Tom's Hardware Verdict

The WeCreat Vision Pro brings a powerful 45W laser and automatic features to the party, but the real strength of this machine is the ecosystem of add-ons and modules that take it to the next level.

Pros

- +

45-watt laser can easily engrave many materials

- +

Fully enclosed work area keeps smoke from escaping

- +

Included MakeIt! software is easy to use without compromising features for power users

- +

Optional 2W IR laser can easily engrave stainless steel

- +

An optional pass-through feeder enables processing material up to 12 feet long

Cons

- -

Optional accessories drive up the price considerably

Why you can trust Tom's Hardware

The WeCreat Vision Pro is a fully enclosed 45-watt laser engraver and cutter that has superseded the original WeCreat Vision machine, a popular choice for home businesses. The Vision Pro features a large build volume of 19.7 x 12.6 inches (500 x 320 mm), a powerful 45-watt laser, and a sleek, satin-black enclosure.

During our review, we engraved slate coasters, silicone watch bands, birch plywood, and even stainless steel with ease. The Auto Pass Through Feeder enabled the processing of long sheets of material, the Rotary Pro worked flawlessly to engrave on stainless steel tumblers, and the 2W IR Laser Module easily engraved a stainless steel bottle opener with no surface preparation required. All these optional accessories can drive up the price, which is the primary drawback of this system.

The WeCreat Vision Pro Super Pack bundle ($3,449.99 as of the writing of this review) is absolutely deserving of a spot on the list of the best laser cutters and engravers, and earned the title of Best Laser Cutter for Home Business, replacing the previous generation WeCreat Vision. The beginner-friendly features like the project library and material test array on the MakeIt! software are simple and intuitive for beginners, but advanced users and small businesses will no doubt appreciate the ability to add accessories à la carte depending on their offerings.

Specifications of WeCreat Vision Pro

Machine Footprint | 26.8 x 20.87 x 9.96 inches (680mm x 530mm x 253mm) |

Engraving Size | 19.7 x 12.6 inches (500mm x 320mm) |

Laser Type | Diode, Class 1 |

Laser Power | 45W |

Laser Spot Size | 0.08mm * 0.08mm |

Laser Wavelength | 455nm |

Motion Accuracy | 0.01mm |

Enclosure | Integrated |

Cutting Platform | Removable |

Air Filter | Optional |

Connectivity | USB, Wi-Fi |

WeCreat Vision Pro: Included in the box

Arriving in a box that measured 36 x 26 x 16 inches and weighed 78 lbs., the WeCreat Vision Pro shipped with all the tools and accessories that are needed to get started. The inside of the Vision Pro is filled with foam and boxes for the accessories, and there are six screws that need to be removed after shipping to allow the unit to lift up and down during auto-focusing.

The laser bed trays, rotary attachment, air assist module, wi-fi antenna, and all of the attachments are included in boxes in the unit as well as all the cables required for use. The Vision Pro also includes a pair of test engravings to demonstrate the machine is functional before shipping. Included are both a bitmap engraving of a cat as well as a linework test that shows fonts, straight lines, and circular profiles in an array.

Design of the WeCreat Vision Pro

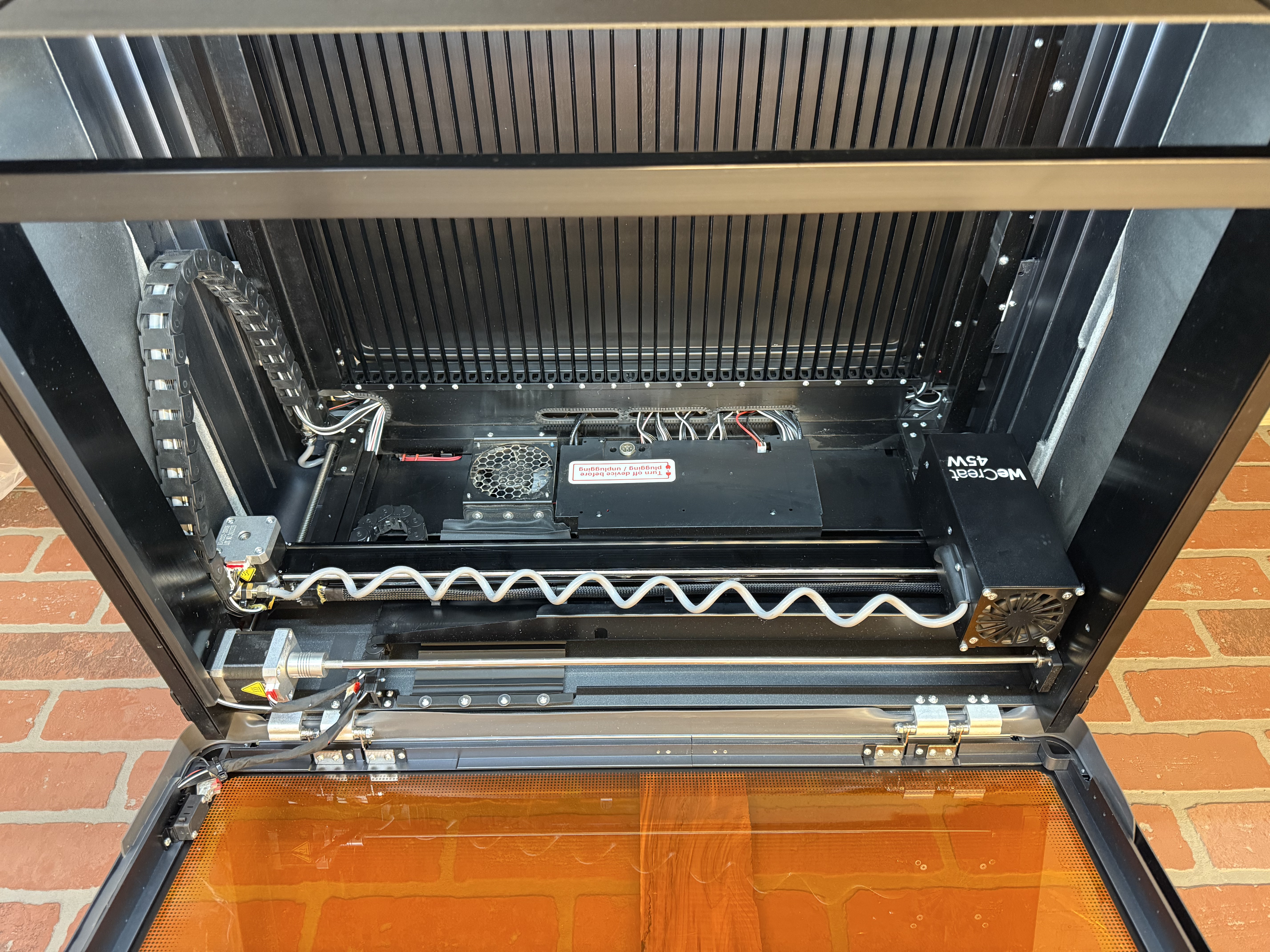

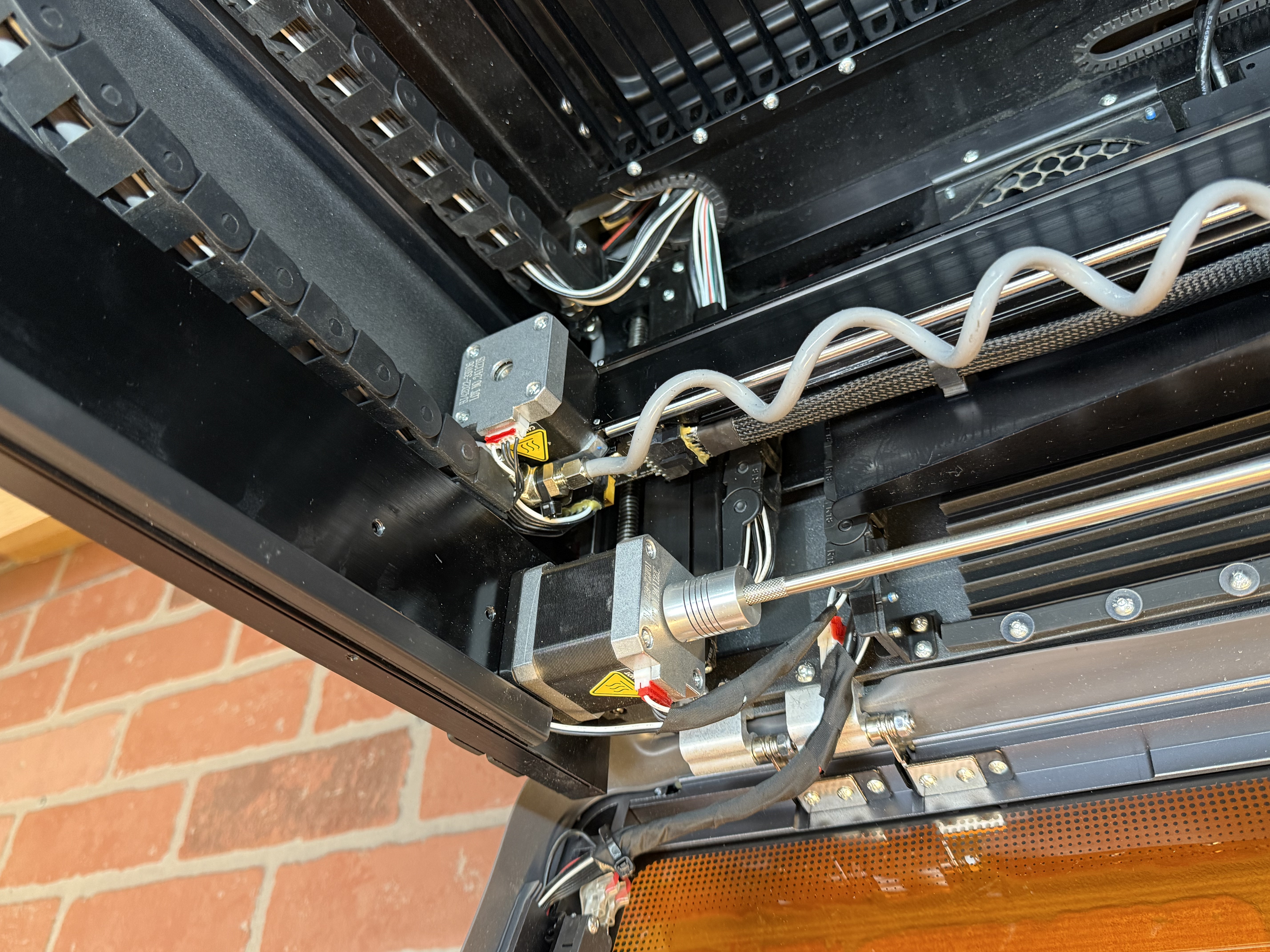

The motion system and internal wiring of the Vision Pro is composed of prosumer components that have been designed with service, maintenance, and replacement in mind. The gantry is stiff and uses linear rods to move the engraving module back and forth in the X-axis, and the cables running up the Y-axis are safely wrapped inside a cable chain that prevents them from getting kinked, tangled, or caught during fast movements. The air assist is external to the unit, and provides compressed air to the toolhead to blow smoke away during engraving and prevents buildup or charring on top surfaces.

