Best Multicolor 3D Printers of 2025: Print the Rainbow

Don’t be boring. Add some color to your 3D printing workflow.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

You are now subscribed

Your newsletter sign-up was successful

The competition for the best multicolor 3D printers continues to heat up. Now more than ever, consumers have more choices when it comes to 3D printing in color.

If multicolor isn't your top priority, check out our list of the best 3D printers overall and our best budget 3D printers for cost-effective, beginner-friendly options.

Bambu Lab didn’t invent multicolor 3D printing but made it reliable, accessible, and fairly affordable with its AMS (Automatic Material System). Before the launch of the X1-Carbon in 2022, we may have seen the occasional two-headed IDEX printer or expensive color add-on devices, such as the Mosaic Palette 3 Pro. However, these machines were often inaccurate and difficult to dial in. Only Prusa Research persisted with its MMU system and finally launched a reliable “full color” mod for its 3D printers.

Anycubic Kobra 3 with ACE was the first to clone Bambu Lab’s AMS. And Creality released its four-color Core XY with CFS late this year. Many others will surely follow.

The much-awaited update to the P1S, the Bambu Lab P2S, was launched in October. However, its U.S. release was delayed by about a month due to tariff issues. The P2S is now available to buy in the U.S. for $549 and $799 for the P2S Combo with AMS 2 Pro.

Not all multicolor printers are created equal. We’ve tested and compared some of the best on the market to help you make an informed buying decision. Below, you will find a list of the best Multicolor 3D Printers.

Quick List

AMS compatible with Bambu Lab X1-Carbon and P1P

The Bambu Lab P1S AMS combo is a powerful multicolor printing machine. It has four filament slots available and supports up to 16 colors. It runs at amazingly fast speeds, is reliable, and is easy to use. It's a great choice for anyone who wants to try color 3D printing for the first time or start a print farm. It costs $699 by itself and $899 for the combo ($200 cheaper). You can find it on sale at the Bambu Lab online store or at a Micro Center near you.

Also compatible with Bambu Lab A1

The Bambu Lab A1 Mini with AMS Lite is a small but mighty color machine that is great for novice users and is kid-friendly. It is super easy to set up, and you'll get almost perfect prints each time. It also runs as fast as the P1S but for $500 less. If you can live with a smaller build volume, then the A1 mini with AMS Lite is worth considering. Available directly from the Bambu Lab site, Micro Center, and Amazon.

Compatible with Prusa Research MK3S+ and MK4S

Not for the faint of heart, the MMU3 requires an experienced maker to install and use. It's an add-on tool for Prusa 3D printers, enabling 5-color printing using a single extruder. It's an awesome mod if you are up for the challenge. As per our testing results, it outputs clean results with very little waste, which makes it eco-friendly than other multicolor 3D printers on the market. Available at Amazon and at Prusa Research.

Show More ⬇️

Built into the Prusa XL Tool Changer

Designed for multicolor and multi-material printing, the Prusa XL allows you to effortlessly combine PLA and PETG filaments in your print jobs. However, this convenience does come at a premium. You can buy the XL semi-assembled for $1,999 with a single tool head or add up to five tool heads for a whopping $3,499.

AMS 2 Pro is compatible with Bambu X1 and P1 series

The H2D with AMS 2 Pro is the latest powerhouse combo from Bambu Lab. Designed for serious crafters, this amazing multicolor and multimaterial machine can support up to 24 colors, and its dual nozzle feature aims to help save filament waste. The H2D AMS Combo is available for a whopping $2,299. Alternatively, if you already have an X1 or P1, you can purchase the AMS 2 Pro separately for $359.

