French 12-color 3D printer claims to be 'the fastest multi-color 3D printer in the galaxy' — Kickstarter pricing starts at $195 and stretches to $775

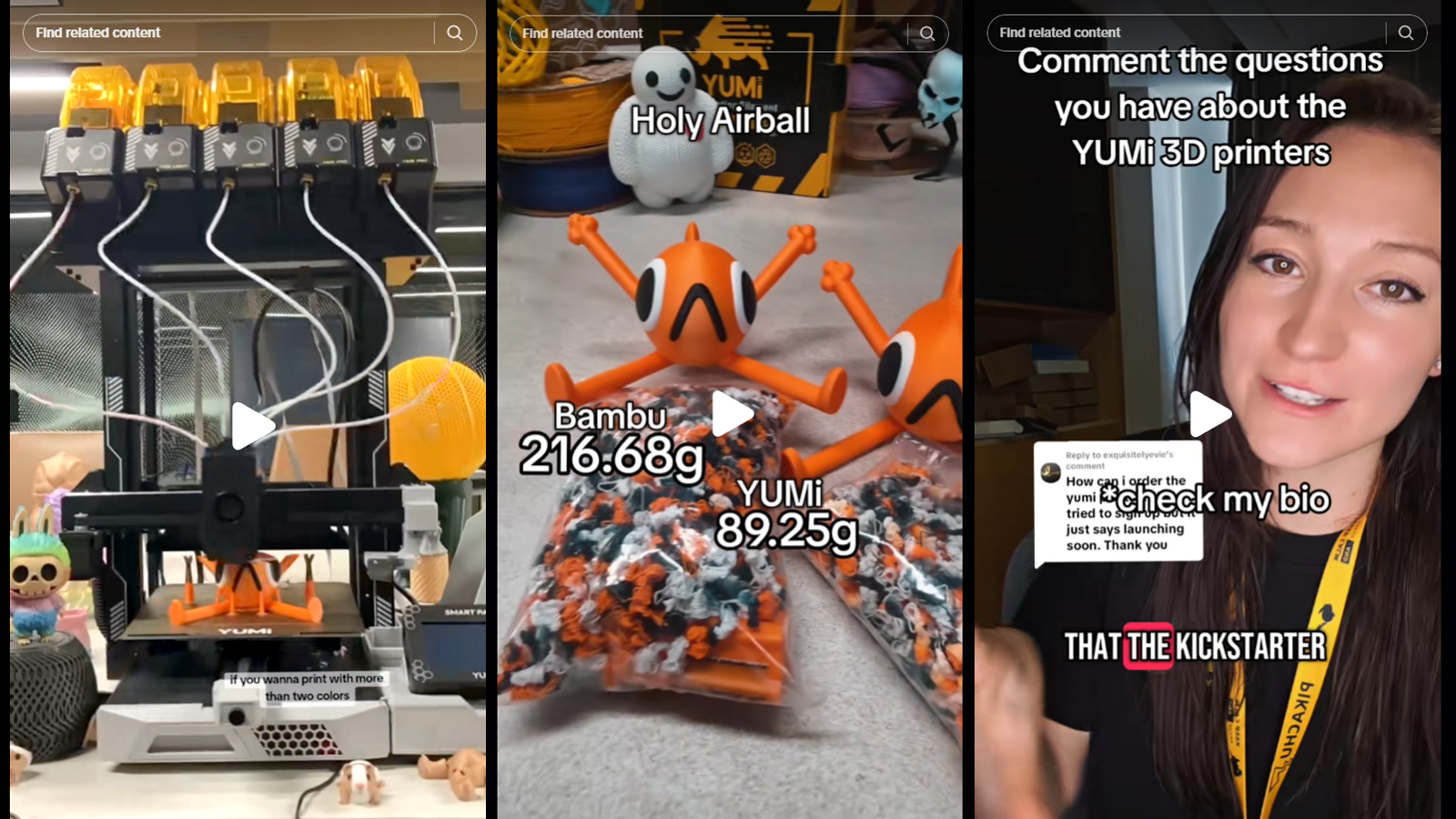

YUMi invites TikTok 3DP influencers to China to weigh in on the process.