The power switch is located on the rear of the Vision Pro, and is located next to the air assist power plug, flexible hose coupling, USB port, and exhaust for the fume extractor. The addition of Wi-Fi is a welcome feature, and allows jobs to be sent without having the engraver directly connected to a computer. The included Wi-Fi antenna worked perfectly for connecting to a local network and I was able to send jobs remotely before starting processing by pressing the green button on the front of the unit.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

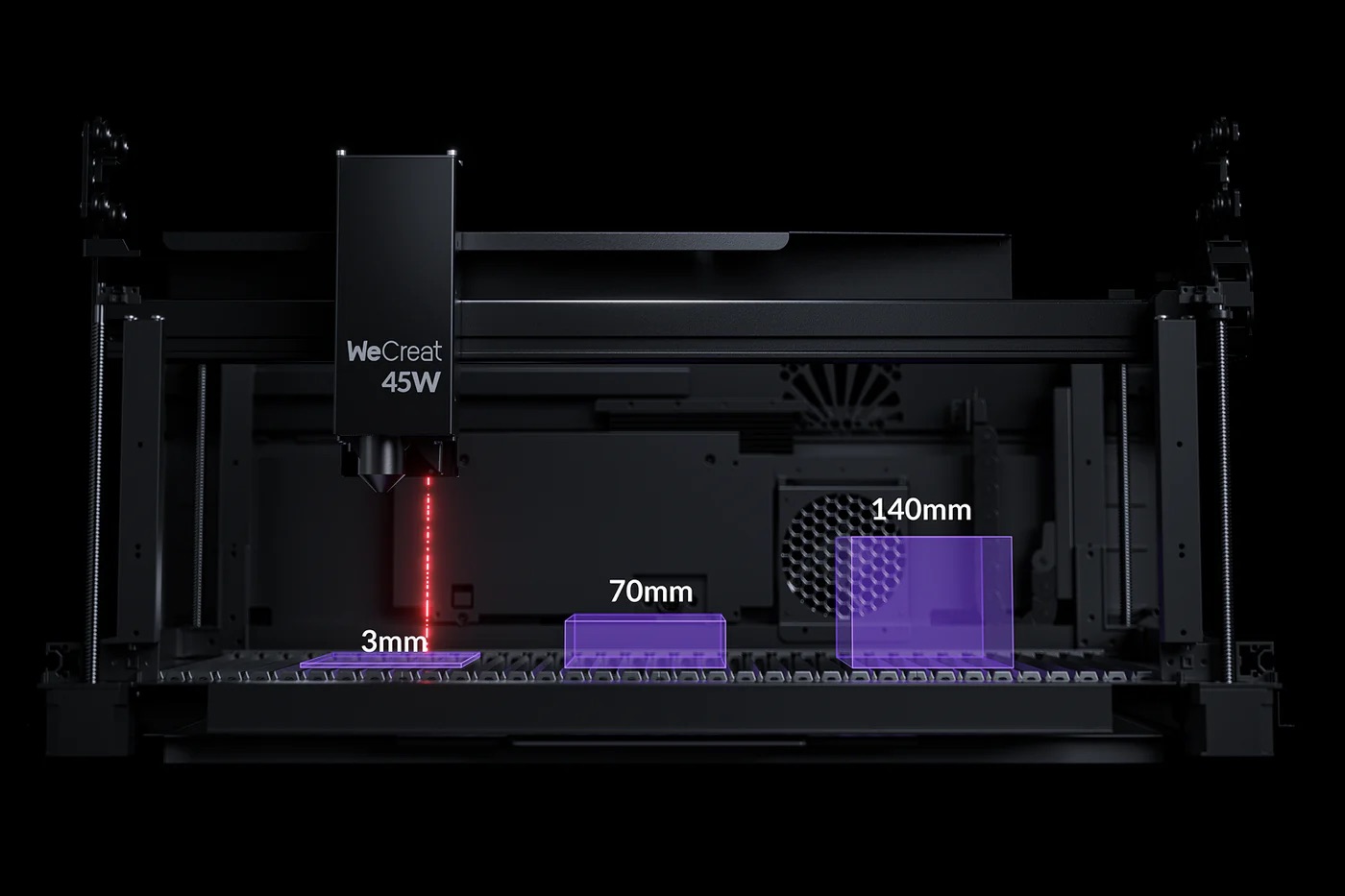

The Vision Pro is a large machine, and occupies a substantial footprint on a workbench. The signature feature of the Vision series from WeCreat is the auto-focusing laser, which moves the entire enclosure and laser gantry up and down to compensate for the thickness of the material. This clever addition allows for a project height of up to 140mm (5.51”), so taller objects can be engraved without needing to manually focus.

This automatic focusing is a unique feature on the WeCreat Vision family of engravers, and it’s one of my favorite things about the Vision Pro. Focusing the laser and setting the height is similar to leveling or calibrating the bed on an FDM 3D printer: simple in theory, frustrating in practice, and everyone has their own process or secret for making it work. Lower cost lasers like the Creality CR Laser Falcon typically use a hinged arm to drop and manually set the offset, a step that is completely skipped by the Vision Pro.

By removing the manual step from the process, WeCreat has significantly reduced the time it takes to set up a build or run trial-and-error tests to find the right offset. The 45-watt diode laser is advertised as being the equivalent of a 60-watt laser due to using a concentrator that WeCreat refers to as BeamFocus.

The HD camera is located underneath the lid of the Vision Pro, and doesn’t require any calibration after assembly. This camera shows the available work area and gives an accurate image that can be used for precisely positioning jobs to avoid misalignment or cutting off the edge of a piece of material. Just like the automatic focusing, this brings down the barrier to entry significantly for new users and makes planning cuts a simple process.

The Vision Pro has multiple safety features integrated, including a fire-retardant metal enclosure, a light-blocking lid for reducing the intensity of any reflected light from the laser, and is rated as a Class 1 laser device. The exhaust port on the back pulls smoke and odor out of the machine through a flexible hose, which can be connected to an external vent, air handling system, or the optional fume extractor designed by WeCreat.

Fume Extractor for the WeCreat Vision Pro

While engraving plywood may only result in a small amount of smoke, using the laser to cut through a 5mm piece of basswood is a quick way to fill a room with smoke and odor. The Vision Pro has an exhaust port on the back, which can be used to mitigate the amount of smoke generated during material processing. The AirGuard Ultra Fume Extractor is an optional accessory that connects to the exhaust port via a hose and filters the air through a 5-stage filter to catch large particulates as well as fine dust and other VOCs (volatile organic compounds).

I tested the Vision Pro in a garage, and the amount of smoke generated during cutting would make using the machine impossible without some level of air handling and filtration. Using the AirGuard Ultra, the smoke is visibly pulled from the enclosure and into the fume extractor, providing much-needed filtration during material processing. Compared to the more industrial look of the original Fume Extractor that was launched with the original Vision and Vista, the AirGuard Ultra looks more like a portable humidifier or a small AC unit.

