Tom's Hardware Verdict

Prusa’s MK4 sticks the landing with exceptional performance and amazing improvements to auto bed leveling, while still keeping a path to upgrade for MK3 owners.

Pros

- +

Fully assembled or DIY kit

- +

Faster than MK3

- +

Direct drive

- +

Linear rods

- +

Dual Z axis

- +

Auto bed leveling

- +

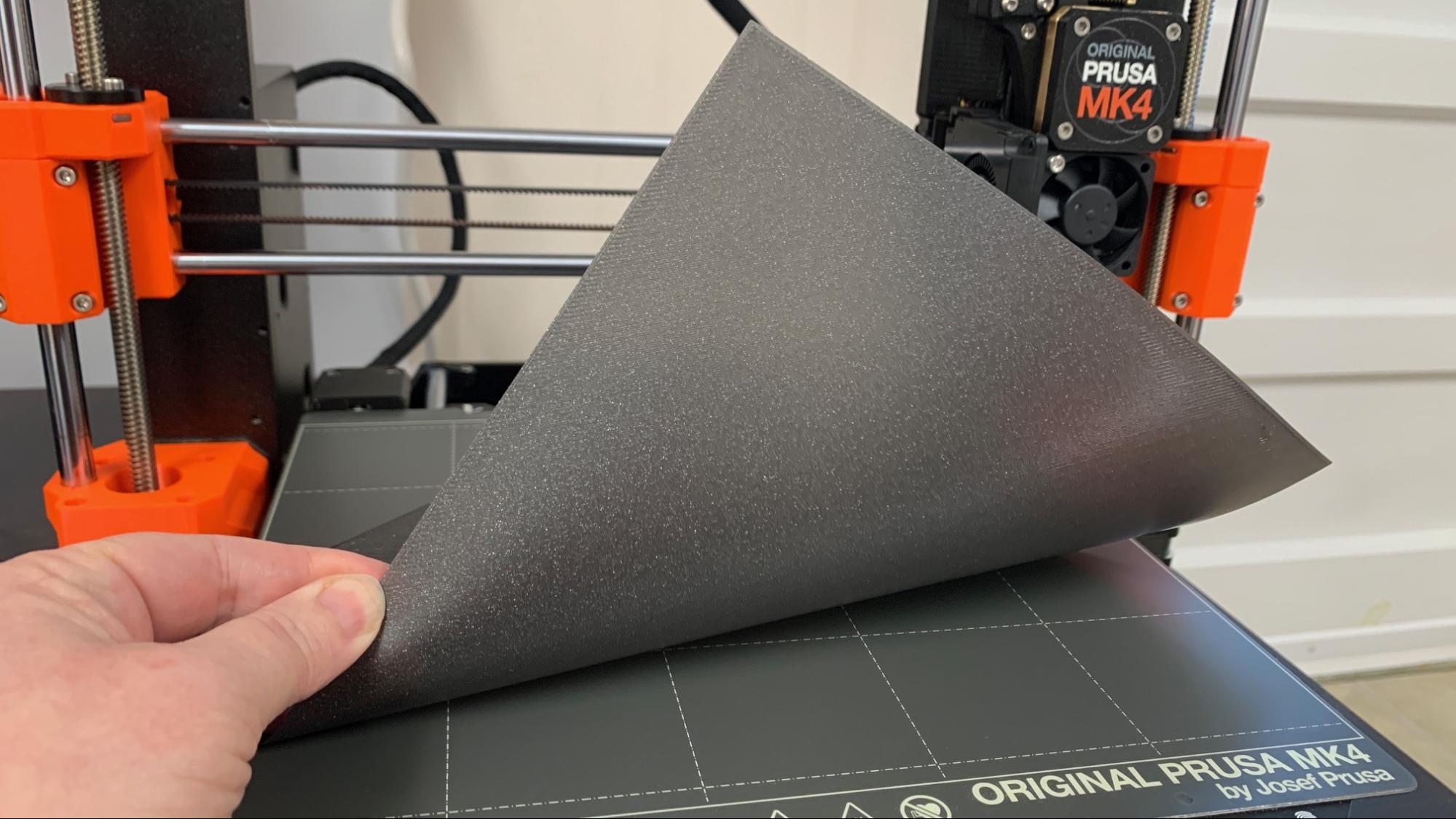

PEI Steel flex plate

- +

All metal hotend

- +

Very quiet

Cons

- -

Expensive

Why you can trust Tom's Hardware

Editor's Note: This review has been updated to include Input Shaper availability and new testing results.

The long-awaited sequel to Prusa Research’s MK3S+ has finally arrived after years of waiting.

On paper, it looks like the Prusa MK4 is merely playing catch up by adding new features we’ve already seen on the market. But somehow, this machine is more than the sum of its parts.

The MK4 has a new take on auto bed leveling that produces perfect first layers and automatically sets the Z height. Also new is a planetary geared “Nextruder” which has larger contact area to grab and control the filament, a 32 bit board, and a quick-swap nozzle.

The MK4’s new custom firmware is heavily influenced by Klipper, which allows for precise high speed printing. Although Input Shaper and Pressure Advance were not available at launch, a firmware update in September rectified the issue. The update is included with all machines manufactured after September, and any purchased before that date can download the updated software for free from Prusa’s website. Input Shaping gives the MK4 a dose of speed, with prints often taking half the time as they did before.

Surprisingly, Prusa Research didn’t increase the price for its flagship printer. Retailing at $1099, the MK4 is still a bit of an investment. You can choose to save money by going the DIY route and buying a kit for $799. Remaining stock of MK3’s are on sale for $899 assembled or $649 as a kit. Owners of MK3S+ machines can also go the upgrade route with kits starting at $249.

The Prusa Original MK4 is one of the best 3D printers we’ve ever tested and lives up to its reputation as a premium printer for makers of all experience levels.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Specifications: Original Prusa MK4

| Build Volume | 250 x 210 x 220 mm (9.84 x 8.3 x 8.6 in) |

| Material | PLA/PETG/TPU (up to 300 degrees) |

| Extruder Type | Direct drive |

| Nozzle | .4mm (v6) |

| Build Platform | PEI spring steel flex plate |

| Bed Leveling | Automatic |

| Filament Runout Sensor | Yes |

| Connectivity | USB drive, LAN, Wi-Fi |

| Interface | Color LCD screen with knob |

| Machine Footprint | 500 X 550 x 400 mm (19.6 x 21.6 x 15.7 in) |

| Machine Weight | 7 KG (15.4 lbs) |

Original Prusa MK4: Included in the Box

The Prusa Research MK4 we reviewed came fully assembled and only needed to be unpacked. It comes with the full tool kit you would get with the build it yourself version. You won’t need these right now, but hang on to them for future upgrades.

Besides tools, the printer comes with a full spool of Galaxy Black Prusament PLA, a USB Stick, a handbook on 3D printing with your new machine, stickers, and a bag of Gummy Bears. The USB stick contains several models, while PrusaSlicer is available for free download from the website.

We also received a few bonus items for the review: an adapter to use traditional nozzles and extra build plates.

