How to Clean and Cure Resin Prints

You don’t need a fancy system to clean your resin prints, but it helps.

Resin 3D printers use UV light to build models layer by layer from a vat of photosensitive liquid. When the print is finished, you’re left with a soft model still coated with resin that needs to be cleaned and fully cured with additional UV light.

How to Handle Resin Safely

Resin is toxic, but no more dangerous than many household cleaners. All resins are classified as a skin irritant, therefore nitrile gloves and safety glasses should be worn while handling uncured resin. If you get any liquid resin on your skin, you’ll need to wash immediately with soap and water.

Once resin prints have been fully cured with UV light, they are safe to handle.

Proper ventilation is also important when working with resin printers. They should be kept in a room with an outside vent or a good carbon filtered air purifier. In a pinch, you can ventilate the room by opening a window.

How to Clean a Resin 3D Print by Hand

You don’t fancy equipment or tools made specifically for 3D printing to process your resin models. Most items can be found at a dollar store or the baking aisle of a big box store.

What You’ll Need to Clean and Cure Resin Prints

- Isopropyl alcohol (91% or higher)

- Nitrile Gloves

- Silicone mat (with lip)

- Silicone spatula

- 2 Large water tight containers

- Tongs (optional)

- Metal Scraper

- Plastic tray

- Side Cutters

- Tooth brush, soft

- Paper Towels

Purchase silicone tools for working with resin whenever possible. Resin doesn’t stick to silicone, which makes cleaning up a breeze. If you can’t find an affordable silicone mat, you can also cover your work surface with a plastic trash bag. I’m currently using plastic shelf liner from IKEA. The jugs holding the isopropyl alcohol are from a dollar store, while the scraper and side cutters came with a 3d printer.

Remember to clean up your tools and work area as you go. Resin cures in UV light (aka sunlight), so any overlooked spills will eventually harden.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

1. Cover your work surface with a silicone mat or plastic sheet. Ideally, you should also place a mat or plastic sheeting underneath your printer to catch resin drips.

2. Put on your safety gear – gloves and glasses.

3. Fill two containers with isopropyl alcohol. They don’t need to be full, just deep enough to cover most of your model.

4. Remove the build plate from the printer, being careful not to drip outside the vat. Use a spatula to scrape extra resin back into the vat.

5. Put the build plate on the plastic tray.

6. Use the metal scraper to remove the model.

7. Place the models in the container of isopropyl alcohol, seal with a tight lid, and gently agitate the liquid for about 30 seconds.

8. Remove the model with a gloved hand or tongs.

9. Remove the supports. Use the side cutters if needed.

10. Dip an old toothbrush in clean isopropyl alcohol and gently brush detailed areas of the print where resin may cling.

11. Place the model in the second container of isopropyl alcohol, replace the lid and gently agitate.

12. Set the model away from sunlight to dry. If you’re in a hurry, you can use a hairdryer. Always make sure your model is completely dry, or the isopropyl alcohol will turn into an ashy residue that’s difficult to remove.

To get as much use out of my isopropyl alcohol, I use a two rinse method. One container is for the First Rinse and will get dirty quickly. This keeps the second container cleaner for much longer. When the First Rinse solution becomes murky, dispose of it properly (more on that later) and replace it with fresh. Now the slightly dirty Second Rinse becomes the First Rinse.

How to Cure a Resin Print in the Sun

Once a resin print is clean and dry, you can expose it to UV light to finish curing. The cheapest method for curing resin is using the sun as your UV light source.

1. Pick a sunny location, like a southern facing window (if you’re in the Northern Hemisphere), or outside if it’s over 70°F.

2. Leave in the sunlight 2 to 8 hours, until the print is no longer sticky.

Sunlight is less dependable than using an electric UV light. It’s difficult to cure resin on cloudy days and impossible at night. But it is free.

How to Make a DIY Resin Curing Station

You can make your own UV light box for curing resin prints from a bucket or cardboard box covered in foil. There are several how to’s on YouTube, like this one from ModBot using a paint can.