Software for WeCreat Vision Pro

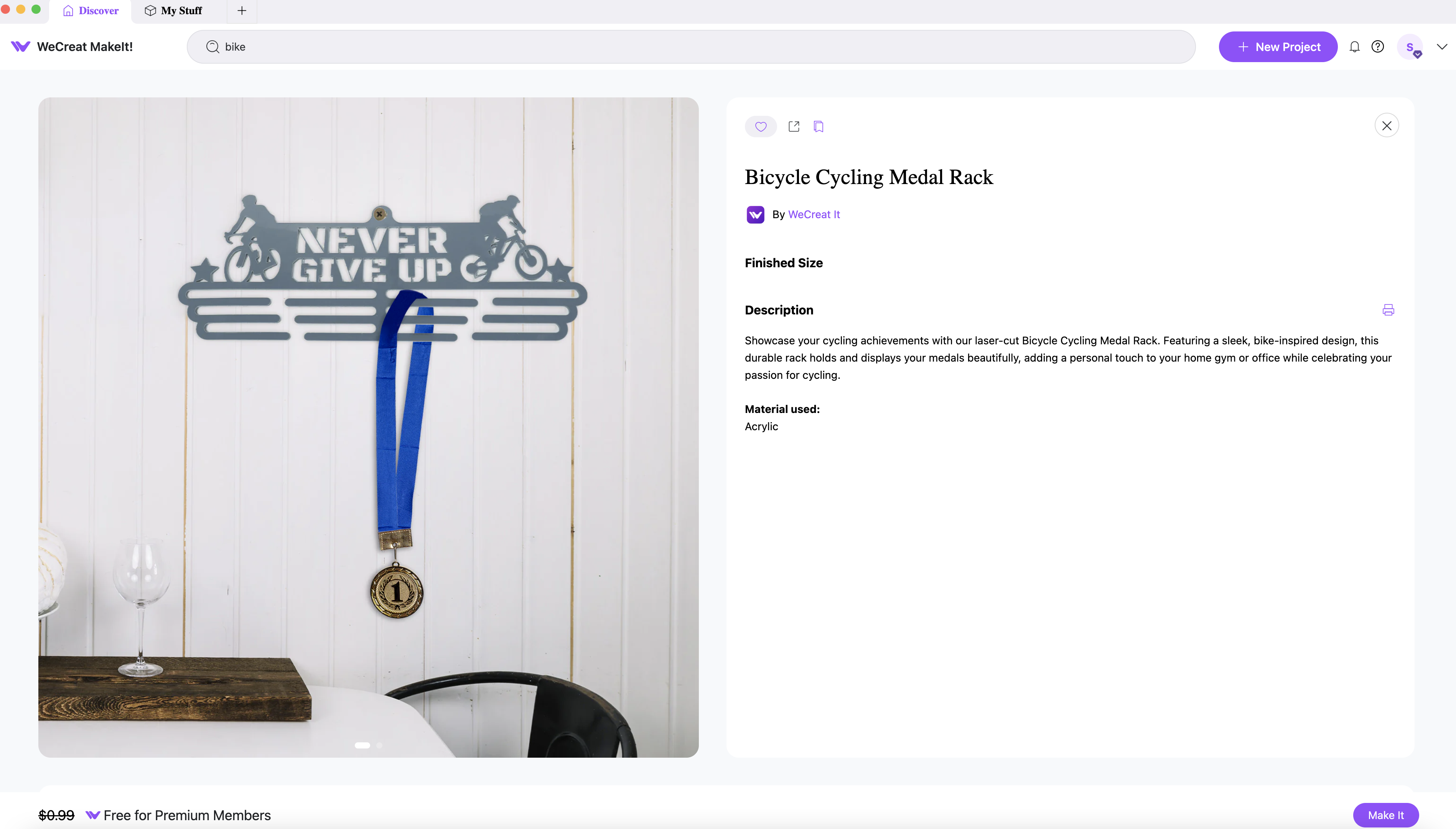

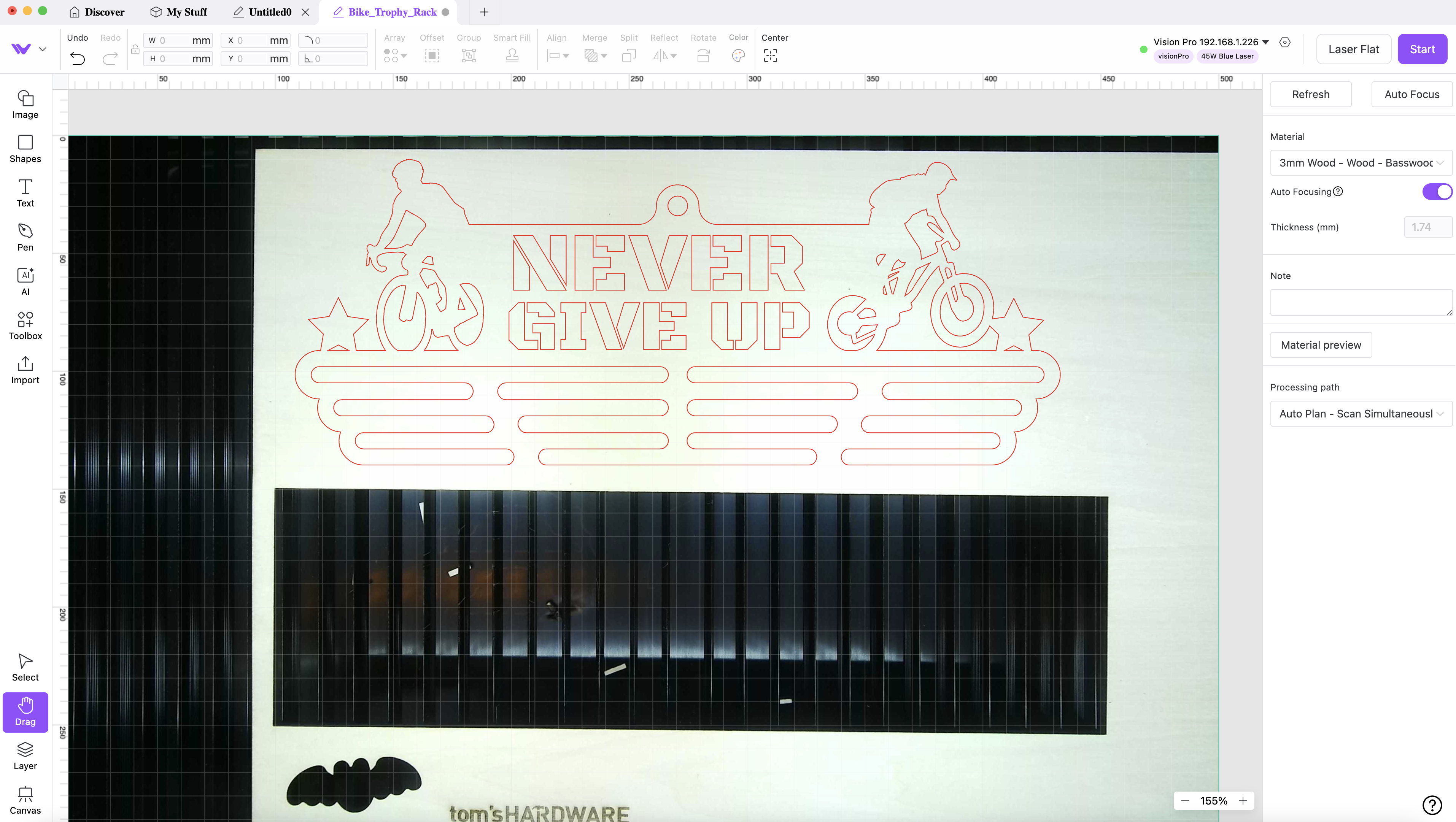

The WeCreat MakeIt! software has two primary uses: a catalog for sorting through projects and a build processing preparation interface. The ‘Discover’ tab in MakeIt! allows users to search for projects based on keywords or materials, so it’s easy to find art designed specifically for a holiday, special occasion, or other interest. For example: I saw this cycling medal display while searching through the catalog, and decided it was perfect to commemorate a recent cycling ride.

The integrated camera in the WeCreat Vision Pro provides a full layout of the available work area, making job layout an easy task. I found a piece of plywood with enough space for my design, set the line type to ‘Cut’, and watched as the Vision Pro cut out the design in 12 minutes and 48 seconds. This was accomplished without any additional work beyond changing the material type in the software; the focusing and cut parameters were all set automatically and without any input from me.

Choosing a project in the catalog and sending it to the laser took me longer than the laser took to cut out the design, and it was ready to hang on my wall in under 30 minutes from when I first saw the design. The MakeIt! software exposes all the parameters required for serious work and dial in the laser, but the default settings worked well enough for me to believe a beginner could get started with the Vision Pro without running into any issues.

