Tom's Hardware Verdict

Formlabs gets a lot of grief for locking customers into a pricey ecosystem, but the results are perfect prints that don’t require a background in engineering or chemistry. The machine is over the top with auto features and sensors while also proving that “high resolution” prints are more than just pixel count.

Pros

- +

Excellent resolution

- +

Perfect Prints

- +

Graphic interface explains every move

- +

Built-in Camera

- +

Sensors galore

Cons

- -

Expensive

- -

Must use Formlabs materials

Why you can trust Tom's Hardware

I never enjoyed resin 3D printing — it's simply part of my job. Then I got the Formlabs Form 4 in for testing, and I finally understood the problem. Consumer-level resin 3D printers — and their associated wash and cure stations — are not only messy but also require too much guesswork. Formlabs eliminated the guessing game by creating a tightly controlled and thoroughly tested ecosystem. That ecosystem also includes all the tools you need for cleanup and a cleverly designed user interface that reduces the mess.

Not surprisingly, this tightly locked ecosystem is also one of its biggest flaws. The equipment and resin can get expensive, and using cheaper “unknown” resin breaks the perfectly orchestrated chain of events that Formlabs planned for you. You can “unlock” the printer to work with 3rd party resins, but the license to open that door is $2,499 — more than half the cost of the printer itself. If you are concerned about saving $50 on a bottle of resin, this isn’t the printer for you.

