Tom's Hardware Verdict

The Kobra 3 Max Combo is a super-sized printer with a four-color spool system that delivers on both quality and speed. Bed adhesion is still a little dicey, but easily addressed with a bit of glue stick or a plate upgrade.

Pros

- +

Massive build size

- +

Color

- +

Excellent auto-leveling

- +

Active filament drying while printing

Cons

- -

Massive footprint

- -

No camera for AI

- -

Wastes filament in color mode

Why you can trust Tom's Hardware

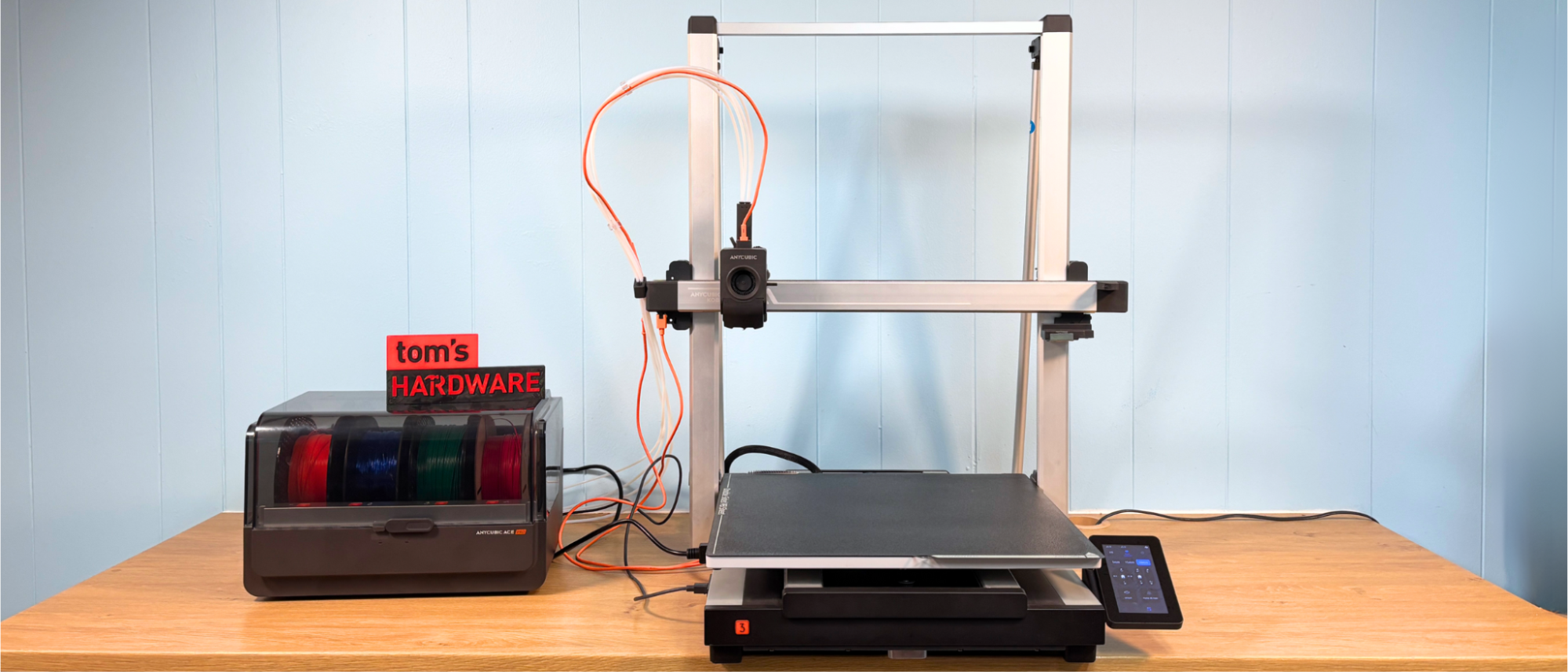

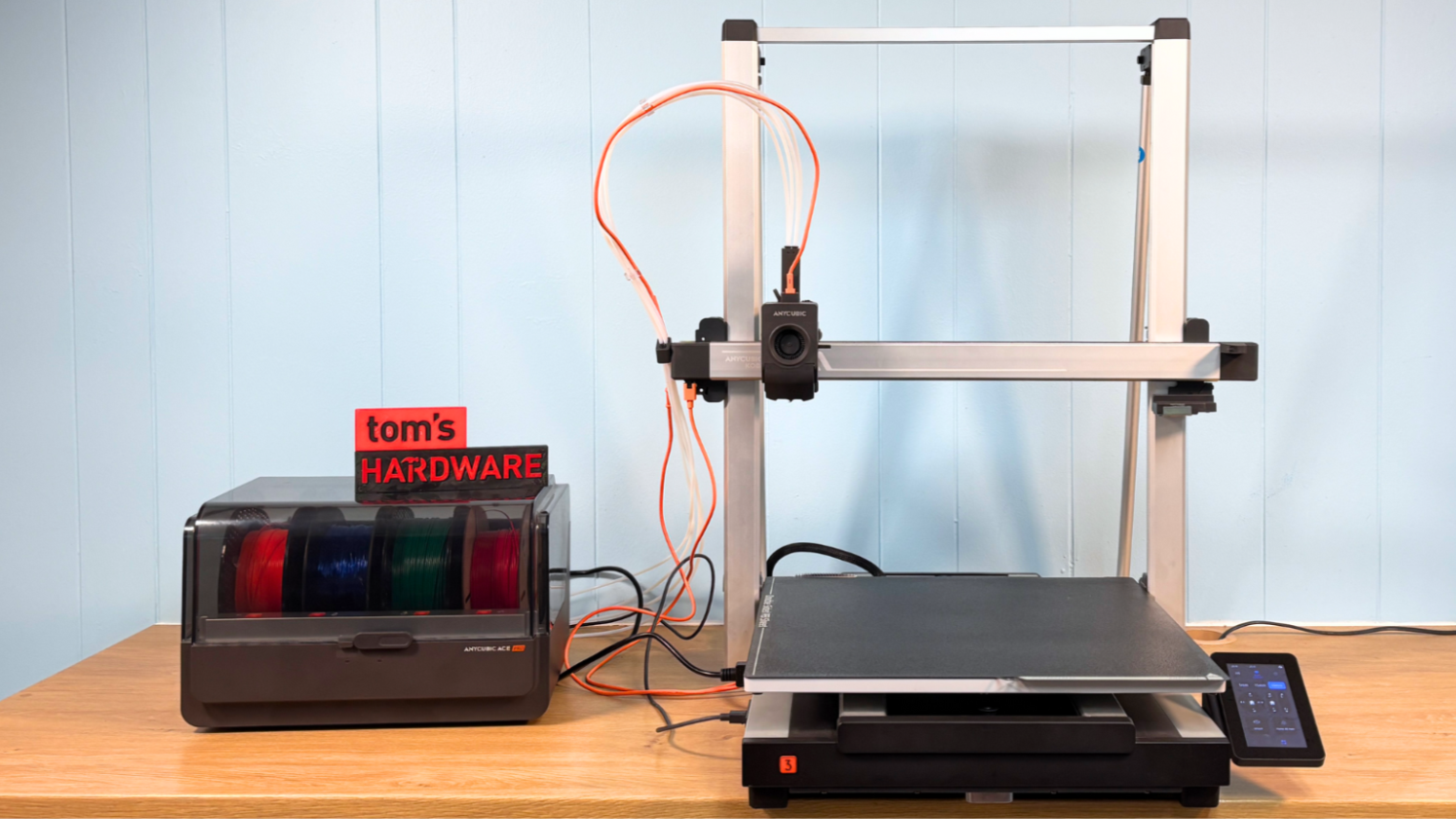

At the time of this review, there are few 3D printers that can compare with the Anycubic Kobra 3 Max. The printer itself is a massive improvement over the Kobra 2 Max, with reliable auto leveling, input shaping, and decent speed. The new slicer is well designed and makes four-color printing with the ACE (Anycubic Color Engine) Pro simple. It’s also the biggest multicolor 3D printer on the market, with competition slow to catch up.

It didn’t look this good when the Kobra 3 Max Combo showed up at my workshop with buggy software. I won’t go into detail on all the things wrong with it, but I will say that if you already bought this machine, you will need to run an update, pronto.

The Kobra 3 Max is a massive beast of a machine just like its predecessors. Its custom “no-its-not-Klipper” operating system does a good job at input shaping, but with a bed the size of a coffee table, you can’t expect Bambu-level speeds. It is much faster than the first Marlin Kobra Max, with a cruising speed of 200 mm/s and acceleration maxing out at 5,000 mm/s².

Its high-flow hotend still wastes a good bit of filament on color swaps, but at least the slicer software now has the means to reduce waste by using purge objects and tuning the amount of filament pushed out between color changes. These updates, as well as the printer’s overall performance during testing, put the Kobra 3 Max Combo on our list of best 3D printers.

