Tom's Hardware Verdict

Formlabs Form 4L pairs decent resolution with insane precision to make exceptional prints at a massive scale. It has “paint by numbers” simplicity, speed, and smart sensors to guide your prints. Though we normally aren’t fans of a closed ecosystem, Formlabs gives users plenty of material options from affordable prototyping to engineering and medical-grade resins. This machine isn’t just a business tool, it's a partner.

Pros

- +

Excellent resolution

- +

Perfect prints

- +

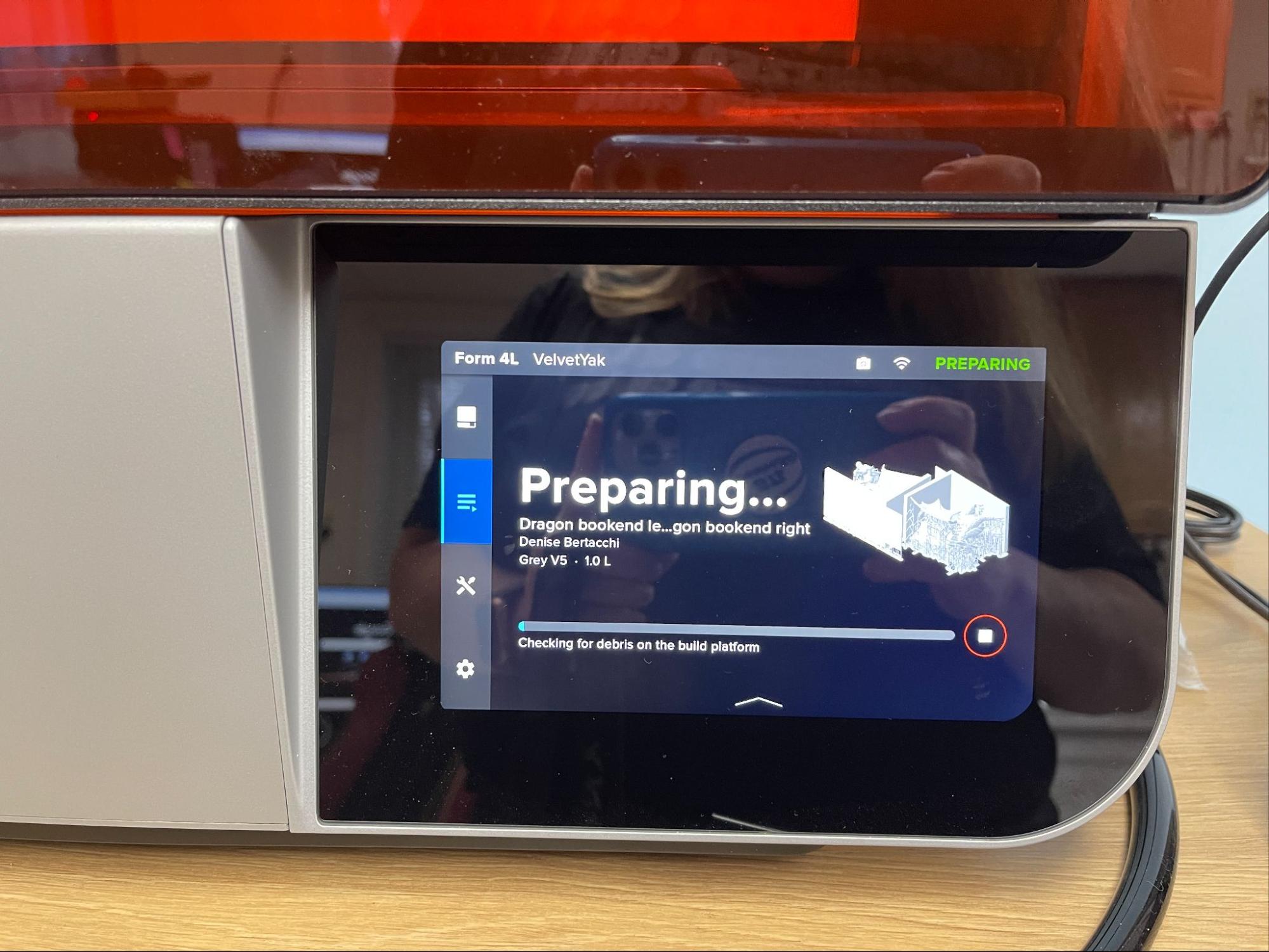

