Centauri Carbon 2 spotted in the wild ahead of Q1 2026 release - multi-material 3D printer's details listed in first official spec page

Not the Centauri Carbon you expected to see the feature come to.

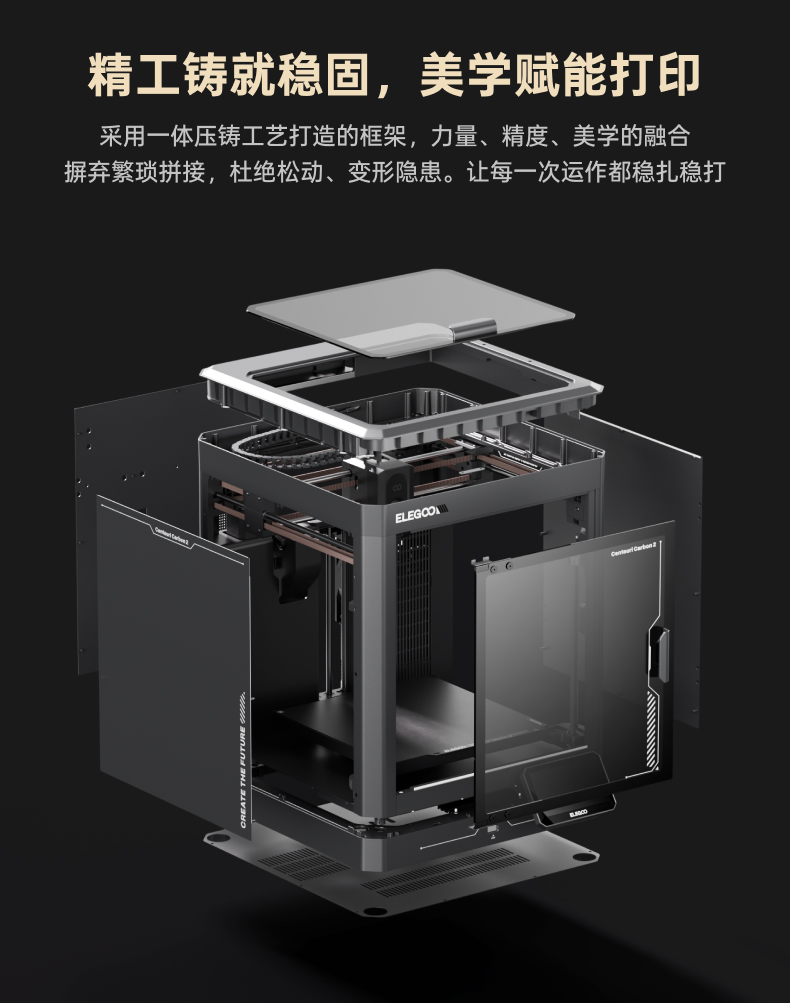

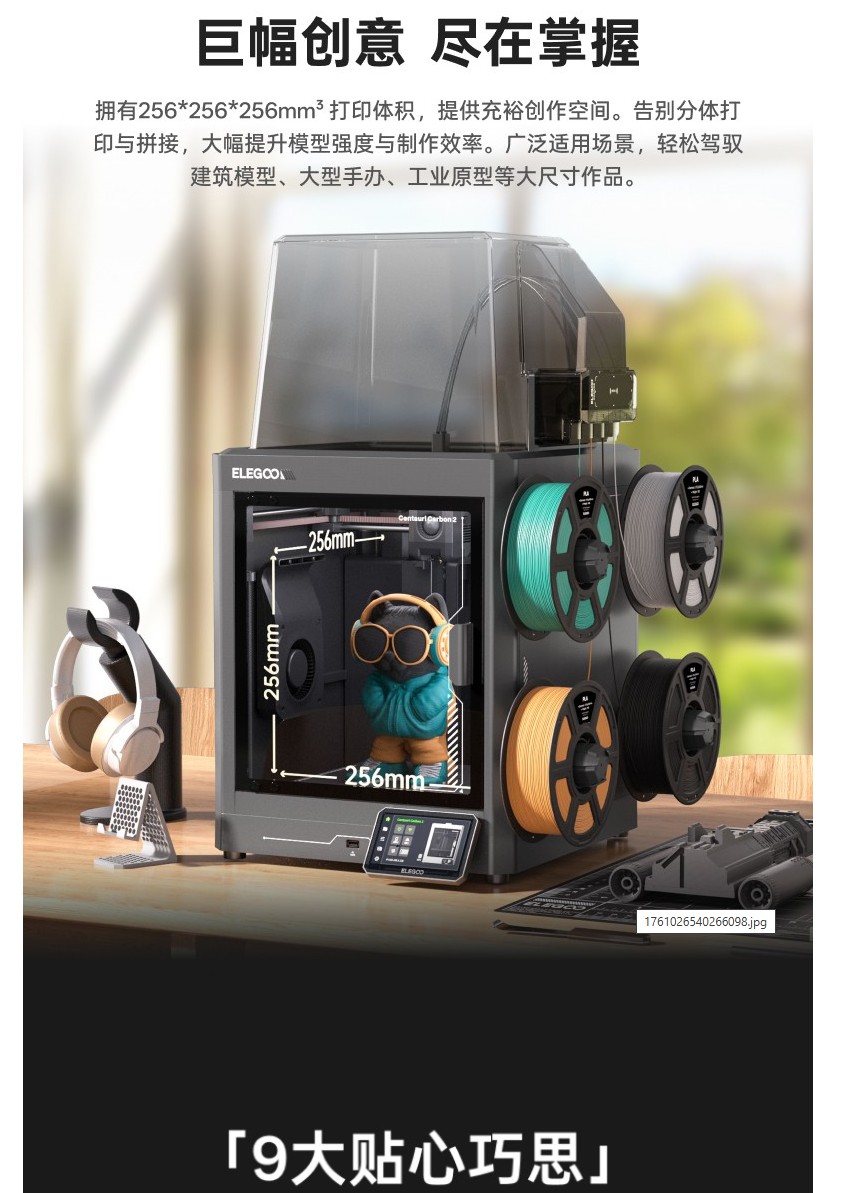

The Elegoo Centauri Carbon, a budget-friendly Core XY 3D printer has been popular in 2025. It seems that in 2026, Elegoo will launch the Centauri Carbon 2, which, according to the official images, has a multi-material system (AMS / MMU depending on brand) for multi-color printing.

Price and release date are still a mystery. The only vague date that we have is Q1 2026 which comes from a press release regarding a delayed release date for a multi-color print upgrade for the original Centauri Carbon.

Here is a full dump of all the images used in the product page.