Specifications: Anycubic Kobra 3 Max Combo

Build Volume | 420 x 420 x 500mm (16.5 x 16.5 x 19.7 inches) |

Material | PLA/PETG/TPU (up to 300 degrees) |

Extruder Type | Direct Drive |

Nozzle | .4mm Proprietary High Flow |

Build Platform | Textured PEI steel flex plate, heated |

Bed Leveling | Automatic + Z height |

Filament Runout Sensor | Yes |

Connectivity | USB, LAN, Wi-Fi through the app |

Interface | Color Touch Screen |

Machine Footprint | 706 x 640 x 753 mm (27.7 x 25.2 x 29.6 inches) |

Machine Weight | 19 KG (41.8 lbs) |

Included in the box: Anycubic Kobra 3 Max

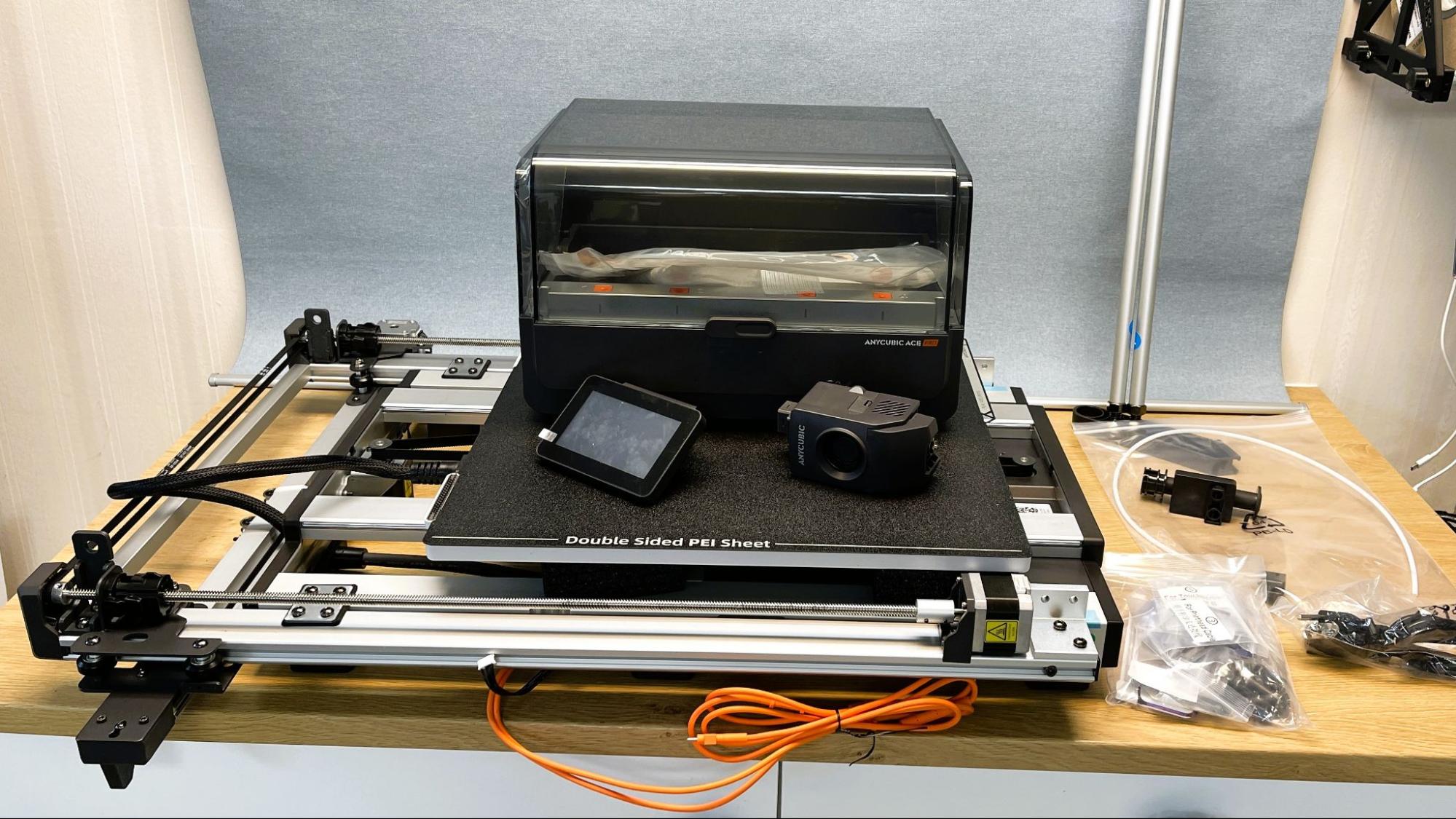

The Anycubic Kobra 3 Max Combo comes with everything you need to get started: tools to build and maintain the printer, grease, a USB stick, and a small sample of PLA.

There’s a paper copy of the quick start guide to help you build the printer. The printer has sample models already loaded, and the USB card has a PDF copy of the manual, Anycubic Slicer, and a profile for PLA to get you started.

Assembling the Anycubic Kobra 3 Max Combo

The Kobra 3 Max comes with the base bolted to the frame, and must be unlocked by removing ten screws from the top and bottom of the gantry. The gantry slots into the extrusions on the base and is easily held in place while attaching it with three screws on each side. The support rods are marked left and right and are simply attached with four more screws.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

The wiring is clearly marked and just has to be plugged in. Then you can attach the print head to the X carriage with four bolts. This is the trickiest part of the assembly, as it’s easy to miss holes and have a bolt fall between the carriage and the gantry.

The orange print head cable is a USB-C and is screwed into place – this doesn’t need to be super tight, and it is easy to strip the plastic threaded holes.

The touchscreen has a connector and slips into place without cables, which is awesome. You then screw it into place.

Since the review unit included the ACE Pro, I did not bother to install the included single spool holder, which can be used for softer TPU.