Graphic interface explains every move

- +

Built-in camera

- +

Sensors galore

Cons

- -

Expensive

- -

Must use Formlabs materials

Why you can trust Tom's Hardware

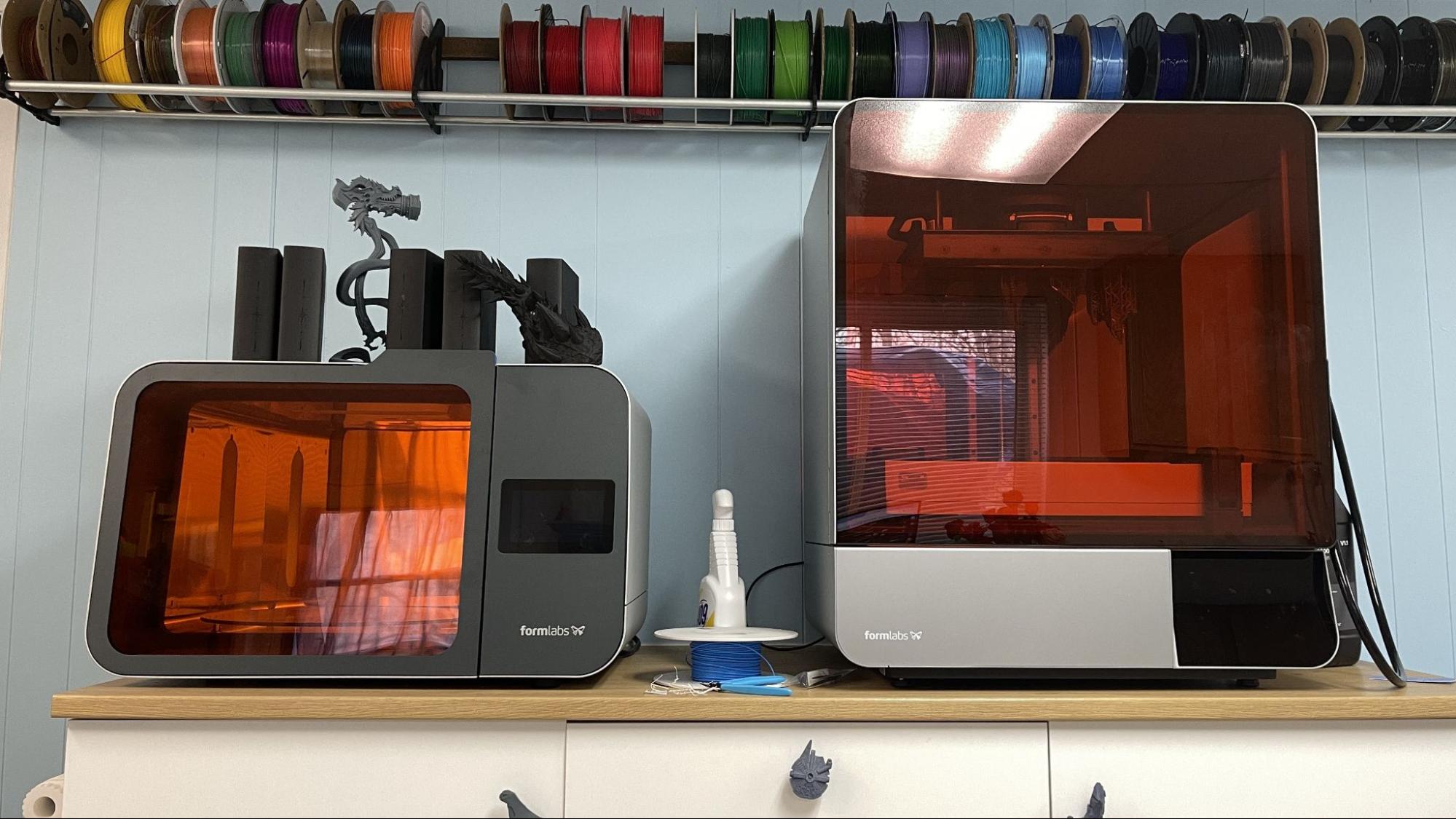

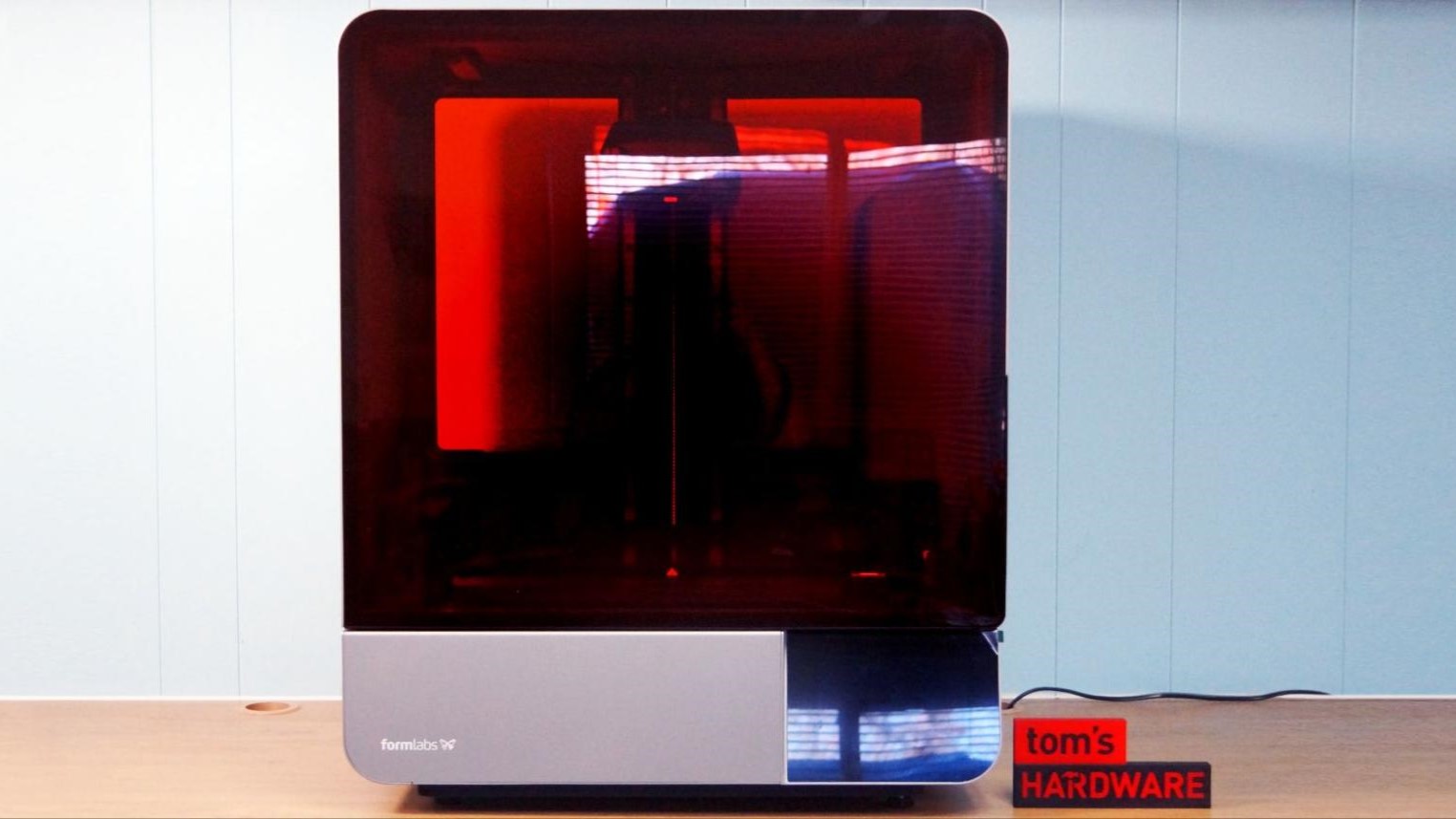

The Formlabs Form 4L is the industrial-size big brother of the Form 4, capable of printing massive resin prints with speed and astounding accuracy. The only thing that’s difficult about this machine is getting it physically into your workshop, which requires a hand truck and a few strong backs.