What You Need

1. Drill a hole near the opening of the bucket for the light’s cord to come out.

2. Line the bucket with foil, using a glue stick to secure it.

3. Peel the backing off the LED light strip and apply it to the inside of the bucket. Cover all sides and the top with the lights.

4. Place the bucket upside down over the turntable to cure resin prints.

It takes approximately 15 minutes to cure an average print using an electric UV light source. Check the technical details of your resin for recommended curing times.

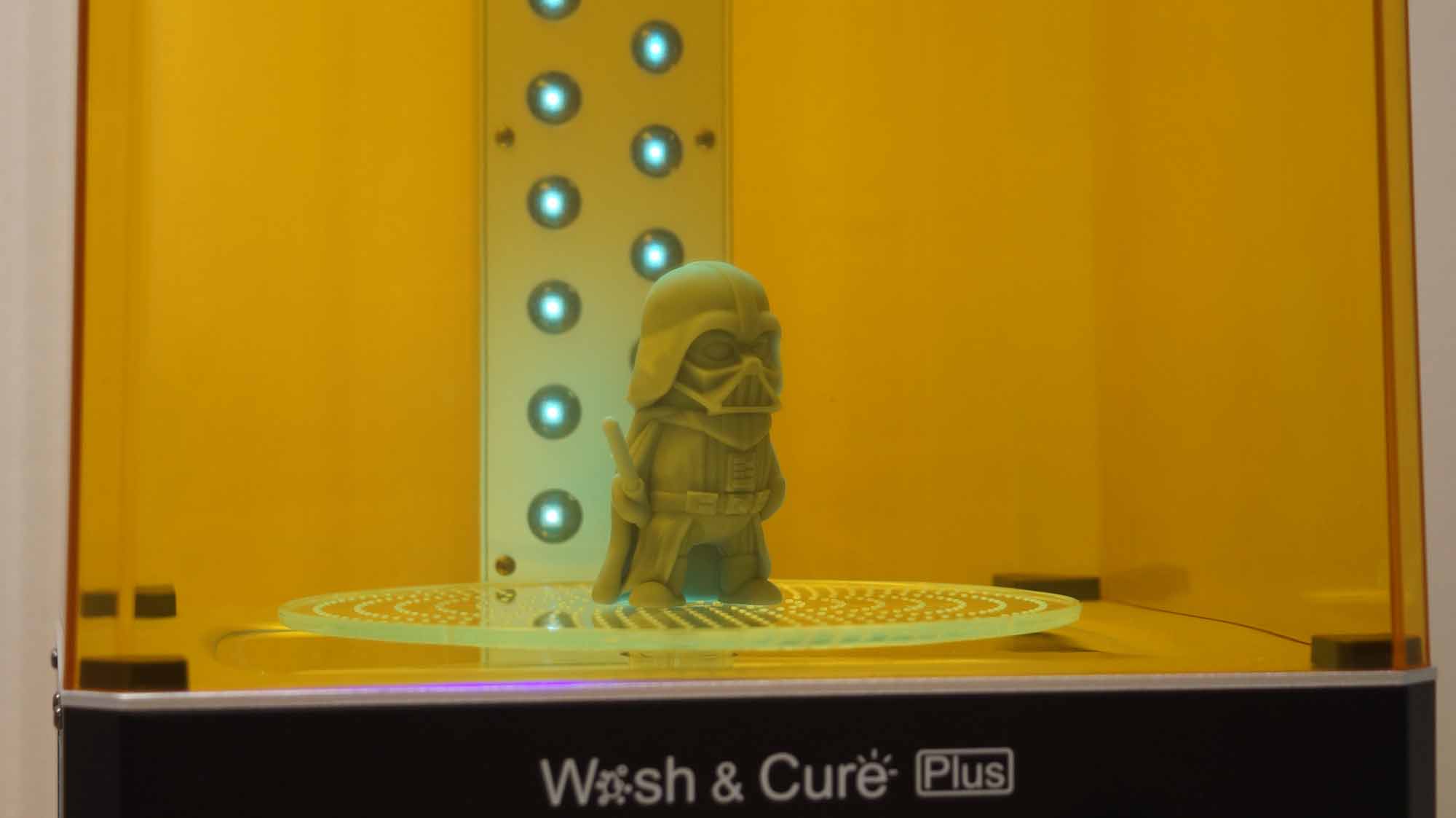

How to Use an All-in-One Wash and Resin Cure Station

Once you process a few resin prints by hand you might be ready to speed things up with a store bought wash and cure station.