Design of the Original Prusa MK4

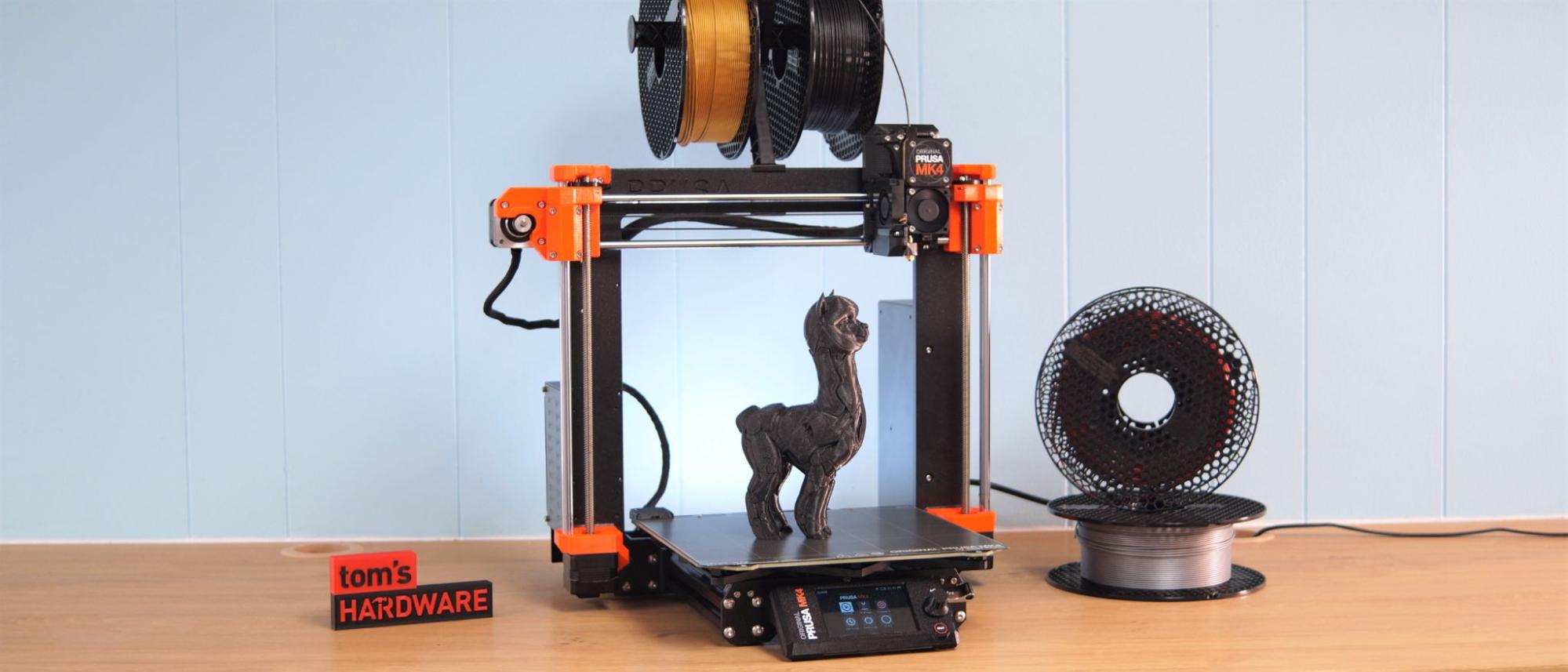

The Original Prusa MK4 is the successor of the often cloned Prusa Original MK3. It bears a striking resemblance to the previous generation, which allows Prusa Research to offer upgrade kits to loyal customers so they don’t need to throw out their old MK3s. More about the kits later.

The MK4 retains the classic Prusa orange and black theme while having updated 90% of the machine, according to Josef Prusa himself in a blog post. The frame is now a powder coated die-cast aluminum-alloy, made in house, that looks quite a bit like the company’s sparkly Galaxy Black filament. The orange parts are still 3D printed at Prusa Research in PETG Prusament, using a farm of MK3’s and MK4s. Prusa has stated that he still uses 3D printed parts to prove his machines are up to the task.

This brings up an interesting point – though the launch of the MK4 was a surprise to everyone outside the company, Prusa Research has been testing the new printers around its office and factory for about a year. This also means the MK4 customers receive, has already been thoroughly vetted by Prusa’s team and should be relatively bug free.

The machine has everything you’d expect to find in a new i3 design. It has dual Z axis, auto bed leveling, whisper quiet fans, a magnetic flex plate and a color screen. Files can be transferred with a front mounted USB port or through WiFi.

What’s most exciting is the new firmware, which Josef Prusa told us in an interview, is based on Marlin, yet heavily influenced by Klipper. The new firmware will allow the MK4 to run faster while still retaining quality.

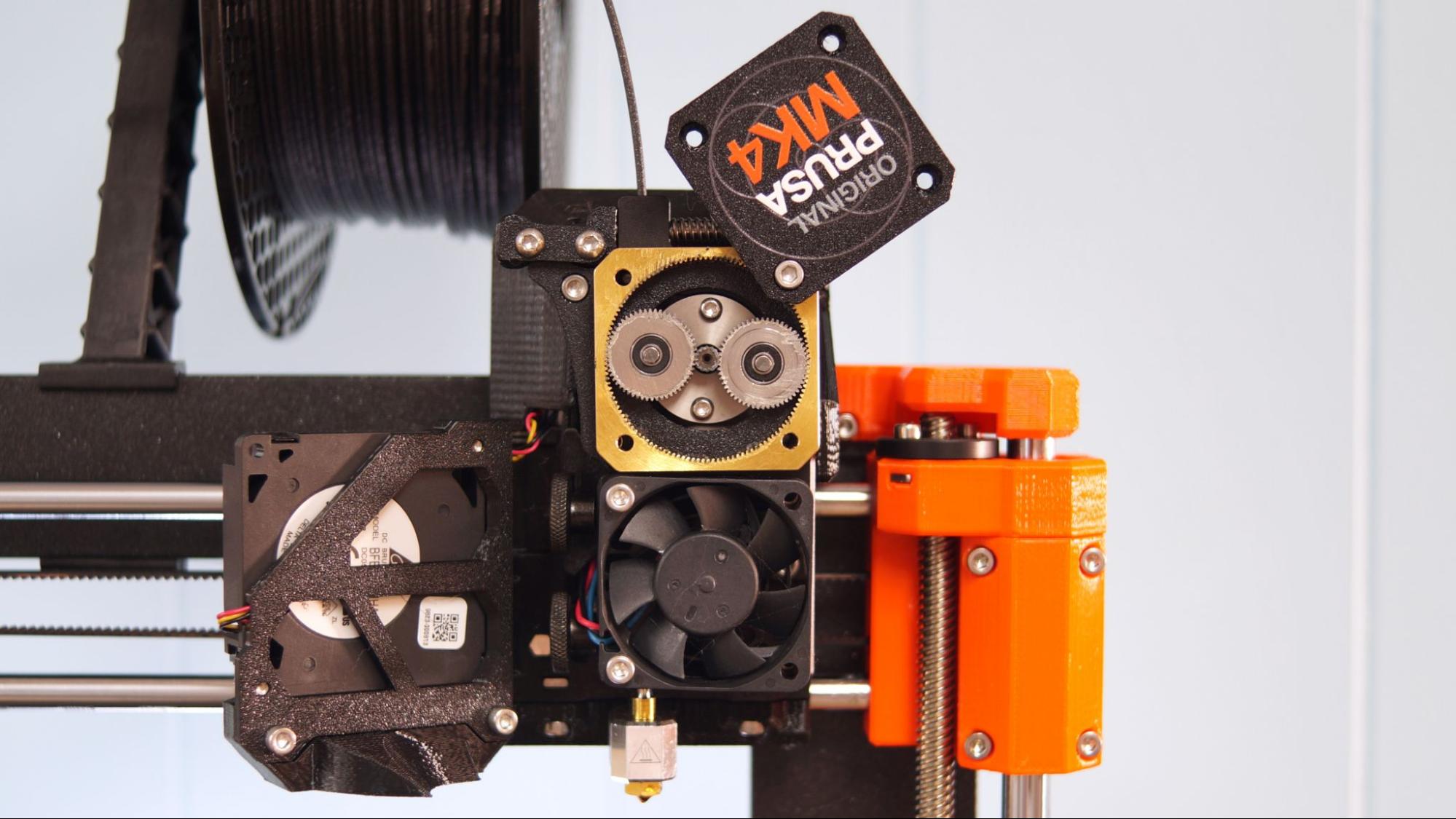

Back to hardware, the E3D extruder and hotend has been replaced with the Prusa made “Nextruder”, which you’ll also find on Prusa’s new XL 3D printer. It uses a 35mm no-slip drive gear powered by a 10:1 planetary gearbox and a pancake stepper motor.