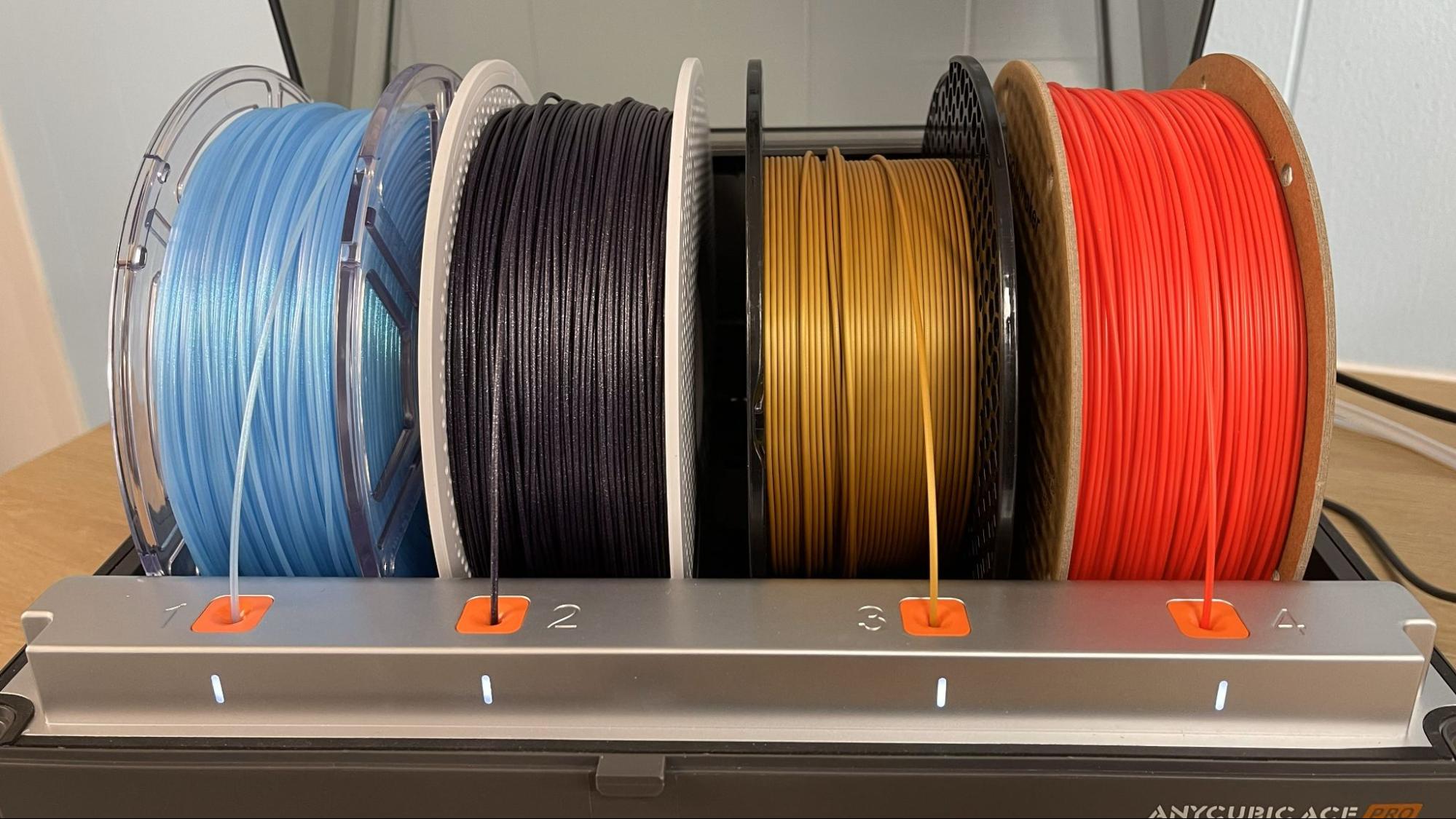

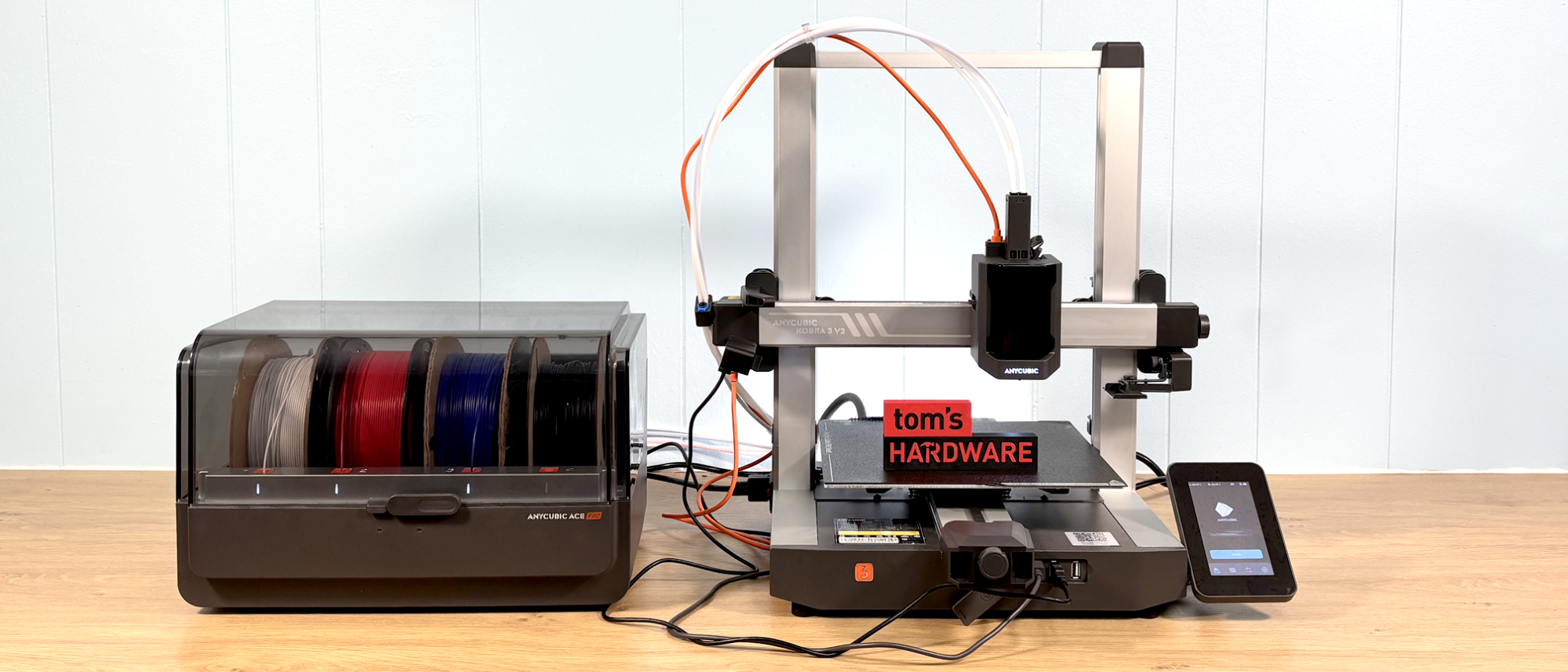

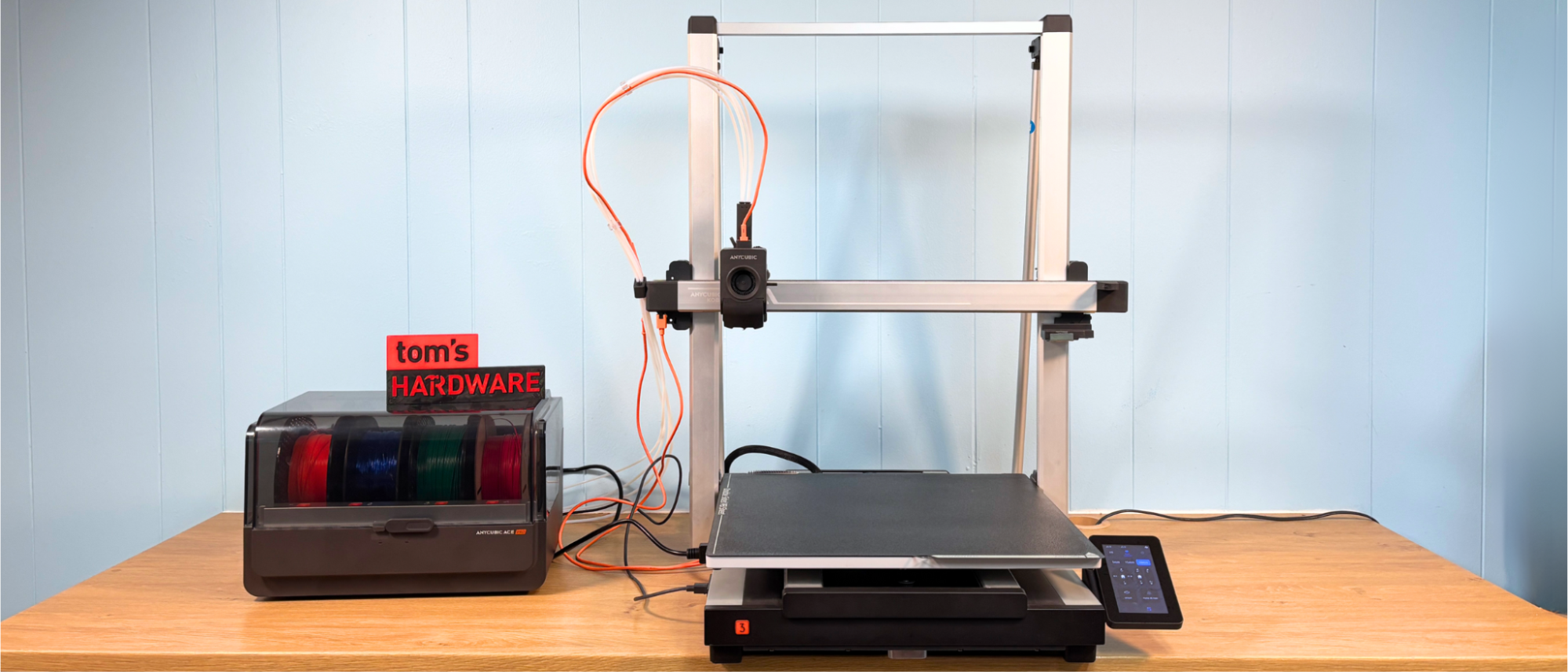

ACE - Only Compatible with Kobra 3

The Anycubic Kobra 3, paired with the ACE Pro system, enables high-quality prints in four to eight colors and doubles as a filament dryer during printing and storage. You can purchase ACE Pro separately for $289, or get the Kobra 3 combo for an affordable $349 and save $169.

Best Tool Changer Multicolor 3D Printer

This affordable Core XY tool changer from Snapmaker comes with four easy-to-swap tool changers, making color change quick and convenient, and supports multiple materials like PLA, PETG, TPU, and ABS. With a $999 price tag, the Snapmaker U1 costs half the price of the Prusa XL. It is available for $849 on pre-order at Snapmaker.

Best Large Format Multicolor 3D Printer

The Anycubic Kobra 3 Max is a reliable, large-format 3D printer that delivers on quality, speed, and color. It comes with a four-color ACE Pro system and a massive 420x420mm build plate, making it easy to print big projects like helmets and armor. It does a great job at input shaping and has excellent automatic bed leveling. Prop makers and cosplayers will love making with this machine.

Denise has been using 3D printing as a creative outlet since 2020 when she got her first Creality CR10s. She’s been a freelance newspaper reporter, online columnist and craft blogger with an eye for kid’s STEM activities. She’s added YouTube to her social media skills and has traveled cross county and overseas to talk 3D printing with fellow makers. She's analyzed nearly 100 different 3D printers, from a tote bag sized delta to a meter wide Elegoo OrangeStorm Giga currently camped out in her living room. When she’s not building 3D printed RC cars or stirring glitter into a batch of resin, you’ll find her at the latest superhero movie with her husband and two sons.