I should note right away that the Formlabs Form 4L is not a consumer-grade machine, but an industrial behemoth with an industrial price tag of $9,999 for a bundle that includes all the basics. Though this is far out of reach of our normal readers, I think it’s fascinating to see what 3D printers can do when you loosen up the cash flow.

This was probably the most daunting machine I’ve reviewed, right up there with the mammoth Elegoo Orange Storm Giga. It arrived by freight truck on three pallets. Since you simply can not operate a Form 4L on its own, we got the whole enchilada with massive wash and cure stations as well. Due to the size and considerable expense of this unit, Formlabs extended us the courtesy of a loaner machine for this review.

Like the Formlabs 4 before it, you need to stay within the company’s admittedly generous ecosystem, which is actually a perk rather than a punishment. The resin is custom-made to perform with its machines, which takes all the guesswork out of the equation. All you have to do is follow the directions on the slicer and check all the boxes on the print screen to get a good print. The resin and vats are tagged with RFID stickers to make sure the computer knows what slicer profiles to offer and also maintains an inventory list.

If you are a school or university, Formlabs will let you unlock the printer for free, allowing you to experiment with third-party resins. Everyone else needs to pay for that privilege. But seeing the depth of Formlabs' material offerings, I think few people in this market actually need it.

I also tested out Formlabs own Resin Washing Solution, which is less harsh and non-flammable, unlike Isopropyl Alcohol. Seeing as it was parked next to the furnace in my laundry room, it seemed like a prudent choice.

With a build volume of 353 x 196 × 350 mm and prices starting at $8,904, the Formlabs Form 4L is a premium business-class 3D printer for people who demand high quality, ease of use, and reliability. Though it is semi-locked into an expensive ecosystem, the company provides a wide range of materials for every application, including medical, and we find it to be one of the best resin 3D printers and best 3D printers overall.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Specifications: Formlabs Form 4L

Build Volume | 353 x 196 × 350 mm (13.9 x 7.7 x 13.8 inches) |

Light Source | LED with plano-convex lens array |

X/Y Axis Resolution | 46 µm |

Normal Exposure Time | NA |

Interface | 7-inch color touchscreen |

Connectivity | USB, Wi-Fi, LAN |

Machine Footprint | 664 x 528 x 794 mm (26.1 x 20.8 x 31.3 in inches) |

Machine Weight | 58.5 KG (129 lbs) |

Included in the Box: Formlabs Form 4L

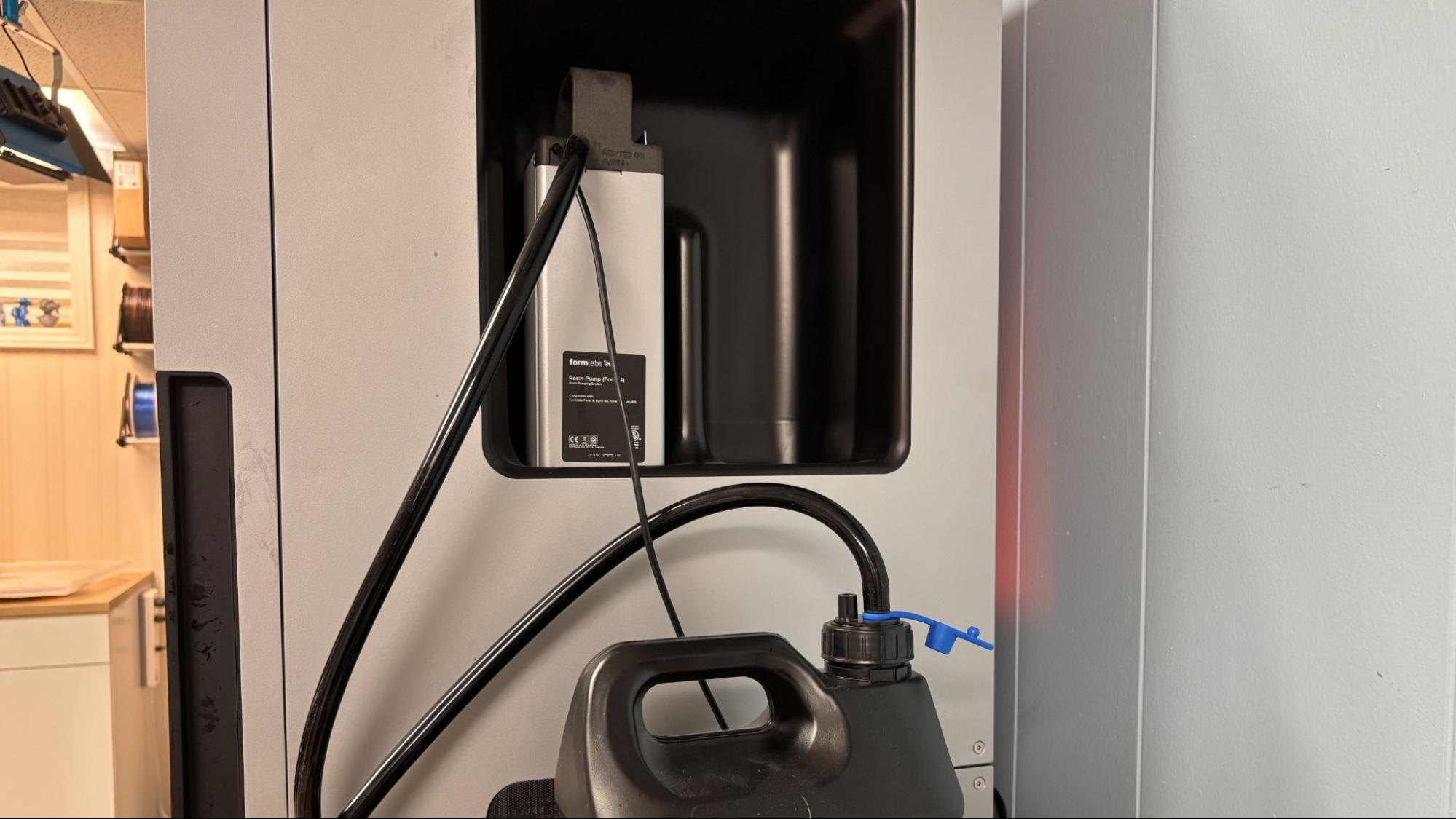

Unlike consumer-level printers we’ve tested, the Form 4L is sold as a bundle and will come at a minimum with one vat and a manual cleaning kit. The kit consists of a large metal tub with a lid for cleaning models, a metal basket, and an assortment of hand tools. We were loaned the complete system, which also includes an automated wash station, a curing station, a metal tray, gloves, funnels, pliers, scrappers, and wipes. Formlabs also provided extra vats and an automatic pump to transfer resin from the 5-liter jug to the printer as needed.

