Best Build Plates for 3D Printers

The best aftermarket build plates to improve your 3D printer.

The build plate is at the literal foundation of your 3D printer, and it can determine the success or failure of your prints more than any other feature. A single greasy fingerprint can be all it takes to turn a delicate model into a pile of spaghetti. And yet, we take the stock build plates that ship with our printers for granted, especially if we paid high dollar for the 3D printer itself.

🟦🟥 Stock Build Plates 🟥 🟦

Before we dive into aftermarket print surfaces, a word on stock plates. Every modern 3D printer we’ve reviewed since 2024 has come with a very usable build plate. Textured PEI flex plates have become somewhat standard, and that’s a good thing. If you’re buying a printer today, you may be quite happy with your stock plate. You may only need this list if your build surface has been scratched, worn down, or otherwise damaged.

3D printing has been constantly evolving, with new technologies emerging every year. My first printer had a rudimentary glass build plate held down with binder clips, but now I have a plate with my own logo embedded right in the center.

There’s a buffet of build plate options out there: flexible, coated, textured, dual-sided, and optimized for specific filaments and print styles. But not all build surfaces are created equal. Here are the best third-party build surfaces you can buy for your 3D printer to get that first layer buttery smooth.

Best Build Plates for 3D Printers at a glance

Why you can trust Tom's Hardware

Best Build Plates | Where to Buy | Price Range | |

Best Overall | Tyson Flex Plate System | $50 – $120 | |

Best All Temperature Grip | BIQU CryoGrip Pro “Glacier” | $14 – $43 | |

Best Cold Grip | BIQU CryoGrip Pro “Frostbite” | $14 – $43 | |

Best for PLA | SliceWorx Dipped PEI | $20 – $70 | |

Best for Every Size / Hard to Find Sizes | WhamBam PEI | $7 – $200 | |

Best Holographic Effects | Holographic Build Plates | $10 – $28 | |

Best for Custom Patterns | Custom Textured PEI Plate | $49 and up |

Best Build Plates For 3D Printers You Can Buy Today

Tyson Flex Plate System

1. Tyson Flex Plate System

Our expert review:

Specifications

Reasons to buy

Reasons to avoid

Tyson Build Plates are a revolution in 3D printing build surfaces. The T-95 plate is made from a thick Tempered 1095 spring steel with a proprietary coating that is truly universal. The plate can handle everything from PLA to PEEK, and the only limits are from the machine you put it on.

