'Open hardware desktop 3D printing is dead' — rise of China's government subsidies, country's permissive patent system cited by Prusa CEO

3D printer companies are raiding the Open Source cookie jar, and it’s starting to hurt.

Josef Prusa, Founder and CEO of Prusa Research, declared “open hardware desktop 3D printing” is dead. It’s a shocking statement coming from a man with the Open Source logo tattooed on his forearm. But it’s also true. Prusa cites the rise of China's 3D printing industry and the country's permissive patent system as a key pain point.

Prusa recently outlined his thoughts on the demise of Open Source Hardware, something he has championed since starting his company “in a moldy basement in Prague, packing printer frames in pizza boxes.” Prusa Research proudly believed in the open-source philosophy, an idea where both people and companies share research and innovations to grow an industry together.

But that Open Source movement couldn’t begin until after patents on the core technology, filed by inventor Scott Crump, started to expire in 2009. Crump founded Stratasys in the 1980s, and its patents limited 3D printing to proprietary industrial machines. The aversion to patents by fans of Open Source is understandable when you realize that 3D printing was kept out of reach for decades by a few corporations.

Early versions of the Original Prusa i3 were plainly Open Source, happily bearing the logos of the many companies contributing parts: UltiMachine motherboards, LDO Motors, E3D V6 hotends, Noctua Fans, and a Meanwell Power supply. The Prusa MK2 and MK3 were more than the sum of their parts: it was a shining example of the Open Source community.

It was also a machine that was easily copied and cloned. In 2017, Thomas Sanladerer posted a YouTube series on cheaply cloning the Prusa MK2, just nine months after the machine’s launch. He admits in the video’s opening that “Prusa is going to hate me for this one,” but since the machine was completely Open Source, it was not only legal, it was a fun challenge.

While Josef Prusa publicly bemoans the loss of Open Source, his company, Prusa Research, has been quietly circling the wagons around newly developed intellectual property. The revolutionary Nextruder, with a fresh set of sensors and a custom nozzle design, remains proprietary. It was introduced for the Prusa XL and used on both the MK4 and the Core ONE. The MK4 launched as a kind of hybrid Open Source, letting users have access to all the STL files for printed parts, but holding back on design files for electronics. It's the same case for the Core ONE, which shares many parts with the MK4.

What changed, you may ask? Prusa blames the Chinese government in his blog post, stating that in 2020, it made 3D printing a “strategic industry.” This means Chinese 3D printer companies benefit from their government’s protection and economic support, with the goal of becoming global leaders in technology. Prusa cites a study by the Rhodium Group on the assessment of China’s State Support, which explains how China supports its manufacturers with grants, tax incentives, and below-market access to financial instruments. In short, it's way cheaper to make a 3D printer in China.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Prusa Research also noticed a massive uptick in Chinese patents on 3D printer technologies. Patents are regional, not global, and Open Source is an honor system many choose to ignore. It only costs $125 US to file a patent in China, but roughly $12,000 to $75,000 to strike one down, according to Prusa’s figures.

Chinese companies are raiding the Open Source cookie jar, so to speak, taking existing ideas and claiming them as their own. Because patents are contained within a country’s borders, this doesn’t mean a company from China can prevent Prusa Research from making printers, but it does mean they can’t sell them in China. It’s going to get ugly when a company uses a Chinese patent as prior art to convince the US Patent Office to issue a patent here, and spend thousands of dollars to correct this kind of oversight.