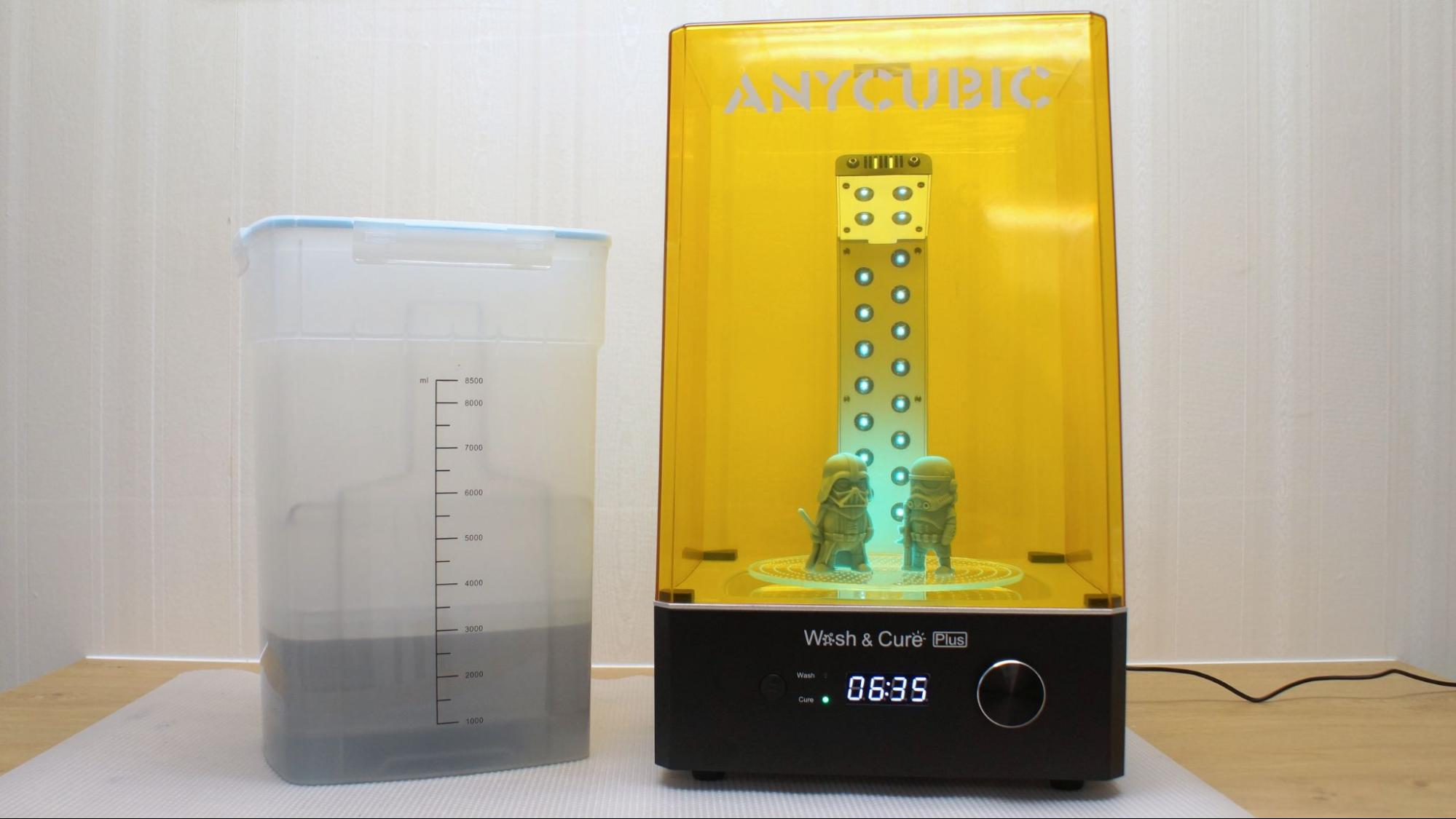

“All in one” designs are very popular and come in sizes to match your resin printer. These machines work largely the same, having one motorized base that spins the agitator for the washing process and the turntable for the curing step. The one I’m using for this article is an Anycubic Wash & Cure Plus.