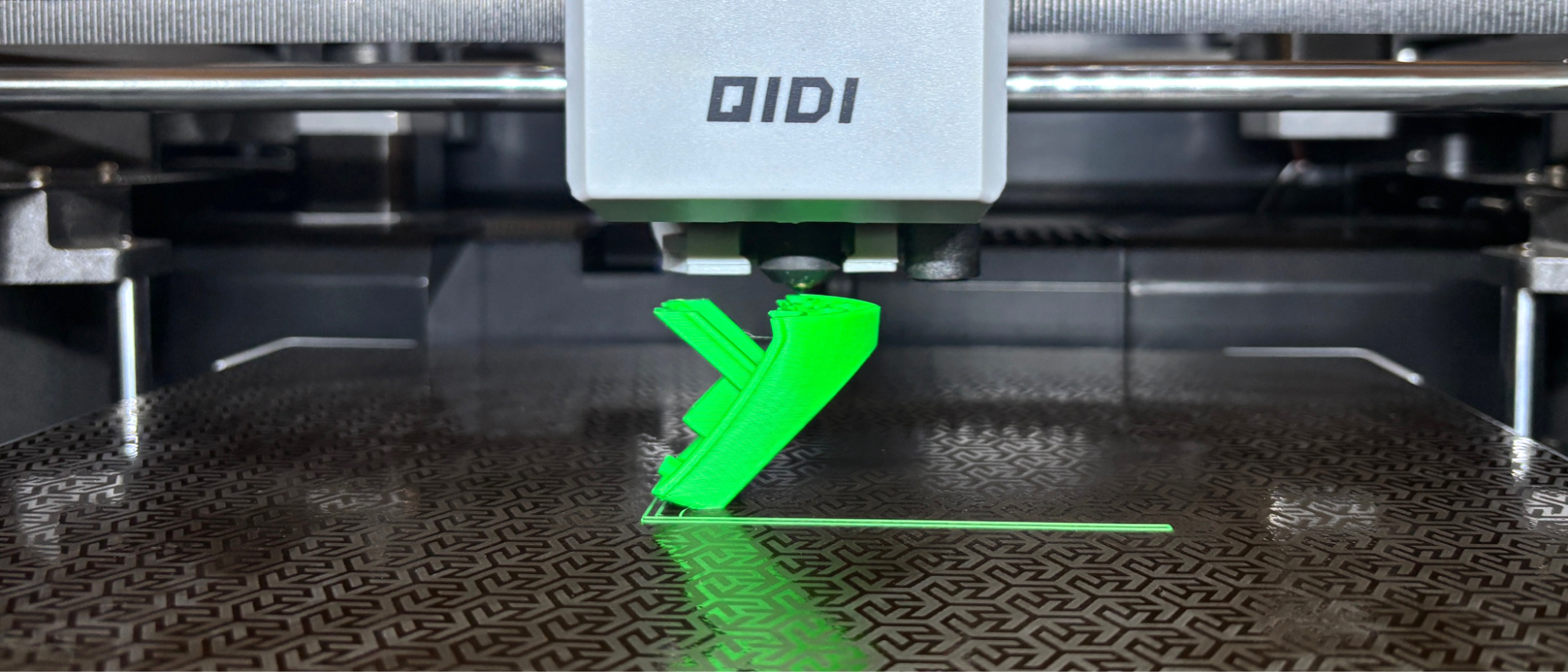

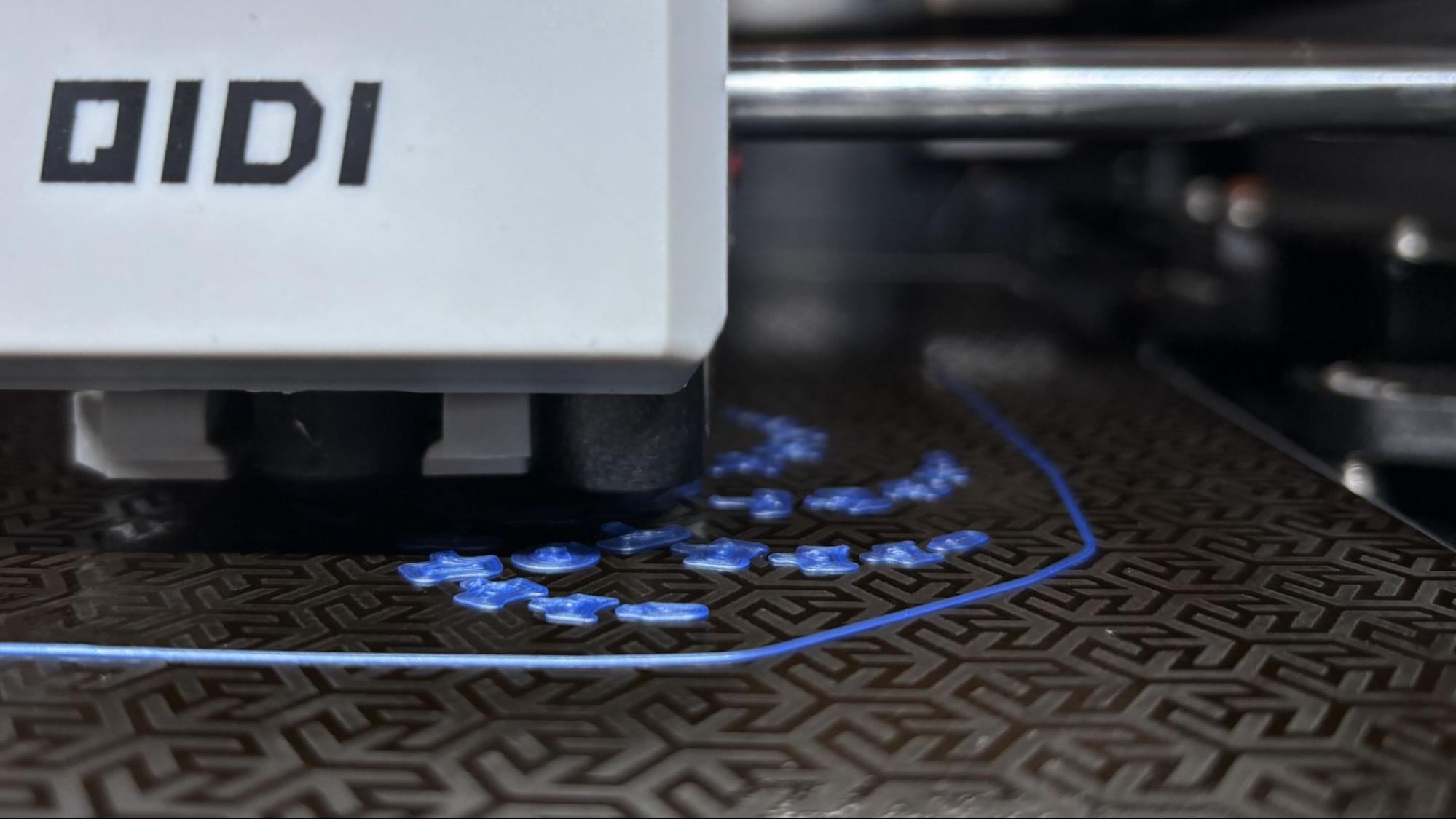

We tested this plate on the Qidi Tech Plus 4 and ran PLA, PETG, TPU, ASA, and Nylon without glue stick or any adhesion aid. Prints pop off easily and release on their own when allowed to cool. The bottom of the print is smooth and glass-like.

For an extra charge, the plate can bear your logo or an etched pattern that will transfer to the bottom of the print.

BIQU CryoGrip Pro “Glacier”

2. BIQU CryoGrip Pro “Glacier”

Our expert review:

Specifications

Reasons to buy

Reasons to avoid

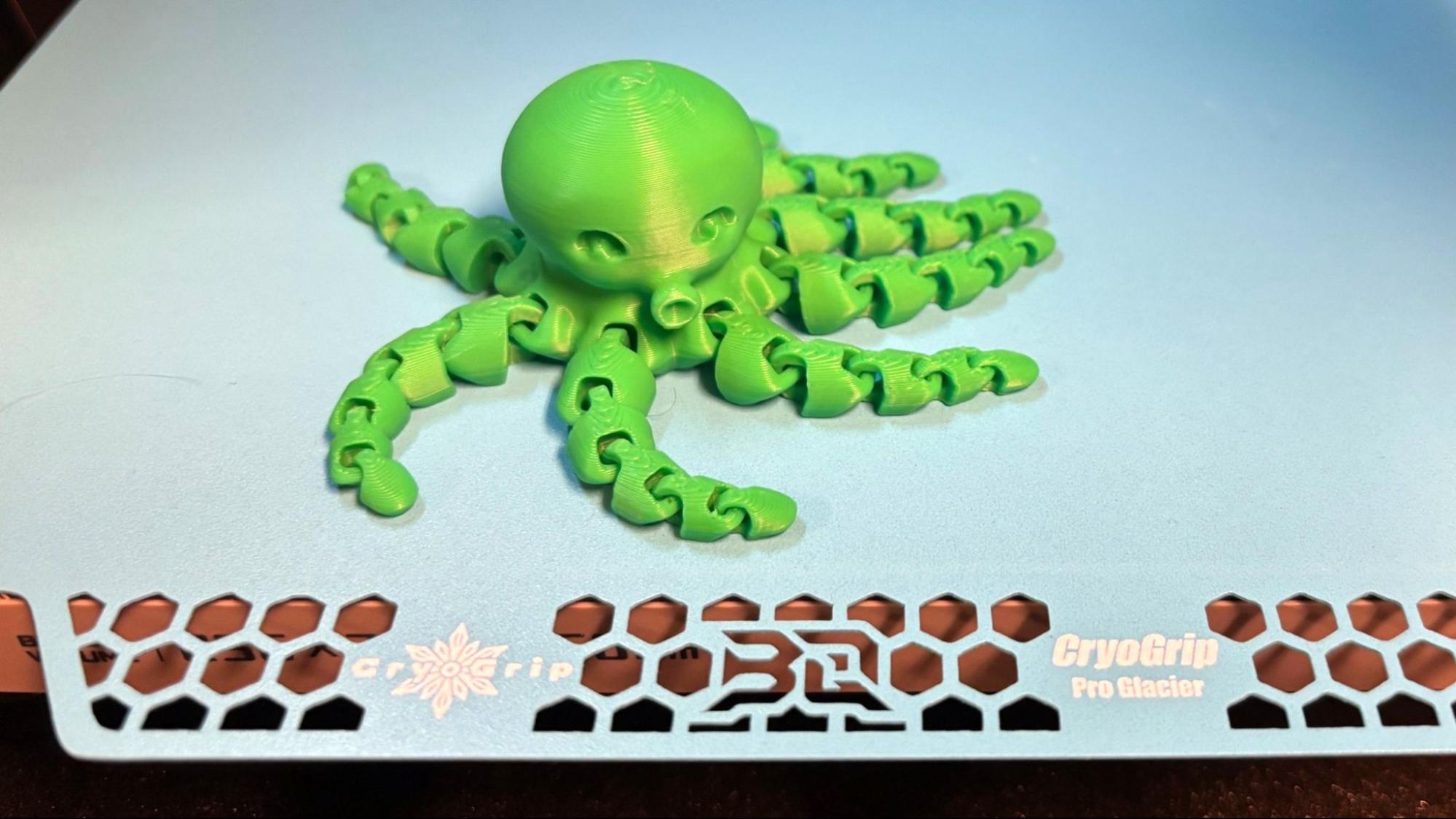

Glacier is one of BIQU’s two new cold plates, which rely on texture and Arctic Fairy Dust to hold down prints with minium heat. Ok, we’re kidding about the fairy dust, but there’s definitely some magic to the “porous oleophobic polymer coating” used on the top surface. Glacier plates have superior holding powers and defy dirt and grease from ordinary handling, and are scratch resistant. They work for every material without a need for gluestick, even TPU.

Because the Glacier is a cold plate, it will continue to hold at room temperature, which is nice if you’re worried about power outages. Most prints come off with a flex after it’s cooled a bit, but smaller things – like flexi animals – may need light persuasion. If you still have problems, 10 minutes in the freezer will help.

BIQU CryoGrip Pro “Frostbite”

3. BIQU CryoGrip Pro “Frostbite”

Our expert review:

Specifications

Reasons to buy

Reasons to avoid

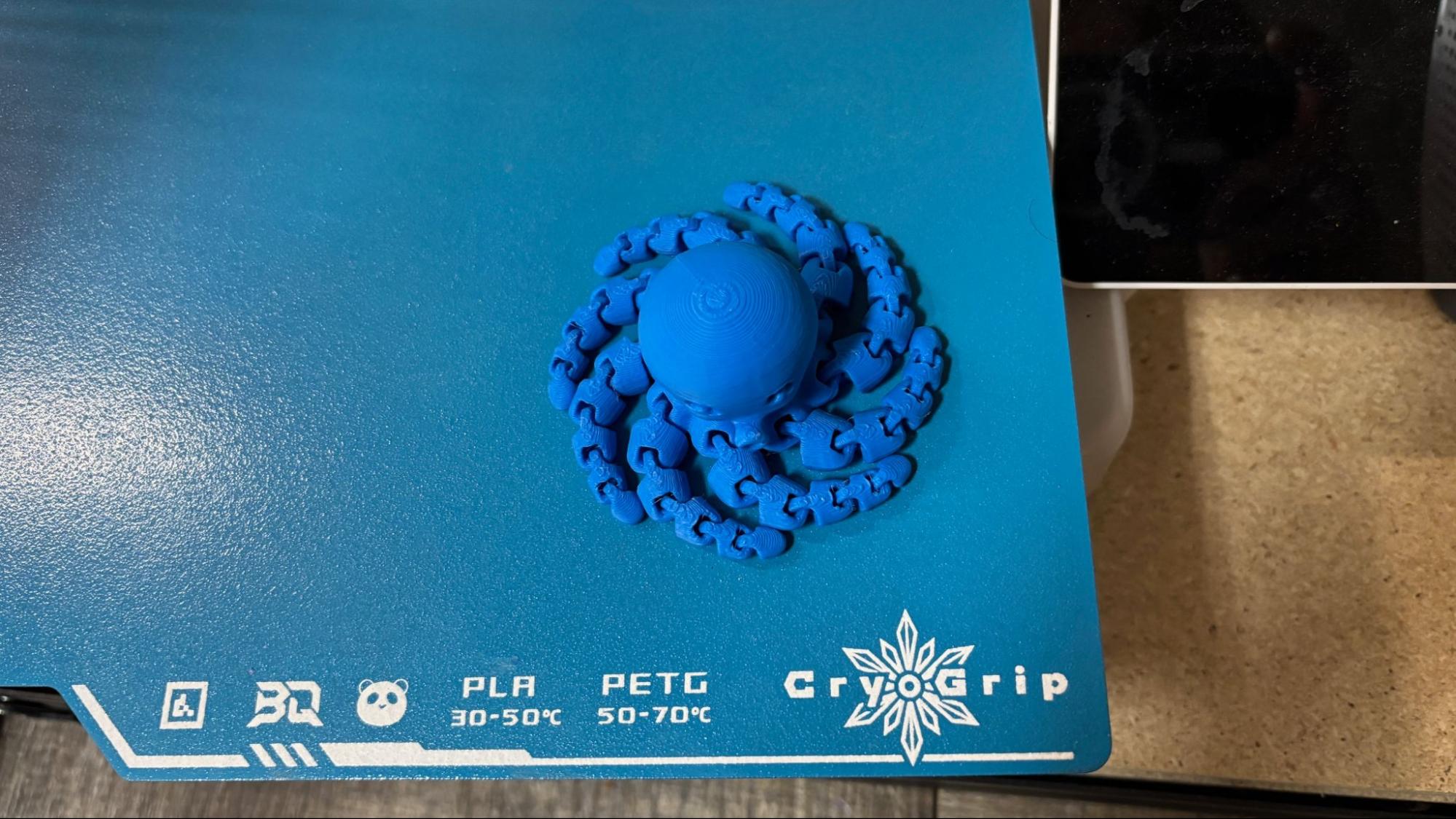

Frostbite is the other new cold plate from BIQU, and could have been called “Rottweiler” considering how well it holds on to prints. It has a courser texture than Glacier, and holds prints at low temperatures. The plate is almost TOO sticky, but if you’ve ever had just one segment of a 3-day print pop off, you’ll appreciate the holding power of this plate. Frostbite plates defy dirt and grease from ordinary handling, and are also scratch resistant.

Because the Frostbite is a cold plate, it will continue to hold at room temperature, which is nice if you’re worried about power outages. Prints need more than a little flex to pop off this plate, and definitely need to cool down before you even try. If you still have problems, 10 minutes in the freezer will help.

SliceWorx Dipped PEI

4. SliceWorx Dipped PEI

Our expert review:

Specifications

Reasons to buy

Reasons to avoid

Like Oreos dipped in chocolate, SliceWorx had a brilliant idea: what if we dip a PEI Flex plate in…rubber? Ok, it's not rubber, and they aren’t saying what the “high quality polymer” actually is, but rubber is pretty close. The coated surface of SliceWorx’s dipped plates is pure genius for those of us hooked on tiny articulated prints with a high failure rate.