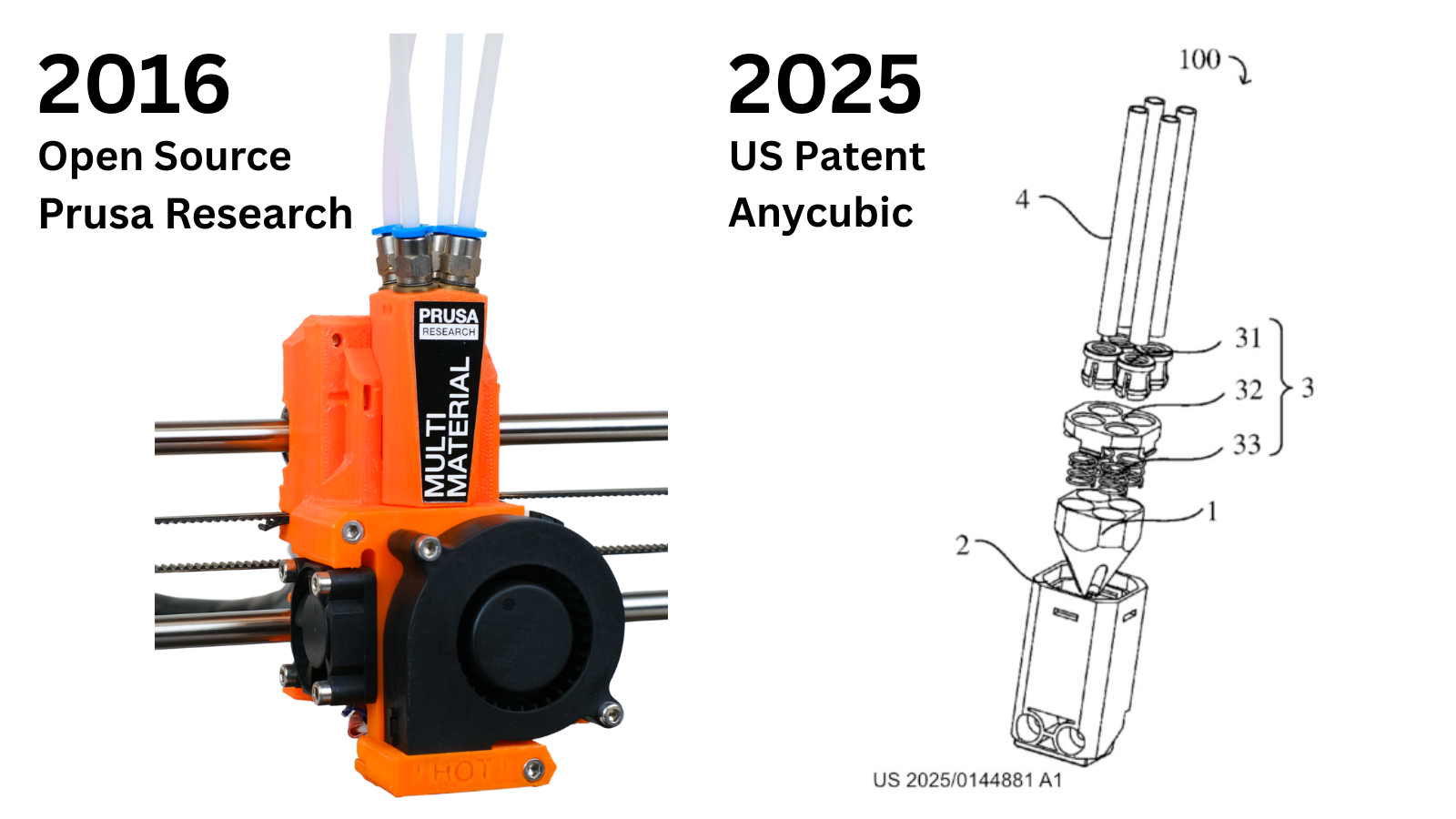

Prusa pointed out that his company’s first Open Source MMU design was recently granted such a US Patent for Anycubic, which uses the tech in the new Kobra 3 Combo. This is getting quite confusing, as the design also inspired Bambu Lab’s A1 and A1 Mini multicolor hub, which launched several years before Anycubic’s color machine.

Of course, Bambu Lab is fighting its own patent disputes, going toe to toe with the American giant that started it all, Stratasys.

Denise Bertacchi is a Contributing Writer for Tom’s Hardware US, covering 3D printing. Denise has been crafting with PCs since she discovered Print Shop had clip art on her Apple IIe. She loves reviewing 3D printers because she can mix all her passions: printing, photography, and writing.

-

ezst036 It doesn't entirely sound like things are matching up here.Reply

The issue seems to be centered around labor costs. Open source was really good at fighting against high-dollar 3d printing machines where all the engineers were making 100k or hundreds per year salary at their mega corporations.

But now, the question has become "Is open source incapable of fighting against slave labor?" That makes open source the more expensive option. It seems that we do have the answer. -

chaz_music Copying others' ideas is not just a human characteristic, as it is seen in nature as a survival technique. So it should not be a surprise in human technology, just a surprise that society does not push for fairness.Reply

Most patent systems have issues, but the Chinese system allowing patents without any reasonable reviewing of prior art is going to ruin their innovation. That will result in a quagmire where only the original prolific patent filers can play in each market.

Note though that our US system is horrible, too. I have given court opinions on patents that should never had been awarded. Some with prior art going back decades, reviewed by lawyers who only have a few years experience out of college and filed by engineers who did not do any reasonable prior art search or just did not know about previous technology. Plus, the US patent database is allowing patents to be filed in topics that are not properly related, or even worse, not using proper industry terms. An example is a company that filed a solar control that was a twist on MPPT - but never using the term MPPT in the entire patent. So they have a stealth patent that trolls would love to buy. Another company filed a US patent that was an article in a magazine and it was granted.