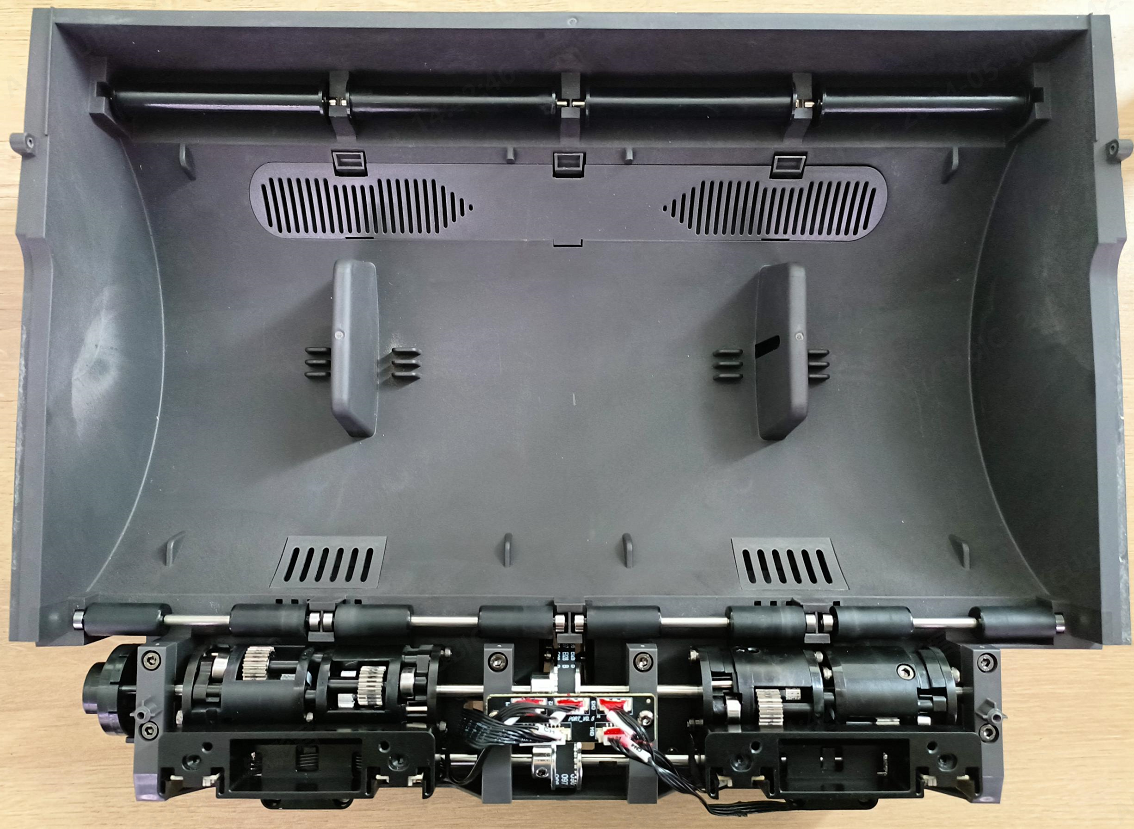

The printer is designed so that it can be sold as either a single color or a combo. This means the filament cutter and purge wiper must be installed, and the single filament hub replaced with a four-color hub. After plugging the ACE Pro to the printer, you can connect the four Bowden tubes.

Leveling the Anycubic Kobra 3 Max Combo

Bed leveling is completely automatic on the Anycubic Kobra 3 Max and works extremely well. It is part of the initial calibration suite and is offered with every print. If I did not need to really jostle the printer to get the flex plate off for the prior print, I did not always re-level. The printer screen does throw a warning if you choose not to level, but it can be ignored.

Loading Filament in the Anycubic Kobra 3 Max Combo

I used the ACE Pro to handle all the filament used in this review. You simply need to feed filament into an unused slot on the ACE Pro, then assign the color and filament type on the printer’s screen. At that point, it is ready to go. Since the ACE Pro does not have individual extruder motors for each slot, you need to give each spool a moment to load before moving to the next or misfeeds can occur. Also, it can take several tries to load in slots 3 and 4. If it does not load, I found pulling the filament out and trying again was all that was needed.

Design of the Anycubic Kobra 3 Max Combo

The Anycubic Kobra 3 Max has the same modern vibes as the smaller Kobra 3 machines. It has a sleek aluminum finish and orange accents. The toolhead shroud shows off its large blower fan for cooling, while discreetly hiding the smaller fan for the heat break on the left-hand side. Both were adequate for the job.

The Combo comes with a four-color material handler, similar in style to Bambu Lab’s original boxy AMS units. Each spool gets its own dedicated Bowden tube from spool to tool head, with the hub mounted directly on top, similar to a Bambu A1 bed slinger. Unlike Bambu Lab, the ACE (Anycubic Color Engine) Pro has a heater that will run while the machine is in use.

The Kobra 3 Max is a reasonably quiet machine at 60dB in standard mode. In many situations, the ACE Pro running with the filament dryer active is louder. You can switch to quiet mode from the workbench, which will also slow the printing speed, but I didn’t see the need to try that.