Printing Safely with Formlabs Form 4L

The Formlabs Form 4L requires the same safety precautions as other resin printers. Uncured resin is dangerous, and the solvents used to clean your prints can be irritating to the skin. Use gloves and safety glasses when pouring resin and handling uncured prints.

Make sure the room you use your resin printer in is well-ventilated to avoid inhaling fumes. Spilled or dripped resin should be immediately cleaned with 99% isopropyl alcohol. After printing, make sure to wipe down your printer and bottles to remove smudges of uncured resin. Always keep your resin tightly sealed and safely stored out of reach of pets and children.

Assembling the Formlabs Form 4L

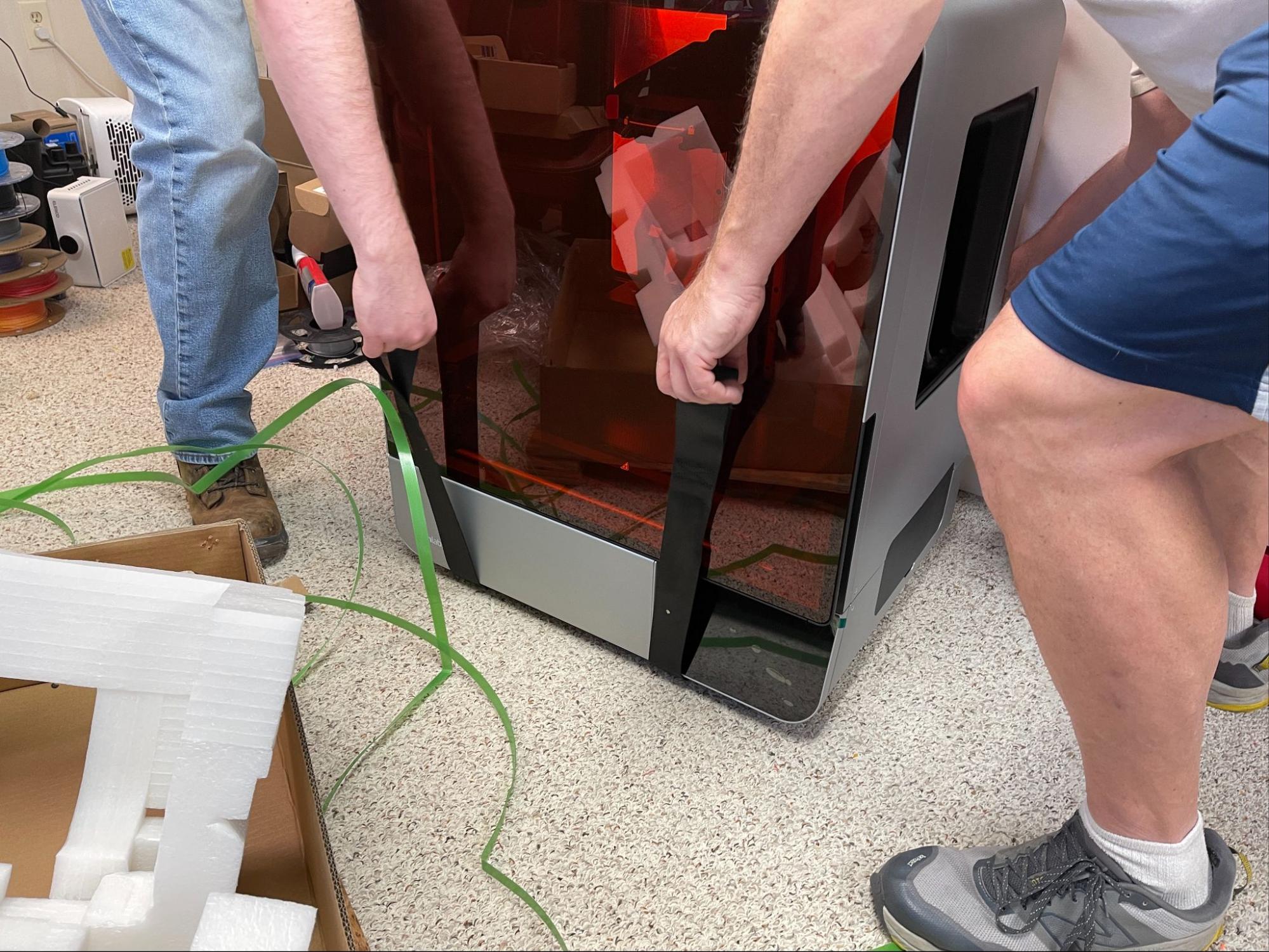

The printer comes fully assembled. You only need to unpack the printer, install the vat, put the wiper in, then lock the vat and build platform in their respective places. However, at 126 pounds, you will need some help getting it into place. The machine comes with lift straps to make it easier to move.

Calibrating the Build Plate on the Formlabs Form 4L

Formlabs Form 4L ships with the build plate factory-leveled.

However, it does have an internal sensor to make sure the machine itself is level so it can accurately read the liquid contents of the vat. During initial set up, the machine will walk you through leveling the four legs on the bottom of the printer, using a provided tool.