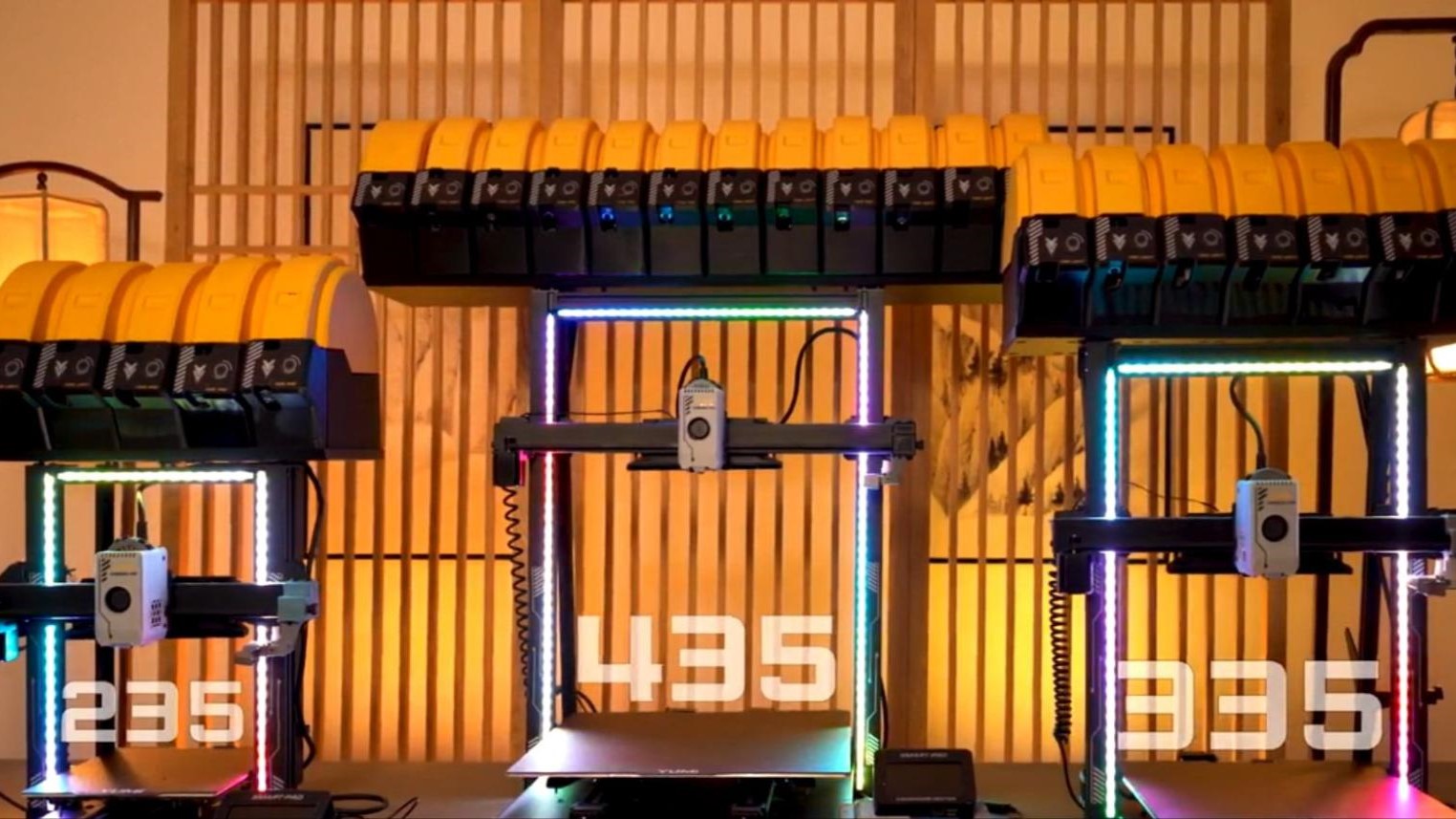

We’ve seen a lot of wild 3D printers launch on Kickstarter, but none are quite like the YUMi, a 12-color modular bedslinger that claims to be “the fastest multi-color 3D printer in the galaxy.” And if you don’t believe it, just turn to TikTok for print demos by American influencers. The new printers tout impressive speed stats of 700mm/s with a max acceleration of 20,000mm/s², but as we'll cover below, remember that those claims are with lowered quality settings. The Kickstarter price for the YUMi 3D printer starts at $195 for the C235 with a single color toolhead and goes up to $775 for the C435 with 12 colors.