Dual Z motors have become pretty standard on larger printers, but dual Y-axis motors for the bed are unusual and most welcome for large, hefty prints. The hardware of the Kobra 3 Max is first rate, but sadly, the camera is an optional item you’ll have to add if you want to turn on AI detection.

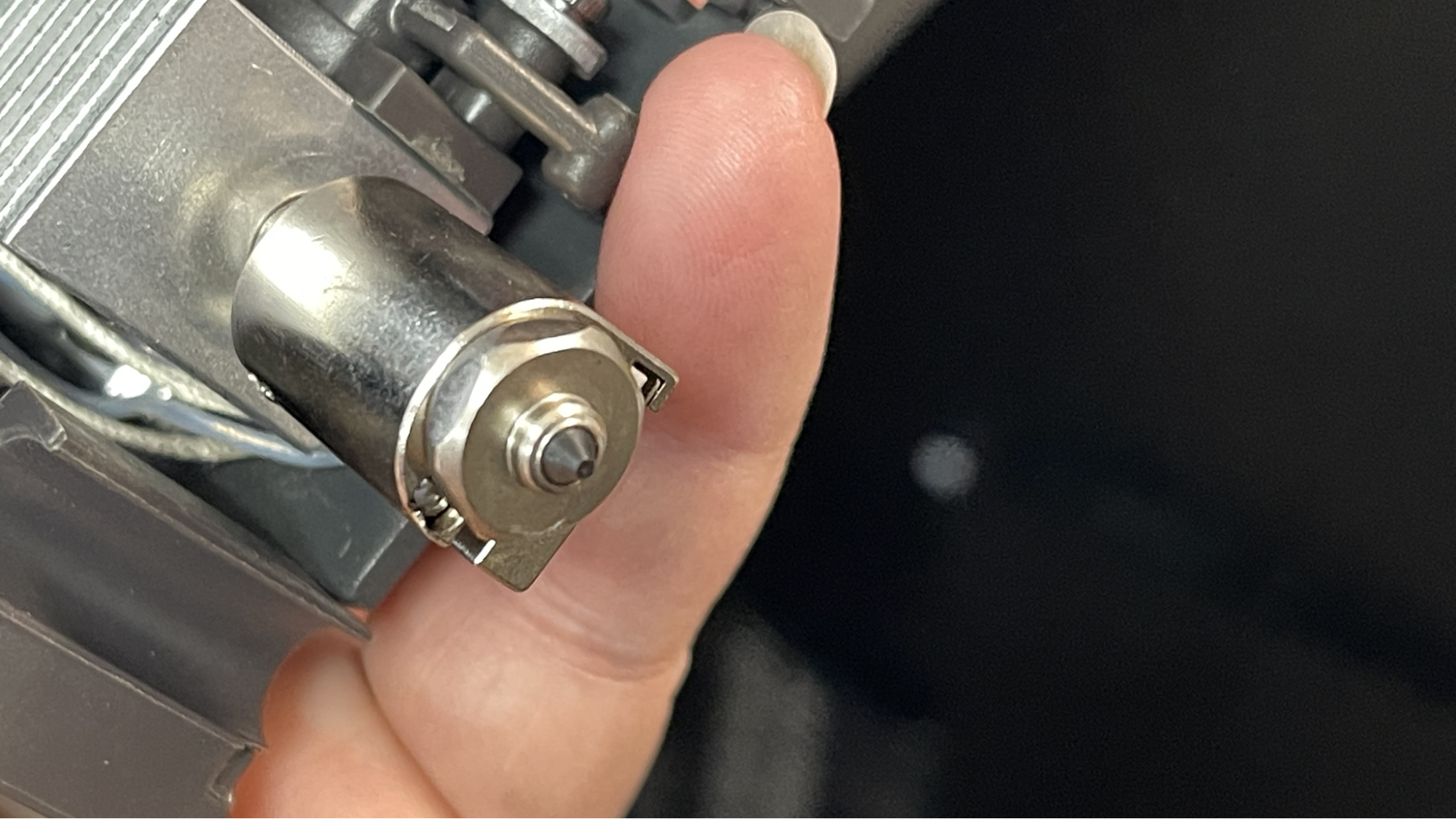

The nozzle has a quick release with a lever that lets you slide it out without having to unplug either the heater or thermistor. The nozzle included with the Kobra 3 Max appears to have a hardened steel tip, which wasn’t mentioned in the specs.

The toolhead cutter is removable to expose the usual point of extruder clogging. In over 600 hours of print time, the one clog I had was cleared by removing the nozzle and cutter. I never had to dig further into the extruder than that.

The Anycubic Kobra 3 Max runs proprietary firmware called Kobra OS. It is closed source and allows no access to the config files and no access to the machine via SSH. Having said all that, it works fine in practice.

The 4.3 inch color touchscreen is bright and responsive with an intuitive interface. Material selection must be done from the screen, with the only drawback being a very limited color palette to choose from. If you have multiple shades of the same color, they can be changed in the slicer, but you may want to take a picture of the ACE Pro before moving on to your slicer.