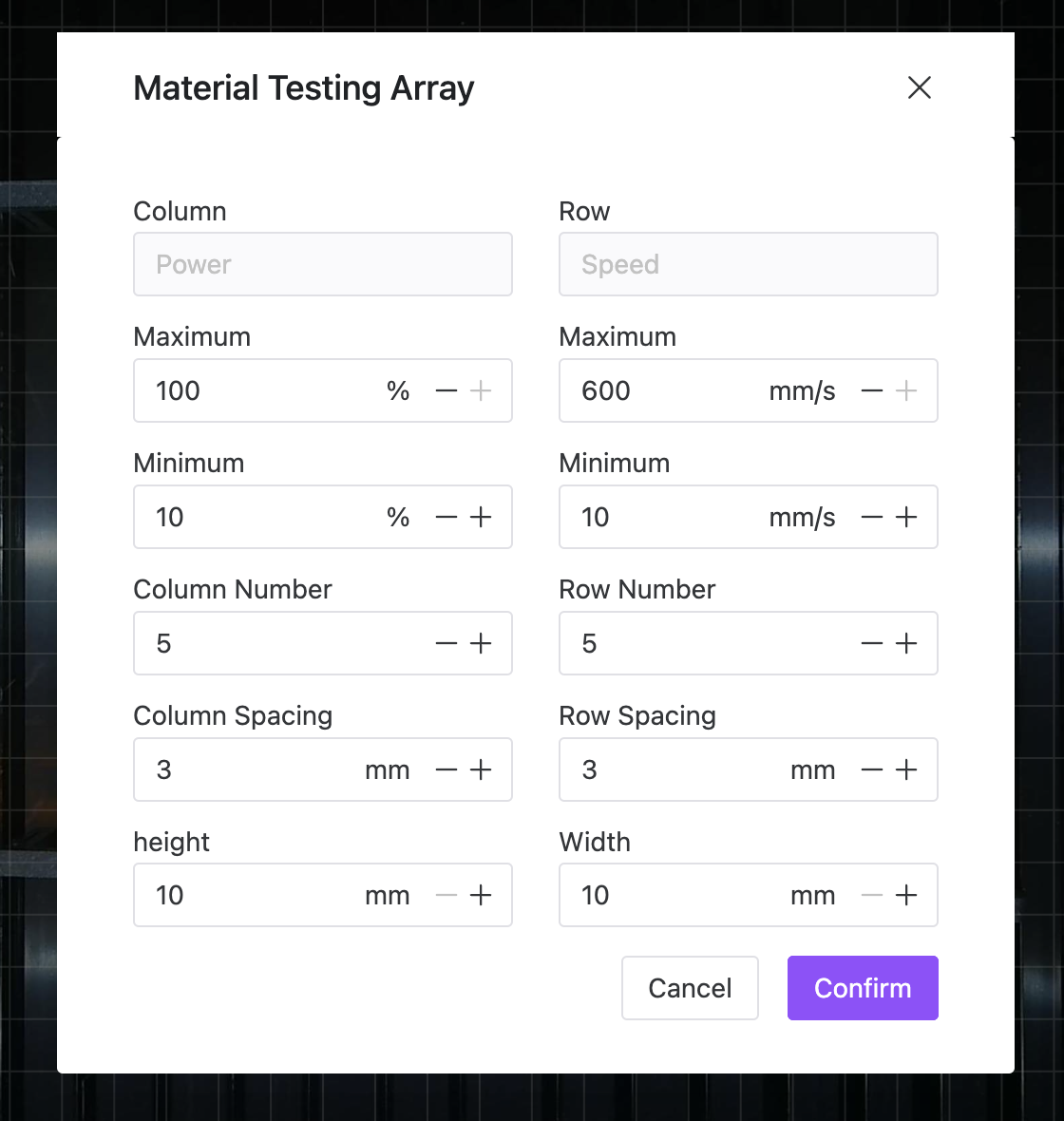

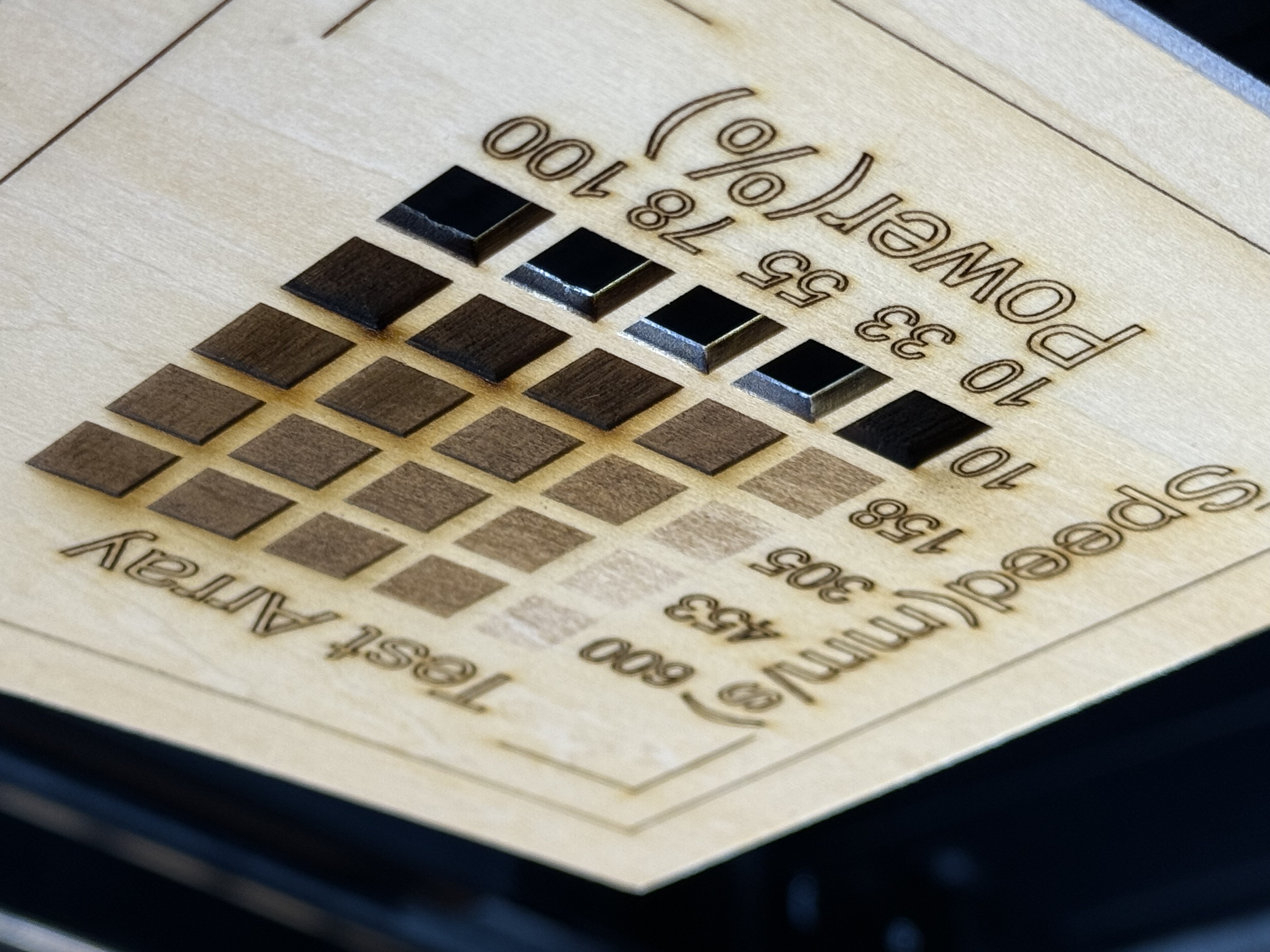

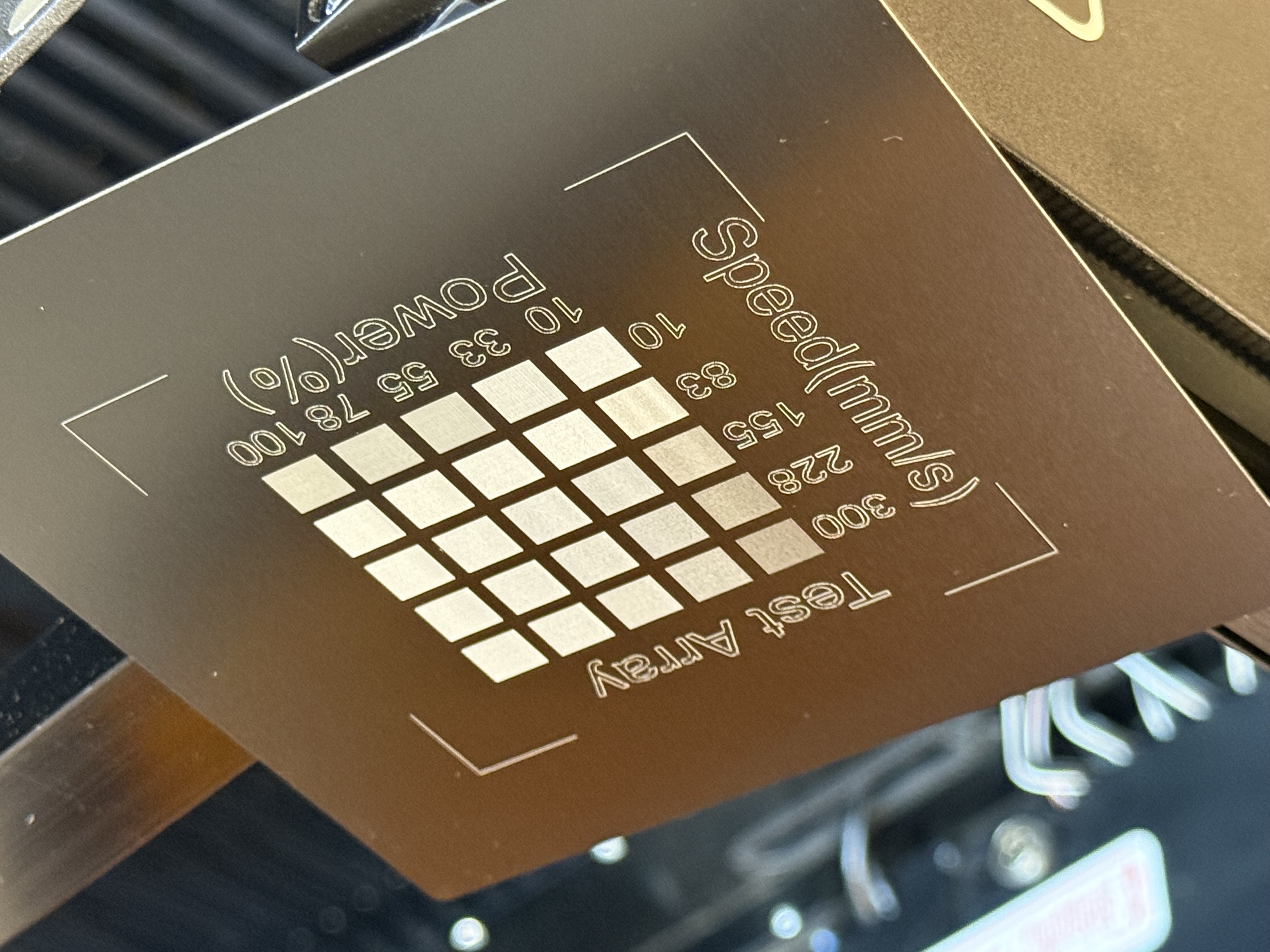

The Material Testing feature is a powerful way to quickly validate new materials and test parameters without having to set up dozens of individual tests. The MakeIt! software includes the ability to generate an array of squares with a min/max power setting as well as min/max speed settings, which is a quick way to test how a specific material will behave during engraving.

I ran an identical test on both birch plywood as well as walnut plywood, and the impact of the parameter adjustment is clear. On higher power and speeds, the birch plywood appears darker while the walnut plywood appears lighter as the top layer is progressively removed. Test swatches like this are helpful to understand engraving depth before committing to a larger or more time-consuming build.

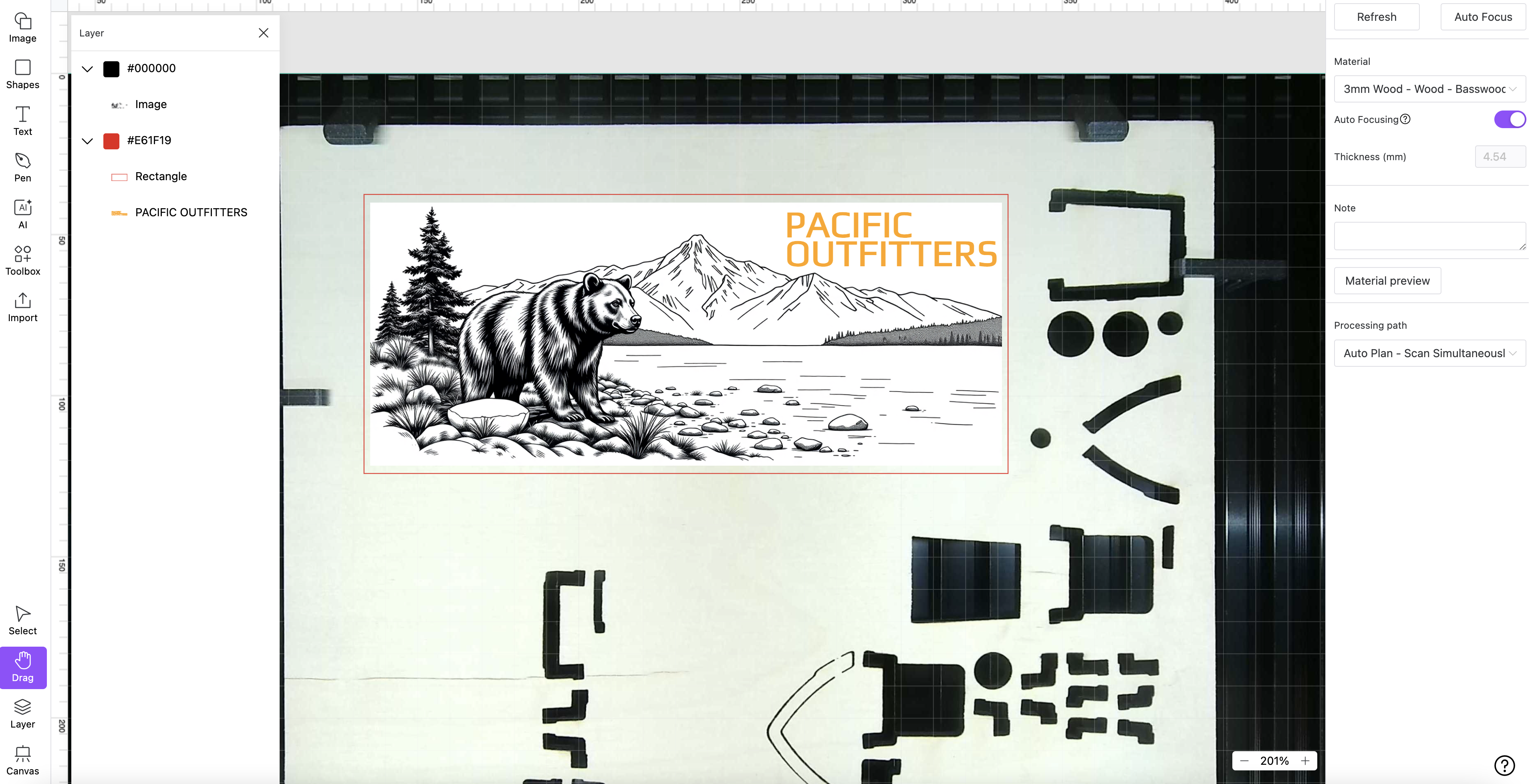

The ‘AI Generate’ feature is an interesting one in that it gives users the ability to enter a prompt (Ex. Highly detailed image of a brown bear by the river, mountains in background, deep engraving style, in black and white) and generates a bitmap image as an output. I marked this feature as a negative on the original WeCreat Vision due to the heavy promotion of this underwhelming feature, but the Vision Pro includes it nearly as an afterthought. I experimented with a few different styles before hitting a daily limit of generated images, and made a logo for a non-existent sporting goods company.