Best Multicolor 3D Printers You Can Buy Today

Why you can trust Tom's Hardware

Best Enclosed Multicolor 3D Printer

Specifications

Reasons to buy

Reasons to avoid

Bambu Lab’s AMS is the first of its kind and has introduced many to the world of multicolor printing. Most of the unit is enclosed in a neat shoebox-sized contraption that can sit on top of or next to your Bambu Lab P1S, X1-Carbon, or P1P. The P1S is an excellent choice for color 3D printing, as the enclosure allows it to print high-temperature filaments like ASA and ABS.

The AMS (Automatic Material System) comes fully assembled and only needs a few wires and tubes connected in order to work. Up to four AMS units can be daisy-chained together to achieve a 16-color print. The system is very user-friendly in the beginning, but maintenance requires a lot of patience to disassemble the machine. The tight bends in the tubing and the constant back-and-forth motion of the filament mean the Bowden tubes will wear out quickly, especially if you’re fond of glitter and other abrasive materials. I wore a hole in one Bowden tube within six months of use.

The Bambu Lab method of cutting filament at the cold part of the toolhead and pushing the rest through results in a lot of waste, affectionately called “printer poop.” This poop can be lessened with tuning in the slicer but can not be eliminated. Most consider this waste a fair trade-off for the convenience of colorful prints.

This method is also slower than others because of the time it takes to swap filament. I timed the swaps at one minute and 46 seconds due to the length of Bowden tube the material has to travel.