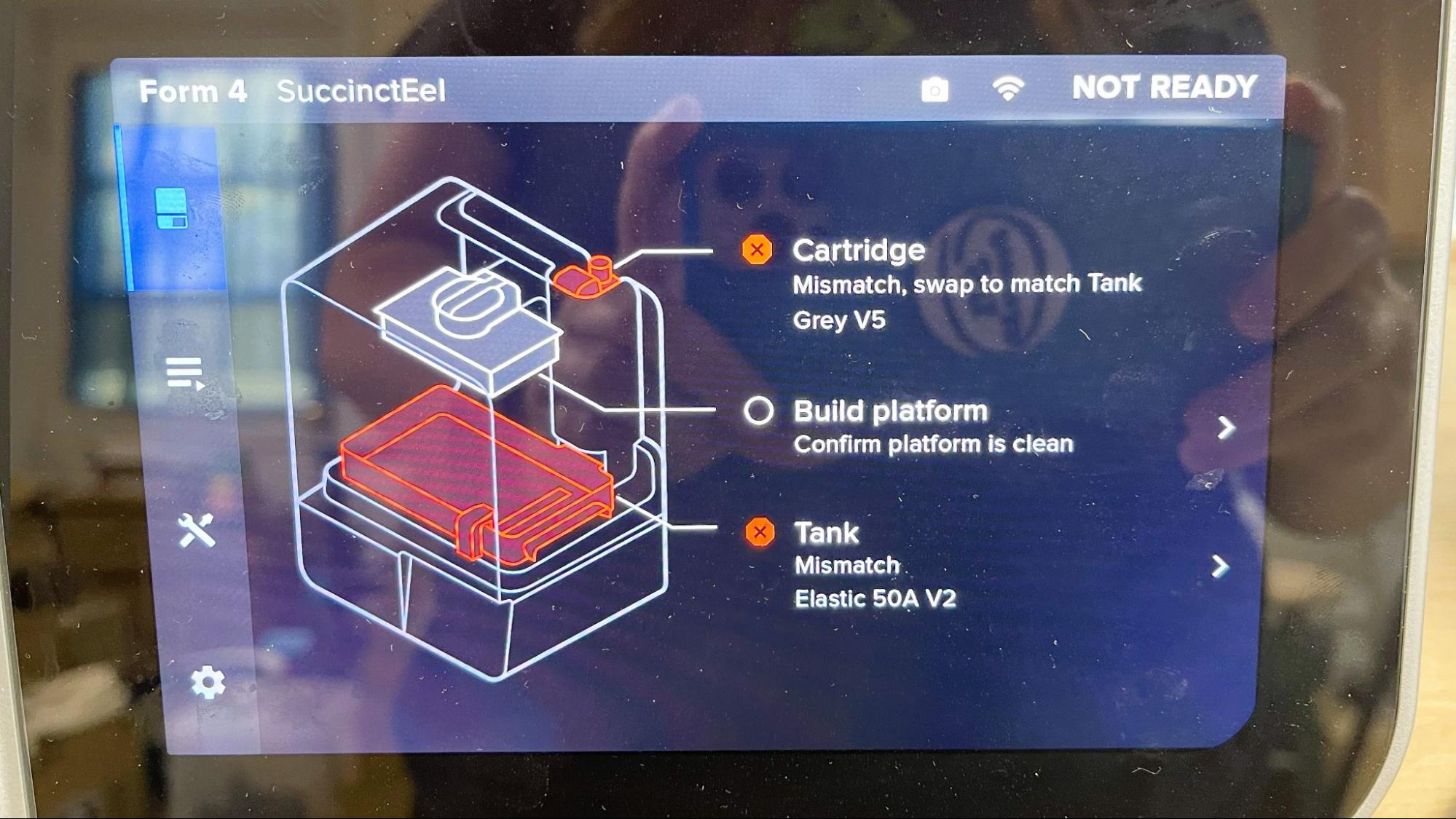

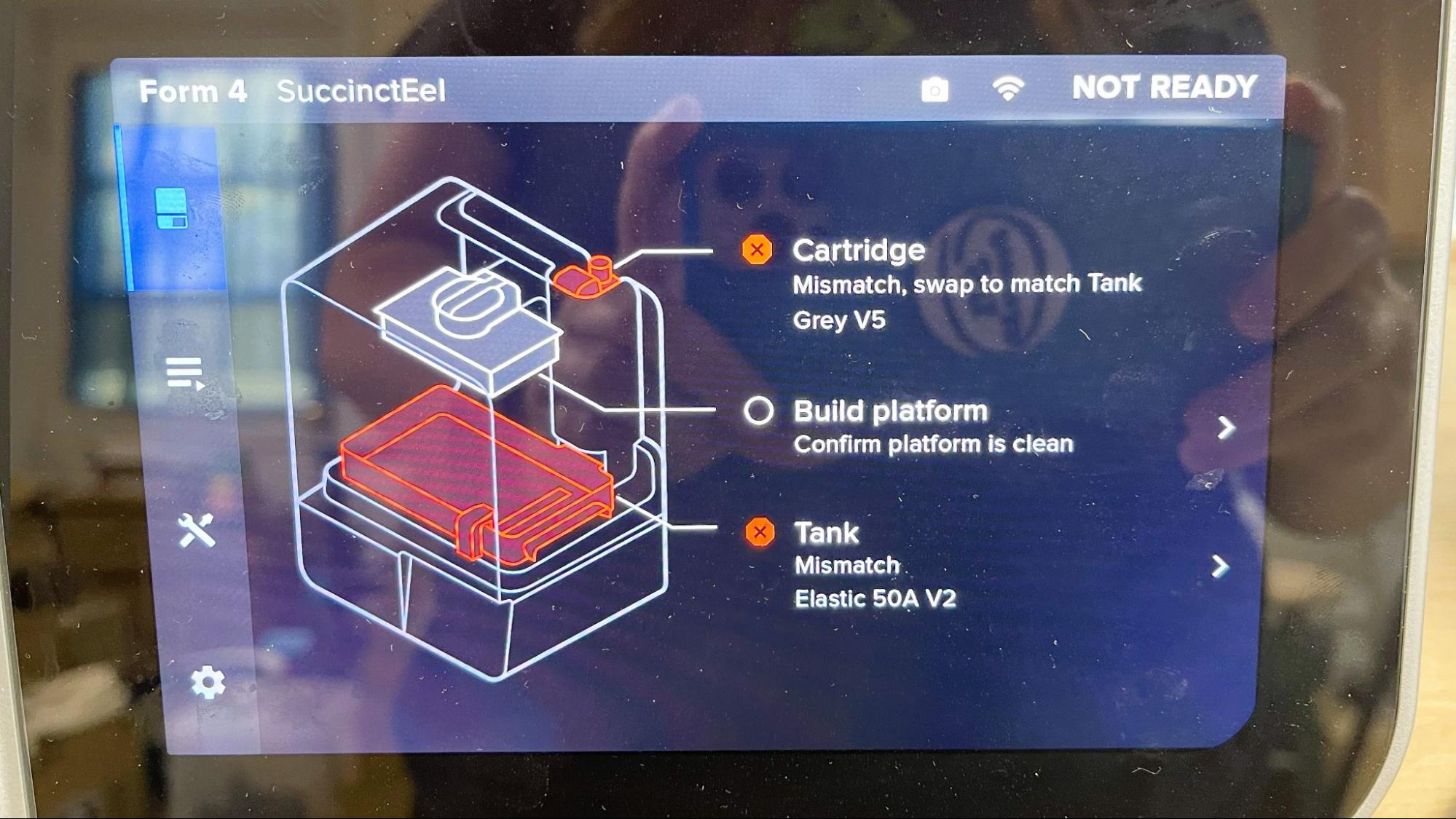

Formlabs makes its machines foolproof by limiting users to components its engineers have designed and tested themselves, ensuring everything works together without error. Resin cartridges and vats are tagged with RFID stickers, so the software can track your materials every step of the way. It uses this information to determine the slicer settings, let you know when to load in more resin, and keep an inventory log for you. All you have to do is insert a bottle of resin into the machine, drop a file in the slicer, and make sure all the Print Validations are green.

The system is designed for businesses that need a steady flow of perfect prints every time and don’t mind paying for it. It really makes sense when you look at the prices of Formlabs' special materials. You don’t want a print fail when you load a jug of $350 liquid silicone. If you follow the guidelines in the slicer, you will get good parts. Using Formlabs Form 4 is so simple that it can be run by an intern or Bob from accounting.

The Formlabs ecosystem extends to the company website, which has written and video directions explaining how to use the machine and clean the models. If you need a reminder, the large color screen takes you through a checklist before printing.