Design of the Formlabs Form 4L

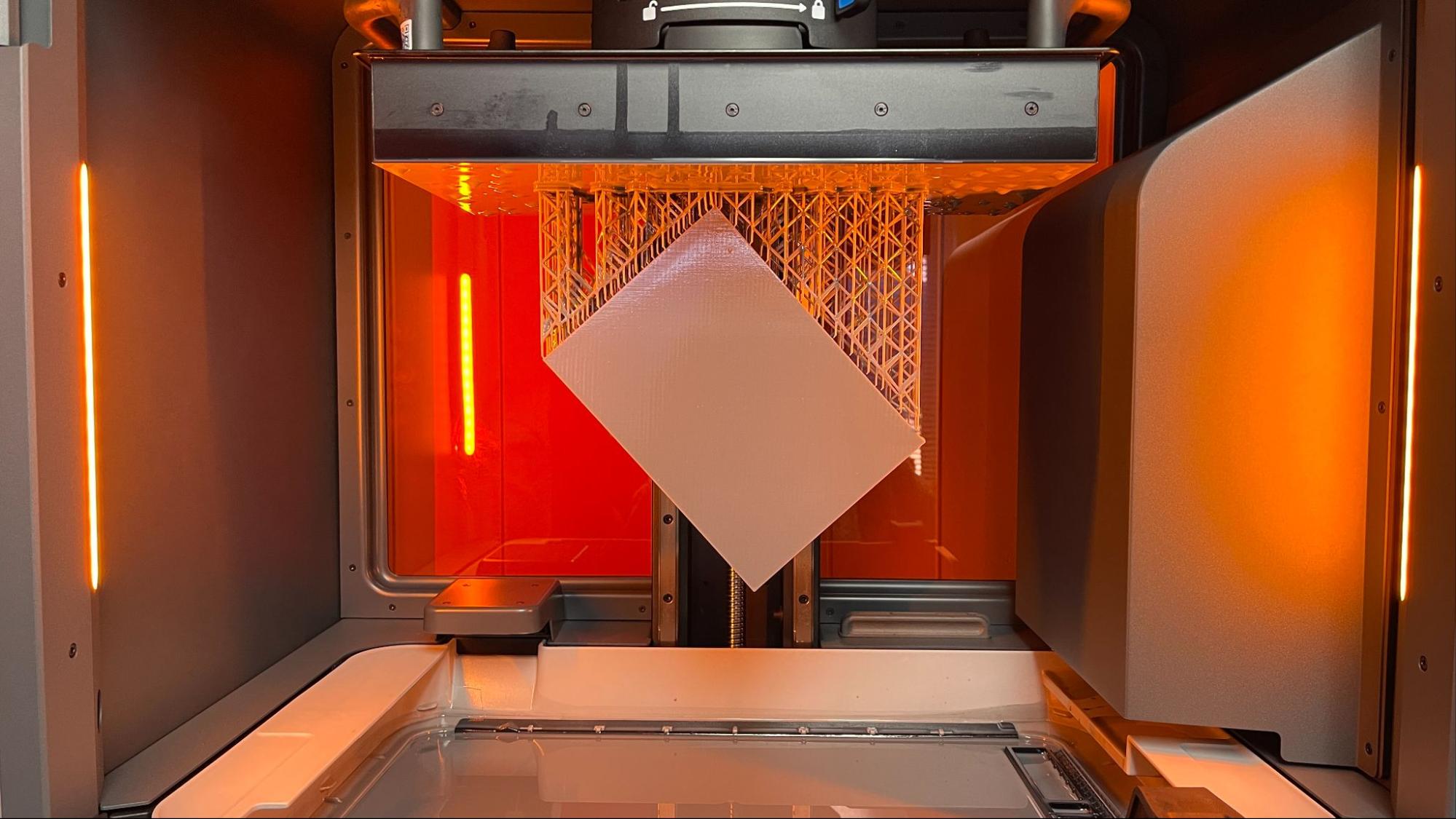

The Formlabs Form 4L is a premium machine built with incredible attention to detail. Due to its size, it has a hinged door that opens like a cabinet, instead of the expected flip-top lid. The oversized vats are the size of cafeteria trays and thankfully are made of light plastic and not metal, but they still require that you handle them with two hands. Everything quickly and securely latches into place: the build plate, the vat, and the wiper. The glass surface over the light processing unit has a non-stick texture to prevent the vat’s film from getting stuck to the glass, allowing the film to gently flex when the build plate lifts between layers.