The bitmap quality is high, and the engraved image on plywood looks almost like a carving or handmade engraving. When making a similar version of the image for a different aspect ratio, I found the image changed too much between each generate to get a consistent feel. The AI function is fun to experiment with but lacks refinement, control and suffers from an unclear daily limit. This feature will likely only be useful to someone looking for a quick image that would be too time-consuming to draw manually.

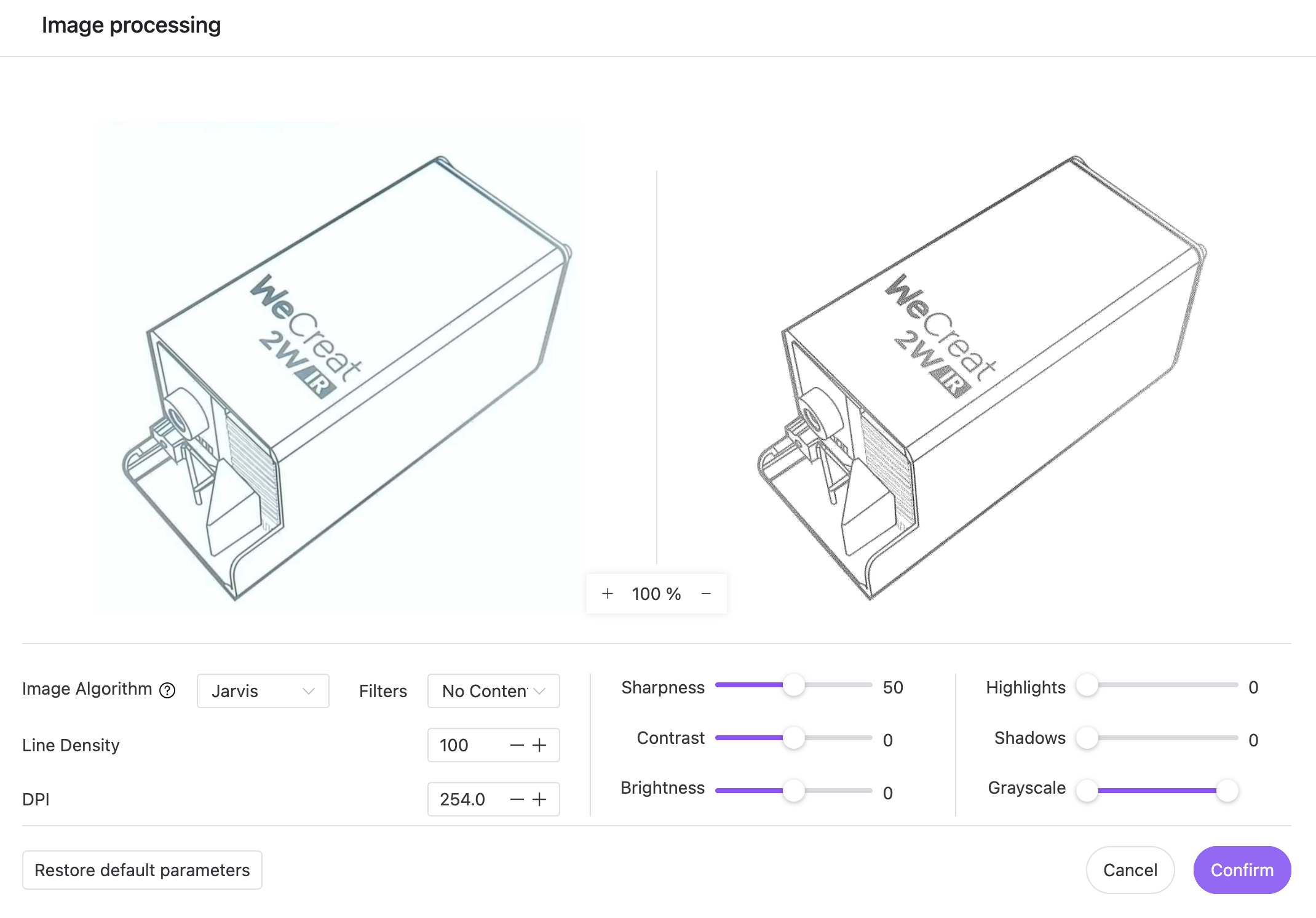

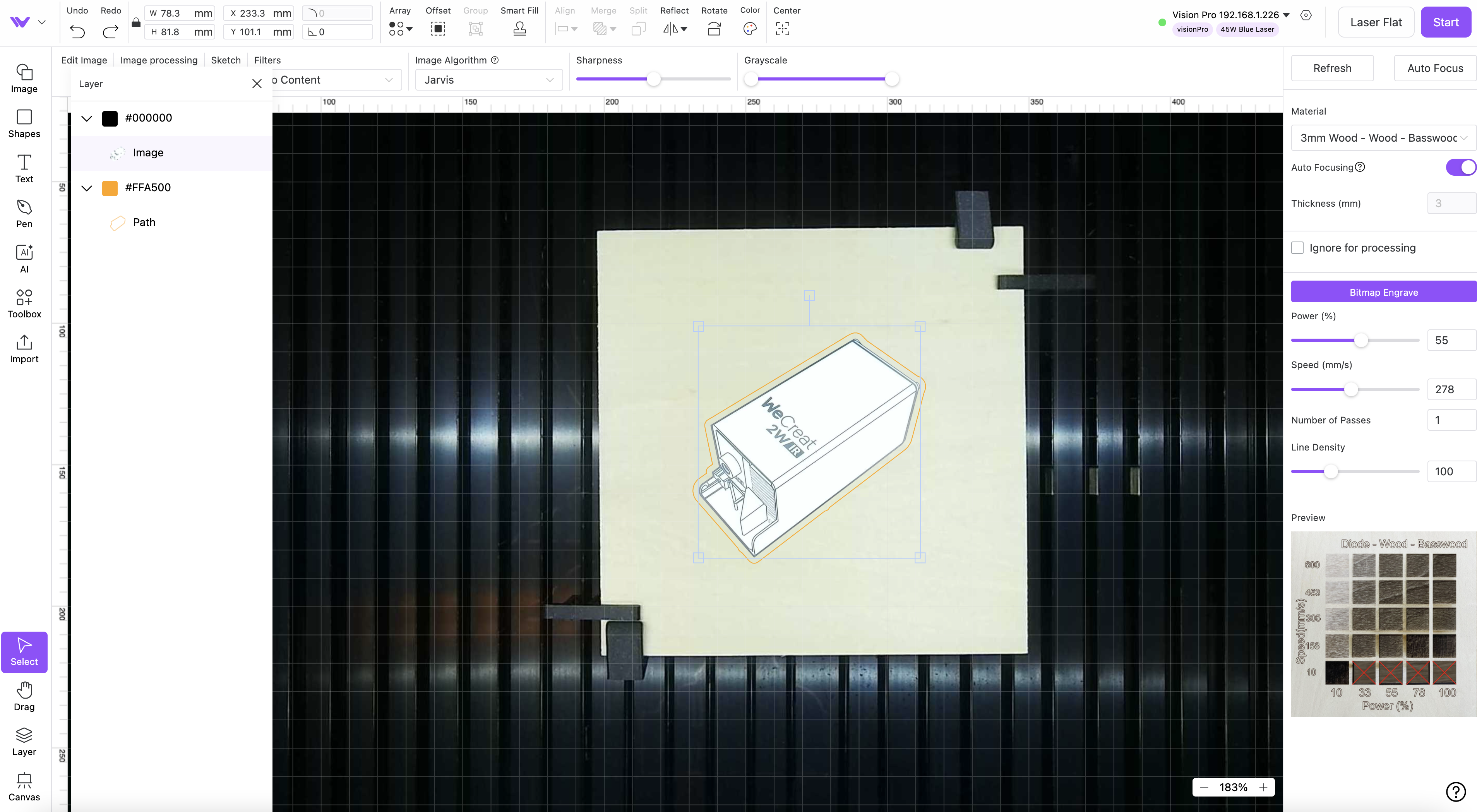

One of my favorite features of the MakeIt! software is the ‘Extract Image’ tool, which allows users to put something under the camera of the Vision Pro, take a picture, and isolate or process specific parts of the image. I placed the box of the 2W IR Laser module in the machine and snapped an image of the component illustration. Then, I extracted and processed the linework I wanted to duplicate. Using the offset tool, I also added a contour around the illustration and assigned it to be a cut line to complete my duplicate of the illustration.

With impressive resolution, the Vision Pro first traced out the bitmap image that I isolated and then cut around the perimeter, creating a scaled-down replica of the illustration I initially extracted. For anyone looking to duplicate an older logo, simple illustration, or other image without needing photo editing software, this feature highlights the power of the MakeIt! software.

Engraving / Cutting with the WeCreat Vision Pro

For users without laser engraver experience, the WeCreat Vision Pro makes it refreshingly easy to go from vector image to finished build in only a few clicks. The projects included in the software are on the simple side, but creating something like a ‘World’s Best Mom’ trophy without any design work is a fun and easy way to make personalized gifts without a degree in digital illustration.

During engraving, the table that the Vision Pro was on would occasionally shake and cause the workpiece to move around on the laser bed slightly. I found the WeCreat Laser Bed Clips by Printables user jekamis and printed a few in Prusament Galaxy Black ABS on a Bambu Lab X1-Carbon, one of the best 3D printers. These worked great for holding the workpiece down during engraving and reducing the impact of vibrations caused by fast travel moves.

One of my favorite materials included in the sample pack was the Dual Layer Silicone watch band, which happened to be compatible with my Apple Watch. This dual-layer material is black on the outside and has a rainbow gradient underneath which is revealed by removing the top layer. Using some of the included images, I added a few fish and some linework to the strap and revealed the colorful artwork by using the ‘Fill Engrave’ mode and default speed and power levels.