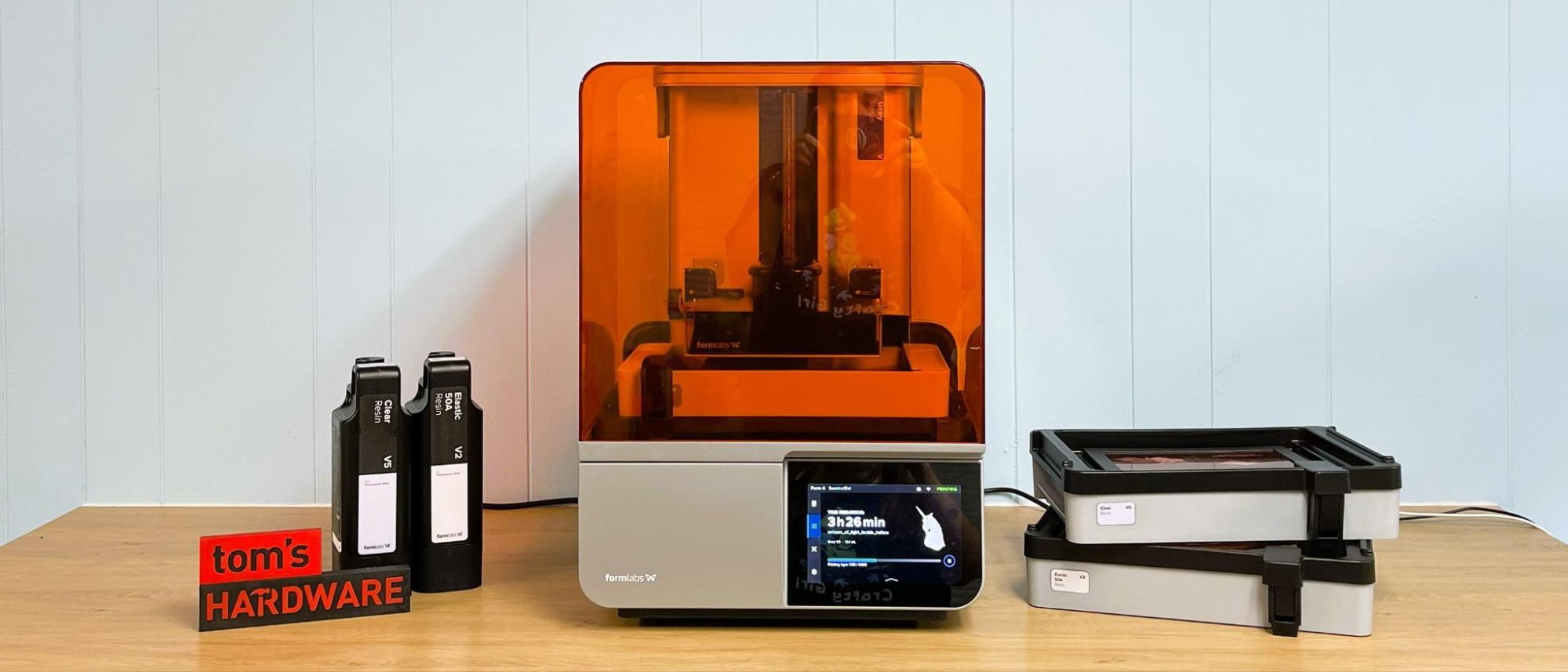

With a build volume of 200 × 125 × 210 mm and prices starting at $4,069, the Formlabs Form 4 is a premium 3D printer for people who demand high quality, ease of use, and reliability. Though it is locked into an expensive ecosystem, the company provides a wide range of performance materials for every application, including medical, and we find it to be one of the best resin 3D printers and best 3D printers overall.

Specifications

| Build Volume | 200 × 125 × 210 mm (7.9 × 4.9 × 8.3 inches) |

| Light Source | LED with plano-convex lens array |

| X/Y Axis Resolution | 50 µm |

| Normal Exposure Time | N/A |

| Interface | 7-inch color touchscreen |

| Connectivity | USB, Wi-Fi, LAN |

| Machine Footprint | 398 × 367 × 554 mm (15.7 × 14.5 × 21.9 inches) |

| Machine Weight | 18.3 KG (40.4 lbs) |

Included in the Box: Formlabs Form 4

The Formlabs Form 4 includes everything you need to get started as soon as you unbox the printer. Unlike consumer-level printers we’ve tested, the Form 4 is sold as a bundle and comes with one vat and a manual cleaning kit. That kit consists of a large sealed tub for cleaning models with a metal basket and an assortment of hand tools. We were loaned the complete system, which also includes a flexible build plate, an automated wash station, a curing station, gloves, funnels, pliers, scrappers, wipes, extra vats, and a device to measure the cleanliness of the washing fluid. The only thing I needed to supply was the isopropyl alcohol to fill the wash tub.

Printing Safety with Formlabs Form 4

The Formlabs Form 4 requires the same safety precautions as other resin printers. Uncured resin is dangerous, and the solvents used to clean your prints can be irritating to the skin. Use gloves and safety glasses when pouring resin and handling uncured prints.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Make sure the room you use your resin printer in is well-ventilated to avoid inhaling fumes. Spilled or dripped resin should be immediately cleaned with 99% isopropyl alcohol.

After printing, make sure to wipe down your printer and bottles to remove smudges of uncured resin. Always keep your resin tightly sealed and safely stored out of reach of pets and children.

Assembling the Formlabs Form 4

The printer comes fully assembled. You only need to unpack the printer, put the wiper in the vat, then lock the vat and build platform in their respective places.

Formlabs Form 4 ships with the build plate factory-leveled. However, it does have an internal sensor to ensure the machine itself is level so it can accurately read the liquid contents of the vat. During the initial setup, the machine will walk you through leveling the four legs on the bottom of the printer using a provided tool.