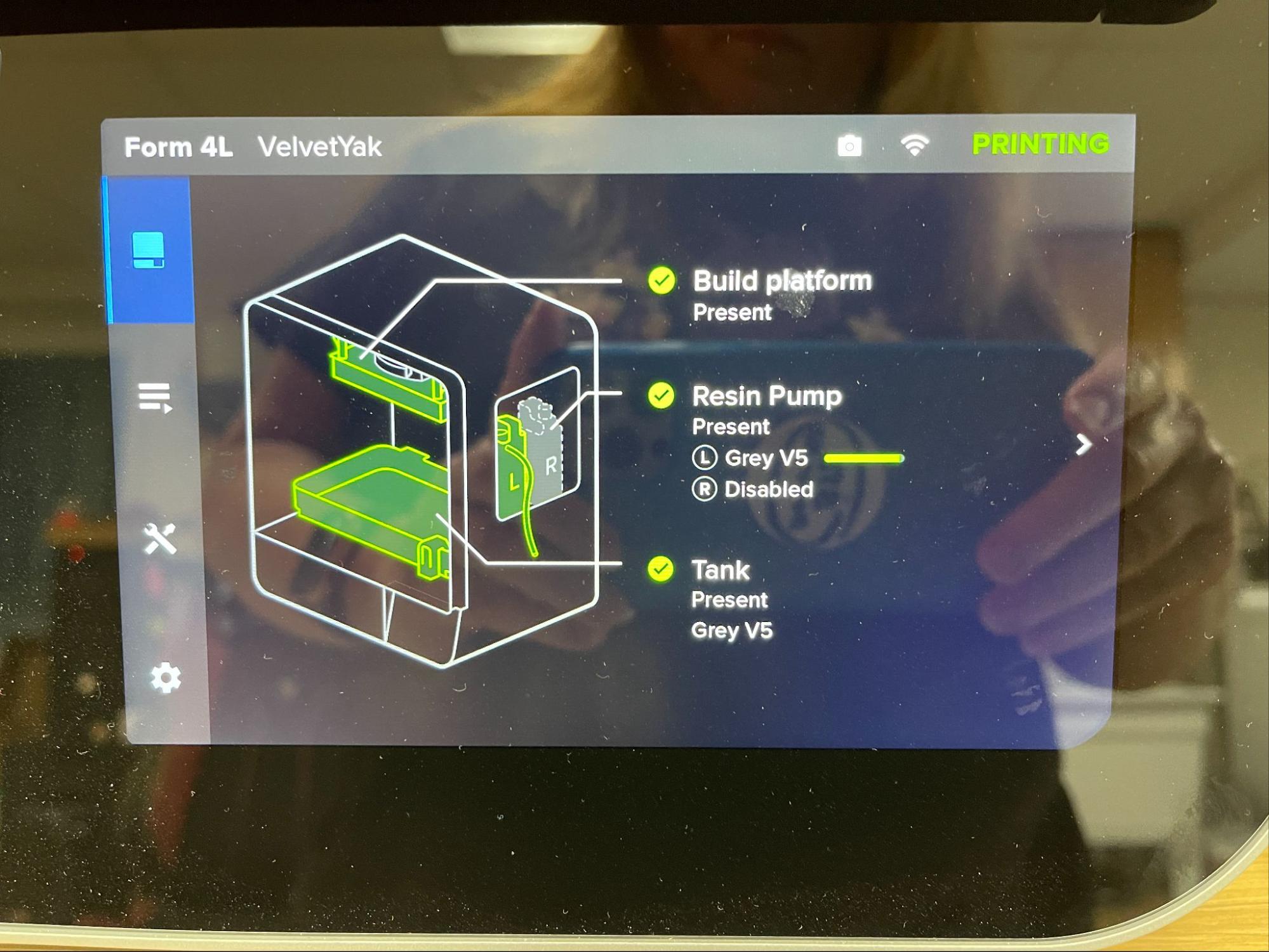

Formlabs resin comes in special cartridges that have a standard bottle cap on the top and a flexible nipple on the bottom. The Form 4L can take two cartridges at a time, and can dispense just the right amount of resin from the bottom opening as needed. If you opt for 5-liter jugs – what I was sent – you can get a pump that fits into the bottle holder and behaves the same way. Jugs come with RFID tags on a plastic chip you slide into a slot on the pump, allowing the printer to recognize the pump and the material it’s feeding. The pump is further connected to the machine with a USB cord.

The vats have a programmable RFID tag, which allows the printer to connect the dots between resin bottles and the vat you use it with. The vats have UV proof lids so you can stack and store them with leftover resin still inside. When you swap vats, the printer will remember what material was in the vat, how much should be left, and how many layers the film has printed. Formlabs suggests buying one vat for each material you regularly use, though the vat’s RFID tags can be reprogrammed if you want to clean it out and reuse for another material. Formlabs estimates the vat could last a year or two for the average user.

The vat also has something I’ve not seen on a consumer machine – a wiper blade. The blade has two purposes: it stirs the resin to keep it well blended, and it feels for debris in the tank. If it encounters a chunk from a failed print, it will stop the printer, alert you and suggest cleaning methods.

The Form 4L has even more sensors that can alert you to dangerous situations. It can track the resin level and will stop when it runs out, it knows if it's sitting on an unlevel surface, and it knows when the lid is open and will ask you to close it. It sounds an alarm if you try to remove the vat without first removing the build plate, which could drip on the glass and cause a difficult to clean mess.

Like the previous Form 4, the Form 4L “only” has 4k resolution, which sounds pretty disappointing when compared to consumer-grade printers with pixel counts of 12, 14 and 16K. But Formlabs proves something I’ve always suspected: sharp details are more about machine precision and the material than pixel count. The Form 4L produces crisp, clean prints with an amazing level of detail and accuracy.