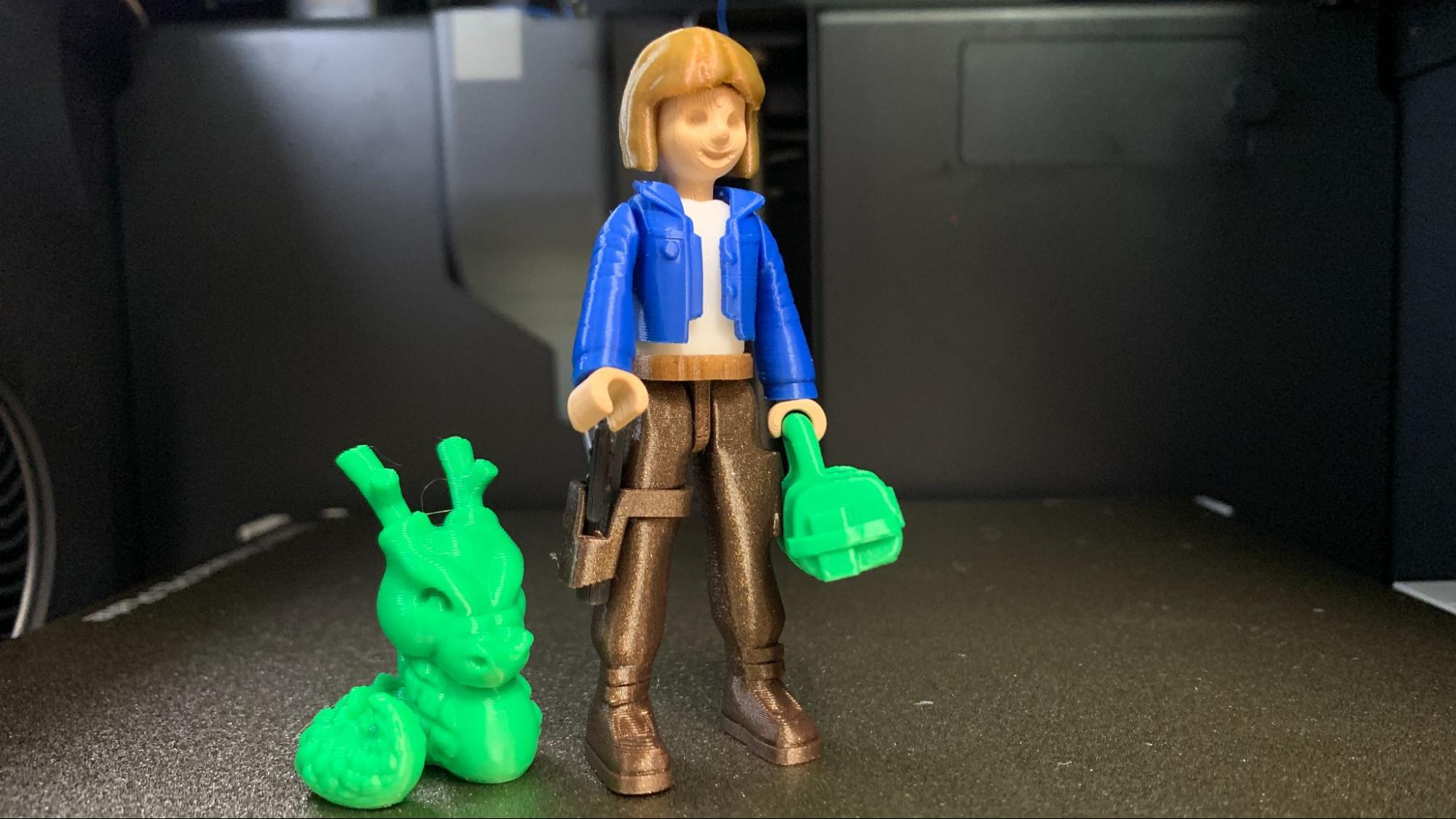

*️⃣ Test Print

PlayAction’s Kay Vess action figure shown above was made using Bambu green PLA, Inland Blue, Black, White, and Light Brown PLAs, Polymaker Starlight Jupiter (hair), and Protopasta Double Espresso (pants), each part printed individually on a shared plate.

The AMS works best with Bambu Lab filament, of which there is a large selection to choose from. Bambu Lab tags each spool with an RFID tag that allows the printer to identify the type and color of the material in the slicer. Many 3D party spools will also work in the AMS, but some spools – like Atomic or Prusament – are too wide. Cardboard spools can be problematic as they create dust that can clog up the mechanism and lack enough friction to work well on the motorized rollers. Members of the community have shared printable adapters to fix most of these problems.

Please note that the Bambu Lab AMS can not print TPU. TPU must be used on a separate, non-mechanical spool holder.

More: Bambu Lab P1S Review

Best Budget Multicolor 3D Printer

Specifications

Reasons to buy

Reasons to avoid

Anycubic Kobra 3 V2 is affordable, reliable and comes with a built-in filament drier to save you both money and table space. It has a camera for AI print monitoring, an improved, leak free hotend and a beefier frame.

It’s an “average” sized 3D printer, with a 255 x 255 x 260mm print volume, and a sweet $399 price tag that is $50 to $100 cheaper than the competition. The ACE Pro material handler is simple to use and easy to maintain. The Kobra 3 V2 uses a high flow hotend to produce excellent prints with an average speed of 200mm/s and input shaping to keep things crisp.

Anycubic Slicer Next is the real game changer. Based on Orca Slicer, it’s an easy-to-use, Open Source program with all the features you’d expect from a brand leader. It allows you to color your own models or use models colored in Bambu Slicer. It also has tools to fine tune your purge volume so you can cut back on wasted filament.