Like the FrostBite plate from BQ, these dipped wonders are strictly for cool filaments like PLA and PETG. They need to be cooled a bit before flexing to remove your prints.

WhamBam PEI

5. WhamBam PEI

Our expert review:

Specifications

Reasons to buy

Reasons to avoid

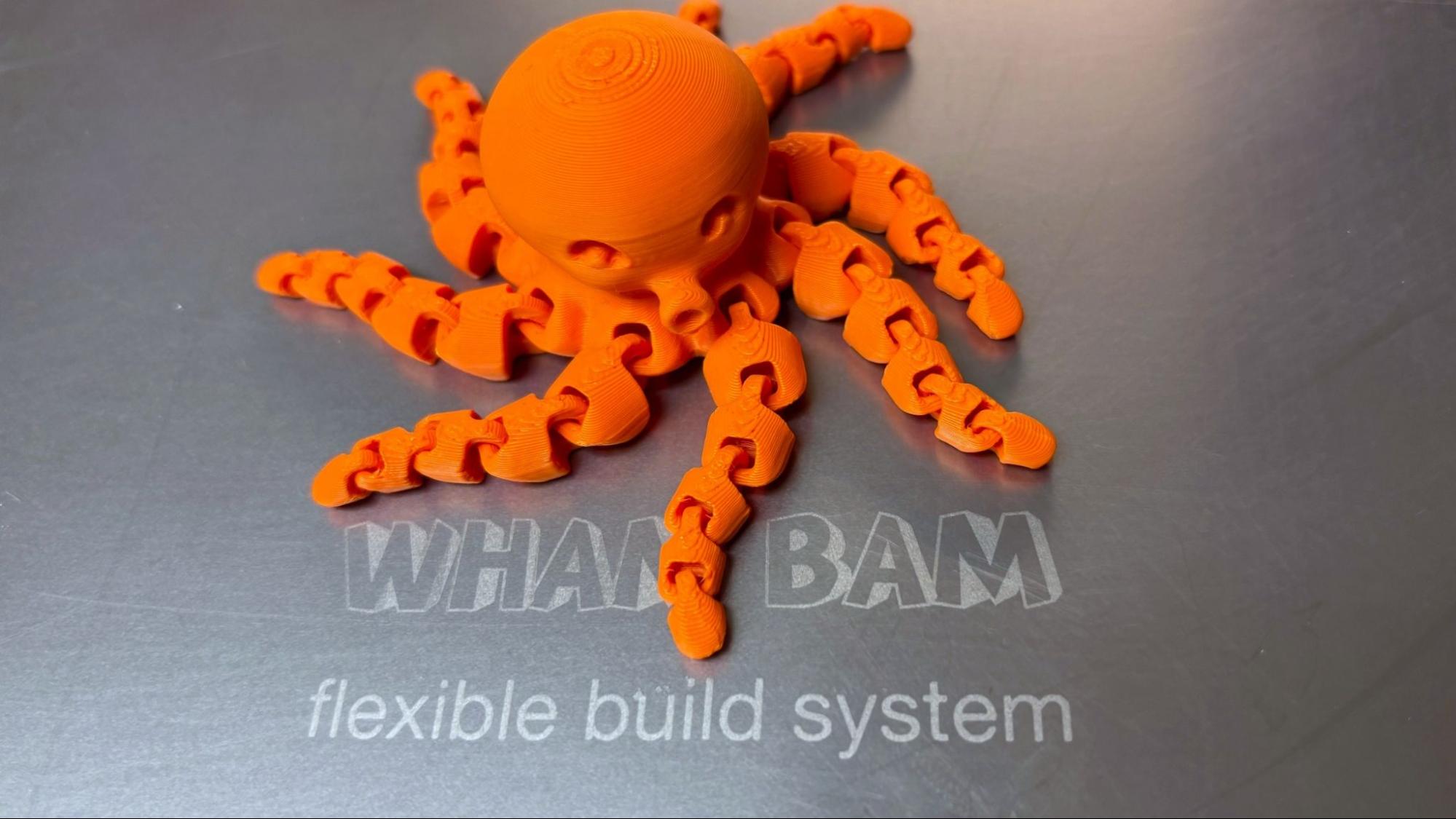

Wham Bam PEI flex plates are no longer “revolutionary” after manufactures adopted PEI sheets for themselves. But their commitment to quality ensures that when you need a better build plate, Wham Bam has you covered with every size imaginable.

