed

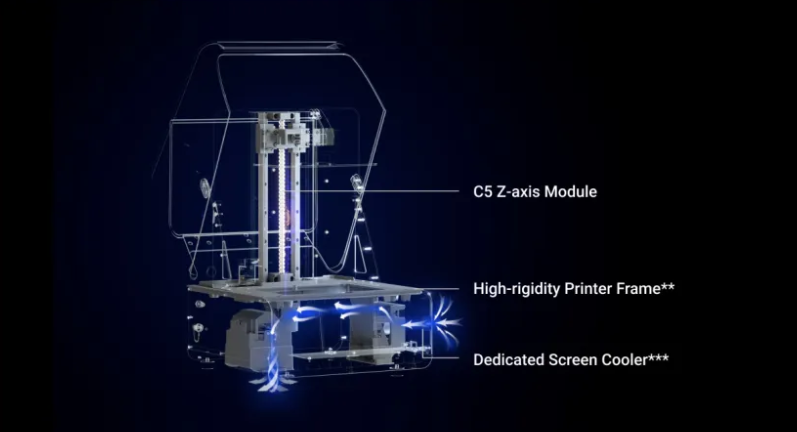

The UltraCraft Reflex from HeyGears is often championed as one of the best 3D printers in its class, offering a high-quality end-to-end 3D printing experience alongside superb levels of detail and excellent material performance for final prints. The newest addition to that printer series, the UltraCraft Reflex RS, builds upon its predecessor's success and pushes the 3D printing process forward with high precision matched with rapid printing capabilities, while also providing an easy-to-use experience. The UltraCraft Reflex RS adheres to industrial-grade C5 Z-axis standards, for precise printing, and ensures long-term reliability having undergone 50KG high load tests over 10,000 runs. The adaptive z-axis compensation of the UltraCraft Reflex RS is capable of accommodating different model angles, sizes, and edge types while printing refined models with near-invisible layer lines.

As important as good-looking final prints and adaptive printing options are, speed also matters in 3D printing. The high-speed printer design of the UltraCraft Reflex RS increases printing speeds up to 33% thanks to Hey Gears’ Dynamic Motion Algorithm 3.0. This 7-stage motion control logic reads real-time data from the printers’ force sensors up to 80 times per second, adjusting the printing speed as necessary to prevent errors and misprints. By reducing the risk of layer misalignment, detachment issues, and redundant time, you can ensure your 3D prints are of professional quality without wasting materials and precious time. Prints can be finished and ready to go in as little as 2 hours when using PAWW10 and printing a model with 50μm print layer thickness at less than 7 cm tall. Print times may vary depending on the model, but print results are comparable to that of injection molded parts.

Professional grade meets easy-to-use printing

With the rise of desktop 3D printers, more people than ever have had the opportunity to launch into prototyping and manufacturing for themselves. While the printers have become more attainable than ever, the process of getting started with 3D printing can still be a barrier to entry for many. Often, the more professional a printer, the more technologically inclined the user needs to be. HeyGears seeks to remove these barriers, however. With the UltraCraft Reflex RS, even a beginner printing enthusiast can get started with their first project in just 15 minutes.

The UltraCraft Reflex RS offers a fully automated 3D printing process that can be initiated by the user and completely set up in just one minute. By using HeyGears Blueprint software for the pre-processing stage, you can benefit from automated features such as auto model repair. You can improve print success rates by detecting defects like inverted normals, holes, and intersecting shells that can prevent slicing and cause other print deformities. One-click slicing can automatically run the entire process, requiring minimal intervention from a new user who may otherwise feel overwhelmed by 3D printing. HeyGears continues to support the evolution of the UltraCraft Reflex algorithms and automation, having iterated the auto-support algorithm 19 times so far to ensure drop rates of less than 1%.

Maintaining your printer is as easy as using it. The UltraCraft Reflex RS features a mechanical monitoring system with a main spindle force sensor and four under-screen force sensors. The sensors detect residual resin as small as 0.2 mm in height and then alert the user of abnormal conditions. The device can also stop the print to minimize the risk of errors or print failure. Each print is completed with a generated report that provides a review of the printing process, pinpointing issues to easily make the necessary adjustments prior to the next print. A 0.15-degree floating screen system provides automatic leveling before each print, eliminating gaps and preventing detachment during the printing process.