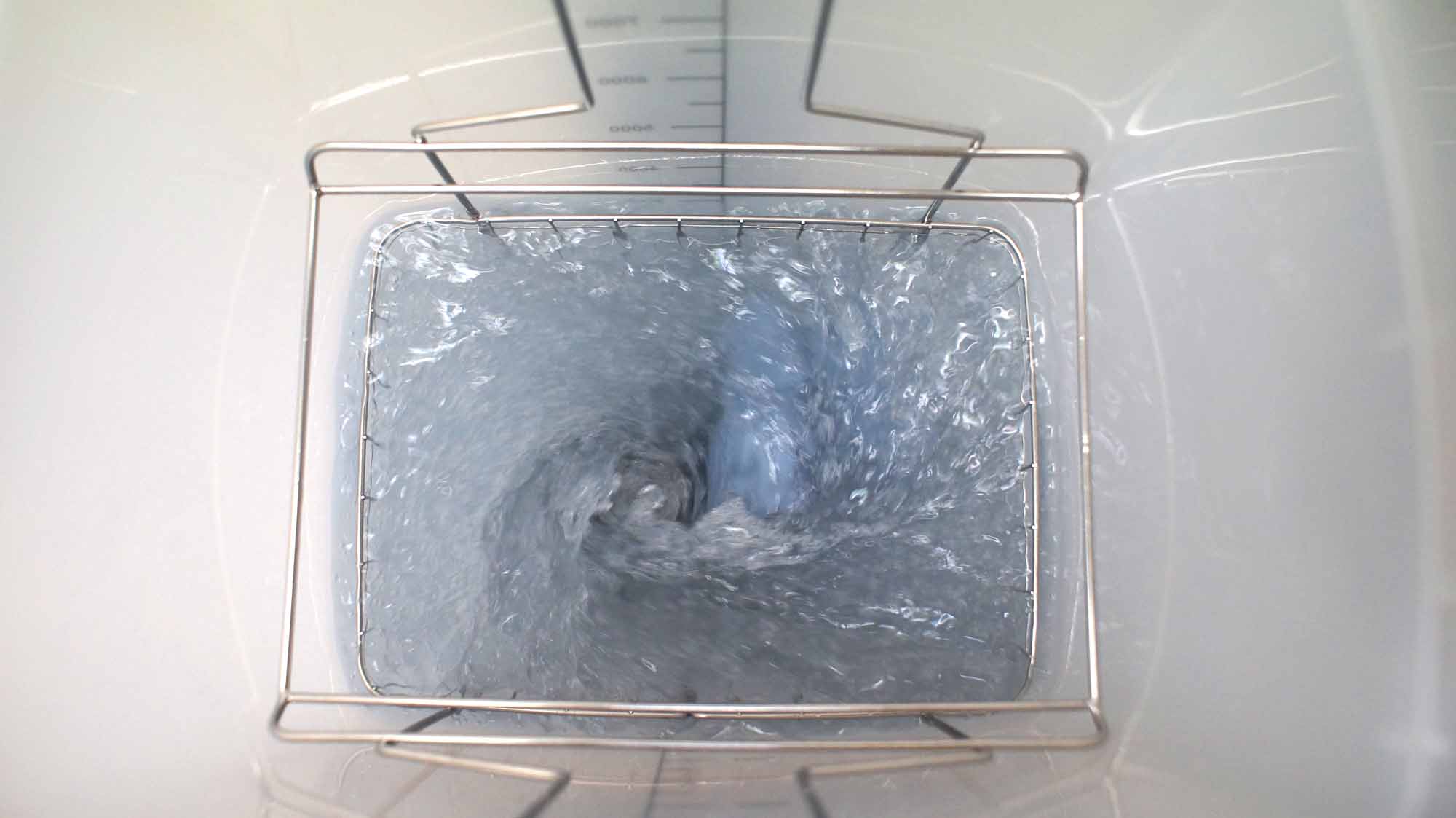

Large units like this one need a lot of isopropyl alcohol – this one can hold up to 2 gallons of cleaning agent. I’m still using a separate container of isopropyl alcohol for a first wash in order to keep the machine’s tank clean for as long as possible.

Due to the agitation process, you don’t need to hand scrub your models and they come out clean the first time. The timer is also more convenient, allowing you to do something else while the machine does the work.

1. Cover your work surface with a silicone mat or plastic sheet.

2. Put on your safety gear – gloves and glasses.

3. Fill a water-tight container and the wash & cure’s tank with isopropyl alcohol. They don’t need to be full, just deep enough to cover most of your model.