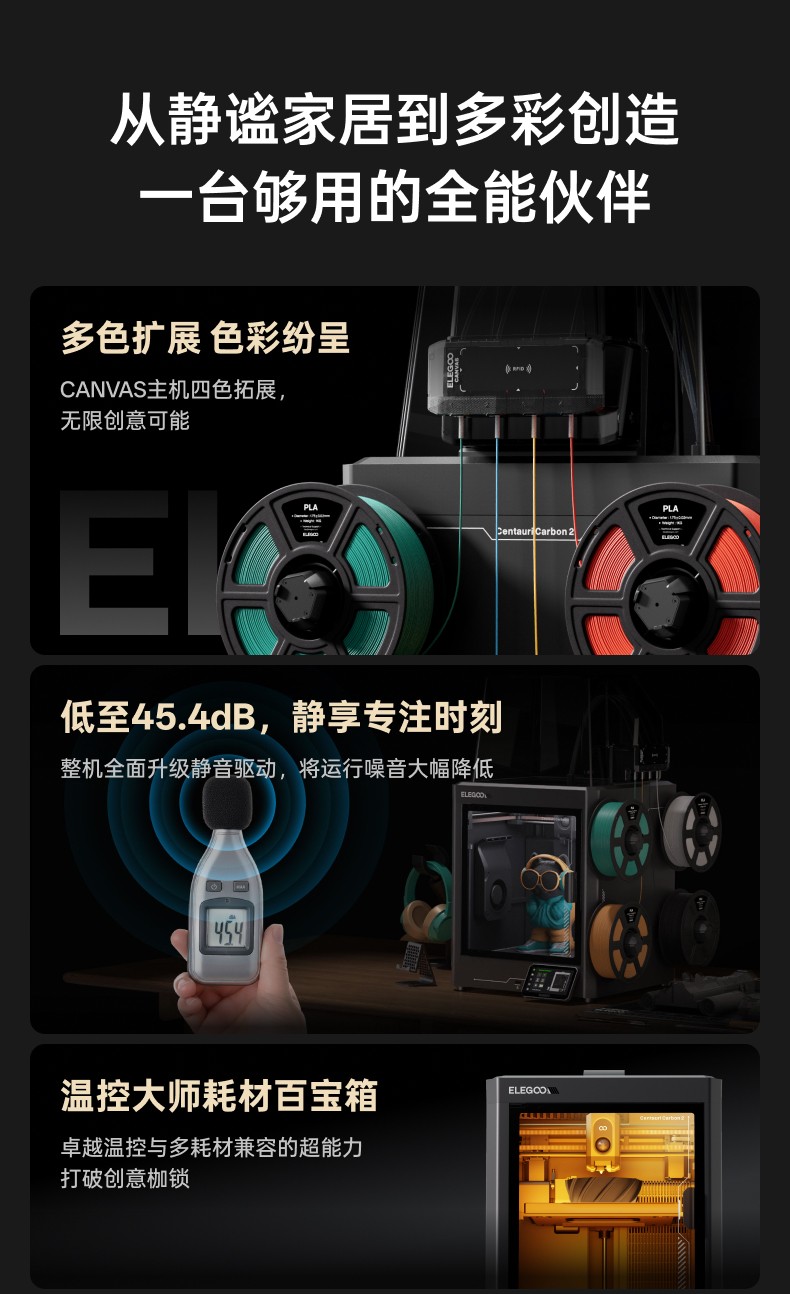

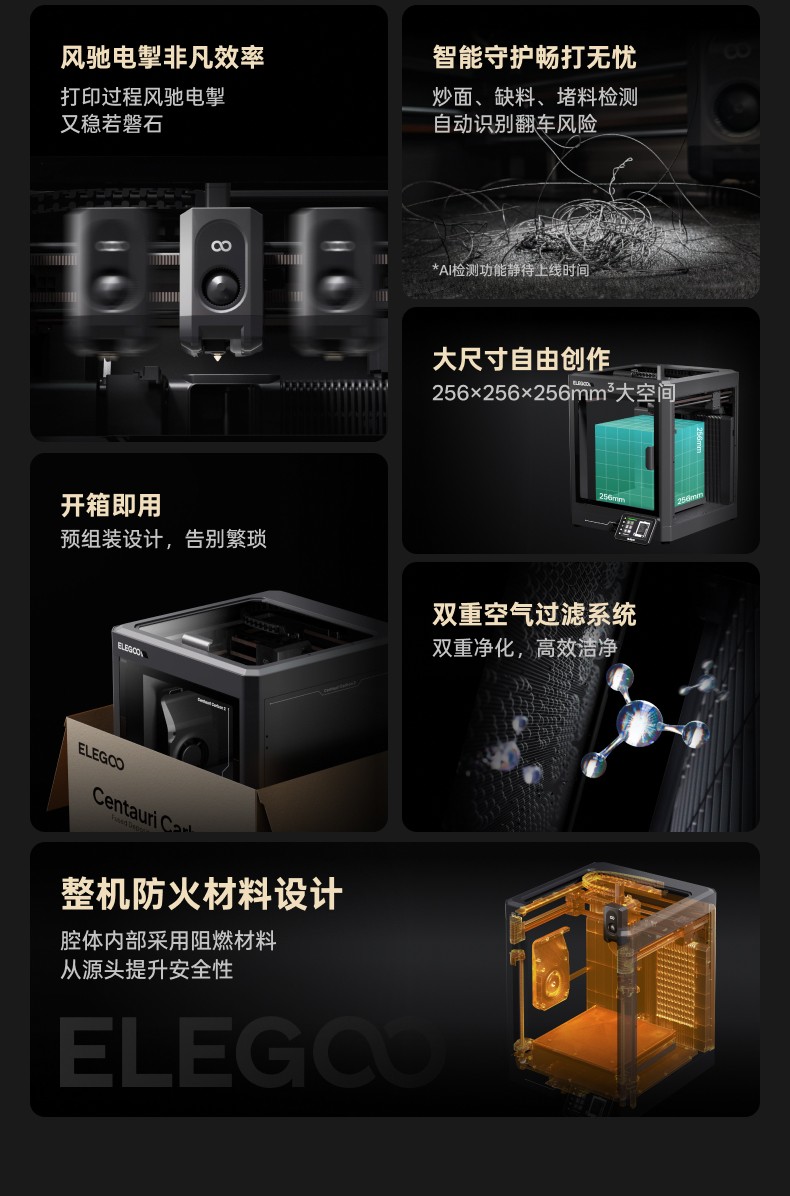

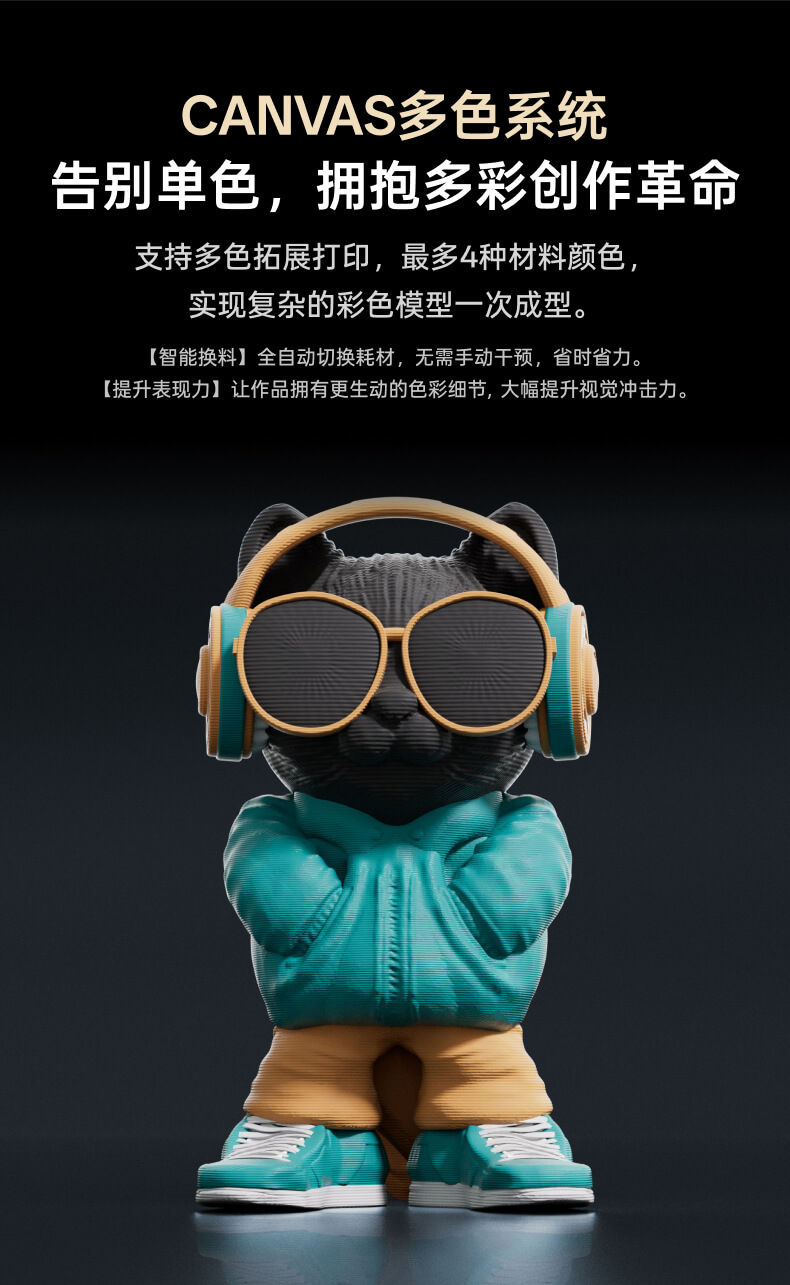

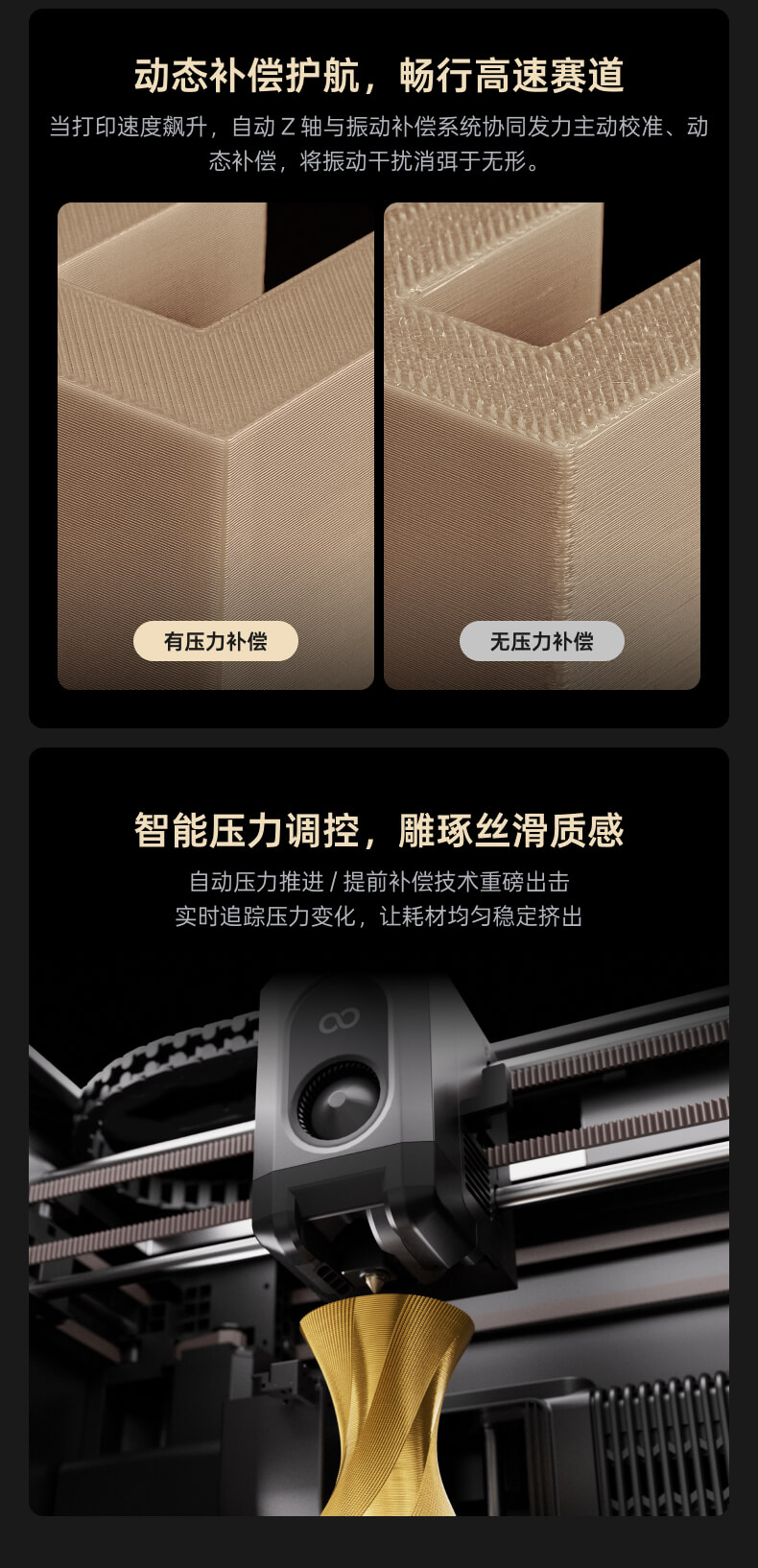

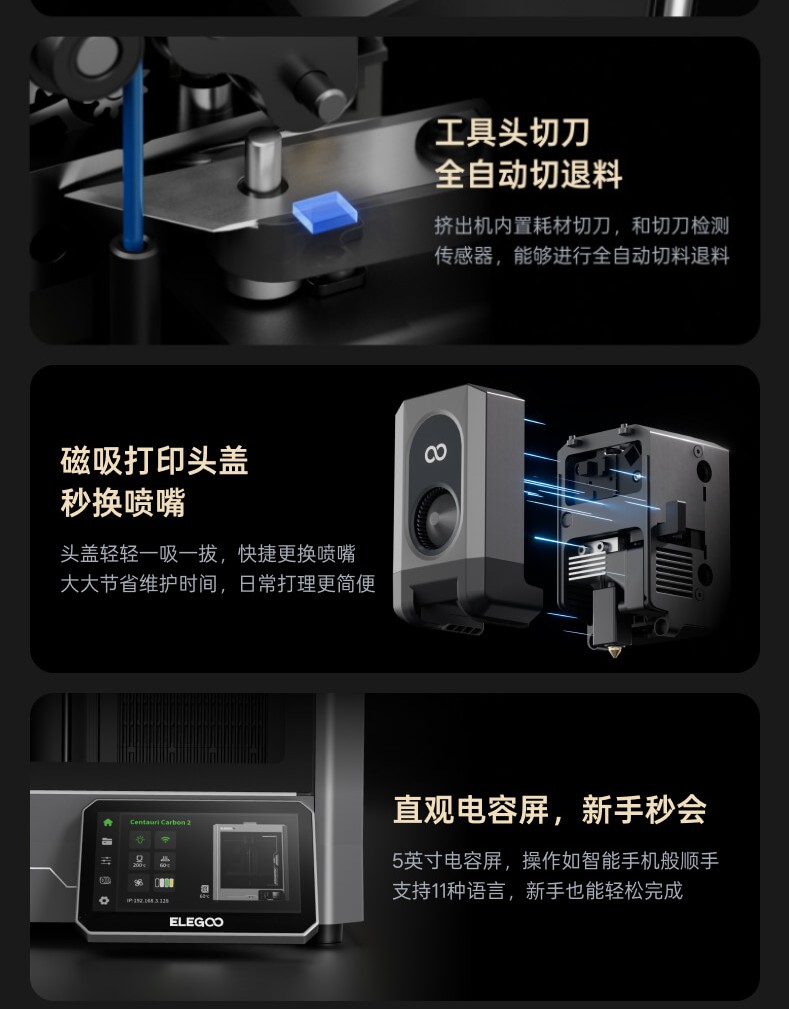

In the machine translated official product page we can see the familiar Centauri Carbon design, but with four spools of filament, feeding into a series of tubes for multi-material printing. The large plastic "hat" casts an imposing shadow over an already large printer. This system is seemingly called "CANVAS" and the design of the filament path looks less clunky than other systems. We'll have to wait and see how it handles in the real world.