It's not unusual for 3D printer companies to turn to online content creators to beta test a new design. However, YUMi’s CEO, Nicolas Michaut, went one step further and invited TikTokers to fly to China and check out his factory. Shannon of PretzelPrints told Tom’s Hardware that she accepted the invite despite YUMi being unable to provide travel expenses or other compensation. She was simply a tourist abroad, and she thanks her Patreon supporters for making the adventure possible.

Shannon is an American 3D designer who sells her whimsical and somewhat spooky models on Cults3D and Patreon. She has been sharing behind-the-scenes videos of the YUMi factory and her travels with her 25k TikTok audience.

“YUMi contacted me on TikTok over a year ago about this project,” she said. “I couldn't turn down an opportunity to see a new factory in the industry I love, and see what YUMi was all about in person, so I agreed,” Shannon told us. She said the opportunity came at a good time for her to take an extended trip and experience the Chinese culture as well as the manufacturing process that goes into developing a new 3D Printer.

During her stay, she tried out early versions of the printer and provided user feedback to the engineers. She also took questions from her audience and tested their suggestions on the developing machines.

Her first visit was for a week, but she later returned for a longer stay. As a full-time designer, she was able to continue her work while abroad and share her experience with her audience. “I have been talking with the team about the work on the back-end for a long time now and was already impressed with the work ethic, care, and determination I saw. Seeing them work in person affirmed my confidence in their ability to create a great product,” Shannon said.

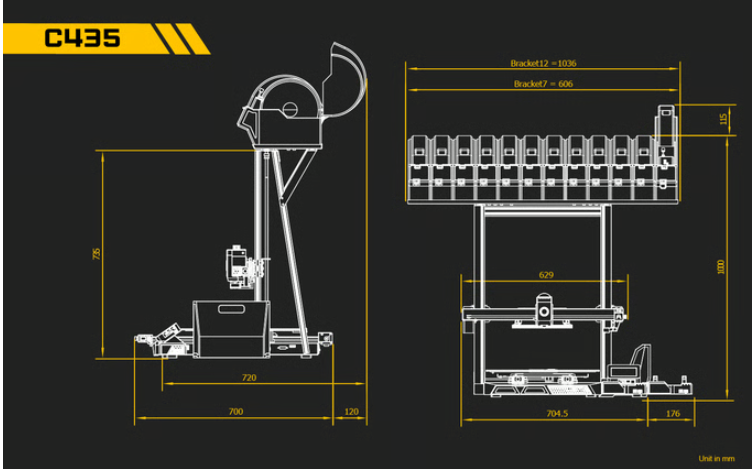

The YUMi 3D printer will come in three sizes: C235 with a 235x235mm build plate, C335 with a 335x335mm plate, and the C435 with, you guessed it, a 435x435 mm build plate. For reference, a Bambu Lab A1 has a 256x256 mm build plate, while an Anycubic Kobra Max has a 420x420mm plate.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

The Kickstarter price for the YUMi 3D printer starts at $195 for the C235 with a single color toolhead and goes up to $775 for the C435 with 12 colors.

YUMi’s stats have the printer running at a top speed of 700mm/s with a max acceleration of 20,000mm/s². We always take these kinds of numbers with a grain of salt, as max speeds are rarely everyday, let alone quality settings. A Bambu Lab A1, for example, hums along with an average print speed of 250mm/s and an acceleration of 6000mm/s².

The printer’s main selling point isn’t really the speed, which is backed by vanilla Klipper, but the modular spool holders. Rather than copy Bambu Lab’s 4-slot AMS or Prusa Research’s 5-spool cluster MMU3, YUMi is giving you a choice. You can outfit your machine with 1 to 12 spool modules and line them up in a bank on top of the 3D printer’s gantry.

A pro version of the spool holder will have a heater so that it can act as a drier for more difficult filaments.

Each spool holder feeds directly into a print hub mounted on top of the toolhead, and YUMi claims it only requires 10cm of retraction. This should allow for rapid color swapping. The colors still share a single nozzle, so there will still be a need for filament purging.

Denise Bertacchi is a Contributing Writer for Tom’s Hardware US, covering 3D printing. Denise has been crafting with PCs since she discovered Print Shop had clip art on her Apple IIe. She loves reviewing 3D printers because she can mix all her passions: printing, photography, and writing.