Design of the Formlabs Form 4

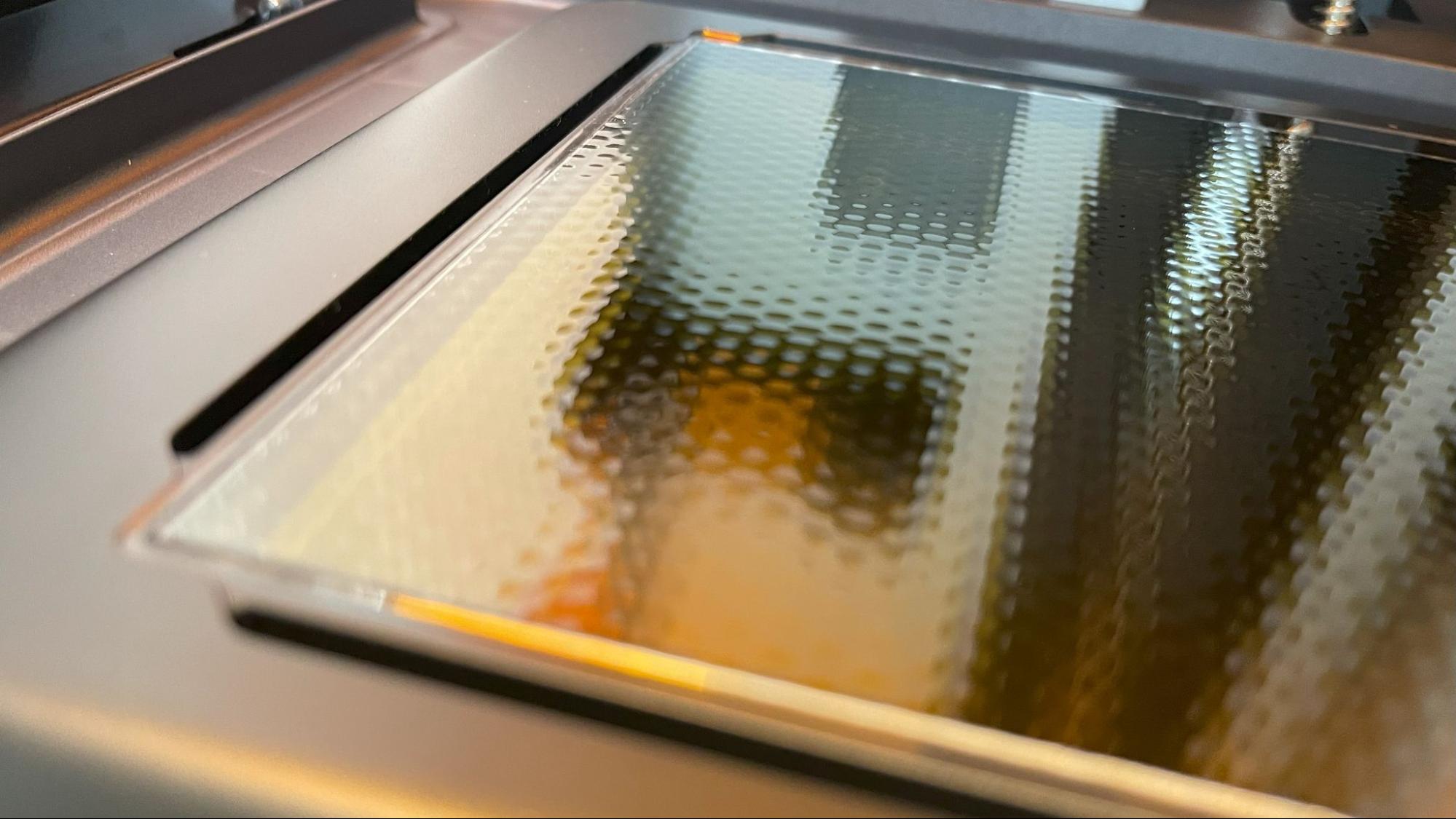

The Formlabs Form 4 is a beautifully built machine with superior attention to detail. It has a flip top lid with a recessed handle, which is easier than consumer machines with lids you need to grasp with both hands to lift off. The vat quickly latches in place without the need for screws. The glass surface over the light processing unit has a non-stick texture to prevent the vat’s film from getting stuck to the glass – allowing the film to gently flex when the build plate lifts between layers.

Formlabs resin comes in special cartridges that have a standard bottle cap on the top and a flexible nipple on the bottom. The Form 4 is able to dispense just the right amount of resin from the bottom opening as needed.

The vats are made of plastic and come with UV-proof lids, so you can store them with leftover resin still inside. If you buy several vats, you can quickly change materials without needing to clean out the goo.

Each resin cartridge comes with stickers to label the vat, while the printer itself uses an RFID tag. This allows the printer to match the vat to the material and eliminate the possibility of cross-contamination. The printer also tracks the life of the vat and will alert you at 75,000 layers that the film may be wearing out. Unlike consumer-grade printers, this film is not replaceable, making the whole vat a $99 consumable. This may seem a bit wasteful, but replacing the film can be tedious and difficult.

The vat also has something I’ve not seen on a consumer machine – a wiper blade. The blade has two purposes: it stirs the resin to keep it well blended, and it feels for debris in the tank. If it encounters a chunk from a failed print, it will stop the printer and alert you. It will also bug you to run a cleaning cycle with a red warning.

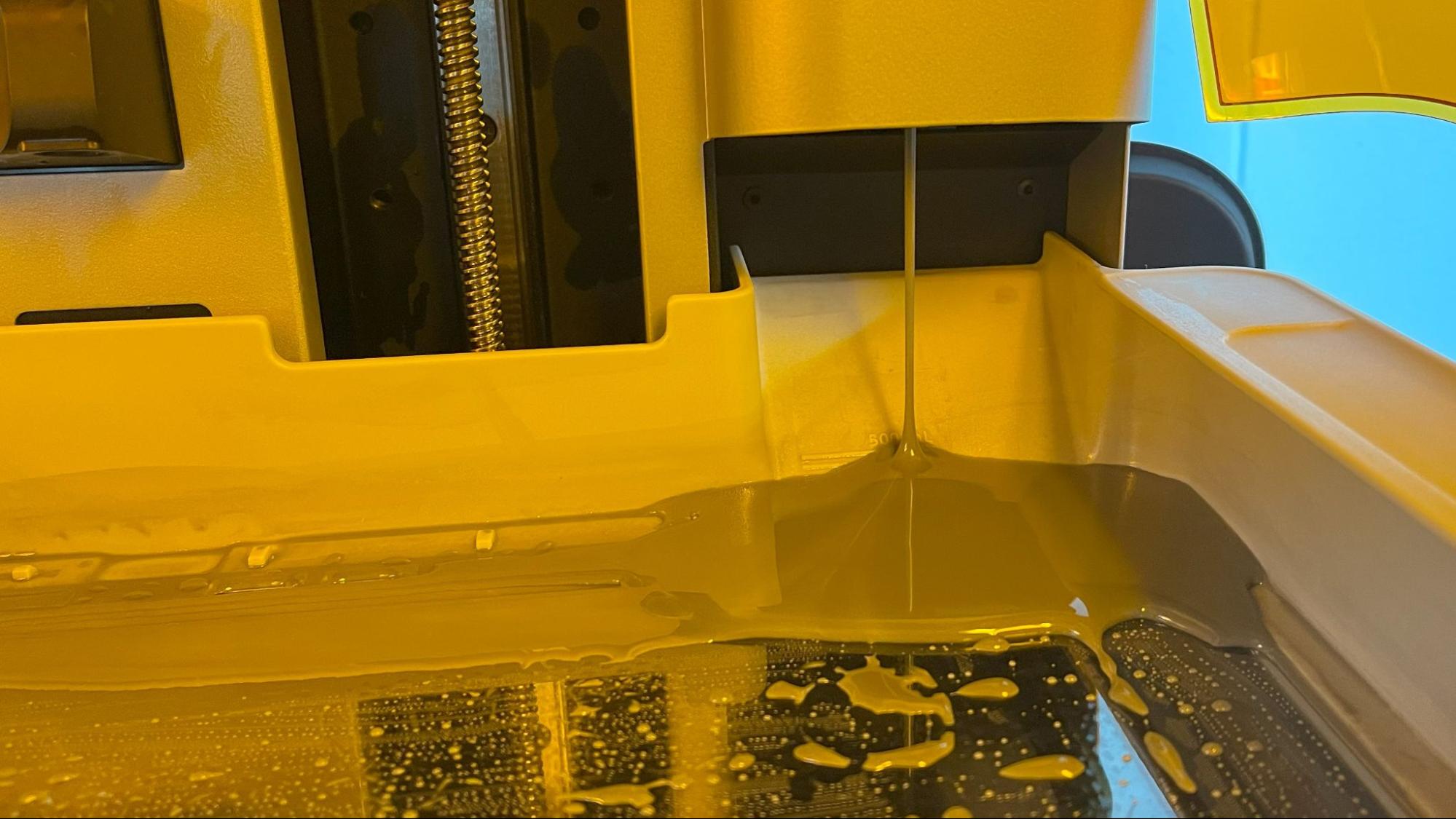

The Form 4 has even more sensors that can alert you to dangerous situations. It can track the resin level and will stop when it runs out, it knows if it's sitting on an unlevel surface, and it knows when the lid is open and will ask you to close it. It sounds an alarm if you try to remove the vat without first removing the build plate, which could drip on the glass and cause a difficult to clean mess.