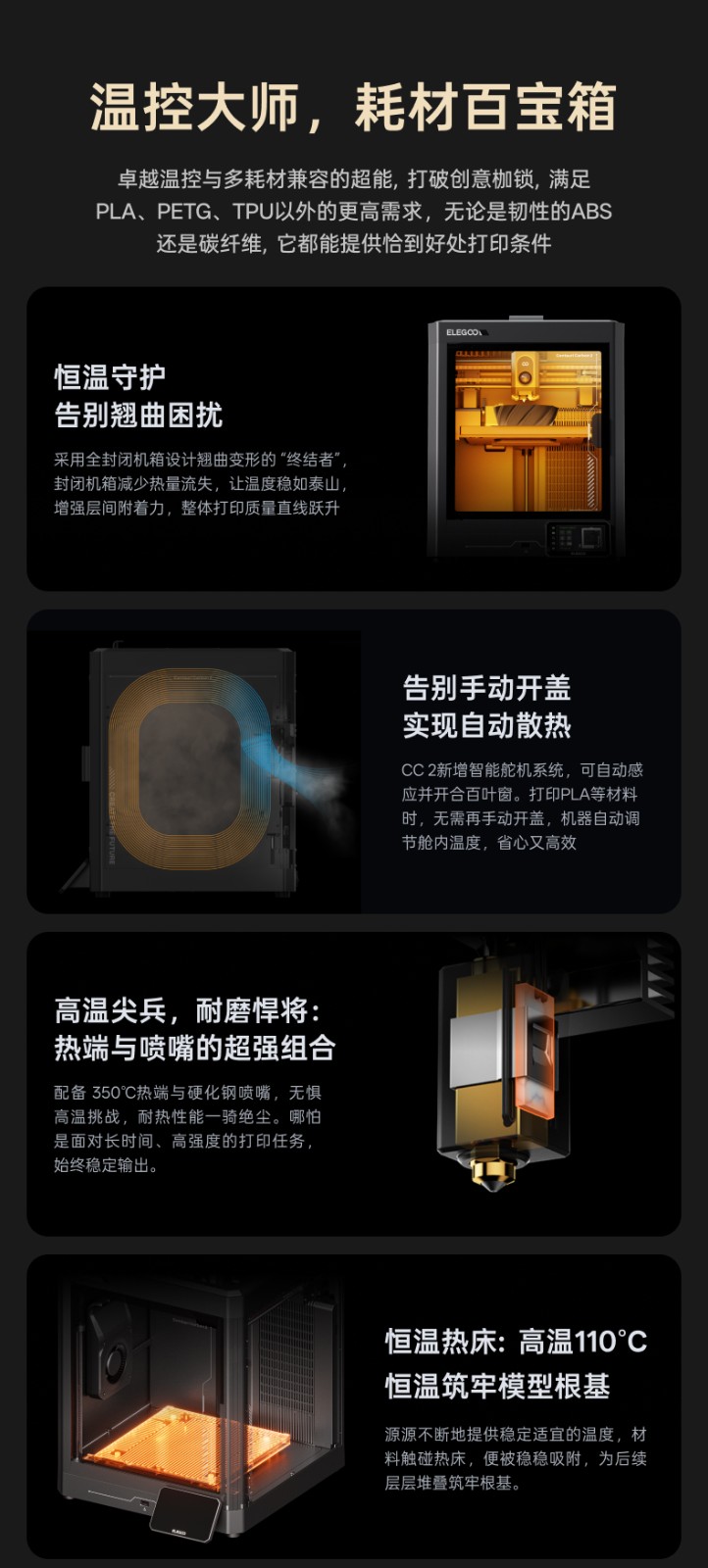

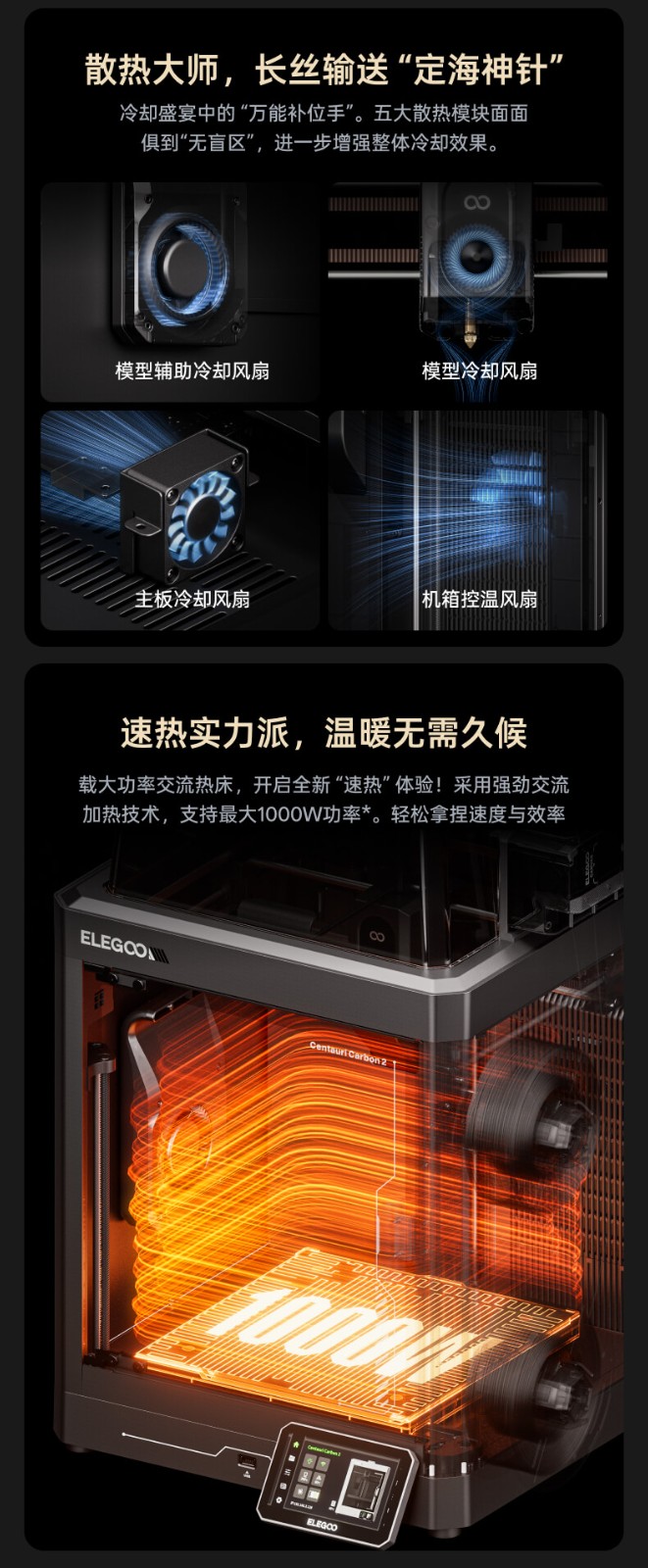

The Centauri Carbon 2 has the same 256 x 256 x 256 mm build volume as its predecessor and what looks like the same extruder and tool head, but the heated print bed is now a 1,000-watt AC heatbed, and a claimed 110C temperature, which matches the original Centauri Carbon.