-

A Stoner I'd rather see low cost metal printers, but a 12 color printer seems pretty good and for less than $1000...Reply

I was hoping my crafty son would want one, but when I offered to buy him one he said he was not interested. -

W3LL3 The fact this project is getting any traction at all is pretty fascinating to me...Reply

I've been in the industry since 2011 and I've printed on dozens of different machines... I've seen Kickstarters come and go and had amazing printers and I've had garbage ones... I currently own 7 different brands in my print-on-demand farm. When I saw this debut, I dug into all their documentation and went through all of their social media posts and videos back to the start of the account... There is hardly even an explanation of their platforms specs and parts and how they're meeting their claims of all of its features or how they developed ANYTHING...

I also see their modular spool system as fine in theory, except when putting more weight above the printer makes for a worse center of gravity and makes minimization of motion, oscillation, ringing, etc much more difficult. So I think that design choice is just silly... They could have just as easily make an extruded aluminum stand/rail that sits behind or to the side of it and it would hardly be an expense...

I am extremely skeptical of this project and the companies start. I'm fairly certain they just found a manufacturer/supplier, picked out a product from proposals, got a CCP business loan which is pushing the 3D Printing Industry HARD right now. The real tell for me though is they are trying so desperately to create a social media "buzz" about it via trying to become influencers themselves and buying promotion from actual influencers... but the content about the "printers" is nonsense and full of clickbaity vague nothing burgers. If they ever make it to market, then basically all the users are going to be bug fixers and alpha testers for years, assuming they ever receive them at all. -

leoneo.x64 Reply

How about adopting another who would be interested? :)A Stoner said:I'd rather see low cost metal printers, but a 12 color printer seems pretty good and for less than $1000...

I was hoping my crafty son would want one, but when I offered to buy him one he said he was not interested. -

M0rtis Reply

Quick question, since you seem to be quite experienced. If I were to get a printer with a consumer sized print volume (300x300mm maybe ?), how easy is it to divide a larger print into smaller sections and then join them together with decent strength later ? Say for example I wanted to make a custom grille or bumper section for my car or something like thatW3LL3 said:The fact this project is getting any traction at all is pretty fascinating to me...

I've been in the industry since 2011 and I've printed on dozens of different machines... I've seen Kickstarters come and go and had amazing printers and I've had garbage ones... I currently own 7 different brands in my print-on-demand farm. When I saw this debut, I dug into all their documentation and went through all of their social media posts and videos back to the start of the account... There is hardly even an explanation of their platforms specs and parts and how they're meeting their claims of all of its features or how they developed ANYTHING...

I also see their modular spool system as fine in theory, except when putting more weight above the printer makes for a worse center of gravity and makes minimization of motion, oscillation, ringing, etc much more difficult. So I think that design choice is just silly... They could have just as easily make an extruded aluminum stand/rail that sits behind or to the side of it and it would hardly be an expense...

I am extremely skeptical of this project and the companies start. I'm fairly certain they just found a manufacturer/supplier, picked out a product from proposals, got a CCP business loan which is pushing the 3D Printing Industry HARD right now. The real tell for me though is they are trying so desperately to create a social media "buzz" about it via trying to become influencers themselves and buying promotion from actual influencers... but the content about the "printers" is nonsense and full of clickbaity vague nothing burgers. If they ever make it to market, then basically all the users are going to be bug fixers and alpha testers for years, assuming they ever receive them at all. -

LordVile Reply

Issue with metal printing is the processing and toxic conditions. My employer bought one to add to their FDM capability and didn’t realise you needed inert gas training to use the equipment which meant they promptly returned it.A Stoner said:I'd rather see low cost metal printers, but a 12 color printer seems pretty good and for less than $1000...

I was hoping my crafty son would want one, but when I offered to buy him one he said he was not interested.

You’re dealing with metal powder, lasers, chemicals and sintering, it’s expensive even in terms of industrial application. -

A Stoner Reply

Might be that. I thought my company would buy into it, but they have not.LordVile said:Issue with metal printing is the processing and toxic conditions. My employer bought one to add to their FDM capability and didn’t realise you needed inert gas training to use the equipment which meant they promptly returned it.