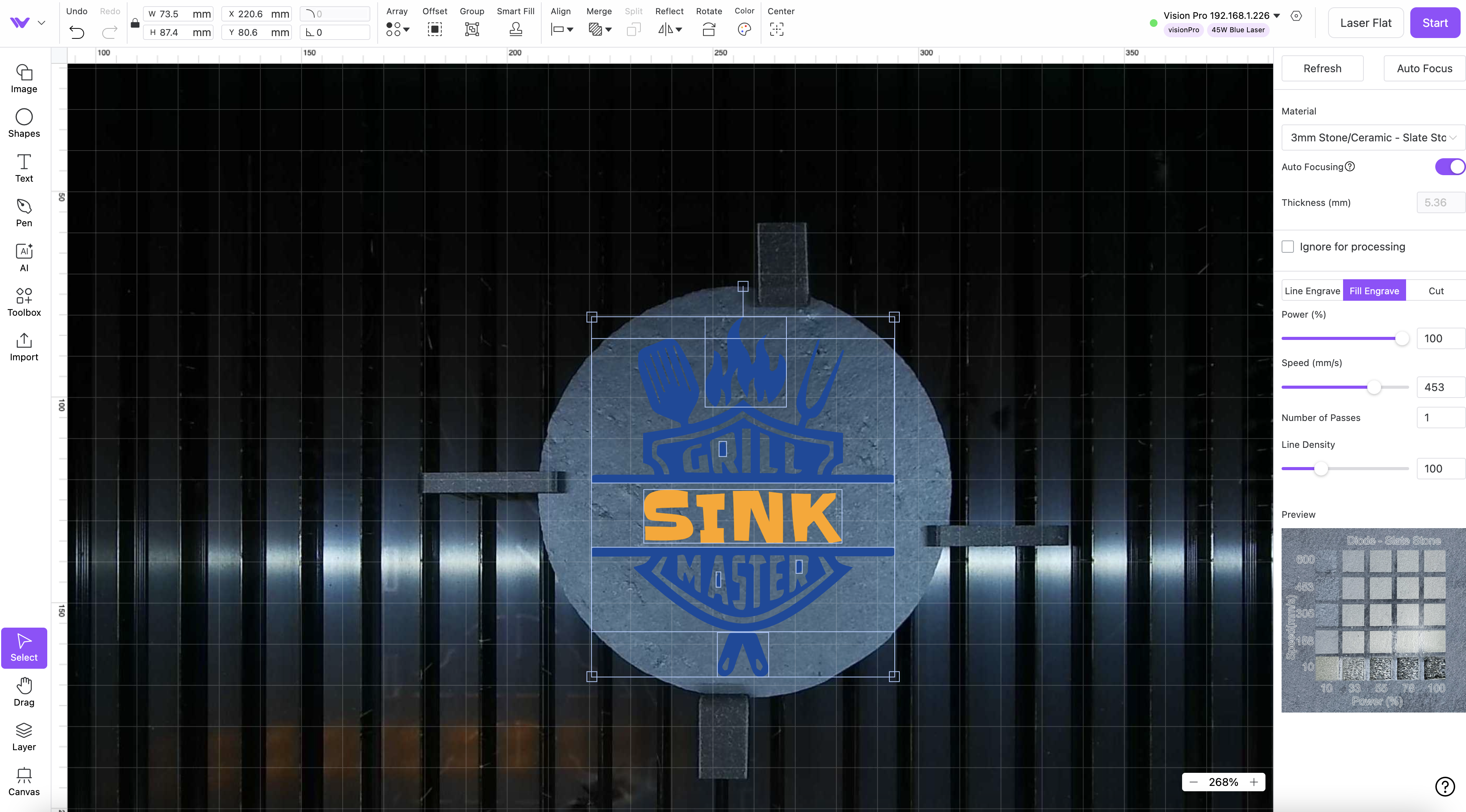

The Vision Pro also includes presets for working slate coasters, a popular item for customization due to their small size, durable nature, and ease of engraving. Using the default power and speed settings for slate, I customized one of the projects in the MakeIt! library by adding my name and scaling to fit the coaster included in the material sample kit.

Using 100% power at a speed of 453mm/s, the coaster took just under 18 minutes and came out perfectly on the first try. When first removed from the work area, there’s some dust from the engraving process scattered across the surface of the coaster. This was removed by gently wiping with a damp cloth, and the engraving looked even and professional after cleaning. Coasters like this are one of my favorite gifts to make for friends and family, as they are fast, durable, and inherently useful to almost everyone.

Using the 2W Infrared Laser Module

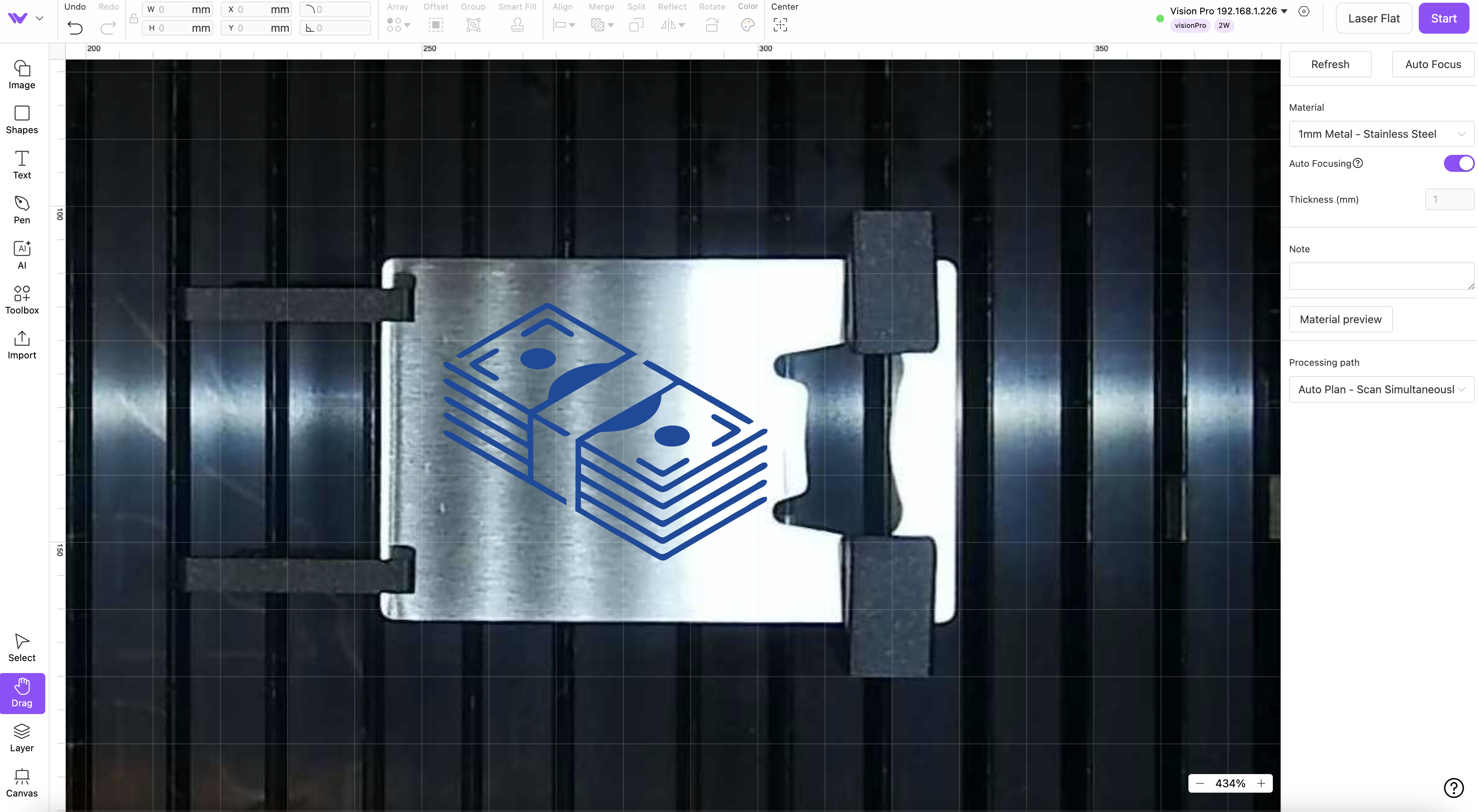

WeCreat included the 2W Infrared Laser Module with the Vision Pro, an optional accessory that is designed specifically for engraving on stainless steel, silver, gold, and other metals. Swapping out between the standard 45W diode module and the 2W 1064nm laser module involves removing 5 screws and took me about 5 minutes. The entire module rests on a PCB that sticks out from the back of the toolhead, which made me a bit nervous when swapping it out due to the relatively fragile nature of most printed circuit boards.

Engraving on a stainless steel bottle opener as a test, I grabbed artwork from the MakeIt! sample library and used the ‘Fill Engrave’ setting to process the design. Engraving this small pattern took about 20 minutes, but the resulting engraved stainless steel bottle opener looks like a professional job that would be at home in a gift shop, tourist attraction, or corporate swag bag.

It’s easy to get excited by the results from using the 2W IR laser module, and the razor-thin linework on a material test array shows that the Vision Pro is ready to tackle the challenge of engraving metal at home. This type of engraving can be used for customizing and personalizing consumer products like bottle openers as well as engraving serial numbers or tracking information on high-value machined components.