Preparing Files / Software

The Anycubic Kobra 3 Max comes with a copy of Anycubic Slicer Next, which is based off Orca Slicer. The software updated several times during the testing phase of this unit. I actually had to throw out an early draft of my review because changes to the purge handling were so significant it radically altered my opinion of the machine.

As of this review, the slicer is nearly identical to Bambu Studio or Orca Slicer. The only thing missing is the ability to adjust the purge on individual colors. This is a huge improvement over the first release, as seen in the original Kobra 3 Combo, which lacked any control over the purged filament. You can now manage your filament waste by purging into the infill, a separate purge object, or changing the total volume of filament cleared out of the nozzle. This wasted filament occurs when swapping colors, as the material already melted in the nozzle is forced out rather than pulled back through the cold section and risking a clog.

Anycubic has a mobile app to accompany its printers, but I did not find it personally very useful. Beginners may enjoy being able to send files directly to the printer from Anycubic’s Maker Online website, but I prefer to use my PC. It can be used to monitor prints and run time lapses, which requires the optional camera.

Printing with the Anycubic Kobra 3 Max Combo

Big printers mean big prints, so knowing where to get the best filaments for 3D printing is essential. The Kobra 3 Max only came with a sample coil, so you’ll want to stock up immediately.

At the start of each print you have the option to level the bed, enable a quick resonance compensation routine, enable dynamic flow compensation, and turn on the filament dryer while printing. In most cases, I did all of the above when printing PETG and older PLA spools that might have become brittle.

The build plate was not 100% reliable for prints past 12 hours long, so I needed to slather it in gluestick for insurance. It would greatly benefit from a super sticky build plate.

I started off testing with a normal-sized Benchy. The printer came with an 18-minute Benchy test print, but I was only able to replicate it at 28 minutes and 9 seconds. My print used Speed Boat Rules (2 walls, 3 top and bottom layers, 10% grid infill, a 0.25 layer height, and 0.5 layer width) and the printer’s default settings. The quality was quite good, with just a little roughness on the hull. This was printed in Matterhackers Build Series Black PLA.

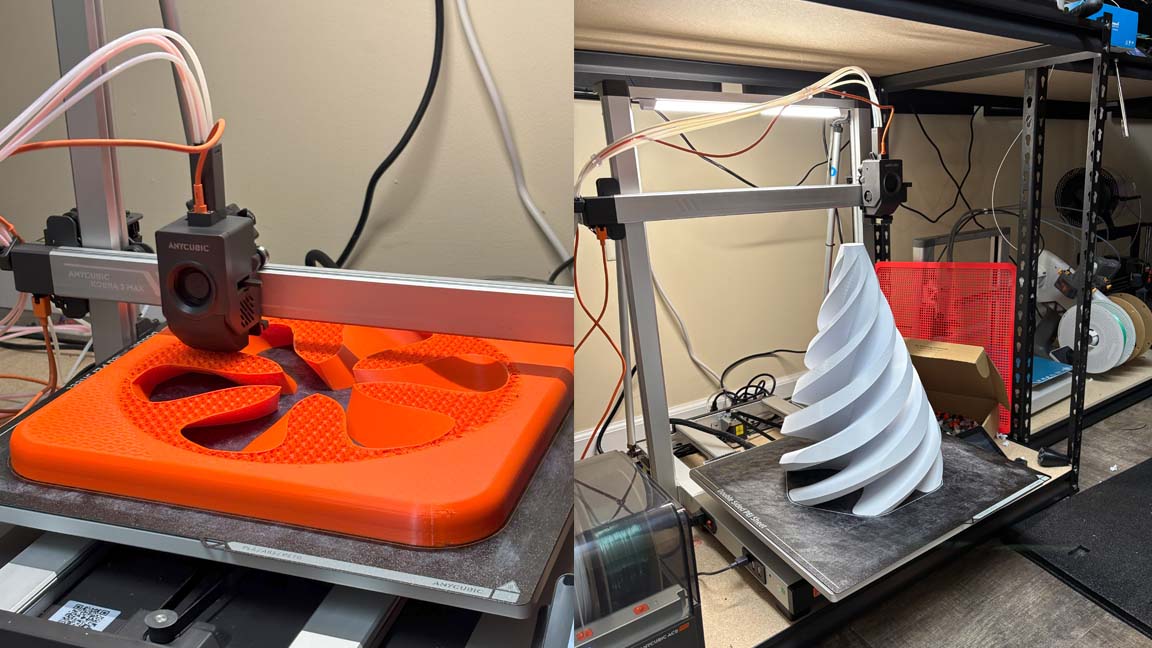

I printed a number of things on the Max, including this TPU “backstop” that I needed to mount next to the printer to keep it from flinging filament poop onto its neighboring printers. The mechanical arm that removes waste filament can send filament blobs several feet unless properly contained. This print came out perfectly smooth without any stringing.

This print maxed out the bed and took 15 hours to complete at a 0.2 mm layer height, using default settings and an average print speed of 50 mm/s. Printed in Bambu Lab Red TPU for AMS.