It’s line of PEI plates are known for consistent quality and come in both a smooth sheet that gives a shiny surface, or a baked on textured plated.

Holographic Build Plates

6. Holographic Build Plates

Our expert review:

Specifications

Reasons to buy

Reasons to avoid

A holographic build plate has a specialized surface that leaves a shimmering “holographic” pattern on the bottom of the print. The plate has an ultra fine textured surfaces that diffracts light and can be transferred to the PLA print.

The holographic sticker is easily scratched, so great care should be taken when removing prints. The effect is also spoiled by finger oils and glue stick, so you’ll need to keep the plates super clean and additive free, which is why PLA is the go-to filament for these special effects plates.

The plates do not have any special gripping powers, so you’ll need to have a well tuned printer, and slow your speed for the best chances.

Custom Textured PEI Plate

7. Custom Textured PEI Plate

Our expert review:

Specifications

Reasons to buy

Reasons to avoid

Ember Prototypes knocked our socks off when it introduced custom PEI plates that bore whatever artwork you wanted to show off on your prints or the printer itself. The plates are not laser cut, but rather uses a proprietary coating that leaves a raised image on the plate that can transfer to the bottom of your print.

While they have some generic artwork available, the best plates are the ones where you supply the art. I had one made up with a hexagon pattern and my logo in the center, which is a little hit or miss as to what will end up on the finished print. Because these are bespoke plates, theres’s no refunds, so double-check your artwork before sending it over.

Best Build Plates for 3D Printers: How We Test

How we test the best build plates for 3D printers

We test all the build plates we recommend.

Our favorite test model for build plate adhesions is the humble “Mini Cute Octopus” by McGybeer – one in each corner – run at default speeds for the printer. We used a Bambu Lab P1P, A1, A1 Mini, QIDI Plus 4 and MK4s, all capable of running at an average speed of 200mm/s. It’s eight tiny tentacles each have 5 sections, meaning there’s 40 individual sections, some as small as 6x11mm.

I tested each printer’s stock plate – many of which failed without the help of glue stick - before switching to the aftermarket plate. Each plate had a few weeks of regular printing in addition to the test prints. The Octopus models will be given to children (for free) at 3D printing festivals when they visit my table, so there is no plastic wasted.

Best Build Plates for 3D Printers: FAQs

FAQs for the best build plates for 3D printers

🟢 What’s the best build plate surface to print on?

A clean one! Many first layer issues can be fixed by washing your build plate with hot soapy water, then drying the plate with a lint free cloth. Preheating the bed and using a little “purple” washable glue stick can also help give some extra stick for your models.

🟢 What’s the best build plate surface for PLA?

Textured PEI is one of the best all around surfaces, very affordable and generally works well for easy going PLA.

🟢 What’s the best build plate for PETG?

PETG is known to bond with just about anything, but a good clean, smooth PEI works best. And it never hurts to add a little glue stick for insurance.

🟢 What’s the best build plate for ABS?

We highly recommend the Tyson Build plate, a specialized high temperature plate that works for all filaments and absolutely excels at high temperatures.

MORE: Best 3D Printers

MORE: Best Resin 3D Printers

MORE: Best Budget 3D Printers

MORE: Best Filaments for 3D Printing

MORE: How to Buy the Right 3D Printer

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Denise Bertacchi is a Contributing Writer for Tom’s Hardware US, covering 3D printing. Denise has been crafting with PCs since she discovered Print Shop had clip art on her Apple IIe. She loves reviewing 3D printers because she can mix all her passions: printing, photography, and writing.