The Form 4 “only” has 4k resolution, which may sound inferior to the latest batch of consumer-grade printers with double or triple the number of pixels. But this machine proves something I’ve always suspected: sharp details are more about the material than the pixel count. The Form 4 produces crisp, clean prints with an amazing level of detail and accuracy.

The build plate on Form 4 is smooth, but our review unit came with the optional flexible plate, so removing prints was never a problem. The flex plate had long handles that wrapped around the build platform, making it somewhat awkward to remove. However, the snug fit means you can pull the plate half off, letting it dangle at a 45-degree angle so the resin can drip back into the vat. I’m not sure if this is an intentional feature, but I found it pretty handy.

This 3D printer needs to be connected to a computer to receive files, either through WiFi, LAN or a direct USB cable. This is because the slicer, PreForm, needs a two-way connection to double check the type of resin that is loaded. It will also track your resin inventory and suggestion when you may need to buy more.

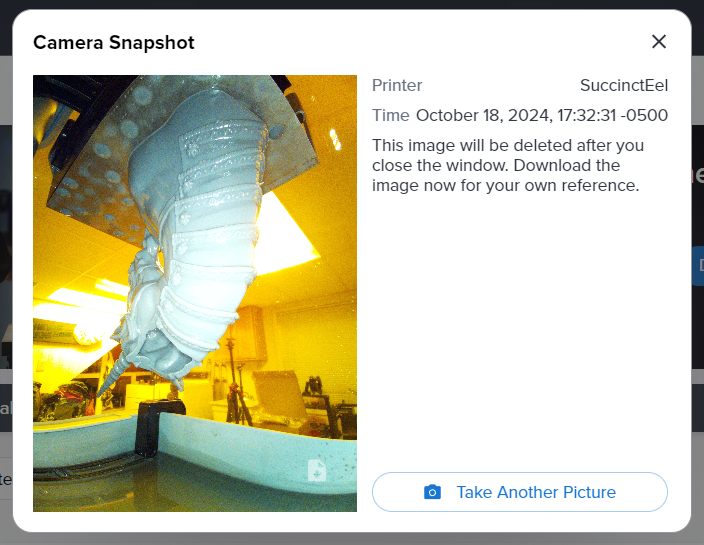

The Form 4 also comes with a built-in camera to monitor the printer and record time lapses.

The wash and cure stations are equally well-designed to make the printing process easy. The wash station has built-in storage for tools needed for cleaning prints, and the lid opens automatically with the touch of a button. If you’ve never had to grapple with a four-latched lock top on your washing alcohol, you can’t imagine how nice this feature is to have.

Once the rinse cycle is done, the basket is automatically lifted out of the rinse fluid so it can immediately start drip-drying. The inner lid has a slot to allow the fluid to drain back into the tank. There’s one flaw with the automatic lid: there’s no gasket on the outer lid, so your isopropyl alcohol will slowly evaporate. I should note the lid is enough to contain the strong smell of isopropyl alcohol, so it’s not all bad.

Slicers Compatible with the Formlabs Form 4

The Form 4 only works with its custom software, PreForm. The software is a free download, and it needs to be connected to the printer via WiFi, LAN, or USB cord.