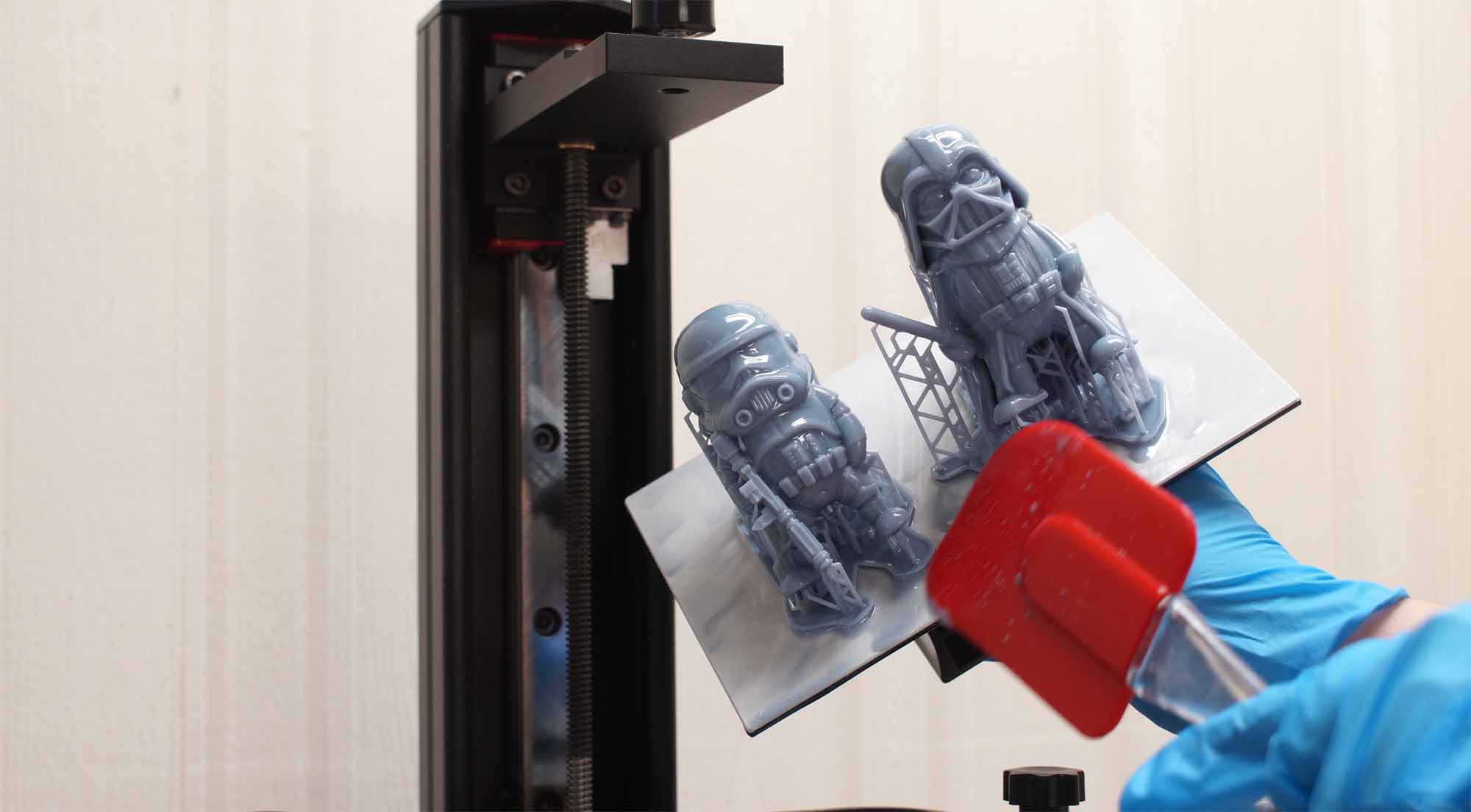

4. Remove the build plate and model from the printer, being careful not to drip outside the vat. Use a spatula to scrape extra resin back into the vat.