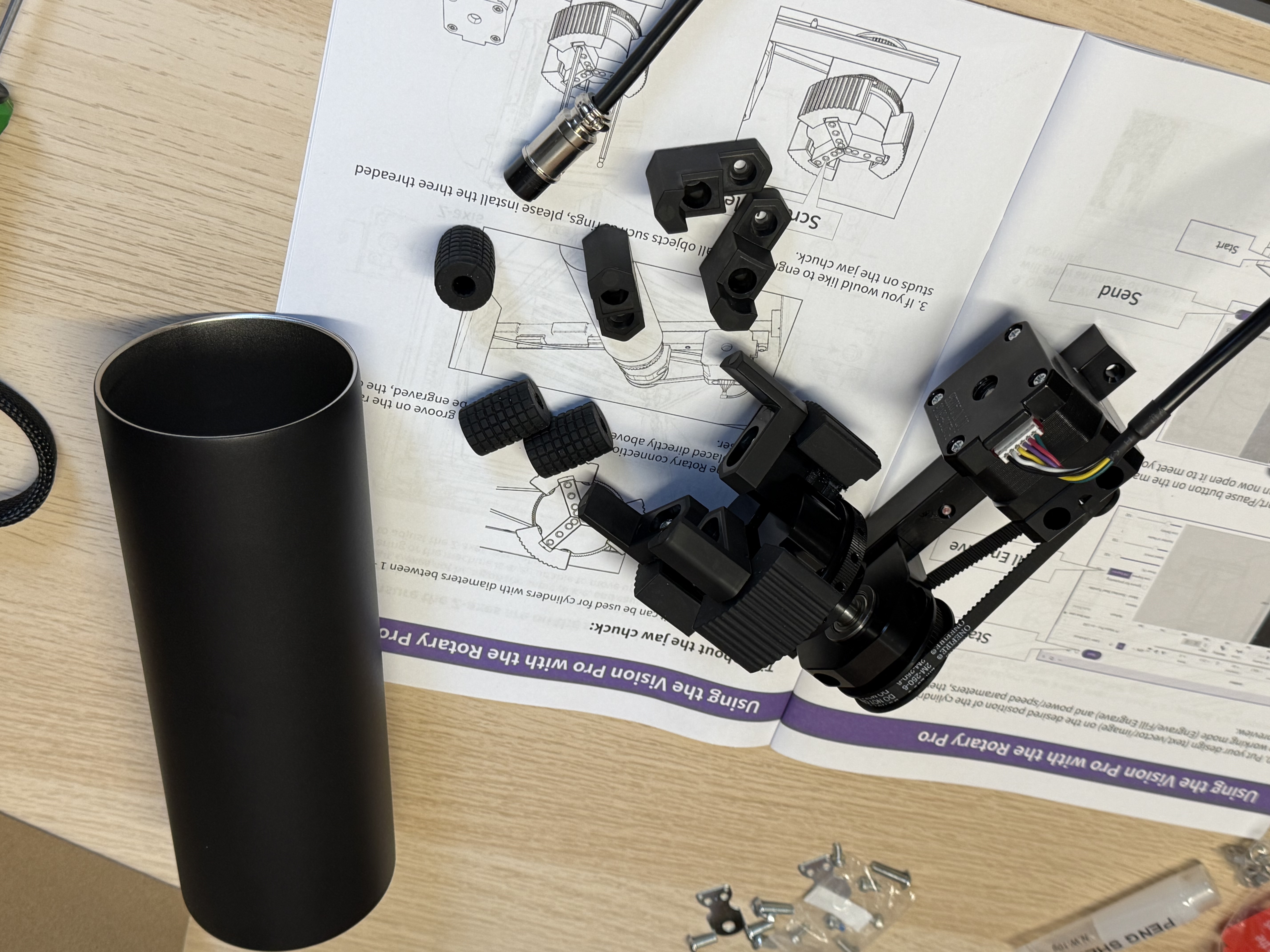

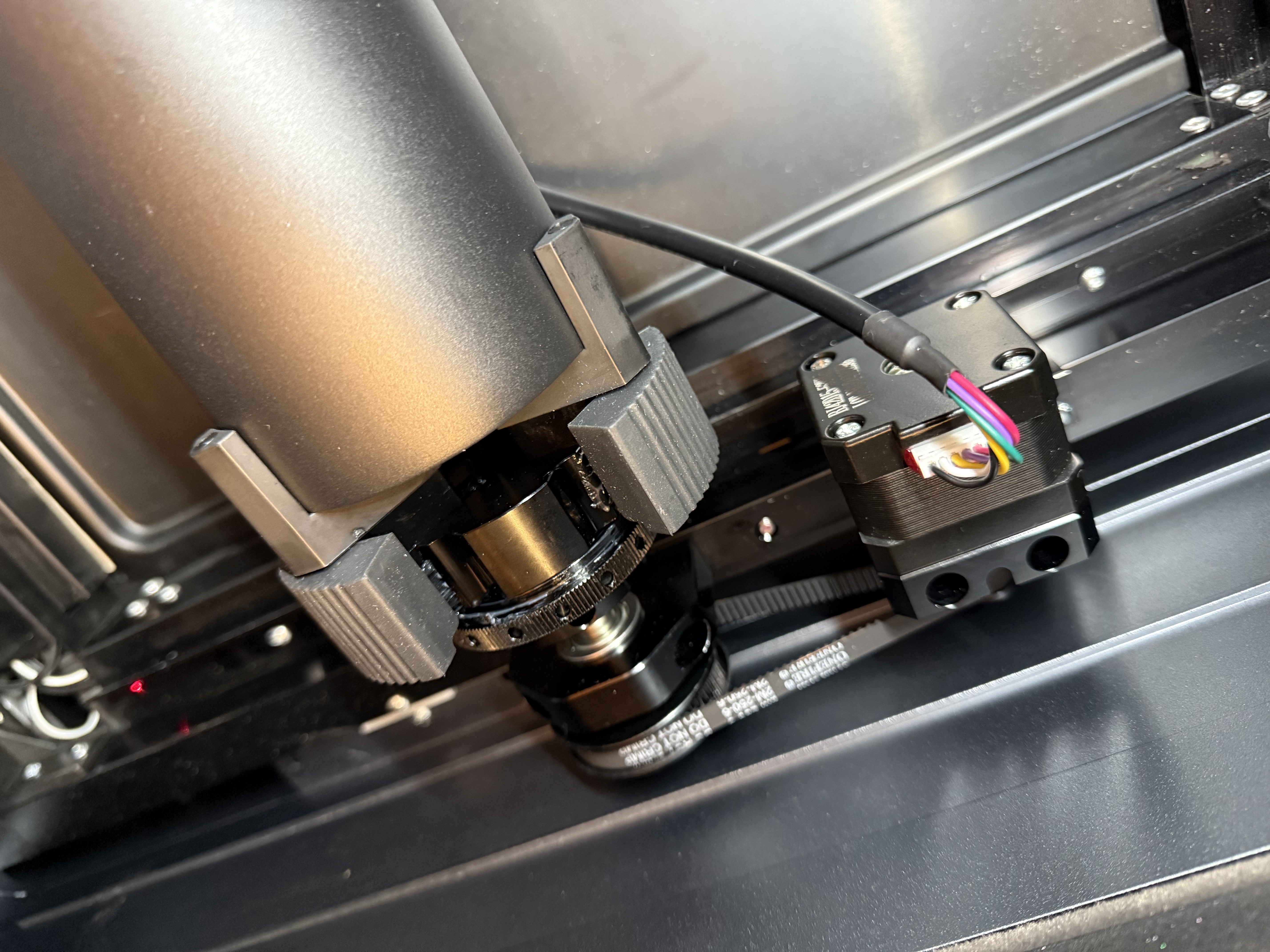

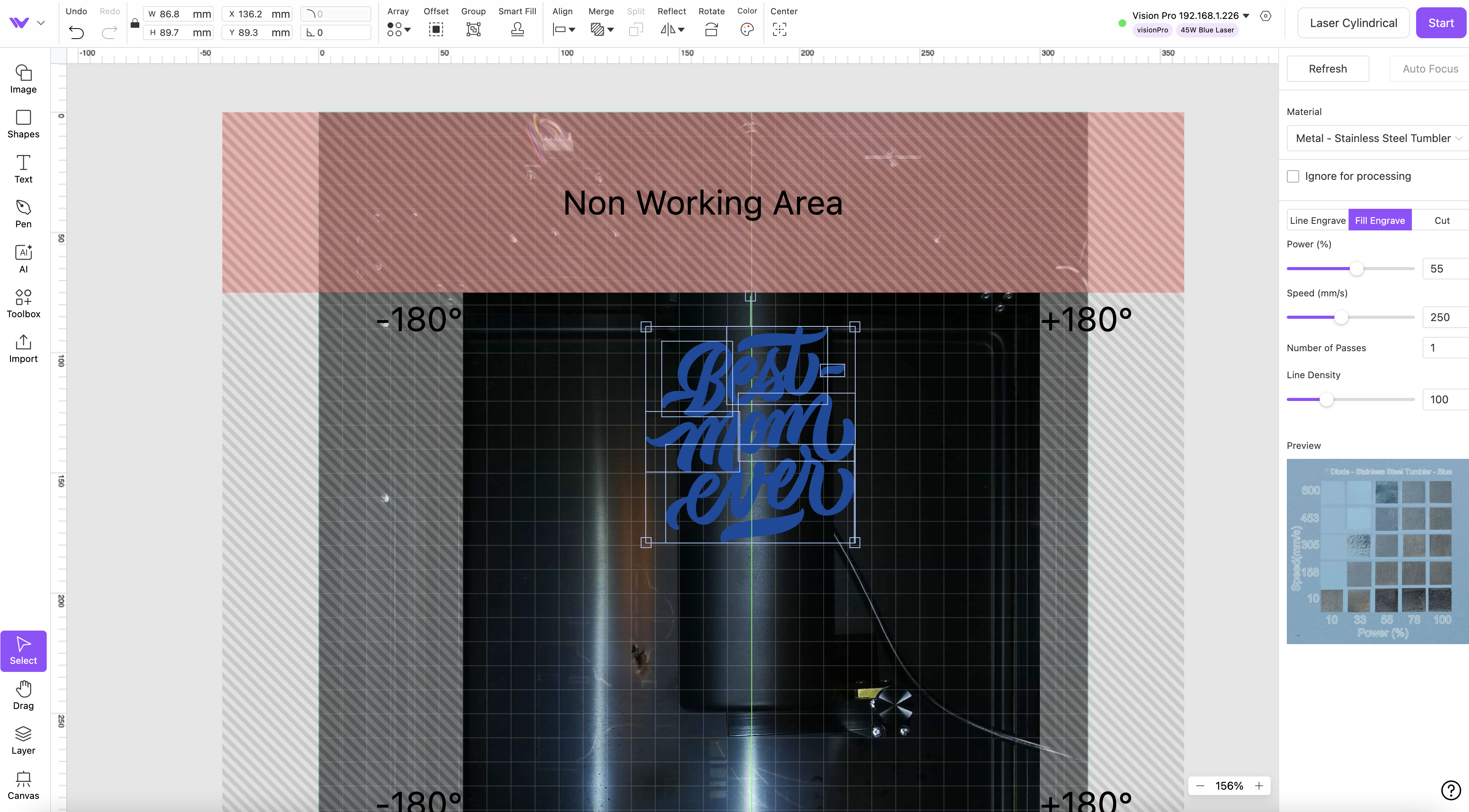

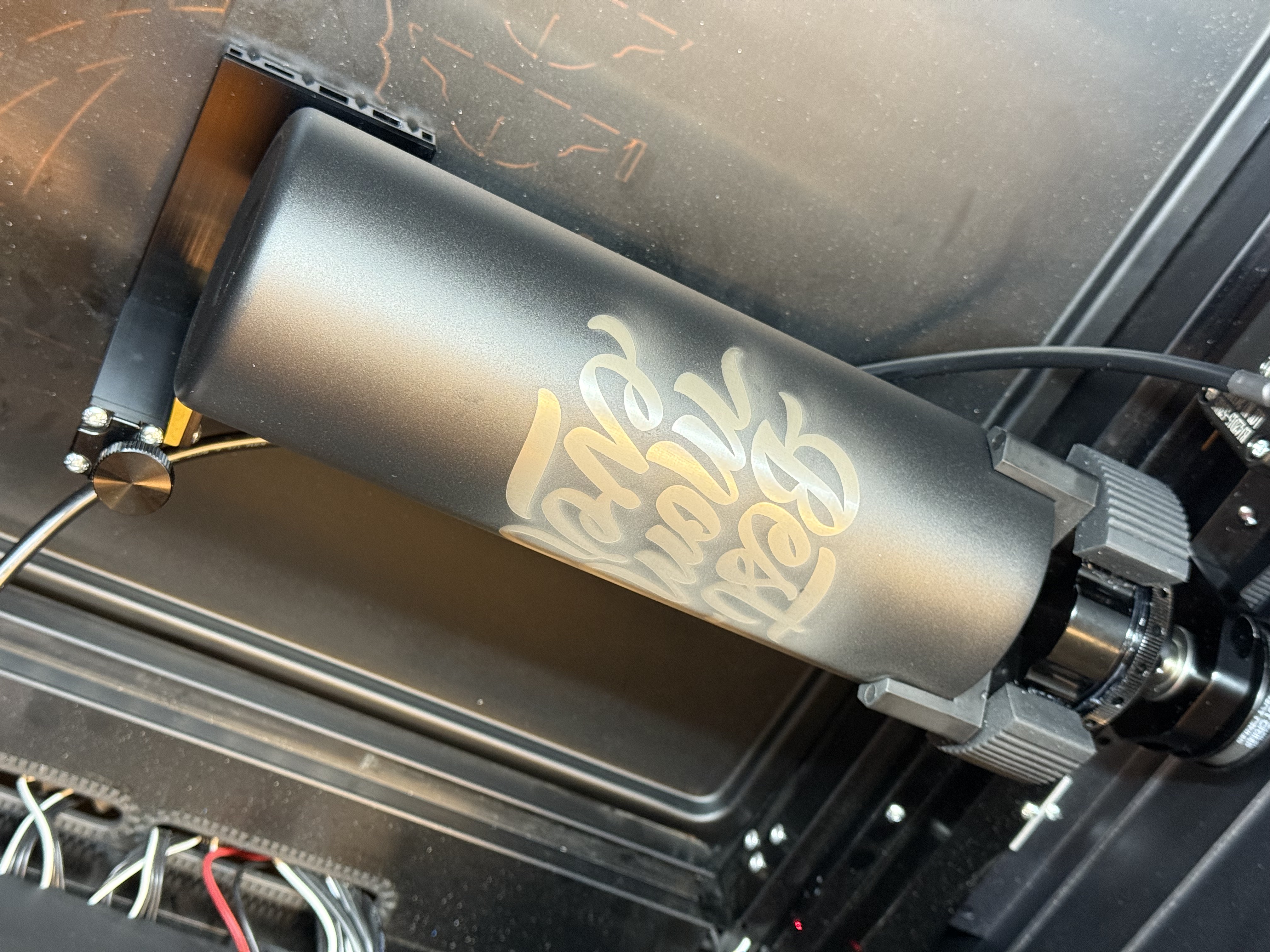

Rotary Engraving with the WeCreat Vision Pro

Like many other laser engravers in this price range, the Vision Pro is capable of rotary engraving for things like drink tumblers, glasses, rings, and other cylindrical objects. The optional Rotary Pro module includes several new features specifically intended for engraving on larger tumblers (such as the incredibly popular Stanley 40 oz.) as well as spherical or smaller objects. Installing the Rotary Pro only takes two bolts and a few minutes, most of which was spent fiddling with the just-slightly-too-short cable to plug in the back of the unit.

The Rotary Pro tagline is “Become an Expert on Your 1st Try”, and I found it to be an accurate description of the rotary process. The MakeIt! software includes a special cylindrical layout when using the Rotary Pro, which shows not only the available work area but also all of the same settings available in the standard layout. Once again, the auto-focus of the Vision Pro is a huge benefit here for hands-free calibration on cylindrical models: just measure the circumference, diameter, lay out the project, and click ‘Start’.

Using the 45-watt diode laser module, I whipped up a Mother’s Day tumbler using one of the provided project files and a coated stainless steel tumbler. Just like the 2W IR laser module, this optional accessory offers tremendous value for the price and will be an easy-to-justify purchase for anyone interested in expanding their small business offerings.

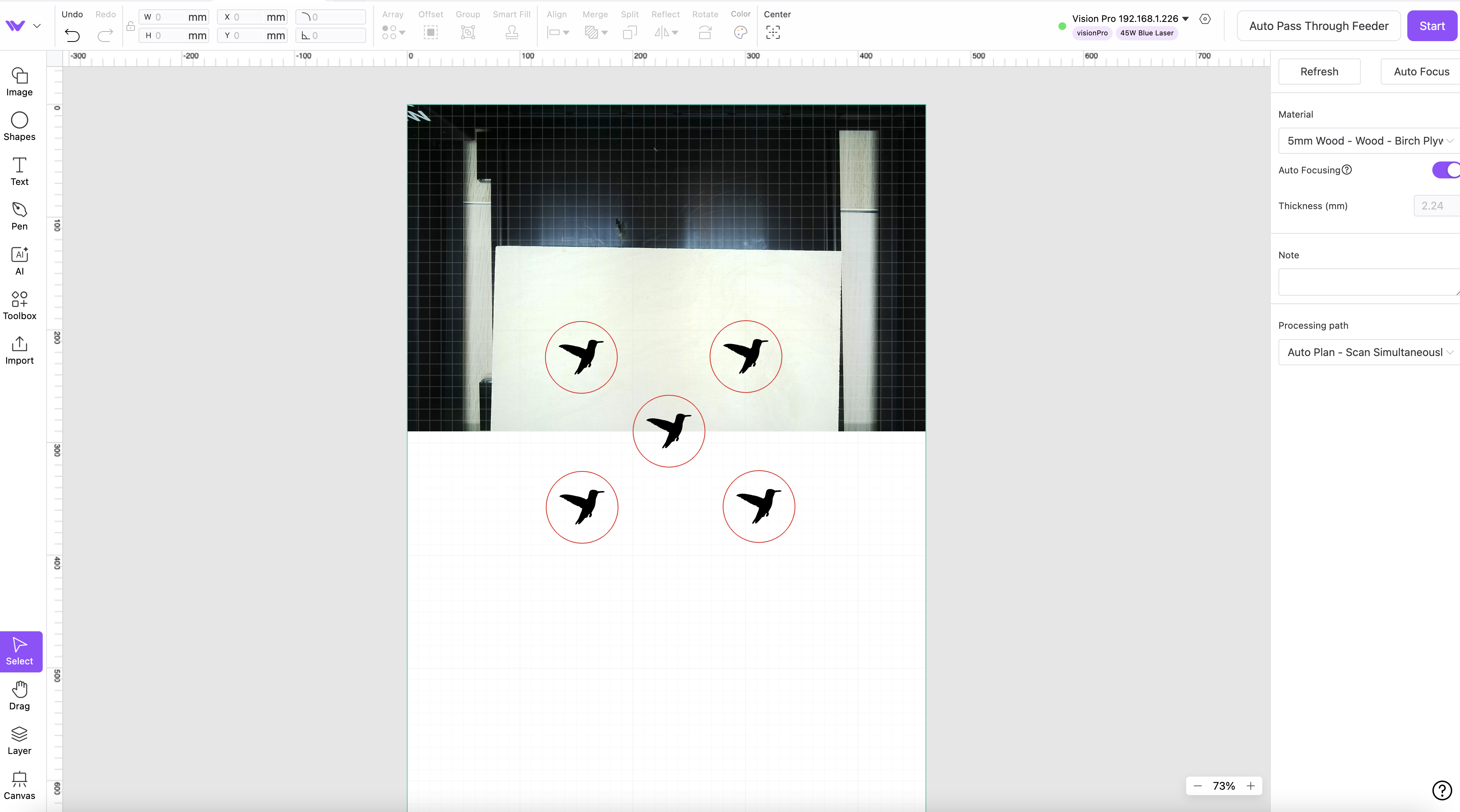

Pass Through Engraving with the WeCreat Vision Pro

If the 500 x 320 mm build area isn’t large enough for your projects or you want to make more parts per job, the optional WeCreat Auto Pass Through Feeder allows you to feed even larger sheets of material up to 460mm x 3700mm (14.17” x 145.67”) for batch processing. The staggering 12-foot length is long enough to fit most sheets of plywood sold at hardware stores and is large enough to cut a sign or engrave an ad for a shop.

The assembly involved setting up the primary base and adding the material rollers, and required the full use of a pair of four-foot tables pushed together. Once assembled, the bottom is removed from the Vision Pro, and the entire machine can be placed on top of the feeder. The Auto Pass Through Feeder uses a knob to adjust the tension on the rollers. This can be adjusted depending on the thickness and type of the material. The second knob can be used to advance or retract the material, which is useful for the material preview on the MakeIt! software. Using a sheet of 5mm birch plywood that measured 12 inches wide and 24 inches long, I adjusted the rollers, advanced the material, and moved on to the software prep.