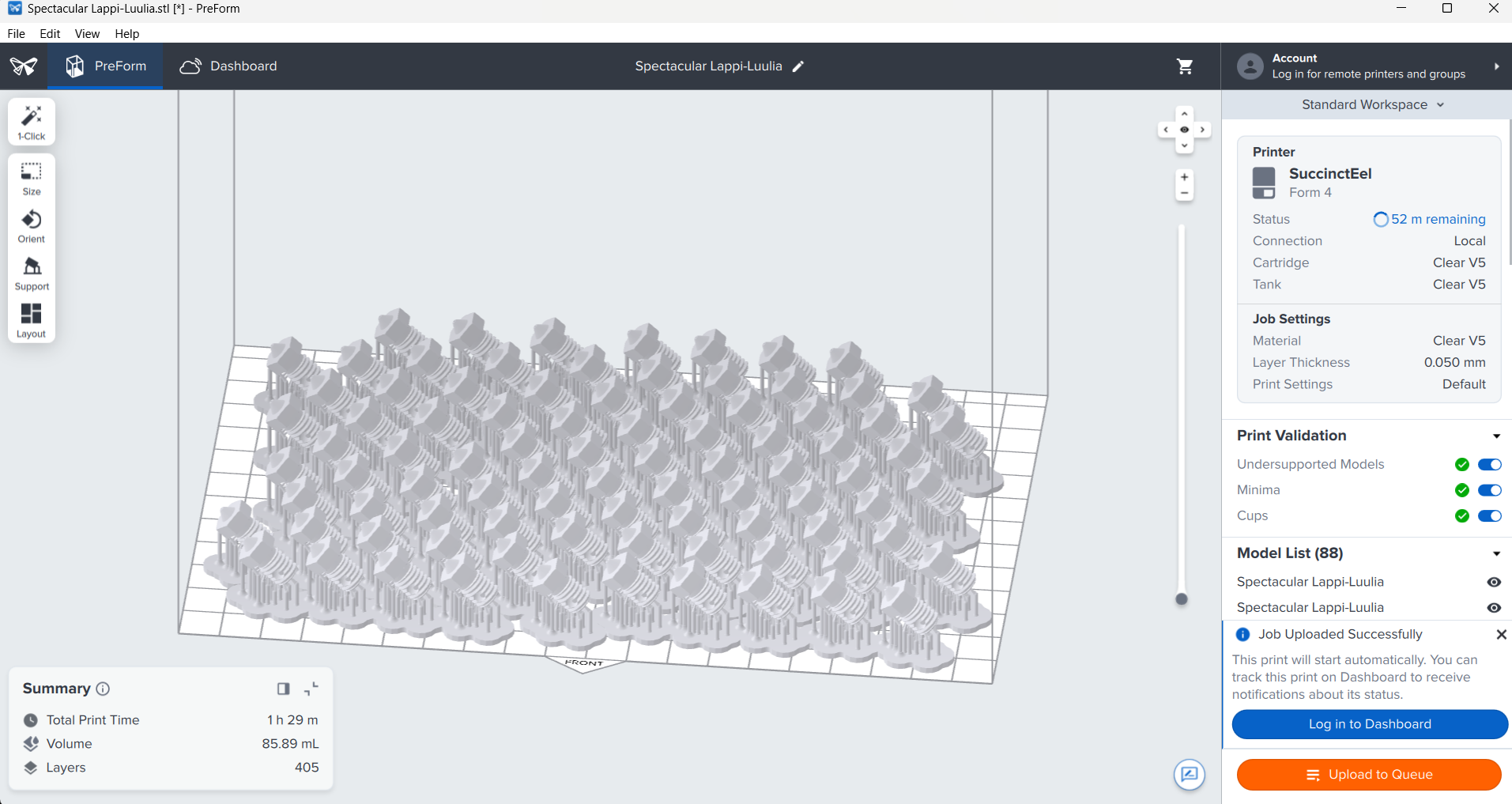

PreForm software is fully automatic and simplified. Because you’re working within Formlabs’ walled garden, there’s no need to tinker with the settings, as the perfect settings have been configured for you. You only pick the layer line size, which determines speed. It defaulted to a .1 mm layer, which is considered quite chunky normally but was listed as “fast.”

The program can do everything a slicer should. It can hollow your model, automatically add supports to the inside and outside, and neatly multiply parts in organized rows. Once the Print Validation area is all green, you’re good to go.

You do have limited ability to tune the printer in the advanced settings, but I found no need for this on my tests.

The Dashboard area takes things a step further. Here you can track your print history, see how much resin is available, and if you have a farm, see which printers are open. It also tracks when you last used each cartridge of resin, estimates how much is left in the bottle, and has a handy link to the Formlabs store to order more.

Washing and Curing Your Prints

Before you can admire your prints, you’ll need to wash them with isopropyl alcohol and cure them with UV light. I like to give prints a 30-second hand rinse in a container of 95% isopropyl alcohol and a 2-minute rinse in the Elegoo Wash and Cure, which is sold separately and retails for $249 at Elegoo.com.

Completely dry the print with a hair dryer on cool – the IPA left on the print will turn white. You can also let the print air dry in a place away from sunlight.

Supports are easier to remove before curing because they are softer. Clip the supports off with side cutters and use tweezers to remove stubborn supports. Remember to always wear gloves while handling uncured prints.

Then place the print in a UV curing station for 15 minutes or outside in bright sunlight for a few hours.

Your IPA should never be flushed down the drain, especially after being contaminated with uncured resin. Instead, keep using the resin until it’s too dirty, then leave the container open to evaporate. The remaining sludge can be cured with UV light or the sun before being thrown away.

Supports should also be cured before being thrown away.

Sample Prints on the Formlabs Form 4

I first tested the printer with the AmeraLabs resin test print using Formlabs Grey V5 resin that was provided for the review. The print looked perfect, with some of the cleanest details I’ve ever seen from that model. The print took 44 minutes to complete using a 50 µm layer height default settings.

Next I ran my favorite Rocket Bust by Wekster, which I’ve been using as a larger comparison test for resin printers. This printed in 4 hours and 59 minutes, using a 50 µm layer height with default settings with the grey Formlabs resin. The Form 4 print is on the right, with a print from the Elegoo Saturn 4 Ultra on the left. The Saturn 4 is a 12K machine with a resolution of 19x 24 microns. Though the Saturn was able to print this file in 3 hours and 13 minutes, the Formlabs appears just a touch more refined, especially if you look at the creases in Groot's face and the details on Rocket’s uniform.

I just can’t get over the clear, crisp details the Form 4 can produce. Here’s one more sample, with two unicorns by Loubie. The left is printed on a Phrozen Sonic Mega 8k S, and the right is the Formlabs Form 4 (again, a 4K machine). The Phrozen machine is aimed at the same commercial market, and has a 43 µm resolution – compared to the Form 4’s 50µm. You can clearly see the Form 4 has cleaner details that appear less blurred.