More: Anycubic Kobra 3 V2 Review

Best Multicolor 3D Printer for Beginners

Specifications

Reasons to buy

Reasons to avoid

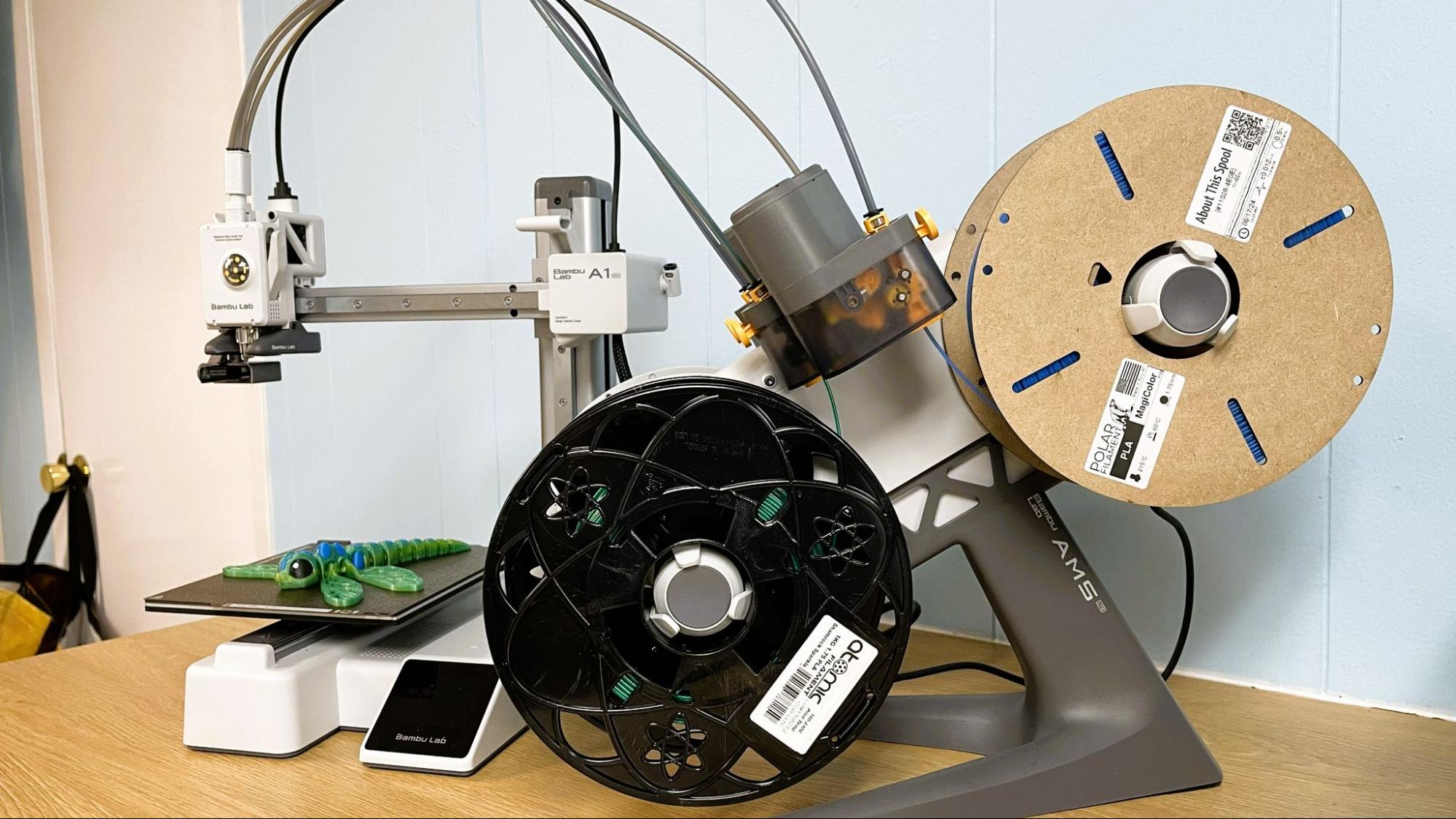

Bambu Lab’s AMS Lite was made solely for the A1 and A1 mini bed slingers. This is my favorite of all the multicolor devices I’ve tested as it is simple to use, easy to maintain and rarely goofs up. The odd looking design is meant to sit on the right side of the printer, but Bambu Lab provides a printable clip you can use to mount the AMS unit on the gantry of the full sized A1.

The AMS Lite (Automatic Material System) comes mostly assembled, with a few pieces needing to be fitted together. There’s one cable to be plugged into the printer and four tubes to guide the filament to the toolhead. Unlike the original AMS, this one can not be daisy-chained, and it is not compatible with the Core XY machines.

Maintenance is much easier on this unit as every thing is out in the open. Spools are held from the center cores, which allows the AMS Lite to use more 3rd party filaments. Cardboard spools are not an issue. Still, some brands do not have the appropriate sized center holes and will not fit. Like the other Bambu Lab AMS this one reads an RFID tag on the spool to identify the type and color of the material in the slicer.

*️⃣ Test Print

Like the original Bambu Lab printers, the A1 line also creates “printer poop” which the A1 flings to the side. The poop can be tamed with tuning in the slicer but can not be eliminated. For the pair of fire trucks (seen above), 166 grams of filament (46 black, 68 red, 41 silver, and 11 blue) were used to print the fire trucks. After tuning, “flushed” 115 grams, down from 200 grams.

Note, the Bambu Lab AMS Lite can not print TPU - TPU must be used on a separate, non-mechanical spool holder.

More: Bambu Lab A1 Mini Review

Best Low Waste Multicolor 3D Printer

Specifications

Reasons to buy

Reasons to avoid

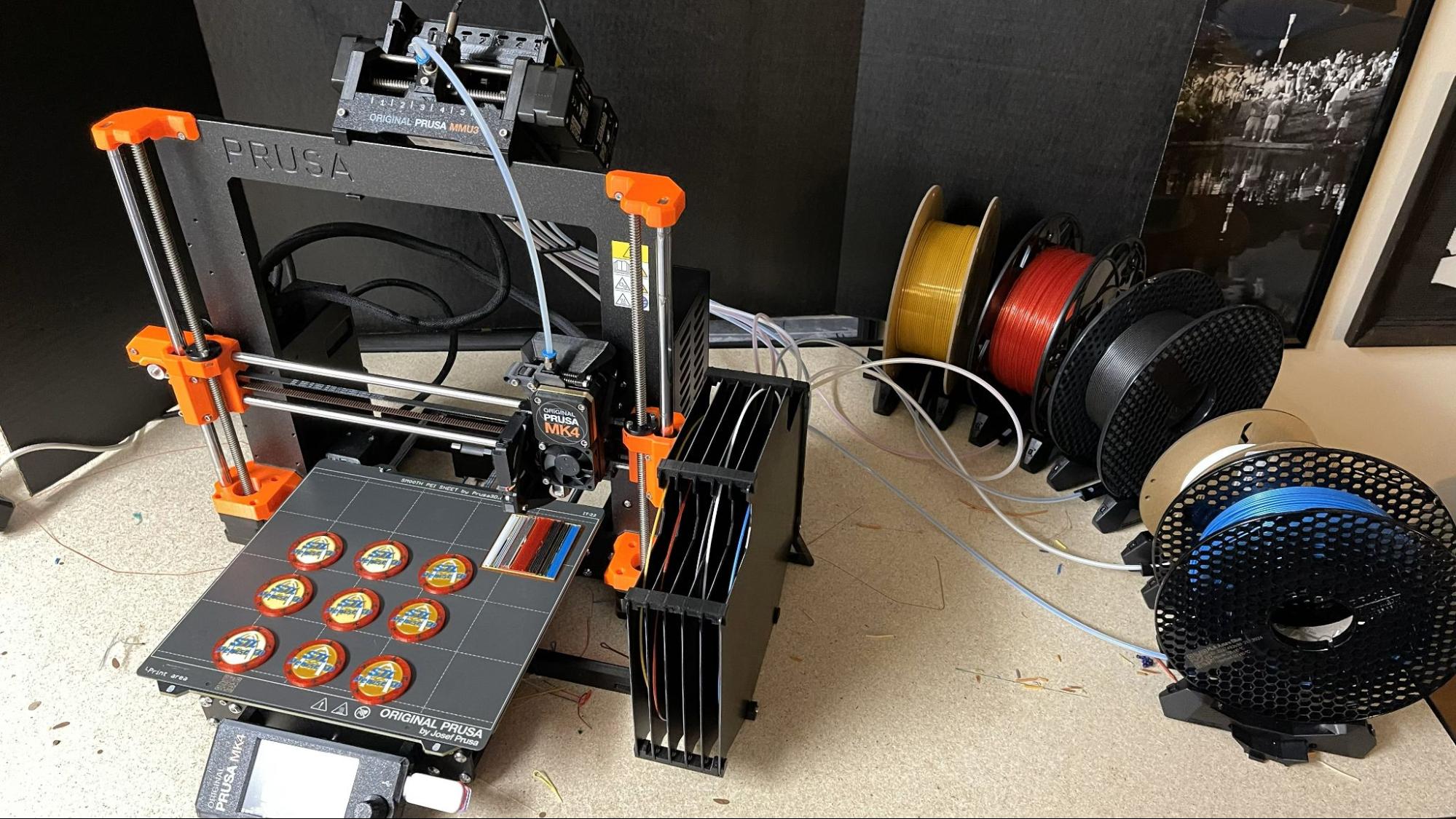

The Original Prusa MMU3 is a modification that can be installed on a Prusa MK4, MK4S and even MK3S+. It requires an advanced understanding of 3D printers to build and requires permanently modifying the toolhead. It also requires a huge amount of table space. If that doesn’t scare you off, then you’re ready for a filament sipping MultiMaterial Unit that can handle five spools of any size with precision. Prusa Research designed the MMU3 to rapidly retract filament from the nozzle, so the only waste is a tuneable purge tower camped out on the rear corner of the print bed.