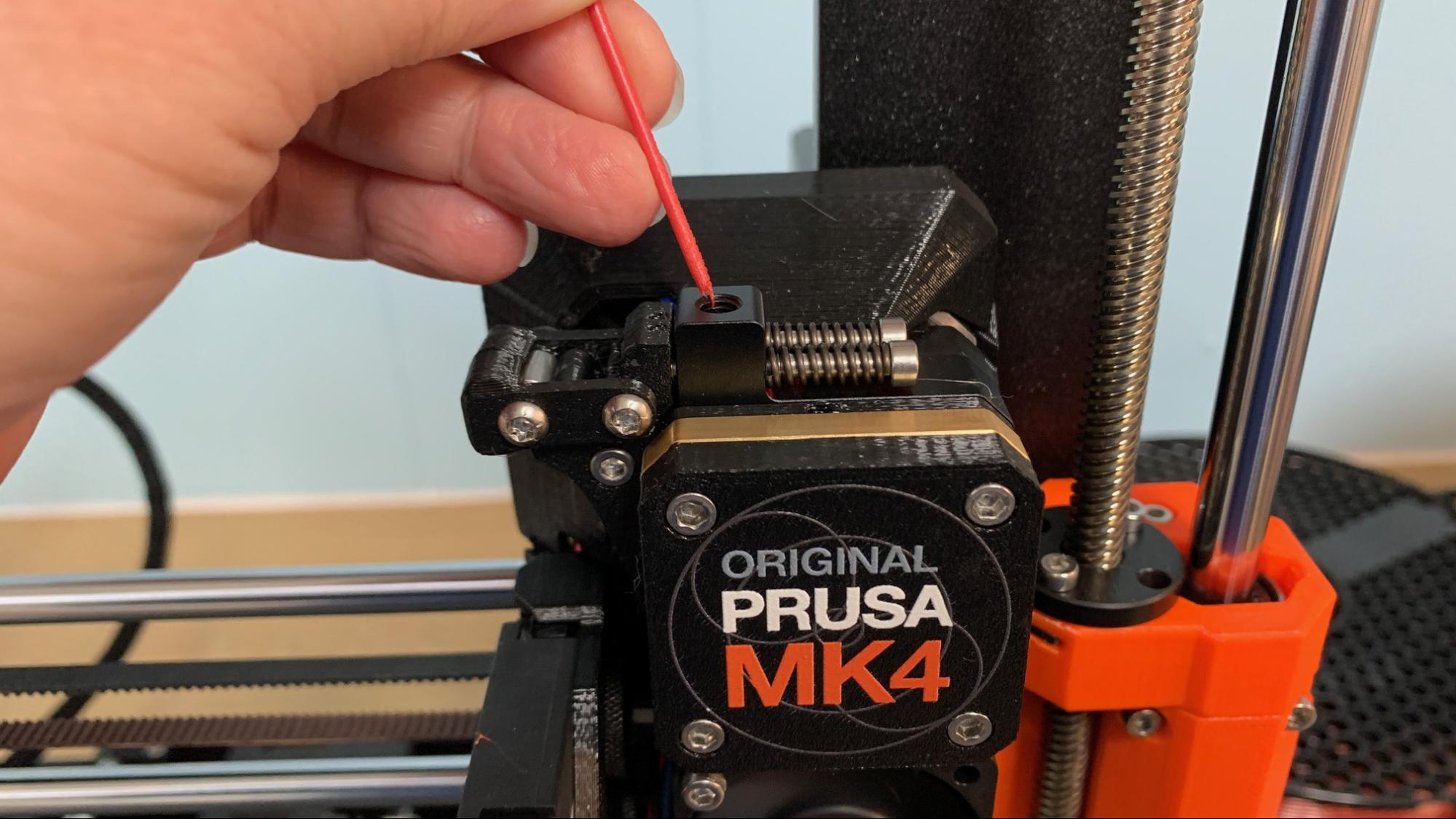

The part cooling fan is mounted on a hinge, allowing it to swing aside for easy access to the hotend, which has also been redesigned. Influenced by E3D’s Revo system, the new MK4 has a quick swap nozzle that includes the heatbreak and an all metal filament guide in one sealed unit.

The new combo nozzles are sold for $27.90 on Prusa3d.com, made of brass and come in sizes from .25 to .8mm. You can purchase an adaptor for $29.99 that will allow you to continue to print with any V6 nozzle. The adaptor is exactly the same as the new nozzle, except it ends with threads for holding a normal V6 nozzle. It may be cheaper to buy an adaptor and continue to use “regular” nozzles.