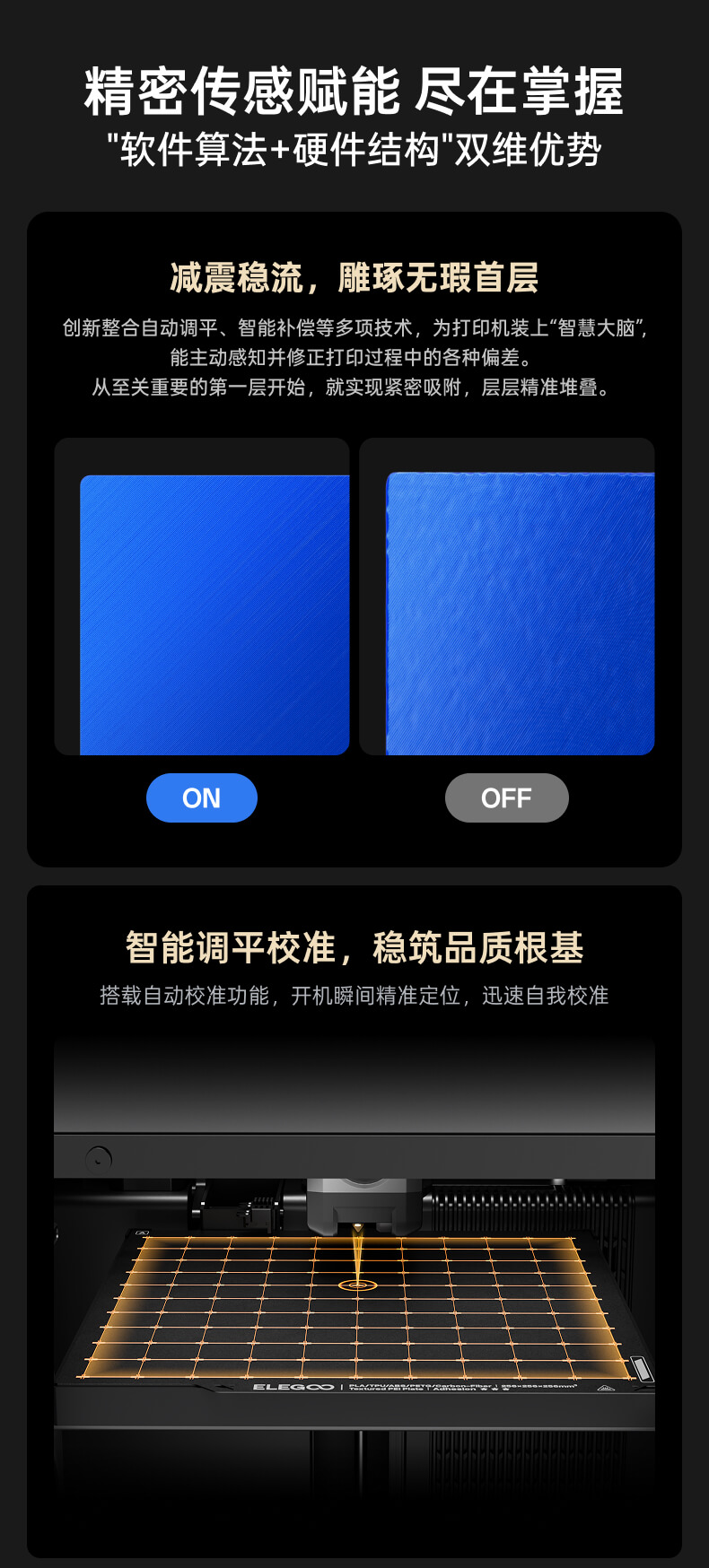

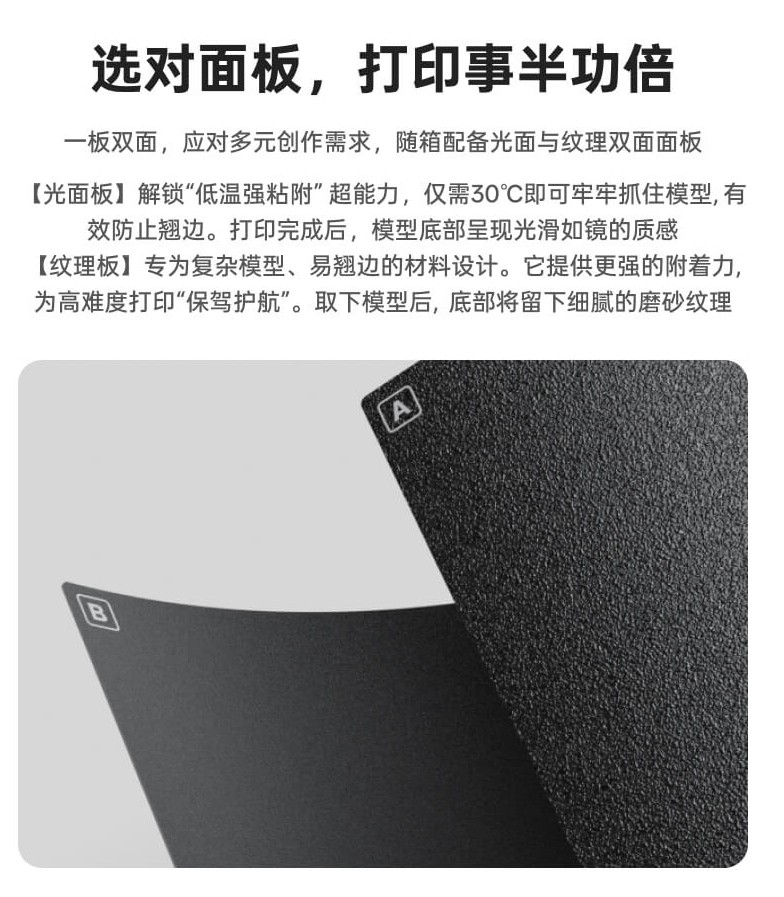

Automated bed leveling looks to be in an 11 x 11 grid, so that's 121 points of contact, just like the Centuari Carbon 1. I can also see that the same lettered, build plates are used, offering the best options for different filaments. It should mean that build plates made for the Centauri Carbon 1 should also work on the new printer.

An unboxing video found on the Elegoo Centauri Carbon Facebook group shows that the multi-color system has an RFID reader, used to quickly identify filament spools. This isn't new, Bambu Lab has done this before, but it shows that Elegoo are still aping the Bambu Lab's designs.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

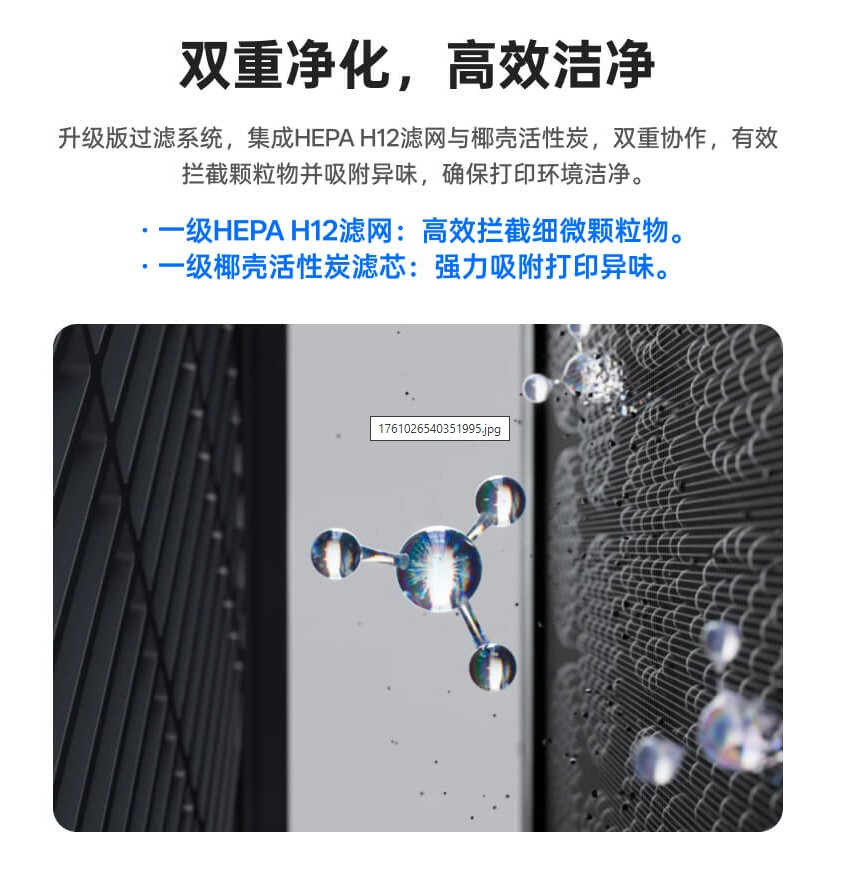

Printable filaments seem to be the usual suspects: PLA, PETG, TPU and ABS. How hot the hot end can get and what it is made of is a mystery for now. Translation did mention an aluminum alloy, but this doesn't sound correct as the original had a hardened steel/brass hot end. So the mystery remains.

Another video from Reddit shows the printer running a self-check process, giving us a look at all four filament tubes going into the extruder, and a new fan placed on the left side of the print chamber.