The MakeIt! software has a dedicated ‘Auto Pass Through Feeder’ mode, which shows a camera preview and allows the user to lay out parts past the view of the camera. I was impressed with how easy the process was, and decided to make some simple medallions to test out the functionality. After creating an engraving and cutting step, I duplicated the model and moved it to a few different locations on the board.

Each individual medallion made a satisfying ‘click’ as the cut line was completed, and the Vision Pro would automatically move the sheet of plywood forward and begin working on the next engraving. The Auto Pass Through Feeder worked flawlessly, and advanced the material during the job each time one of the medallions was complete.

Bottom Line

The amount of ancillary equipment like fume extractors, air compressors, and other safety equipment means that buying a laser can be a daunting experience for a first-timer. The WeCreat Vision Pro is clearly targeting the market of prosumers who want a laser for small business but don’t want to source everything piece-by-piece. The large, enclosed, and vented build area combined with a fume extractor allows users to hit the ground running within minutes of unboxing, not hours. If you are thinking about striking out on your own with a business manufacturing custom engraved trophies or collectibles, it’s easy to see the Vision Pro as an essential part of your growth.

Overall, I was impressed with the Vision Pro during testing and wouldn’t hesitate to recommend it to a beginner as a first laser. I also wouldn’t hesitate to recommend it to a power user looking for advanced functionality with the optional add-ons, so it’s safe to say the Vision Pro has earned its spot on the list of the best laser cutters and engravers as the Best Laser Cutter for Home Business.

The Vision Pro, as reviewed (Super Pack variant), is currently listed at $3,449.99 if purchased as a bundle. Ordering the Vision Pro as a standalone unit and purchasing all the accessories separately totals to $4,269.94, an amount that should make users think about buying the bundle if they’re considering expanding the abilities of the Vision Pro in the future. If you like the integrated ecosystem of the WeCreat family but are looking for something slightly less expensive, the WeCreat Vista is available for $699.99, but lacks several of the advanced features of the Vision Pro. For an even more economically priced model, the $169.99 Two Trees TTS-55 also shows up on our list of the best laser cutters and engravers and offers a no-frills, stripped-down experience.

Andrew Sink first used a 3D printer in 2012, and has been enthusiastically involved in the 3D printing industry ever since. Having printed everything from a scan of his own brain to a peanut butter and jelly sandwich, he continues to dive ever more deeply into the endless applications of additive technology. He is always working on new experiments, designs, and reviews and sharing his results on Tom's Hardware, YouTube, and more.