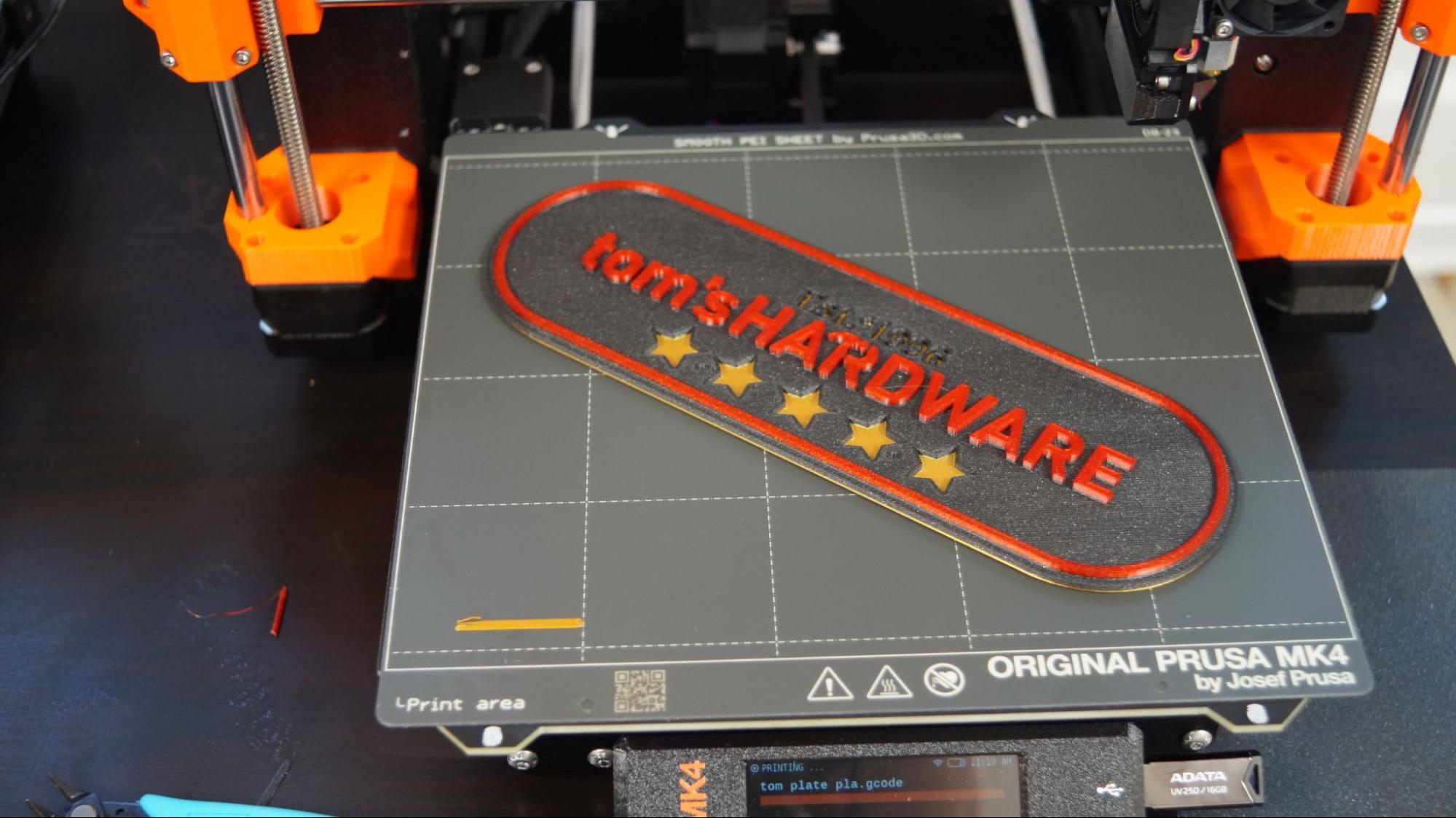

Bed leveling is fully automatic, with no manual adjustments. First layers go down perfectly smooth thanks to a load cell sensor that has replaced the old PINDA probe. The sensor is connected to the nozzle, which allows the MK4 to physically tap the print surface for a more precise measurement. The sensor is also used to calculate Z height, and it does it so well that there is no need for human intervention. Of course, there’s still a live Z adjustment available in the menu should you need it. During testing, we did not.

One of the fun tests you can do to check out the MK4’s first layer handling is to print a single layer thick rectangle the size of the entire bed. It peels up like a sheet of paper. None of the other printers I have running were able to duplicate this feat as well.

The MK4 has built in WiFi, another new feature we love seeing on printers. This allows you to securely access your machine from a local area network or through Prusa Research’s cloud based Prusa Connect.

Upgrades for MK3 Owners

Prusa is known for offering customers upgrade kits to prevent his machine’s from becoming obsolete. The MK4 is keeping with the tradition.

There are three kits available. The MK3.5 upgrade contains the 32 bit board and a touch screen for $249. This gives you more processing power and access to input shaper when it’s made available. You also gain Wi-Fi. This is the best bang for your buck, especially if you have added a new hotend you want to keep.

The MK3.9 kit is $499 and includes the board, screen and Nextruder. There’s also a full MK4 upgrade for $579 includes everything in the previous kits plus the new stepper motors.

Assembling the Original Prusa MK4

The Prusa MK4 we reviewed came fully assembled and only needed to be unpacked. Simply pull it out of the box and plug it in. The only screws I needed were to mount the spool holder’s filament guide.

Every Prusa MK4 is given a thorough inspection before shipping. A checklist showing the parts inspected is included in the box. You’ll also find a sample print stuck to the bed from its factory test.

Note: if you purchased the DIY kit version of the MK4 you’ll need to set aside around 8 hours to assemble it but you will save $300.

Once the machine is turned on, you’ll see a cartoon version of Josef Prusa to guide you through setup. The MK4 will run a few hardware checks then walk you through loading filament. Once the material is loaded you can pick your first print from the USB card. It will perform a bed level check and set the Z height before printing (and without asking you for help).

Leveling the Original Prusa MK4

Bed leveling is a no-brainer as the MK4 Is fully automatic. There are no manual adjustments and no need for adjusting the Z offset. The printer uses a load cell sensor connected to the nozzle, which physically taps the print surface for precise measurement.

The printer trams the bed and calculates the required z height before each print.

Loading Filament on the Original Prusa MK4

Loading filament is very simple. Simply place filament into the hole on the top of the extruder and it will automatically detect it and pull it in. The screen will then ask what kind of material you’re using to set the temperature. Once it gets hot enough it will pull the filament into the hotend and ask if the color has changed. If it has, you can say yes and move on. If the answer is no, it will purge more material.

To remove material, go to the Filament menu from the main screen and click unload. It will remember what material was last installed, determine if the filament is still there and then heat to the appropriate temperature. Once hot, it will retract the plastic until you can easily remove it.

Preparing Files / Software for Original Prusa MK4

Prusa Research makes one of the most popular free slicers, PrusaSlicer. It includes profiles for Prusament — Prusa’s house made filament-– and a handful of popular 3rd party material. I’ve found that picking “generic” works for most brands.

If you prefer Cura, it has a profile for the old MK3, which is similar enough to the MK4 that it will work quite well.