*️⃣ Test Print

During testing, our MMU3 was paired with a MK4, and produced remarkably clean prints with very little waste. It suffered a couple feeding errors and worked best with fresh, dry filament. The spool holders have adjustable rollers that can handle both plastic and cardboard spools in any size, including half spools and 3KG spools. The spool is only pulled in one direction – retractions are absorbed by the buffer, so there is no fear of tangling. Loading the MMU is a little tedious, as the only motor is located on the MMU itself and filament has to be manual fed through the buffer to the printer.

The MMU3 is a complex device that sits on top of and around your MK4 bed slinger. The bulk of the MMU perches on the printer’s gantry, while a buffer cartridge sits on the side and a mass of tubes connects to a tabletop, five slot spool holder. Our MMU3 took an additional 23 inches of table space next to the printer with an untidy mess of tubes.

The MMU3 is sold as an “upgrade” and currently is not offered with a bundled discount. The DIY kit requires printing the parts and assembling the device from scratch. Attaching the MMU3 to your printer requires modifying the toolhead sensors.

Note, the Prusa MMU3 can not print TPU.

More: Prusa MK4S 3D Printer Review

Best Multi Material 3D Printer

Specifications

Reasons to buy

Reasons to avoid

The Original Prusa XL is a 3D printer purpose built for printing with multiple colors and/or materials. It is a Core XY tool changer, meaning each filament gets its own hotend and nozzle. The printer has a single motion system that can pick up each tool head one at a time. There’s no need to clear the nozzles of filament before changing colors (or materials) and each tool head can have its own temperature setting. This system is perfect for mixing various materials, though you still need to work a little slicer magic if you want different materials to bond well – like PLA and TPU. It also works well if you want to print in PLA and use PETG as a non-stick support material.

*️⃣ Test Print

This Prusa Research toolbox (above) from Printables which uses PLA, PETG and TPU. The three materials are in four colors: black and orange Prusament PETG, white Prusament PLA, and red Ninjatek Cheeta for a gasket.

The Prusa XL can be purchased with one, two or five tool heads. Tool heads can also be added at a later time, up to five. The machine is rather pricey – costing $3,999 with five tool heads. This is also Prusa Research’s largest machine, with a 360 x 360 build plate.

Loading filament is a bit of a chore, with each tool head needing nearly five feet of Bowden tube from spool holder to nozzle. The machine is direct drive, so the material needs to be hand fed through the tubes until it hits the extruder. Each toolhead needs to be heated, with the filament fed through to the nozzle, just like a single color printer. Though loading takes more effort, over all print time is shorter than a Bambu Lab printer, as there is no need to respool the filament between color swaps.

The Prusa XL can handle any size spool, up to 2KG, with standard spindle type spool holders mounted to the sides of the printer. It has no problem with 3rd party filaments. TPU is a little tricky because of the length of Bowden tube you need to manually push it through, but it will work. You can also use a separate spool holder on the table, or mounted above, if you need to handle bigger spools or use a dry box.