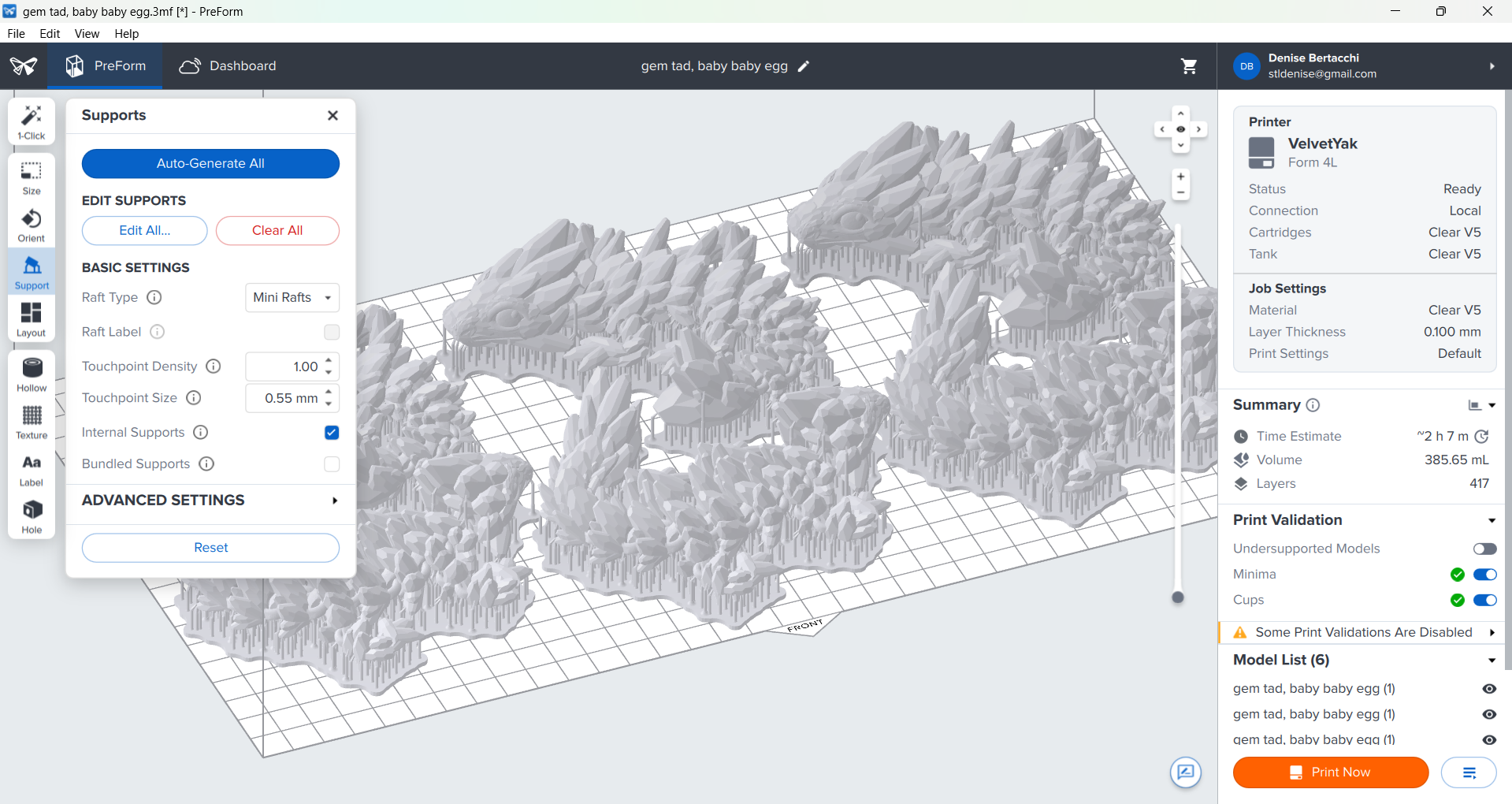

Formlabs printers need to be connected to a computer to receive files, either through WiFi, LAN, or a direct USB cable. This is because the slicer, PreForm, needs a two-way connection to double-check the type of resin that is loaded. It will also track your resin inventory and suggest when you may need to buy more.

The Form 4L also comes with a built-in camera to monitor the printer and record time lapses.

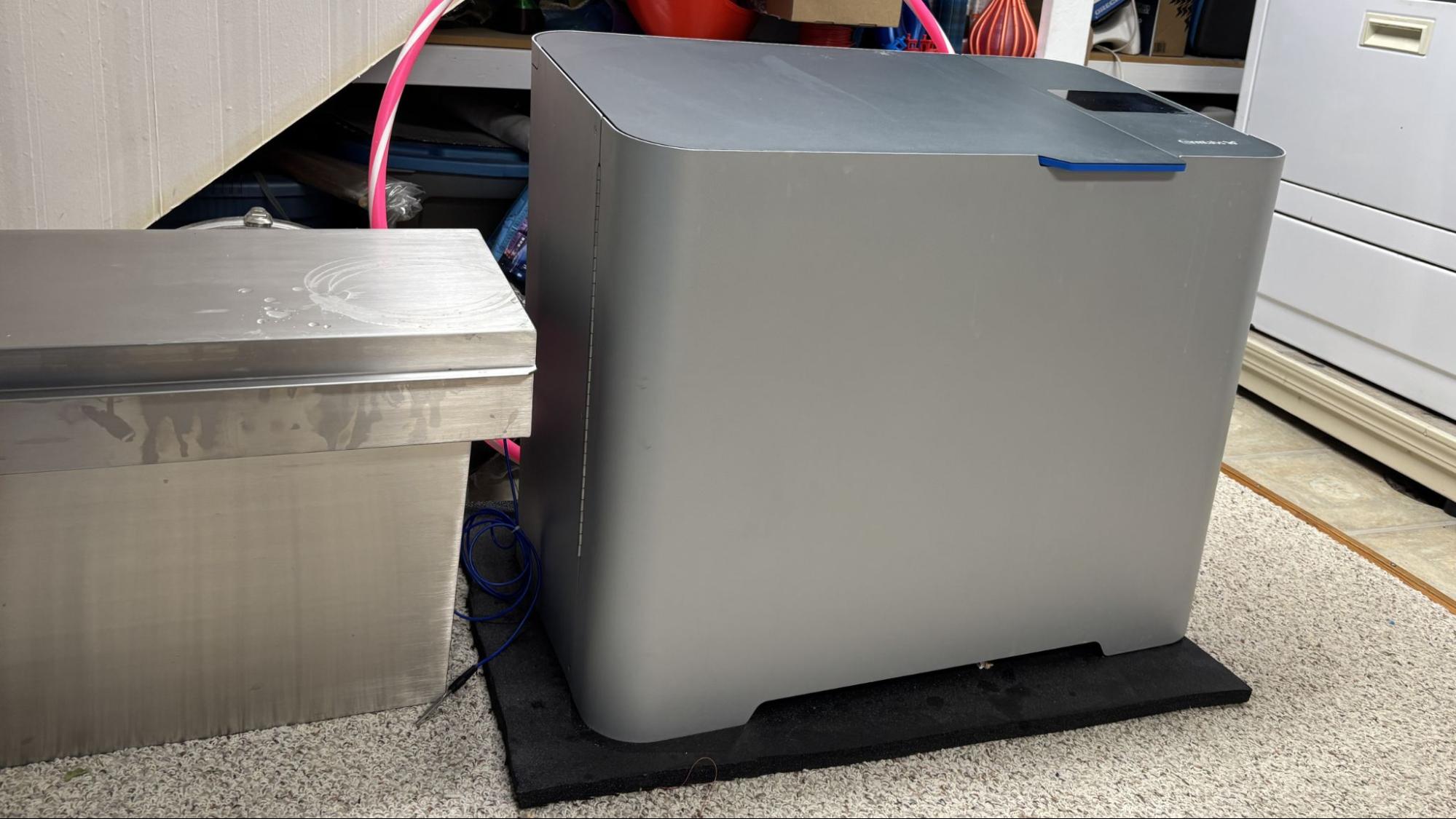

The wash and cure stations are equally well-designed to make the printing process easy. The wash station sits directly on the floor and is the size of a small deep freezer capable of holding 11 gallons of solution. The lid opens with the touch of a button, and the screen lets you program the wash cycles. The basket is motorized, and like the smaller wash unit, it will raise out of the solution when the timer goes off to avoid soaking too long. It has a built-in sensor to monitor the cleanliness of the washing solution, plus a storage compartment for a battery-powered pump to remove the liquid to a bucket or barrel once it’s done.

Formlabs only sent five liters of their low-odor, non-flammable washing solution. This only filled the tank a few centimeters, but since it was recommended to follow up with a soapy water rinse, I made do. The chemical solution was placed in the slightly smaller handwashing tank, and I filled the machine washer with water and a splash of dish soap. It was a bit more work, but the parts came out squeaky clean.

The curing oven is comparable to a full-sized microwave, complete with a glass platter the size of a medium pizza. This was no doubt the best curing station I’ve used with a resin printer. It was preprogrammed with every Formlabs resin, so all I needed to do was pick the material, confirm the settings, and push the button. It knew if the resin needed a heated chamber or not, and how long to run the UV light. The glass turntable is something I’d like to see more often – it cleaned up easily and never got cloudy, as plastic turntables do.