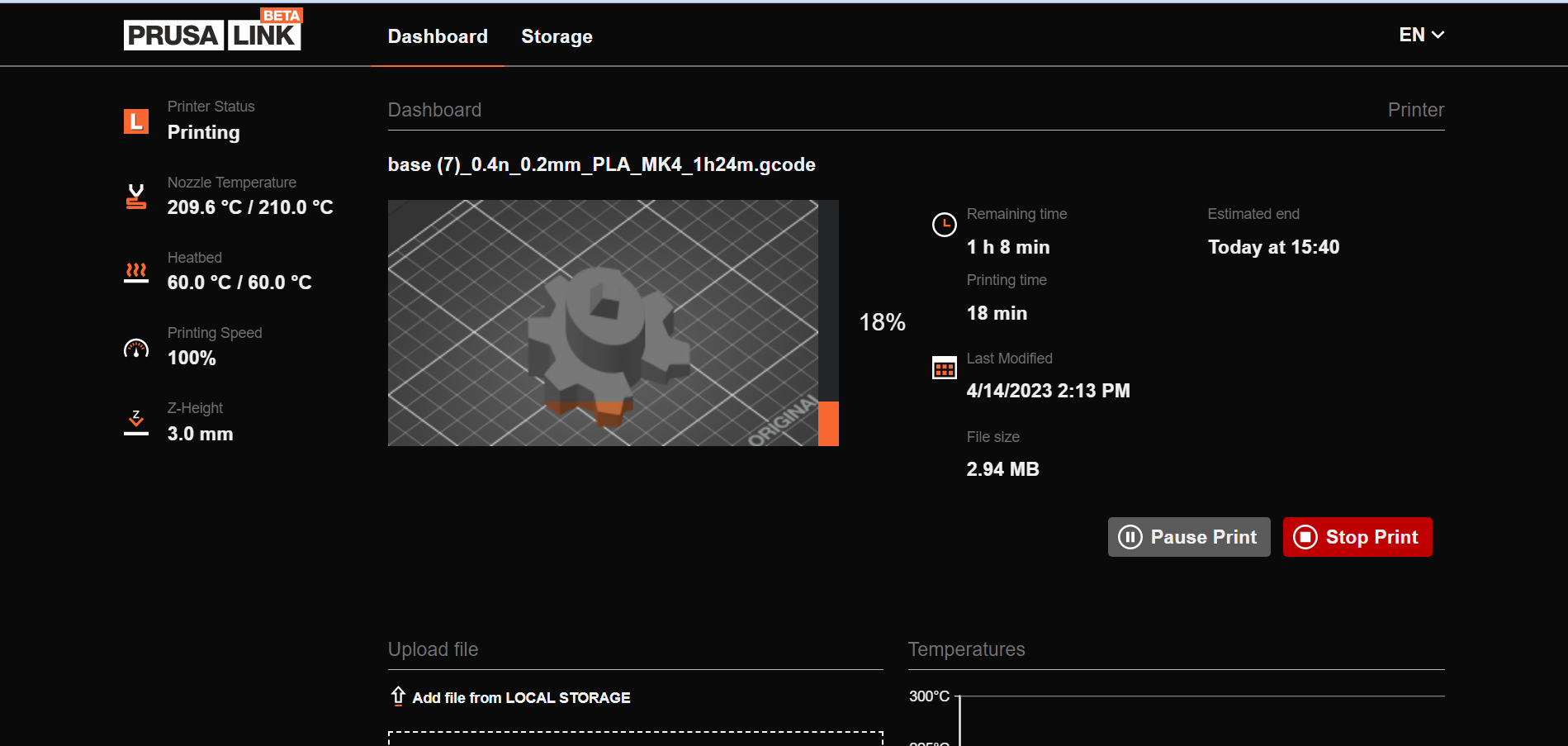

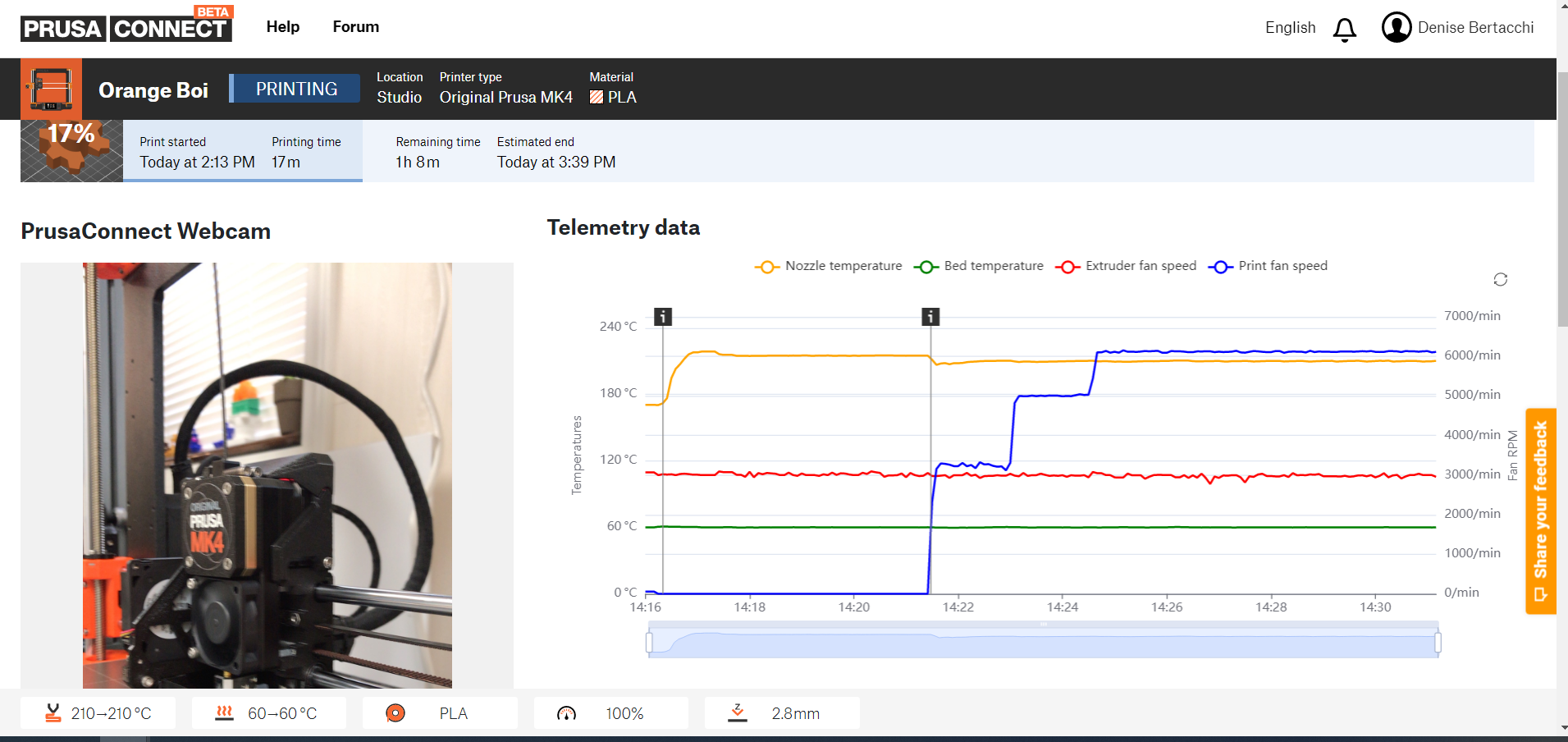

To use the MK4’s WiFi you have to use a separate program, either Prusa Link or Prusa Connect. Prusa Link is a bare bones portal that connects to your printer over LAN or WiFi. You access it by typing in the printers’ network address. Prusa Link only allows you to upload files, start and stop a print, see the thumbnail and a few stats about your machine. However, once Prusa Link is established, you can connect your printer directly from Prusa Slicer and send a file to the printer without needed to open any other programs.

Prusa Connect is a more feature rich cloud based program, and can be used to control a single printer or a fleet of Prusa machines. It is not configured to work for 3rd party printers.

Prusa Connect gives you full remote access to your printer, rather like Klipper’s Mainsail. The program lets you see stats, the machine’s history of prints and stores up to 2 GB of files for free on the cloud. You can also access the machine’s USB storage and pull files from there, which is handy if you have a library of prints you repeat. You can also control the machine’s movements, temperatures, and change speed or flow during a print.

The webcam feature is intriguing, yet limited. It only takes still photos and doesn’t save them. If you want to take time-lapse video you’ll still need another method. It is really nice that you can use any webcam or old smart device with a camera. The camera is freestanding and needs its own power plug. I’m using an old iPhone 7 connected to a power strip with a USB charging port.

Prusa Link and Prusa Connect are still in beta and we hope to see more features released for these programs in the future.

Printing on the Original Prusa MK4

The MK4 comes with a full roll of Prusament PLA Galaxy Black. If you want more colors and materials like silks and multicolor filaments, you should check out our guide to the best filaments for 3D printing for suggestions.

The USB stick has several pre-sliced models to show what the MK4 can do. I picked the Robo Alpaka, which is support free and full of intricate details and overhangs. The print turned out crisp and perfect. Printed in the supplied Galaxy Black, pre-sliced by Prusa Research with a .2 layer height, this took 4 hours and 53 minutes to print with Input Shaping.