In relation to this article: Human innovation is getting to a tipping point that needs some sort of global fairness laws and a global patent rethink. And books as well. Already, authors are refusing to create more books, because they get copied online and then scraped by AI without any financial return for the authors. Some books culminate decades of research. And even in my own fields of expertise, I have knowledge that appears to be unique and unknown to my peers and I use that when I do my consulting. But that knowledge won't get passed along due to no value returned for the incredible effort to develop that knowledge (some took years of simulation work). I would expect the same is happening here with the 3D printing technology. -

edzieba Funny how open source 3d printing only 'died' when Prusa gave up open sourcing their printer, but Marlin and Klipr development (also open source, and which Prusa relies on*) continues unabated.Reply

Sounds more like open source printing will continue unabated, but it's just Prusa that's approaching the chopping block and panicking. Sour grapes that high-volume printer manufacturers are now just ignoring Prusa and aiming to replicate Bambu Labs' success instead?

* Not to mention the RepRap Mendel on which the Prusa line was based. And Slic3R, which Prusaslicer is based on (forking chain went: Slic3r > Prusaslicer > Bambu Slicer > Orca Slicer). -

S58_is_the_goat Prusa is just upset they don't have any talented people designing printers. The xl is a joke and didn't work when it was released, took a year to get it to work and people still complain about bugs.Reply

Took them 2.5 years to release a competitor to the x1c and its average at best with bottom of the barrel components, ex prusa engineer admitted they used ali express quality stepper motors, that's why vfa is included for free in every print.

Even if they brought the prices down it would still be a tough sell. They don't even know how to integrate a camera into the core one, it's literally an afterthought. -

jp7189 Reply

I wish this wasn't the case, but you're pretty spot on. I was at the show where the XL was publically shown off for the first time, and everyone was putting in pre-orders (and i was sorely tempted). By the time it actually shipped and got good, the industry has passed by. Last year at the same show, Prusa fans' were locked on to the fact that the XL wastes less filament on material change, and they all chanted that like a mantra because it was the only advantage left.S58_is_the_goat said:Prusa is just upset they don't have any talented people designing printers. The xl is a joke and didn't work when it was released, took a year to get it to work and people still complain about bugs.

Took them 2.5 years to release a competitor to the x1c and its average at best with bottom of the barrel components, ex prusa engineer admitted they used ali express quality stepper motors, that's why vfa is included for free in every print.

Even if they brought the prices down it would still be a tough sell. They don't even know how to integrate a camera into the core one, it's literally an afterthought. -

tanon Reply

You're right, this doesn't add up at all.ezst036 said:It doesn't entirely sound like things are matching up here.

The issue seems to be centered around labor costs. Open source was really good at fighting against high-dollar 3d printing machines where all the engineers were making 100k or hundreds per year salary at their mega corporations.

But now, the question has become "Is open source incapable of fighting against slave labor?" That makes open source the more expensive option. It seems that we do have the answer.

On the one hand, he's talking about Open Source, which, by definition, means publicly disclosed designs/plans and on the other hand he's talking about patents, which should be impossible to claim on open source designs, as that's the very definition of prior art.

It sounds like what's actually going on is that his open source designs are being examined by Chinese firms, modified in a non-trivial way to make them better (or, more likely, cheaper to manufacture) and then those new designs are being patented.

If that's the case, that is indeed somewhat sad, but that's the way the World has worked since patents were first introduced. Practically nothing is ever a totally new and novel invention - everything builds on prior designs and ideas.

If you don't like that, then the answer is simply to keep your designs proprietary and not disclose them, rather than releasing them as open source, then lamenting the fact you can't gatekeep them later on. -

tanon Reply

You hit on a very interesting point here.chaz_music said:In relation to this article: Human innovation is getting to a tipping point that needs some sort of global fairness laws and a global patent rethink. And books as well. Already, authors are refusing to create more books, because they get copied online and then scraped by AI without any financial return for the authors. Some books culminate decades of research. And even in my own fields of expertise, I have knowledge that appears to be unique and unknown to my peers and I use that when I do my consulting. But that knowledge won't get passed along due to no value returned for the incredible effort to develop that knowledge (some took years of simulation work). I would expect the same is happening here with the 3D printing technology.

Off-topic here, but when I think about it, the open (and free) access to information that has resulted from widely available computer storage and the internet, could almost be considered to be a real world implementation of the Socialist model of universal public property ownership; so it's interesting to see the problems/contradictions/lack of fairness associated with that kind of system - something which is typically overlooked or simply assumed to not exist, by proponents of that system.