Compatible with a variety of resins

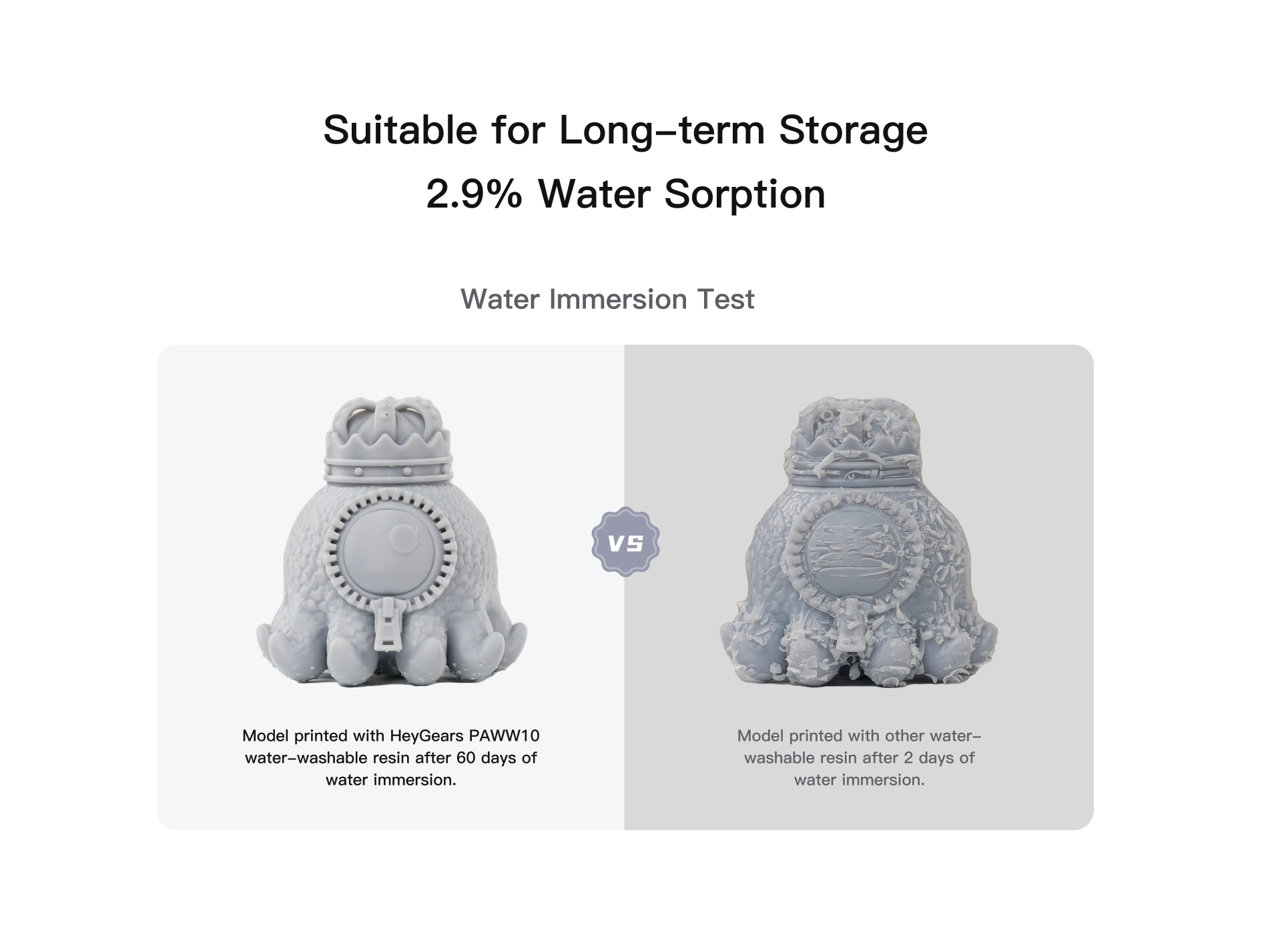

3D printing needs vary greatly depending on whether you’re a professional or a hobbyist, and each print can have specific needs for the resin used to print it. HeyGears has expanded the line of resins available for the UltraCraft Reflex RS to cover all of your printing needs. UltraPrint PAWW10 resin, for example, is highly durable with strong forming capability and features a low water sorption rate of just 2.9% that makes it perfect for printing figures and miniatures. It is a water washable modeling resin, and ideal for customers who may be sensitive to the smell of alcohol commonly used with washing other resin types. UltraPrint PAS10 is a standard modeling resin with a matte finish ideal for miniatures. It ensures precision with a tolerance of ≤0.5 mm, making it a reliable option for users prioritizing accuracy and finish.

Regardless of your printing needs, you can trust the UltraCraft Reflex RS and compatible resins are going to provide the professional quality results you want in an easy-to-use, precise and fast device that pushes the boundaries of what 3D printing can be.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.