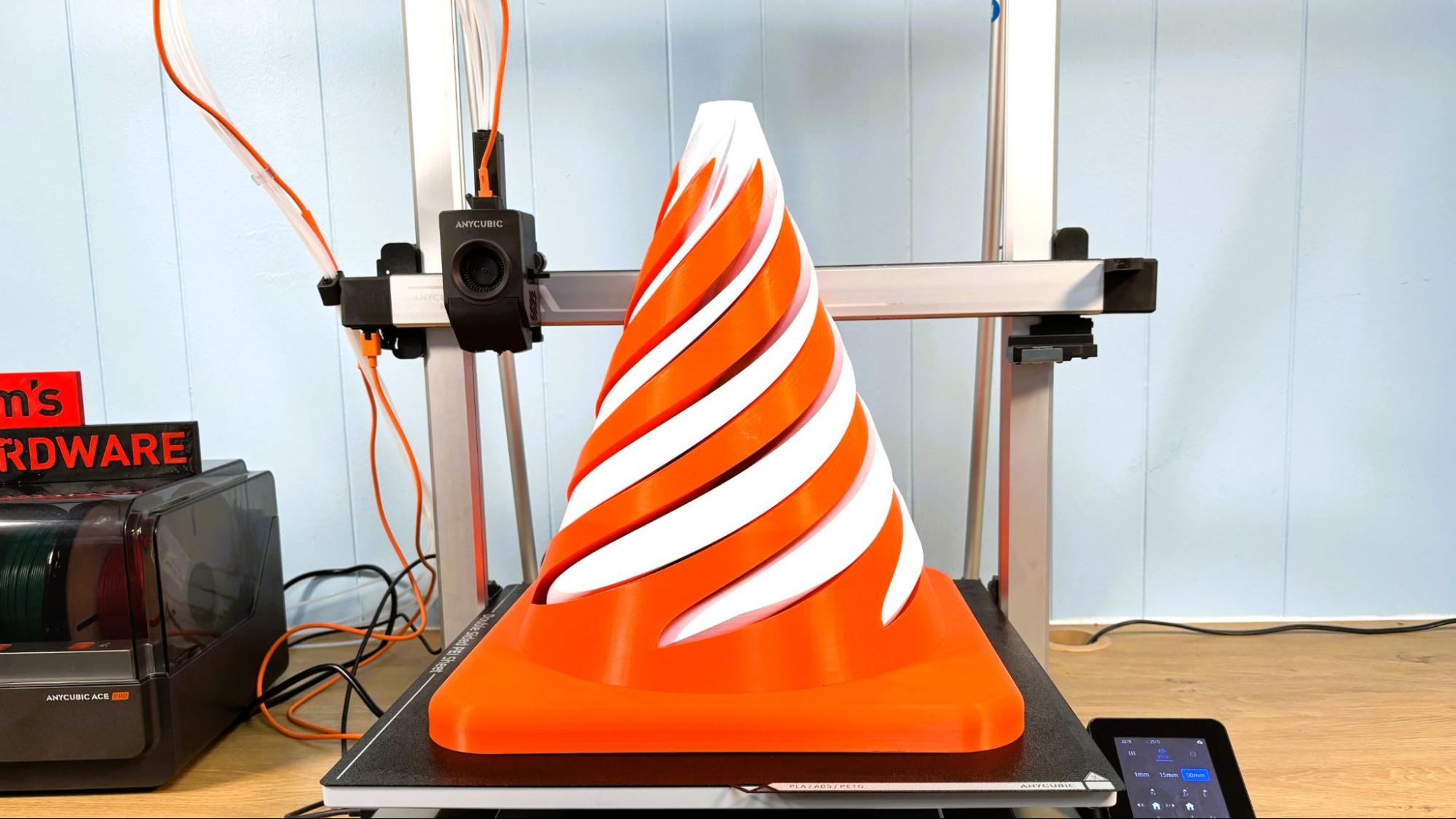

For PETG, we needed something big and fun, so we ran this life-sized traffic cone fidget. Each color had to run by itself, but it still took about three days total to print. Enlarging the print 1200% made the tolerances extremely loose and pushed its ability to bridge to the limits. The finished print is extremely smooth, with one small layer line from when I ran out of filament on the white and took too long to find a second spool.

This was printed with a 0.28 layer height, three walls, and default settings, with an average print speed of 130 mm/s. The larger orange print took 47 hours to print, while the smaller white portion took 37 hours. It used 1821 grams of orange Prusament PETG and 1395 grams of white Inland PETG from Microcenter.