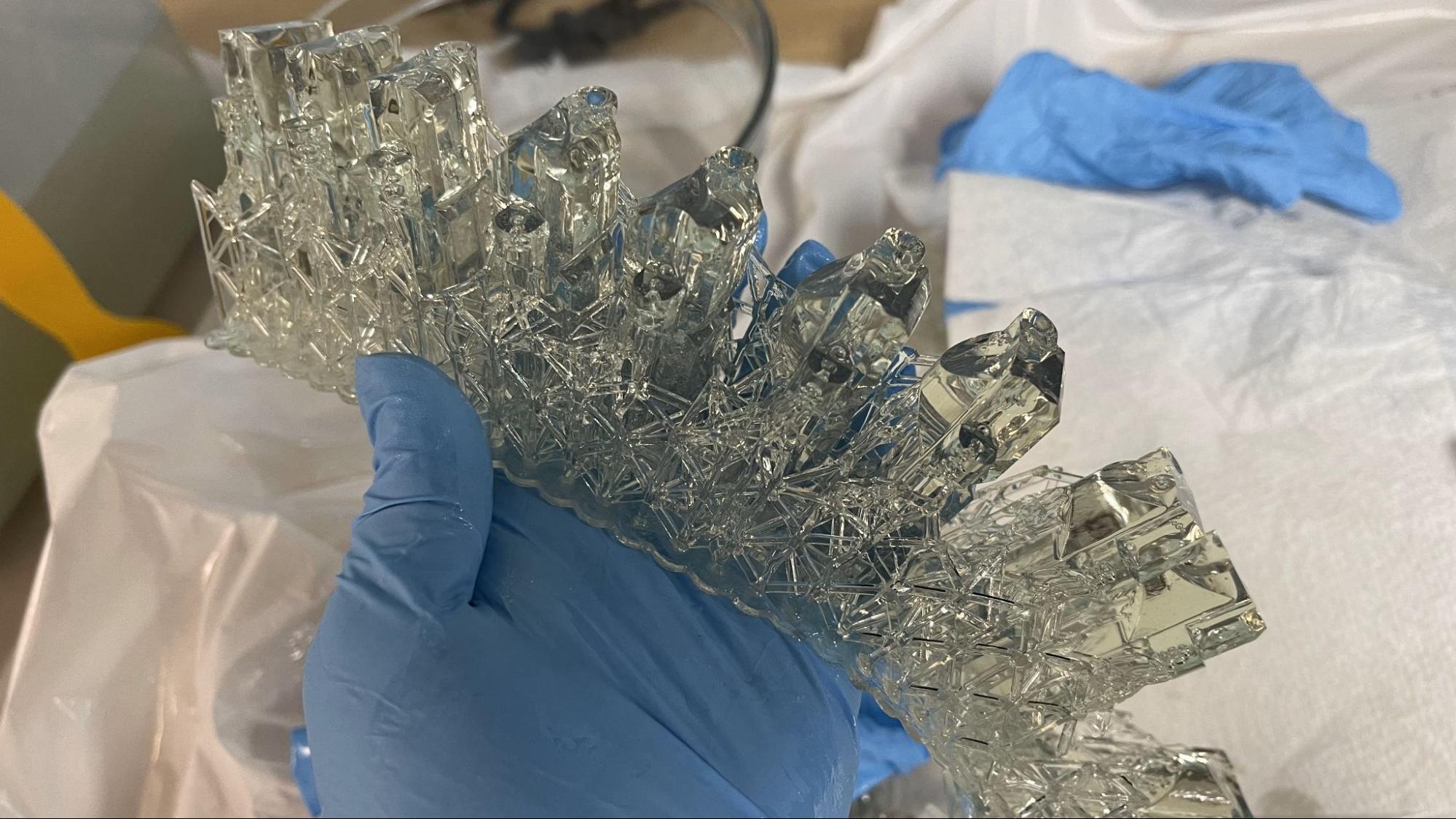

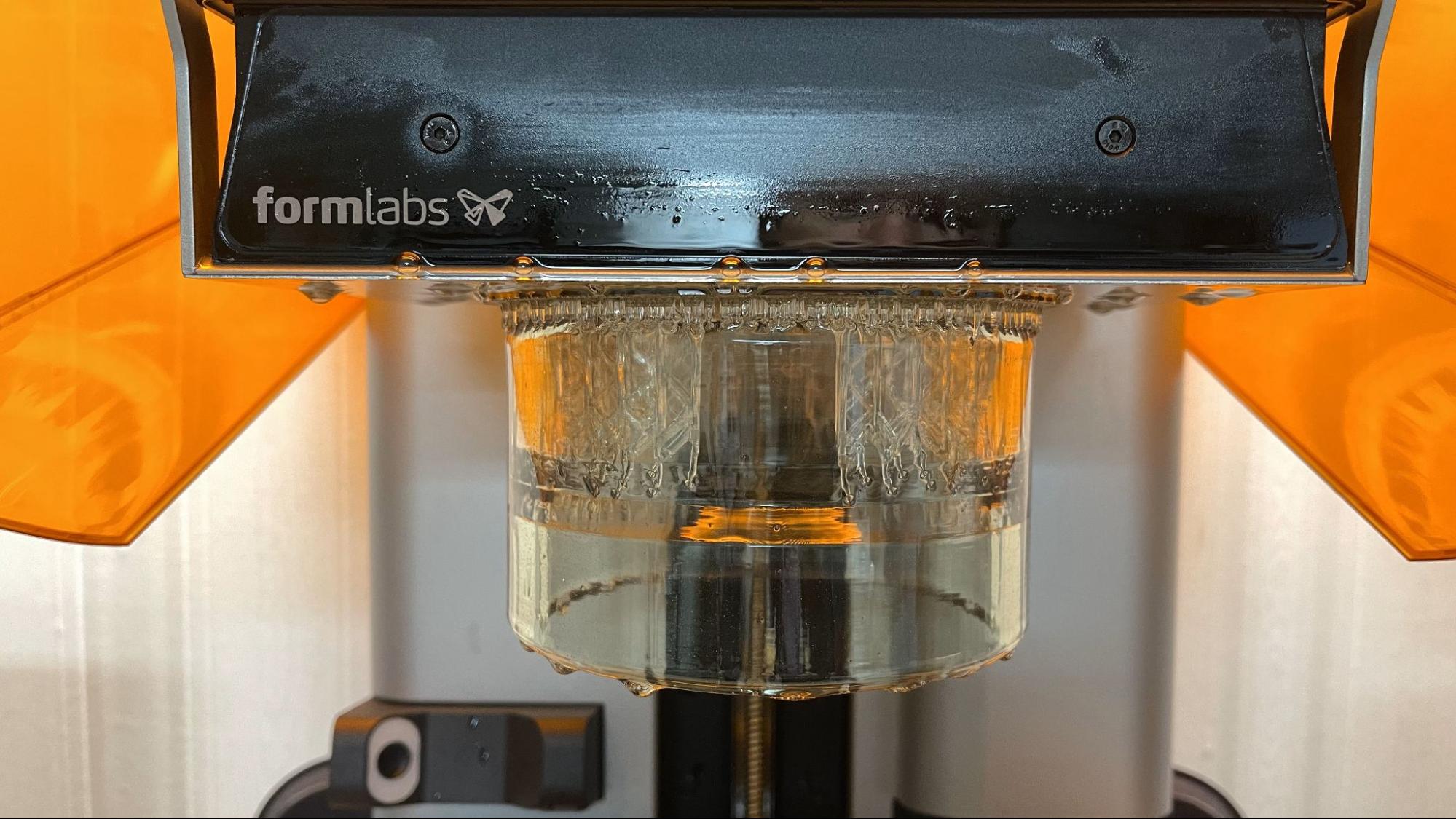

Formlabs sent two other types of resin with the printer for testing, and they were both impressive. Below you can see a very clear crystal dragon printed with Formlabs Clear V5, using a standard 50 µm layer height and default settings. It only took 1 hour and 50 minutes to print. I did not apply any sealant to the surface to make it more clear, this is just how it turns out. When sealed with Modpodge, you can get even more translucent clarity.