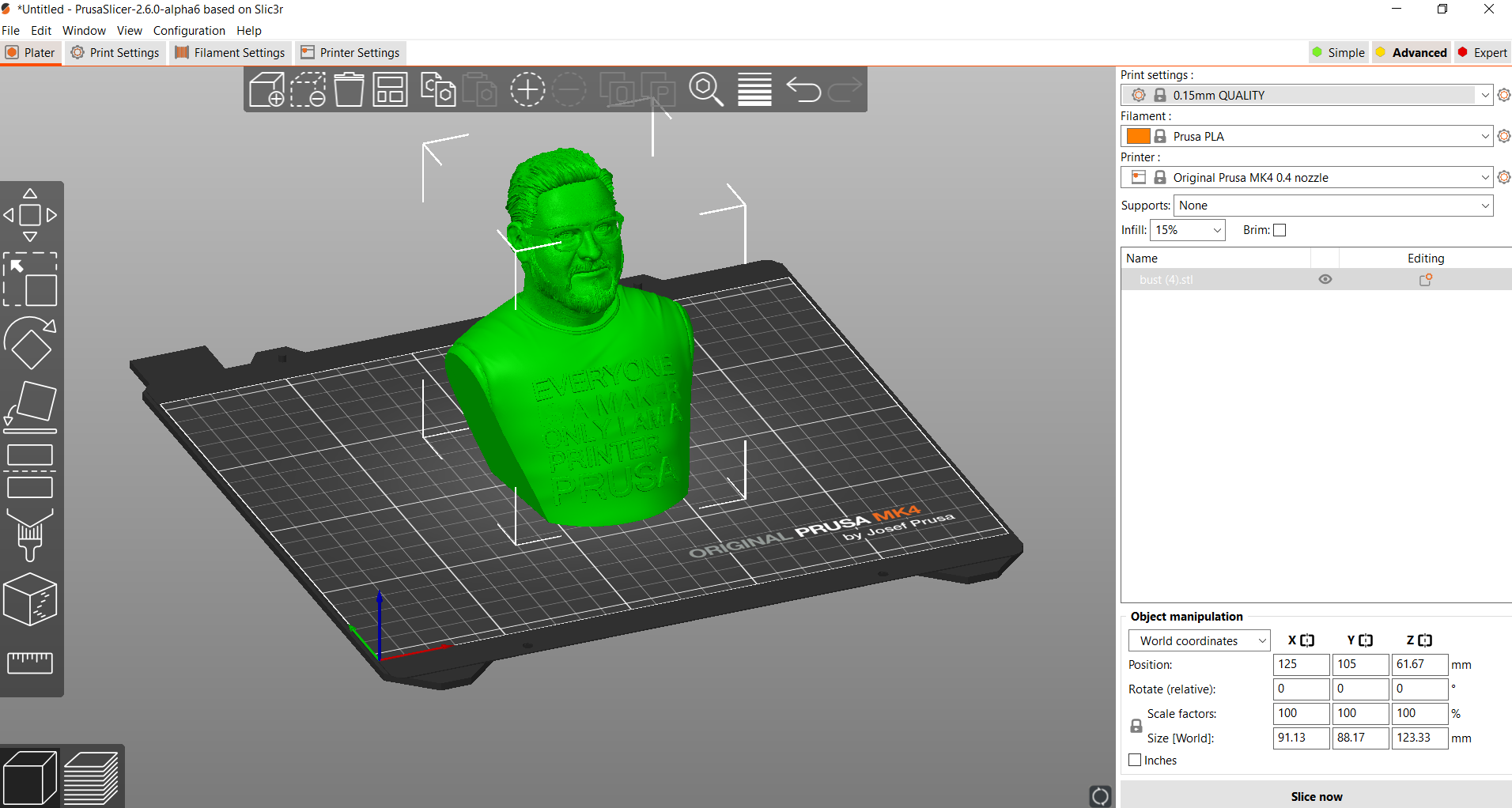

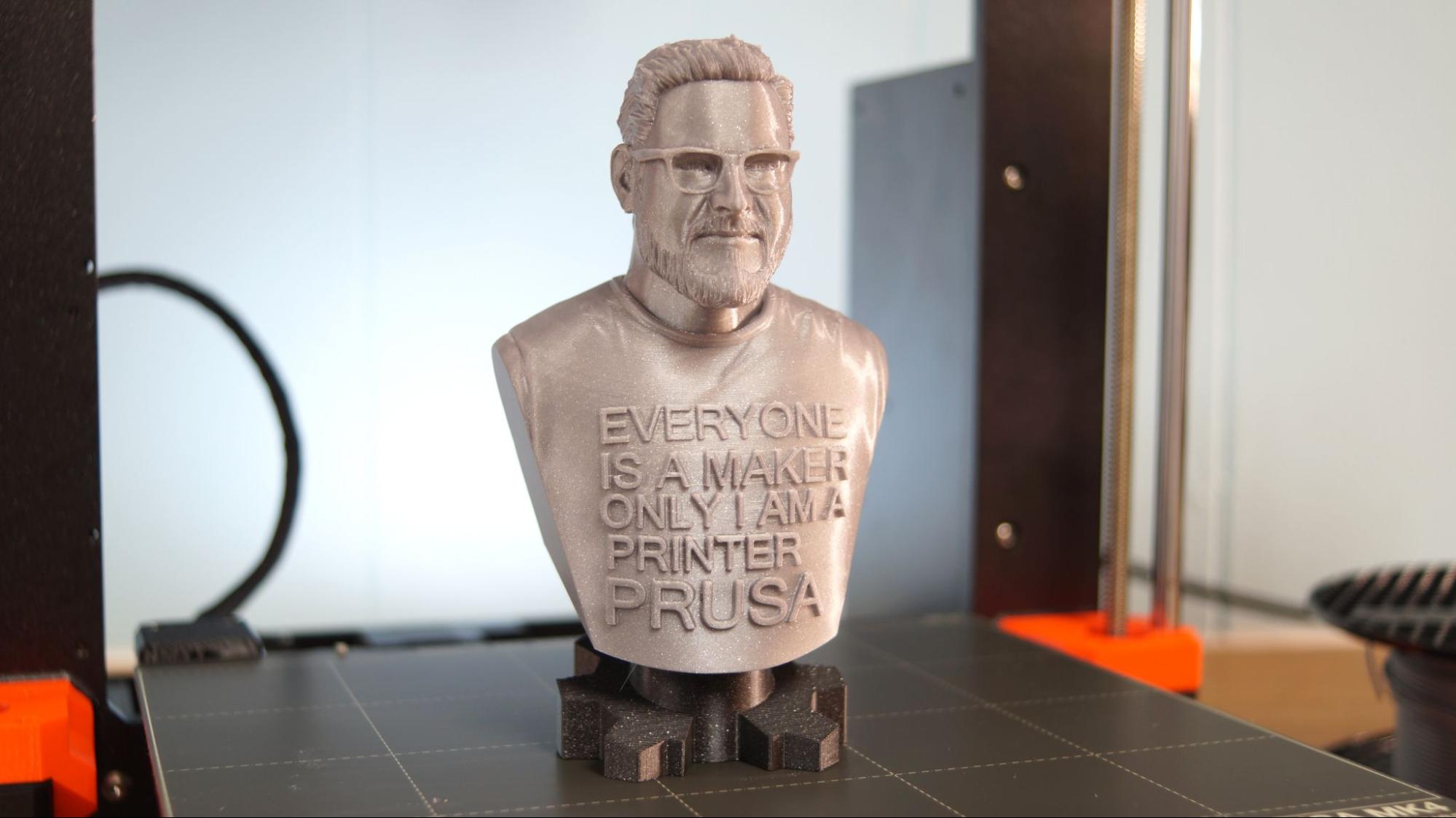

Next I printed this bust of Josef Prusa by Fotis Mint. Fotis is an excellent designer and there’s a lot of detail in this sculpt. I used a .15 layer height and the “structural” setting, which printed at a leisurely 45mm/s with 90mm/s on the infill. There were no supports and every letter is crisp, there’s detail in the hair and glasses and the skin came out super smooth. The print took 6 hours and 21 minutes altogether. The bust was printed in Prusament Galaxy Silver, and the base is in Prusament Galaxy Black.