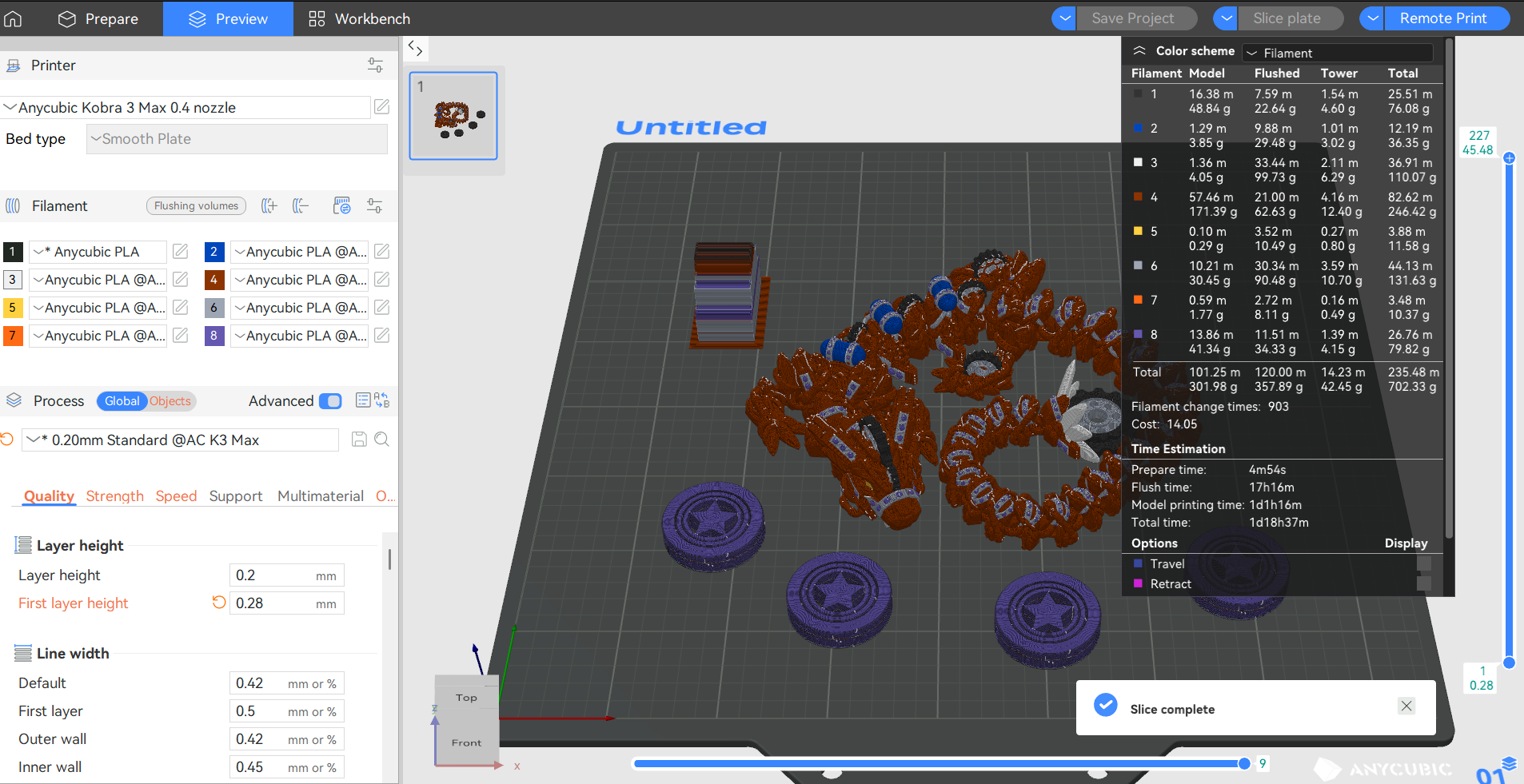

The Kobra 3 Max can run eight colors when you hook up another ACE Pro, so I rummaged around for eight spools of PLA. To do this, we had to print a new eight-color hub to replace the standard one and feed eight tubes into the toolhead.

Unfortunately, the first dragon was printed before the slicer purge settings improved, so it wasted 820 grams of filament to make a 220-gram print. However, after the improvements, I ran the model through again, and it “only” flushed 357 grams of filament and gave me four 35-gram fidget spinners I used as purge objects.

This took 48 hours to print, using a 0.2 layer height and an average print speed of 75 mm/s. There were 902 filament swaps. The filament was a wide variety of odds and ends, but the primary base color was Bambu Lab’s Bronze PLA.

Bottom Line

The Anycubic Kobra 3 Max Combo is a massive machine, understandably priced at $999 and currently on sale for $649. It’s the best max-sized bed slinger I’ve had in a long time with reliable, fully automatic bed leveling. The build plate is not the best, but is easily replaced if you don’t want to burn through a few glue sticks. If you want to print big and with a pop of color, this machine is very good.

I’m glad this review was delayed because it gave Anycubic a chance to update its software, which was only half-cooked on launch day. With the updated software, this machine cuts down the wasted filament of the original Kobra 3 printer easily by half.

If you want a massive printer that works great out of the box, the Elegoo Neptune 3 Max is still a good single-color machine, and quite a steal at $350. If money is no object, and you want a higher quality large-format color printer, then you should check out the Prusa XL toolchanger, which costs $3,499.

Denise Bertacchi is a Contributing Writer for Tom’s Hardware US, covering 3D printing. Denise has been crafting with PCs since she discovered Print Shop had clip art on her Apple IIe. She loves reviewing 3D printers because she can mix all her passions: printing, photography, and writing.