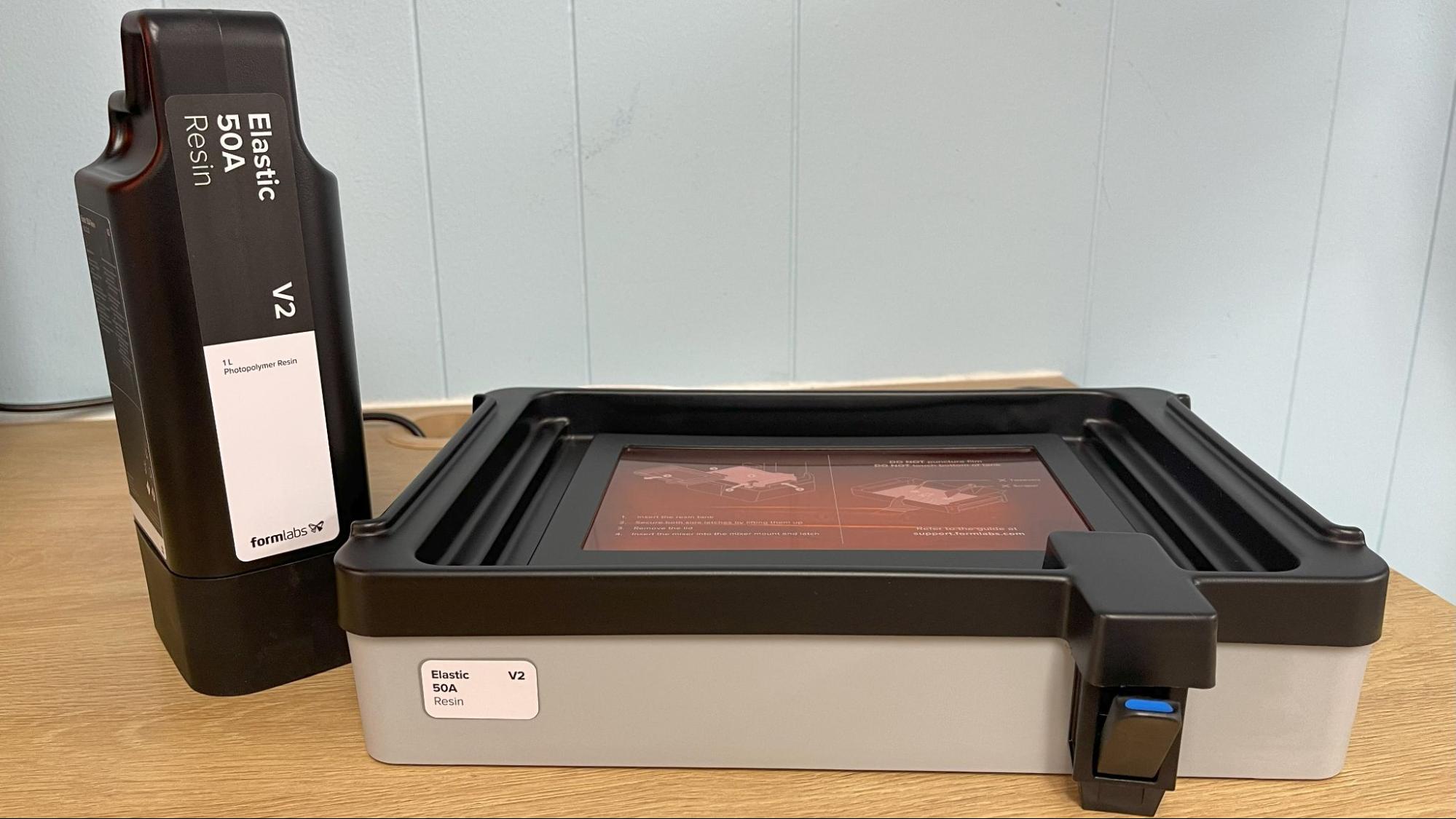

The other resin sent was something totally new for me – a silicone like Elastic 50A Resin V2. The prints are soft and squishy and quite tough. Formlabs suggest using this material to print wearable straps or “soft tissue anatomy and medical models.” I printed tires and treads for my RC cars, which is probably overkill, but oh so cool. Because this material is very soft, it can only print at a 100 µm layer height and needed lots of support. This dragster tire took 4 hours to print.

The Elastic 50A Resin V2 needs to be cured in a bowl of water, and when dry has a frosty green appearance. It feels like a stress ball. It is also the most expensive material I’ve ever printed with, retailing for $199 for a liter.

Bottom Line

The Formlabs Form 4 is a great tool for businesses who need perfect parts for production or prototyping, and don’t have time to waste on tinkering around with the printer. Its locked-down ecosystem is both a blessing and a curse, though Formlabs recently reduced the prices on some of their more common resins.

The $4,069 starting price tag pushes it out of the consumer market, though I’ve seen it used in Maker Spaces, where Form 4’s reliability and easy-to-use nature really shine. This kind of machine would also be an excellent tool for school and university programs where you want to spend time designing and producing parts. The helpful guides on the user interface and the constant reminders to follow procedures allow makers to concentrate on their design skills and less on their knowledge of chemistry.

If you’re looking for a resin printer that delivers the same quality at a slower speed and cheaper price, check out our favorite medium-sized resin, the Elegoo Photon Mono X2, which is a heck of a deal while it’s on sale for $179.

Denise Bertacchi is a Contributing Writer for Tom’s Hardware US, covering 3D printing. Denise has been crafting with PCs since she discovered Print Shop had clip art on her Apple IIe. She loves reviewing 3D printers because she can mix all her passions: printing, photography, and writing.

-

Mindstab Thrull That "Bob from accounting" comment looks like an old Magic: the Gathering reference to me...Reply