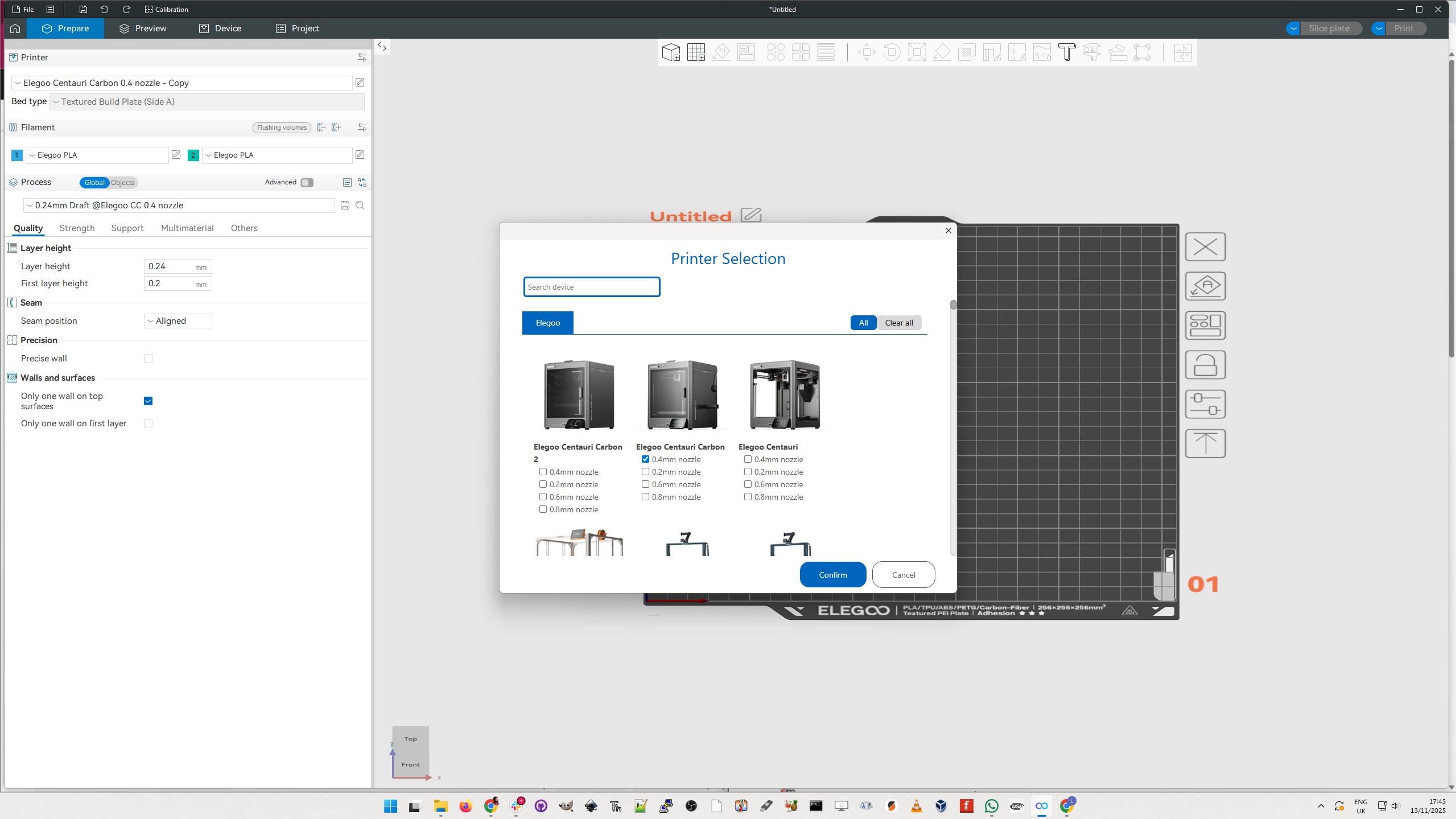

Version 1.2.0.19 of Elegoo Slicer seemingly has support for the Centauri Carbon 2, and I know that for a fact because this is my copy, which I use with my own Centauri Carbon 3D printer. I accidentally setup multi-color printing when looking for the printer.

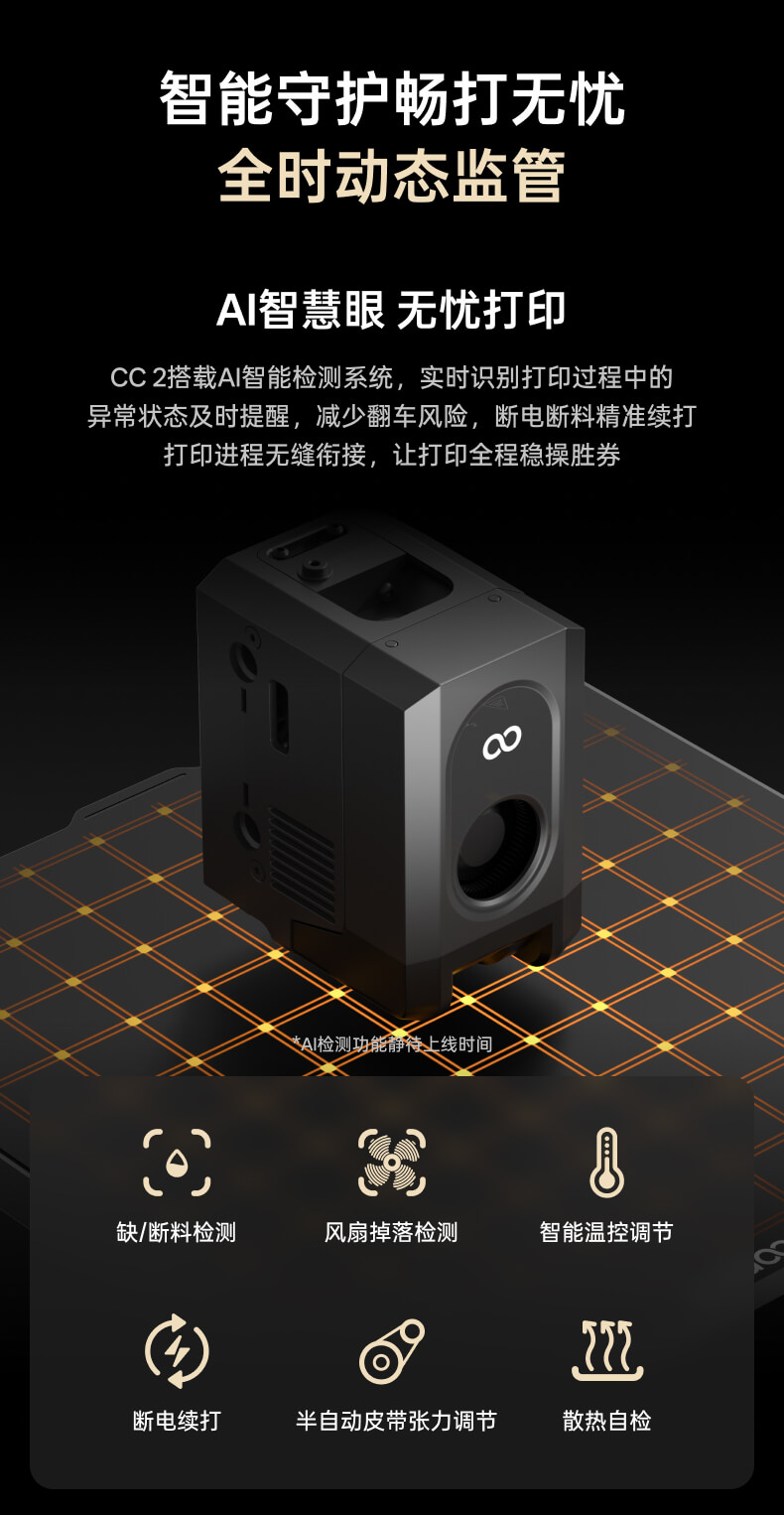

Over-the-Air (OTA) software updates look to be handled just like the Centauri Carbon 1, and the printer is using Wi-Fi to receive prints over the network. There is a reference to 6GB+ in the text and using an AI translation service on the image, it possibly refers to on-device storage.