More: Original Prusa XL Review

Best Multitasker Multicolor 3D Printer

Specifications

Reasons to buy

Reasons to avoid

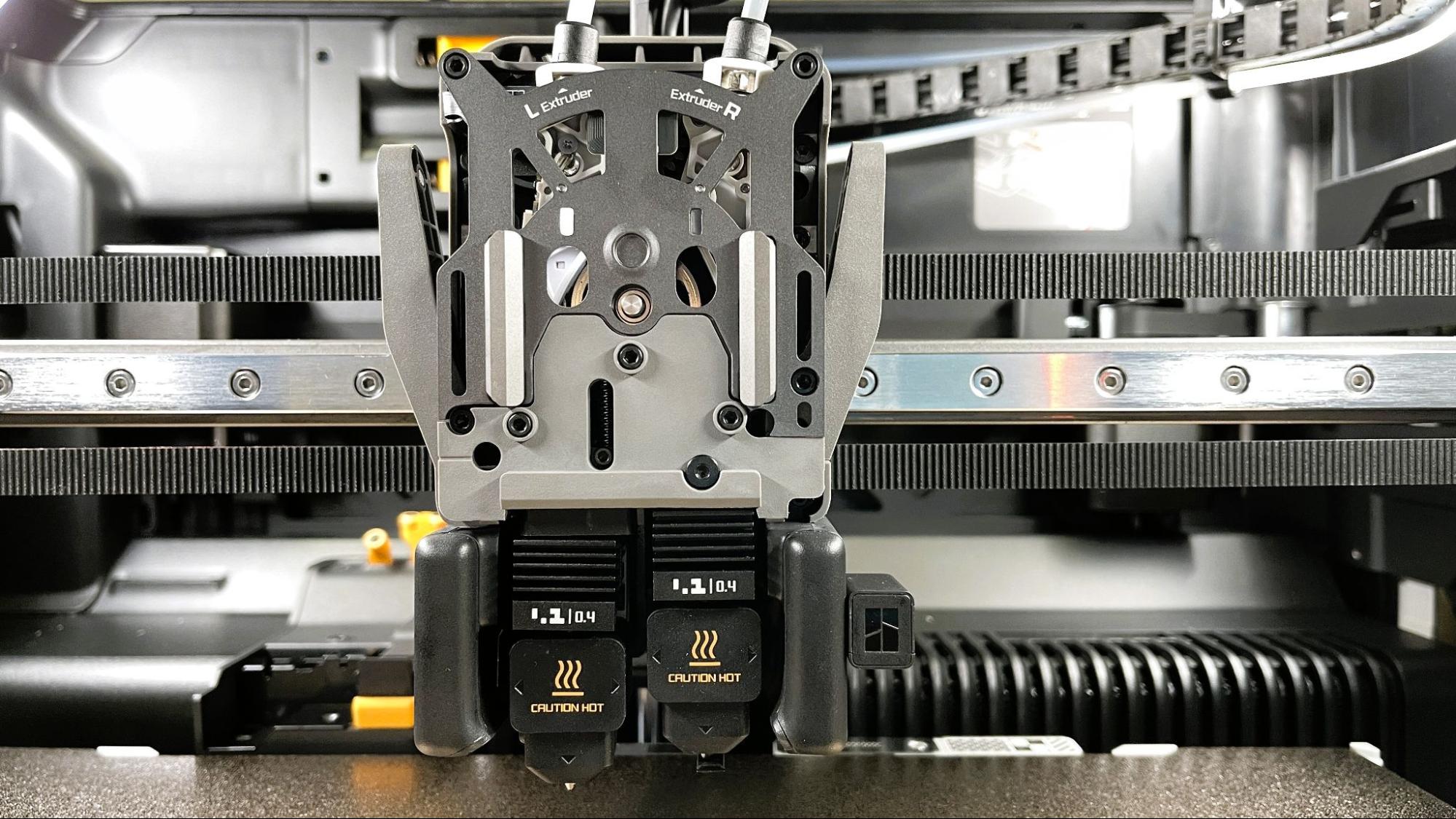

Bambu Lab’s H2D packs a double whammy: it has two nozzles on a single hotend, allowing it to print two different materials without purge waste. Each nozzle can operate at a different temperature, allowing it to combine drastically different materials like ASA and TPU in one model.

The dual nozzles also work well for saving filaments. For example, when only one color is used in a nozzle, there is no need to purge, only prime, saving both time and material. The most common set up for the H2D combo is a four color AMS on the right nozzle and a single spool on the left. The left can print support material, or the main color of a multicolor print, or an expensive filament you don’t want to waste.

Each nozzle can also hook up to several AMS units, for a max of 25 colors.

*️⃣ Test Print

The dragon book nook above was printed in blue and purple CoPE. The black box is Protopasta Empire Strikes Black PETG and was printed separately. The dragon and claw printed in 36 hours and 50 minutes, using a 0.2 layer height and standard settings for high-speed PLA, while the box took another four hours and 46 minutes to print using standard 0.2 layer heights and ordinary settings.

The H2D also introduced a pair of Bambu Lab’s newest AMS units: the four spool AMS 2 Pro and the single spool HT AMS. Both units have built in heaters and circulation systems for drying filament, and desiccant packs to hold the humidity at bay while printing. The AMS 2 Pro can heat up to 65C, and the HT can go to 85C. The HT unit also has a bypass allowing you to feed soft TPU or gritty carbon fiber without going through the feeder motor – instead it simply freewheels and allows the toolhead to pull the filament through.

Combined with the H2D’s enclosure, intelligent cooling system, and 350C high flow hotend, there are very few filaments this machine can’t handle.

More: Bambu Lab H2D Review

Best Budget Multicolor 3D Printer

Specifications

Reasons to buy

Reasons to avoid

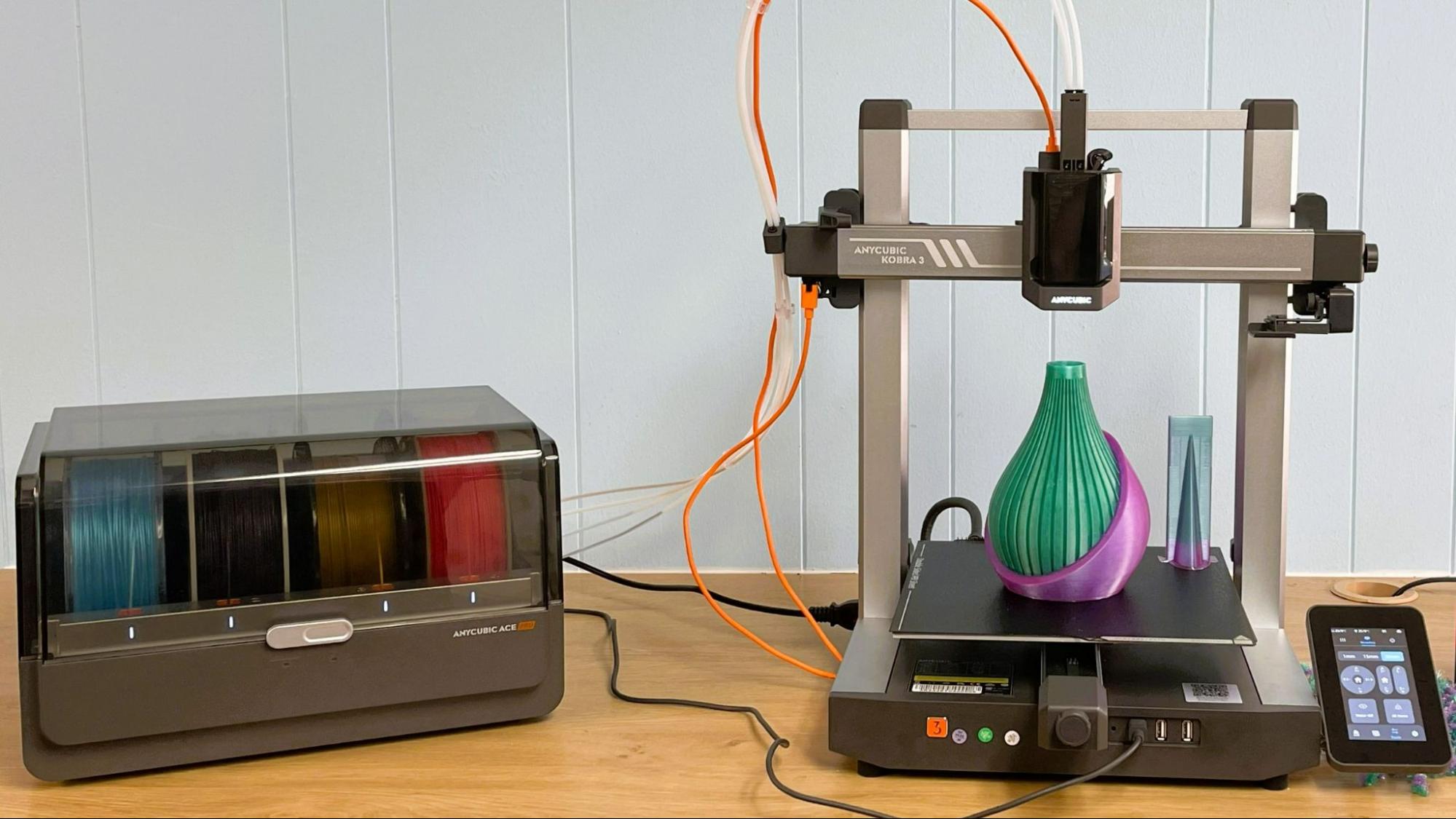

The Anycubic ACE (Anycubic Color Engine) is the first “clone” we’ve seen of the Bambu Lab system. It’s a boxy multimaterial handler custom-made for the new Kobra 3, which has a toolhead similar to the Bambu Lab A1. The ACE pulls double duty as a filament drier and can dry filament while the printer is off or on.