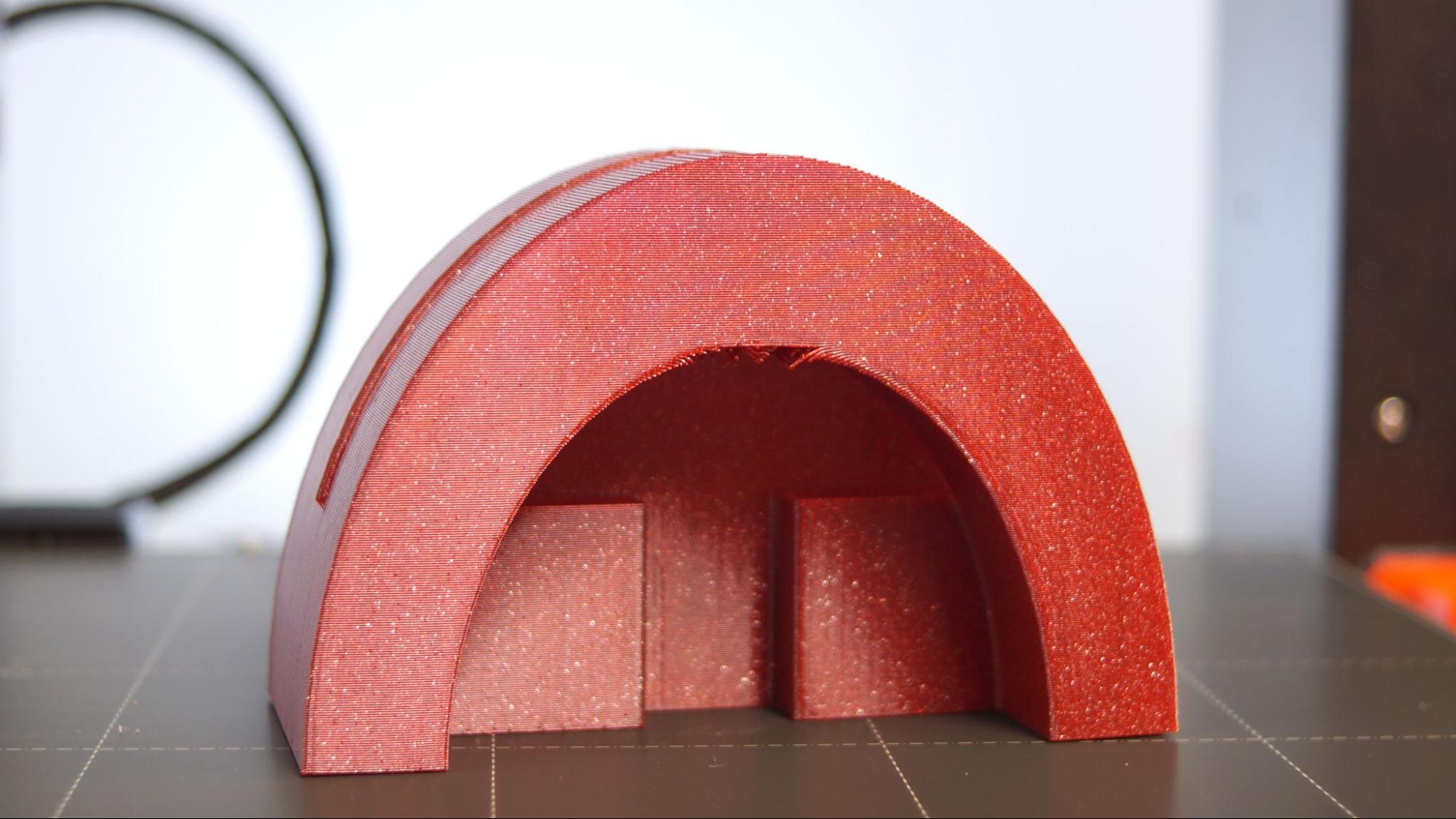

To test PETG I whipped up a phone holder in Tinkercad that could hold my old iPhone at the correct angle to monitor prints. This printed incredibly smooth and without noticeable layer lines with a tiny fail right where the arch was not supported. It’s printed in Prusament Carmine Red at a .3 layer height, with 70mm/s on the walls and 200mm/s on the infill and took 1 hours and 42 minutes to print.

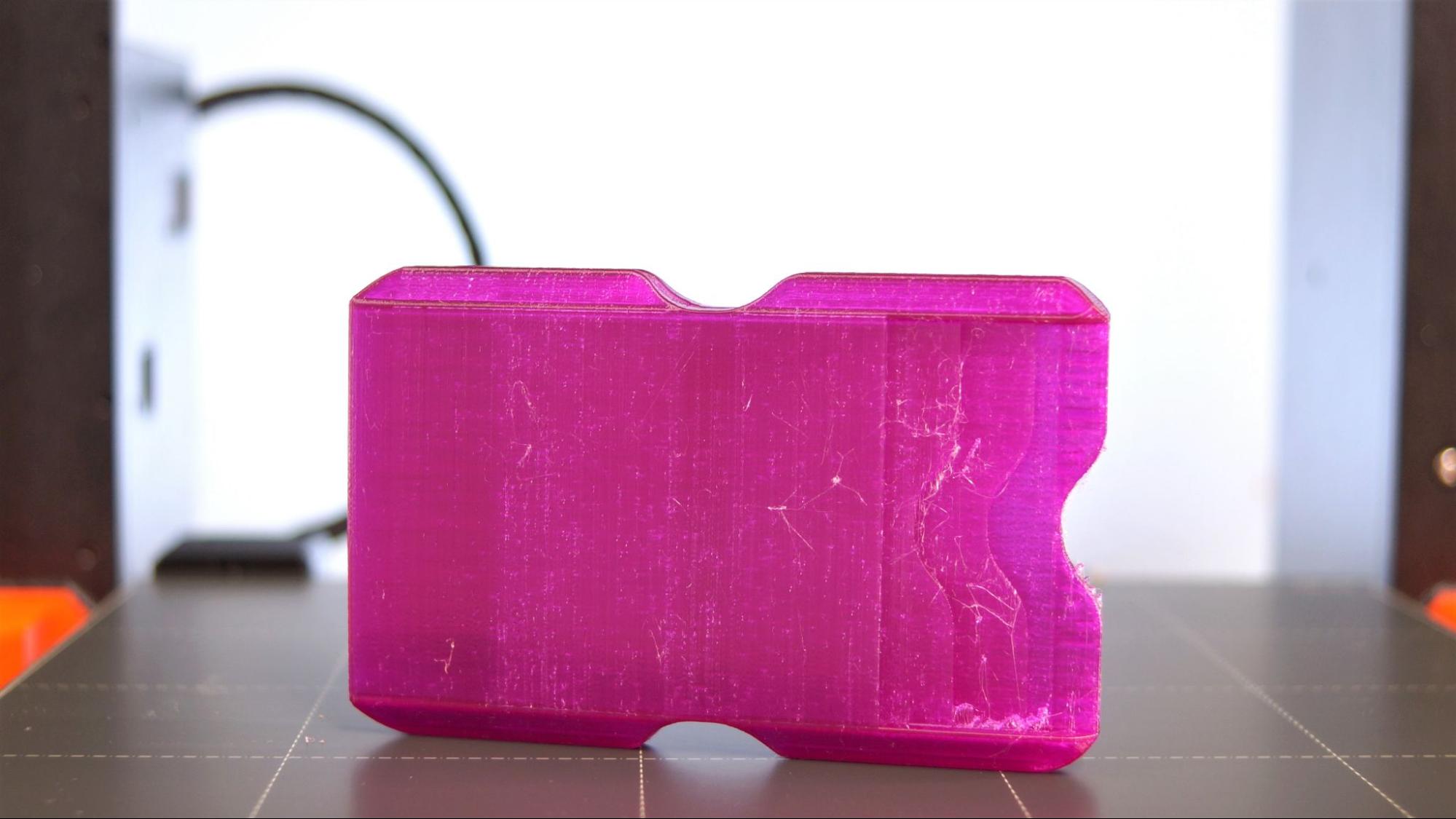

For TPU I printed a wallet, something that can be difficult for some printers. The wallet was still stringy, but all the pockets opened up and were bonded strongly. This was printed in Matterhackers’ Build Series TPU in Translucent Purple, with .15mm layer height, a 50mm/s speed and took 5 hours and 4 minutes.