5. Place the build plate on your covered work surface or plastic tray.

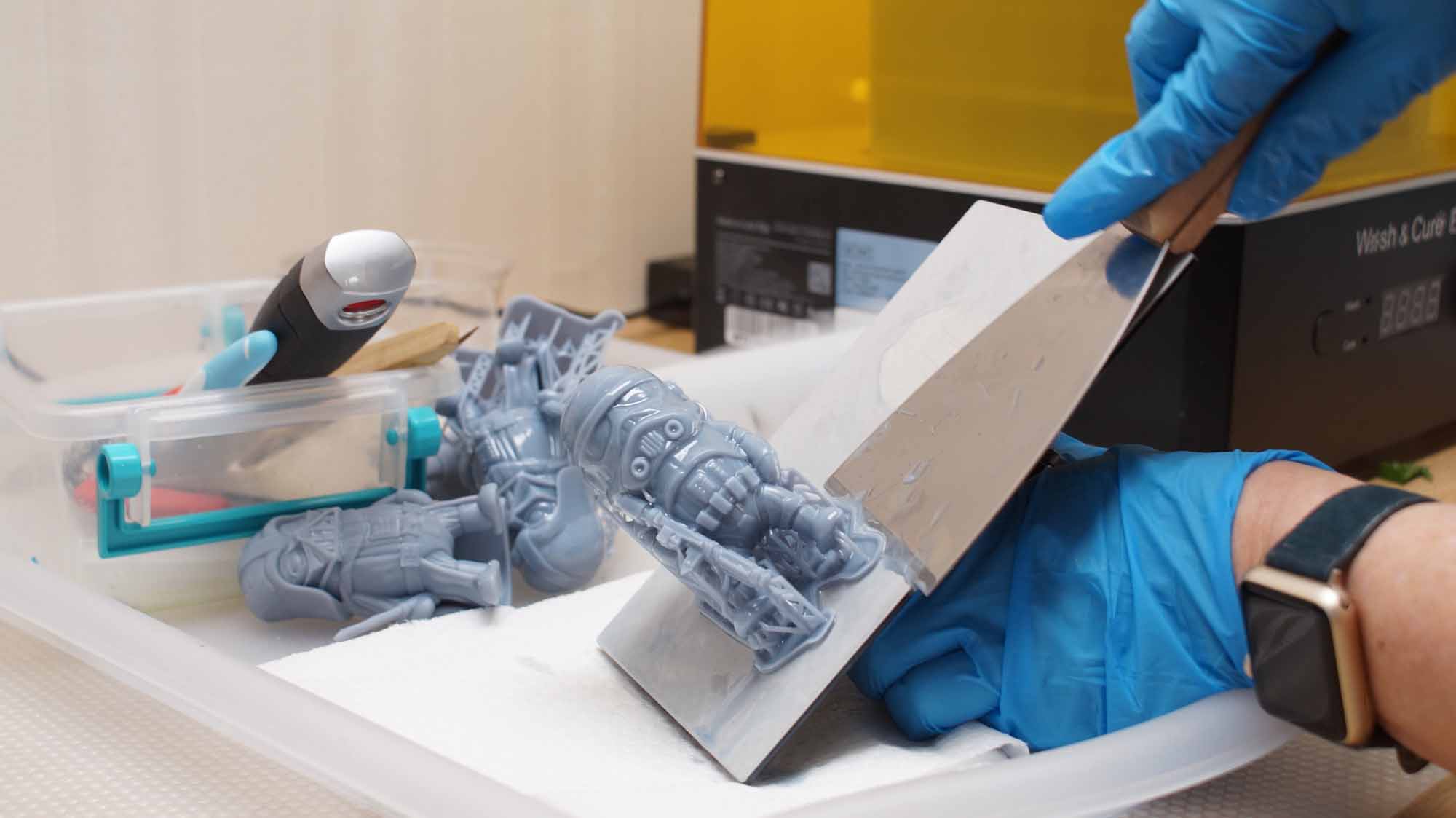

6. Set the edge of the metal scraper on the model’s supports and gently scrape them off the plate.

7. Place the models in the container of isopropyl alcohol, seal with a tight lid, and gently agitate the liquid for about 30 seconds.

8. Remove the model with a gloved hand or tongs.

9. Remove the supports. Use the side cutters if needed.

10. Place the model in the wash and cure tank. Set the timer for 2 minutes.

11. Dry the models. Use a hairdryer if you’re in a hurry.

12. Remove the tank from the wash & cure. Place the turntable on the base.

13. Put the model in the wash & cure. Replace the lid.

14. Set the timer for 15 minutes. Always check the resin manufacturer’s website for suggested curing times, some resins need more or less curing.

What if Your Resin Print is Still Sticky?

If your print is still sticky after curing, don’t worry – it can be saved! All you need to do is clean it again with isopropyl alcohol and a toothbrush, then return to the UV light for another spin.

Isopropyl Alcohol Alternatives

91% isopropyl alcohol can be expensive and sometimes hard to find, but there are alternatives. You can also use Mean Green cleaner, denatured alcohol and acetone.

Mean Green is currently the cheapest alternative and cleans nearly as well as isopropyl alcohol.

What about Ultrasonic Cleaners?

Some makers use an ultrasonic cleaner instead of a wash & cure machine. These are highly effective, but should be used with caution. Never fill an ultrasonic cleaner with flammable liquids like isopropyl Alcohol, which can be aerosolized by the machine and cause a fire. Only use these with a nonflammable cleaner like Mean Green.

What do I do with Resin Trash?

To properly dispose of resin trash you should cure everything with UV light before throwing it into the regular garbage. Trash can be cycled through your curing station or put in a clear bag and exposed to sunlight.

Dirty isopropyl alcohol can be left in an open container to evaporate, then expose the leftover resin gunk to sunlight or your curing station. Make sure you don’t leave isopropyl alcohol where animals or small children can get to it – remember, it is poisonous.

Denise Bertacchi is a Contributing Writer for Tom’s Hardware US, covering 3D printing. Denise has been crafting with PCs since she discovered Print Shop had clip art on her Apple IIe. She loves reviewing 3D printers because she can mix all her passions: printing, photography, and writing.

-

chewyalf How often do you change the contents of the container? And can you fill half with alcohol and the other half water or do you recommend pure alcohol. THANK YOU!Reply