Slicers Compatible with the Formlabs Form 4L

The Form 4L only works with its custom software, PreForm. Software is a free download, and it needs to be connected to the printer via WiFi, LAN or USB cord.

PreForm software is fully automatic and simplified. Because you’re working within the Formlabs’ walled garden, there’s no need for you to tinker with the settings – perfect settings have been found. You only pick the layer line size, which determines speed. It defaulted to a 0.1 mm layer, which is considered quite chunky normally, but was listed as “fast”.

The program can do everything a slicer should – it can hollow your model, automatically add supports to the inside & outside, and neatly multiply parts in organized rows. Once the Print Validation area is all green, you’re good to go.

You have limited ability to tune the printer in the advanced settings, but I found no need for this on my tests.

The Dashboard area takes things a step further. Here you can track your print history, see how much resin is available, and if you have a farm, you can see which printers are open. It tracks when you last used each cartridge of resin, how much it estimates is left in the bottle, and has a handy link to the Formlabs store to order more.

Washing and Curing Your Prints

Before you can admire your prints, you’ll need to clean off the extra resin. Normally, I wash them with isopropyl alcohol and cure with UV light, but for this printer, I used Formlabs’ bespoke Resin Washing solution, which is a non-flammable and low-odor alternative to alcohol.

Prints should be allowed to air dry before being placed in the curing station.

Supports are easier to remove before curing because they are softer. Clip the supports off with side cutters and use tweezers to remove stubborn supports. Remember to always wear gloves while handling uncured prints.

Then place the print in a UV curing station for 15 minutes, or outside in bright sunlight for a few hours.

Your wash solution should never be flushed down the drain, especially after being contaminated with uncured resin. Instead, keep using the resin until it’s too dirty, then leave the container open to evaporate. The remaining sludge can be cured with UV light or the sun before being thrown away.

Supports should also be cured before being thrown away.

Sample Prints on the Formlabs Form 4L

I first tested the printer with the AmeraLabs resin test print using Formlabs Grey V5 resin that was provided for the review, which sells for $79 per liter. The print looked perfect, with some of the cleanest details I’ve ever seen from that model. The print took one hour and 17 minutes to complete using a .05mm layer height at default settings. Though it was unnecessary to run a test print – there’s nothing I could really change in the slicer – it was nice to set a baseline expectation of what the printer can do. The entire model was crisp, and I could see details, like windows in the buildings, that consumer printers often obscure. The raft on the bottom was stuck a bit too tight, and being very thin, broke off.

Next, I ran my favorite Rocket Bust by Wekster, which I’ve been using as a larger comparison test for resin printers. I ran it twice, once using speedy .15mm layers (comparable to more detailed settings on an FDM printer) and again with super fine .05mm layers. The fast model printed in one hour and 20 minutes, and is really quite good. There are visible layer lines, but the part is clear and precise. The finer mode produced a perfectly smooth print with no layer lines in 4 hours and 54 minutes. The fast print is on the left, and the slower one is on the right. The dots on his shoulder are from supports that were not filed off.

Next up is a book nook model that comes in three parts: a box, the dragon head, and the claw. The box is printed on its own in Black Resin V5, which sells for $79 per liter. I didn’t hollow it out, so it’s a hefty 543 grams, taking 433 mL of resin. It printed in 7 hours and 54 minutes using thick 0.1 mm layers. The dragon was also printed in speed mode, taking 8 hours and 25 minutes with 0.1 mm layers. I was able to use PreForm’s slicer to hollow the dragon and add holes, so it is a much lighter weight and only took 150 mL of resin. Using the 0.1 mm layer height saved nearly 15 hours of print time and only left the slightly visible layer lines. The book nook is 200 mm tall, not quite 8 inches.

Dragon Emerging Book Nook by CraftyKid 3D

Formlabs makes an impressive Clear V5 resin, which sells for $79 per liter. Below, you can see a very clear crystal dragon using a standard 0.05 mm layer height and default settings. The one on the left is unfinished, while the one on the right is sealed with Modpodge. This dragon is printed at 95% to squeeze him onto the rectangular bed, but is completely solid and printed flat without supports. He needs a gentle touch to pop him off the bed with a scraper, but the smooth bottom surface is much nicer this way. There are no layer lines to be seen, he has excellent flexibility, and was printed in 3 hours and 49 minutes.

Though not pictured here, Formlabs has released a similar clear resin called Creator Super Clear for $45, which can be used on any consumer resin printer.

The last resin I tested was Formlabs’ Tough 2000 Resin, which has the strength and stiffness of ABS. I used this one to test some practical prints, like a clip that refused to break, a hefty little hammer, and a working wrench. I printed each tool solid for added weight. The hammer may not be good for framing houses, but it did a great job tapping a chisel to get prints off the Formlabs build plate.

The whole set took 2 hours and 36 minutes to print on one build plate, using faster 0.1 mm layers. I tested the wrench on some bolts, and it really works.

Bottom Line

The Formlabs Form 4L is a great tool for businesses that need large models and accurate prototypes fast and don’t want to assign a mechanic to run their printer. My test prints barely scratched the capabilities of this machine. The optional “open material mode” means the ecosystem isn’t as locked down as you might think, and can be purchased for a one-time fee. The open mode is also free for schools and universities.

Its $8,904 starting price tag pushes it right out of the consumer market and probably past a number of small businesses. But this kind of machine would be an excellent tool in an educational setting, where you want to spend time on producing parts, not worrying about how to make them print. The helpful guides on the user interface and the constant reminders to follow procedure allow makers to concentrate on their design skills, not their knowledge of chemistry.

If you’re looking for a premium resin printer that delivers the same quality with a smaller build volume, then definitely check out the smaller Formlabs Form 4 for $3,499. If you need something with a similar massive build size, a smaller price tag, and don’t mind getting a little experimental with your slicer settings, check out the Phrozen Sonic Mega 8K S for $1,299.

Denise Bertacchi is a Contributing Writer for Tom’s Hardware US, covering 3D printing. Denise has been crafting with PCs since she discovered Print Shop had clip art on her Apple IIe. She loves reviewing 3D printers because she can mix all her passions: printing, photography, and writing.