Bottom Line

The Prusa Original MK4 is a delightful machine to use, but you’re going to pay extra for Prusa’s reputation for quality and customer service. Retailing at $1099 for a pre-assembled machine and $799 for a DIY kit, the Prusa MK4 is not a budget machine, but it is definitely the best machine a beginner could start on. It’s perfect for makers who need a reliable workhorse and anyone who wants a tool, not a project.

As the MK4 remains open source, it’s also extremely easy to find parts and repair with a little bit of knowledge and help from your favorite YouTuber.

Fans of the Prusa brand are ecstatic for all the updates, especially the 32 bit board, KIipper-like speed, and the new method for auto bed leveling. The real question is whether people new to the hobby will think it’s worth $1099 when companies like Creality and Bambu have speedy Core XY machines for much less.

If you like the MK4, but want something less expensive, much faster and with the same level of calibration sensors, check out the $699 Core XY Bambu Lab P1P. However, if you want to save a lot of money while still getting the perks of auto bed leveling and an easy to remove build plate, the Elegoo Neptune 3 Pro.

MORE: Best 3D Printers

MORE: Best Budget 3D Printers

MORE: Best Resin 3D Printers

Denise Bertacchi is a Contributing Writer for Tom’s Hardware US, covering 3D printing. Denise has been crafting with PCs since she discovered Print Shop had clip art on her Apple IIe. She loves reviewing 3D printers because she can mix all her passions: printing, photography, and writing.

-

bigdragon The MK4 is an impressive printer. I understand the price given Prusa's reputation and robust community. Having access to a lot of other makers sharing lessons learned, mods, and replacement parts is critical to making 3D printing work.Reply

However, I think Bambu has the edge. Not only have they provided some very reliable and quick printers, but they're also making material changes easy. Material and tool changers are the future. The new hotend design for the MK4 appears to indicate Prusa knows this is coming too. I think the 3D printing world is going to make a major jump forward in the next 12 months assuming patent trolls don't get in the way. -

Gam3r01 Reply

The biggest criticism I have heard out of Bambu printers is concerns over the lack of future support.bigdragon said:The MK4 is an impressive printer. I understand the price given Prusa's reputation and robust community. Having access to a lot of other makers sharing lessons learned, mods, and replacement parts is critical to making 3D printing work.

However, I think Bambu has the edge. Not only have they provided some very reliable and quick printers, but they're also making material changes easy. Material and tool changers are the future. The new hotend design for the MK4 appears to indicate Prusa knows this is coming too. I think the 3D printing world is going to make a major jump forward in the next 12 months assuming patent trolls don't get in the way.

Its a reasonable concern for a newer company on the market, if their printers are using any proprietary hardware replacement parts could be hard to come by in the future if something did happen causing the company to go belly up.

Unrelated, why the gummy bears? -

PlaidMan About the gummy bears: assembling a Prusa is a major project; as the review says, the MK4 takes 8 hours. Each chapter of the instruction manual includes a certain number of gummies to reward yourself based on the time & complexity. Presumably they don't want the people who buy it pre-assembled to feel left out.Reply

My coworker absolutely loves his new Bambu. I have a really tough decision to make, going Bambu or upgrading/replacing my Prusa MK3S+. -

peachpuff "Prusa Research has been testing the new printers around its office and factory for about a year."Reply

Testing for a year and no input shaping on release? Sounds a bit suspect.

I think a con of this printer is its dated design, core xy is where it's at now, even creality is coming out with one soon. That will most likely be my next printer. -

jackt You at Toms should stop to use the shiny plastic, it makes it harder to see the quality of the print!Reply -

jp7189 Reply

I recently got a bambu x1 carbon with the AMS package, and I love it. I've had 4 printers dating back to 2014 and have had my fair share of tinkering and upgrading and fruatration and sense of accomplishment. For better or worse, Bambu does away either all that. It just prints. No fuss. And it does it extremely well and extremely fast. They have their own slicer, and I haven't even messed with any settings there either. I don't have any expectation of being able to tinker, upgrade,etc. Which I would have said to be a huge negative, but now that I have the Bambu I can't imagine why I would want to anymore.PlaidMan said:About the gummy bears: assembling a Prusa is a major project; as the review says, the MK4 takes 8 hours. Each chapter of the instruction manual includes a certain number of gummies to reward yourself based on the time & complexity. Presumably they don't want the people who buy it pre-assembled to feel left out.

My coworker absolutely loves his new Bambu. I have a really tough decision to make, going Bambu or upgrading/replacing my Prusa MK3S+. -

USAFRet Reply

How long have you had your bambu?jp7189 said:I recently got a bambu x1 carbon with the AMS package, and I love it. I've had 4 printers dating back to 2014 and have had my fair share of tinkering and upgrading and fruatration and sense of accomplishment. For better or worse, Bambu does away either all that. It just prints. No fuss. And it does it extremely well and extremely fast. They have their own slicer, and I haven't even messed with any settings there either. I don't have any expectation of being able to tinker, upgrade,etc. Which I would have said to be a huge negative, but now that I have the Bambu I can't imagine why I would want to anymore.

I'm seriously thinking of that same package.

Currently:

Ender 3 S1 Pro

Ender 3 MAX

Previous:

CraneQuad

Bibo

Micro3D

Nothing currently wrong with the 2x Enders, just looking to level up.

The CraneQuad has me a bit gunshy about multi-filament feeders.

Have you had any issues with that? -

jp7189 Reply

About 3 months. I print mostlyUSAFRet said:How long have you had your bambu?

I'm seriously thinking of that same package.

Currently:

Ender 3 S1 Pro

Ender 3 MAX

Previous:

CraneQuad

Bibo

Micro3D

Nothing currently wrong with the 2x Enders, just looking to level up.

The CraneQuad has me a bit gunshy about multi-filament feeders.

Have you had any issues with that?

ABS, but have done a little PC and PETG too. The thing that puts the Bambu X1 over the top is the full enclosure. I don't do a lot of multimaterial printing, but I love the fact that I can leave 4 spools of different colors or materials loaded and they stay in a dessicated environment. The few multi prints I have done turned put great. Just be prepared to waste a lot of filament down the purge shoot if the object changes colors frequently.

I had an original Taz that I messed with a lot. It felt like I had as many successes as failures with that one, but mostly do to me always messing with stuff.

Then I got the 1st Gen Sigma from bcn3d. It was a good printer, but it had a bunch of quirks that I need to engineer solutions to.

Then I got a seemecnc boss delta 300. Mostly just because I wanted a delta. Generally a good printer but their single hotend, double extruder setup doesn't work with Cura >4.51, and I felt stuck in a dead-end. Also with the very long bowden tube I was never able to dial out stringing problems, and overall quality was meh.

The Bambu is the first printer I haven't touched a thing on. I haven't tweaked any settings. I didn't need to run countless iterations of print tests trying to dial in this or that.

When I watch it sling "slow" materials around at lightning speeds, I still think..no way is that going to come good at that speed. And then it does, and looks better than anything I've ever been able to achieve on the other machines.