You’re dealing with metal powder, lasers, chemicals and sintering, it’s expensive even in terms of industrial application. -

USAFRet Reply

That is all in how you design it. Where the pieces wil join.M0rtis said:Quick question, since you seem to be quite experienced. If I were to get a printer with a consumer sized print volume (300x300mm maybe ?), how easy is it to divide a larger print into smaller sections and then join them together with decent strength later ? Say for example I wanted to make a custom grille or bumper section for my car or something like that

And of course, what method you use to mate them. Glue, snap fit, something else.

And something like a grill for a car needs to be done with the proper material. Standard PLA, for instance, will not work. -

YUMi_Nico maybe you can take 1 for youReply

A Stoner said:I'd rather see low cost metal printers, but a 12 color printer seems pretty good and for less than $1000...

I was hoping my crafty son would want one, but when I offered to buy him one he said he was not interested. -

YUMi_Nico Reply

I really think you haven’t looked deeply enough at our materials or videos.W3LL3 said:The fact this project is getting any traction at all is pretty fascinating to me...

I've been in the industry since 2011 and I've printed on dozens of different machines... I've seen Kickstarters come and go and had amazing printers and I've had garbage ones... I currently own 7 different brands in my print-on-demand farm. When I saw this debut, I dug into all their documentation and went through all of their social media posts and videos back to the start of the account... There is hardly even an explanation of their platforms specs and parts and how they're meeting their claims of all of its features or how they developed ANYTHING...

I also see their modular spool system as fine in theory, except when putting more weight above the printer makes for a worse center of gravity and makes minimization of motion, oscillation, ringing, etc much more difficult. So I think that design choice is just silly... They could have just as easily make an extruded aluminum stand/rail that sits behind or to the side of it and it would hardly be an expense...

I am extremely skeptical of this project and the companies start. I'm fairly certain they just found a manufacturer/supplier, picked out a product from proposals, got a CCP business loan which is pushing the 3D Printing Industry HARD right now. The real tell for me though is they are trying so desperately to create a social media "buzz" about it via trying to become influencers themselves and buying promotion from actual influencers... but the content about the "printers" is nonsense and full of clickbaity vague nothing burgers. If they ever make it to market, then basically all the users are going to be bug fixers and alpha testers for years, assuming they ever receive them at all.

All YUMI printers are designed and made by our own team — over 50 injection molds created for this project, plus all our custom electronics. Our source code is public on GitHub, so with your experience, you can easily see the real work if you take a few minutes to check.

Our factory is open — if you ever come to China, near Hangzhou, you are officially invited to visit us in person. -

MogulManni Reply

This is exactly on point.W3LL3 said:The fact this project is getting any traction at all is pretty fascinating to me...

I've been in the industry since 2011 and I've printed on dozens of different machines... I've seen Kickstarters come and go and had amazing printers and I've had garbage ones... I currently own 7 different brands in my print-on-demand farm. When I saw this debut, I dug into all their documentation and went through all of their social media posts and videos back to the start of the account... There is hardly even an explanation of their platforms specs and parts and how they're meeting their claims of all of its features or how they developed ANYTHING...

I also see their modular spool system as fine in theory, except when putting more weight above the printer makes for a worse center of gravity and makes minimization of motion, oscillation, ringing, etc much more difficult. So I think that design choice is just silly... They could have just as easily make an extruded aluminum stand/rail that sits behind or to the side of it and it would hardly be an expense...

I am extremely skeptical of this project and the companies start. I'm fairly certain they just found a manufacturer/supplier, picked out a product from proposals, got a CCP business loan which is pushing the 3D Printing Industry HARD right now. The real tell for me though is they are trying so desperately to create a social media "buzz" about it via trying to become influencers themselves and buying promotion from actual influencers... but the content about the "printers" is nonsense and full of clickbaity vague nothing burgers. If they ever make it to market, then basically all the users are going to be bug fixers and alpha testers for years, assuming they ever receive them at all.

Back in my heyday, you had to be smart to scam an engineering hobby out of 6-figs. Or say no compensation while self promoting your stake in a pump and dump to promote the other reason the PaDer hired you for.

This was a reckless group of people to try this imaginary con on out on. Longshot that CEO gives the pledges back once the story breaks, his cover story as a businessman didn’t pass muster for more than a small cuppa. Factory owner will take the fall once he’s long gone to his next if they got stake for partnership. These cons always give “stock” and no cash so some other part owner becomes the chief shareholder instead.

People still fall for the a grift unchanged since 1970. Reading, wanks, it is not complex to learn.