Though the ACE can be bought separately, it is currently only compatible with the Kobra 3, a speedy bedslinger with a custom toolhead and a hub to accept four Bowden tubes from the ACE. Like the Prusa Research MMU, each spool of filament has a dedicated path from the spool holder to the extruder. This means the printer only needs to retract the filament a few inches before swapping colors.

My only complaint with the ACE system is the lack of filament tuning in the bespoke slicer. The Kobra 3 uses a cutter to separate filament at the cold part of the toolhead, with the good filament pulled back a few inches while the leftover filament is pushed through the nozzle in the form of “printer poop.” Currently, this poop can’t be adjusted.

*️⃣ Test Print

Terra de Verdant’s Yovi Vase (above) was printed in Greengate Emerald PETG and a transition roll of Greengate Purple Reign. This print had 197 grams of wasted material compared to 185 grams of the vase.

The Anycubic website says users will be able to use two ACE’s with one Kobra 3 sometime in the future. And while the ACE can dry TPU, it can not feed it through the system and should be used with a separate spool holder.

More: Anycubic Kobra 3 Review

Best Tool Changer Multicolor 3D Printer

Specifications

Reasons to buy

Reasons to avoid

The Snapmaker U1 brings tool changer efficiency to the masses with an affordable machine that also boasts hands-free calibration. Unlike traditional MMU systems, which have all the spools feed through one nozzle, a tool changer features a dedicated filament path and hotend for each spool. This allows color swaps without wasteful purge and true multi-material functionality, ultimately saving the user money while avoiding plastic waste.

Because each head can be programmed with its own heat settings, it's much easier to combine different filament types into one print. Combinations like PLA with PETG supports or even TPU and ABS are possible if you interlock them properly in the slicer. That’s something that single-nozzle machines struggle with.

Best of all, the price makes this technology a bit more accessible: the U1 retails for $999 (with the Kickstarter launching at $749), putting it in the same range as a Bambu P1S, but with features usually reserved for far more expensive machines. It runs OrcaSlicer and Klipper, giving users open-source flexibility, security and a strong performance out of the box.

More: Snapmaker U1 Review

Best Large Format Multicolor 3D Printer

Specifications

Reasons to buy

Reasons to avoid

The Kobra 3 Max is the biggest 3D printer we’ve tested that can also handle multicolor prints. It’s not only big, but it has very good speed for the size and works reliably. The combo comes with a one ACE Pro system to handle four colors, but you can purchase a 2nd unit (or borrow one from a second machine if you have one) and print eight colors with a special eight-color hub attachment. The ACE Pro also does double duty as a filament drier.

The 420x420 build plate makes this the largest bedslinger we’ve tested. It has ample room for cosplay pieces or even a good-sized droid. Just make sure you have room for this beast, as it requires a full three square feet of operating space to allow the bed to move back and forth. I had to pull the rack it’s sitting on away from the wall, and was unable to operate it on my studio’s IKEA counter.

The Kobra 3 Max produces excellent prints with an average speed of 200mm/s, thanks to a high-flow hotend and input shaping to keep things crisp. The stock bed on our printer was lacking in grip, so you may need to give it a good scrub to rough it up or add glue stick.

Read: Anycubic Kobra 3 Max Review

The difference between Multi Material or Multicolor 3D Printing

There’s a difference between printing four colors and printing four materials.

👉 Multi Material 3D Printing

Combining PLA, PETG, and TPU in one print has inherent risks, as these materials print at different temperatures and won’t even bond to each other. Some hurdles can be overcome with slicing tricks, but you still have to deal with less than ideal bed temperatures and the risk of clogs created by residue from the different materials. (Note, only the Prusa XL can print TPU with other colors/materials.)

👉 Multicolor 3D Printing

Bambu Lab’s printers won’t let you mix materials of wildly different temperatures, limiting itself to multicolor. Machines with separate toolheads are better at handling incompatible materials, though Prusa Research got around the problem with a rapid retraction method that yanks enough filament out of the nozzle so that clogs aren’t a problem.

MORE: Best Resin 3D Printers

MORE: Best Budget 3D Printers

MORE: Best Filaments for 3D Printing

MORE: How to Buy the Right 3D Printer

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Denise Bertacchi is a Contributing Writer for Tom’s Hardware US, covering 3D printing. Denise has been crafting with PCs since she discovered Print Shop had clip art on her Apple IIe. She loves reviewing 3D printers because she can mix all her passions: printing, photography, and writing.

-

Grobe So I wonder one thing - I've trying to learn to use FreeCAD on Linux - simply because. And thus it begs the question if some of those 3D printers require windows and/or commercial software in order to be used in practice ?Reply

I couldn't read that from the article nor its links. -

USAFRet Reply

The model can probably be produced in any 3D CAD application.Grobe said:So I wonder one thing - I've trying to learn to use FreeCAD on Linux - simply because. And thus it begs the question if some of those 3D printers require windows and/or commercial software in order to be used in practice ?

I couldn't read that from the article nor its links.

The key software is the slicer. This prepares it for the printer.

Ultimaker Cura is Linux friendly, and free.

https://ultimaker.com/software/ultimaker-cura/ -

USAFRet I have a Bambu X1 Carbon.Reply

The associated BambuStudio is also apparently Linux friendly.

https://forum.bambulab.com/t/bambu-studio-on-linux/78092/2 -

nameofstandard Reply

The majority of slicers have Linux support. Prusa slicer, Bambu studio and Orca slicer have Linux support (for some you must get it from the releases page on Linux)Grobe said:So I wonder one thing - I've trying to learn to use FreeCAD on Linux - simply because. And thus it begs the question if some of those 3D printers require windows and/or commercial software in order to be used in practice ?

I couldn't read that from the article nor its links.

As for FreeCAD the saying is its free because you pay with your time remains true even with the latest updates. It remains in a constant state of the next update being hailed as the true fix to what is a deeper problem of direction that results in a lot of other problems that only get nibbled away at slowly as more are added.