I can see a reference to a camera, and machine translation is a bit sketchy here, but there are no references to resolution, leaving me to surmise that it is the same 720p camera as the original. The camera was OK, but the LED light system was very poor on the original, and I cannot see any claims of improved lighting for the Centauri Carbon 2.

The Centauri Carbon 2 is a bit of a mystery for now. We know it exists, and we can surmise some details from the product page. The biggest change is seemingly multi-material printing, something that was touted for the original Centauri Carbon, specifically a Q3 2025 release, which has come and gone. For now we need to wait until Q1 2026 to see what the Elegoo Centauri Carbon 2 has to offer.

Follow Tom's Hardware on Google News, or add us as a preferred source, to get our latest news, analysis, & reviews in your feeds.

Les Pounder is an associate editor at Tom's Hardware. He is a creative technologist and for seven years has created projects to educate and inspire minds both young and old. He has worked with the Raspberry Pi Foundation to write and deliver their teacher training program "Picademy".

-

Crazyy8 If they keep it cheap compared to the P1S/A1 and their AMSs, it's guaranteed to be a success. Around $370-$400 for the AMS and CC2 would be great, though what would be better is if they didn't lie about the standard Centauri printer. There were supposed to be 2 printers released, Centauri and Centauri Carbon, only the latter got released.Reply -

gggplaya Anycubic Kobra S1 is $459 right now, but has a much better filament holder with a built in dryer.Reply

So this needs to be <$400 to be competitive.

But personally, I won't buy a multi-color system unless it can keep my filament dry. Even if it doesn't have a built in dryer, as long as you can store it for months in a holder and be ready to print at a moment's notice. -

USAFRet Reply

Why would you be leaving the filament in the system for 'months'?gggplaya said:But personally, I won't buy a multi-color system unless it can keep my filament dry. Even if it doesn't have a built in dryer, as long as you can store it for months in a holder and be ready to print at a moment's notice.

Are you not using the machine for other things? -

gggplaya ReplyUSAFRet said:Why would you be leaving the filament in the system for 'months'?

Are you not using the machine for other things?

I have a Bambu X1c with 4 AMS units with various colors and several other stronger filaments like PAHT-CF and PETG-CF. Most of my other filaments are PETG in different colors. I have 2 spools of black PETG, which is what I mainly print with. The Black PETG will only last a few weeks at most before I use both spools, but the other colors may take several months to fully expend.

The more expensive PAHT-CF may require a full year before I use it all. It's only 0.5KG but I use it very sparingly due to cost. I only use if it I really need the strength or temperature resistance. Plus I have to open the window and install my duct system to properly ventilate.

But even for a single AMS unit with 4 spools. There are certain colors you may not use very often. Or you might only use colors for lettering and print everything else black. So it should stay airtight for a few months with just a few dessicant filled pods to keep the humidity down.

The RH in my basement is about 40%, so not ideal for an open air spool. I just checked my phone, the RH currently is about 18% for my AMS units. I haven't opened some of them in months, or turned on the active dryer. So they're fairly airtight.

I don't run a print farm, I only use it for personal projects and friends and family.

Why do I have 4 AMS units when I don't do the volume of a print farm?? Because I like printing from my phone. I can choose the material and color when I'm at work or out somewhere. -

USAFRet OK. I also have an X1C, but only 1 AMS.Reply

If I had more local space, I'd get another.

Rarely do I have a filament in there, unused, for long. And once it comes out, into a vacuum ziplock.

But with PLA, I've not seen many humidity issues. Even with filament sitting unbagged. -

gggplaya ReplyUSAFRet said:OK. I also have an X1C, but only 1 AMS.

If I had more local space, I'd get another.

Rarely do I have a filament in there, unused, for long. And once it comes out, into a vacuum ziplock.

But with PLA, I've not seen many humidity issues. Even with filament sitting unbagged.

I used to print in PLA when I had a creality printer, but since getting my Bambu a few years ago, I only print in PETG. I haven't used PLA in some time. I prefer the bending properties of PETG over the more brittle but harder PLA. Also, I've had PLA warp outside in the sun, but PETG hasn't done that to me yet.

PETG absorbs more moisture before printing, but after printing it holds up better in wet conditions compared to PLA.

PETG will usually print fine when slightly wet, but you'll see occasional bubbles in the print. Most people don't care. But I like my prints pristine and smooth. So I always dry my PETG well and keep it dry. When PETG is really wet, you'll get alot of stringing, which is when people feel the need to dry their filament. -

USAFRet Reply

Right.gggplaya said:I used to print in PLA when I had a creality printer, but since getting my Bambu a few years ago, I only print in PETG. I haven't used PLA in some time. I prefer the bending properties of PETG over the more brittle but harder PLA. Also, I've had PLA warp outside in the sun, but PETG hasn't done that to me yet.

PETG absorbs more moisture before printing, but after printing it holds up better in wet conditions compared to PLA.

PETG will usually print fine when slightly wet, but you'll see occasional bubbles in the print. Most people don't care. But I like my prints pristine and smooth. So I always dry my PETG well and keep it dry. When PETG is really wet, you'll get alot of stringing, which is when people feel the need to dry their filament.

For things outside, PLA is NOT an option.

I've done a few with PETG. Doing a thing with ASA right now.

And the ASA needs predrying as well. -

drumstyx646 Wow...Elegoo has some gall to be targeting a release like this -- they JUST admitted they'll be dropping the ball on the AMS/MMU promise on the first version. It takes quite a while to bring a product to market -- as in, definitely longer than mid-Q4 to any point in the following Q1 -- clearly they've been working on this for a long time, and they knew exactly what was required to make this stuff work.Reply

Evenwith the benefit of the doubt, at best, they've made promises here that they KNEW had a non-negligible chance of going unfulfilled.

However, whether they should be given the benefit of the doubt deserves some thought: barely 2 months ago they were caught lying about the carbon not running Klipper in any way, shape, or form. Having been caught with their hand in that cookie jar, they complied with the license requirements of Klipper, and released the source code for the firmware. Come to think of it, could that be related to why they NOW say the machine won't/may not get an AMS/MMU? Honestly kind of absurd that 3D printing companies think the MMU features, of all things, is the important IP to protect.

I miss Neptune era Elegoo.