TSMC Builds Advanced Wastewater Treatment Plant to Fight Droughts

TSMC to increase usage of wastewater in chipmaking process.

Taiwan Semiconductor Manufacturing Co. already owns some of the world's most sophisticated semiconductor production facilities that use the latest equipment to build advanced chips using leading-edge process technologies. According to a Nikkei report, by the end of the year the company will also own a state-of-the-art wastewater treatment plant that will enable TSMC to use industrial wastewaters for production of chips.

To improve its water supply, TSMC is building the world's first industrial wastewater treatment center that could "ultimately meet nearly half of its daily need for water for chip output," reports Nikkei. The plant will be located near the city of Tainan and will start to work by the end of 2021.

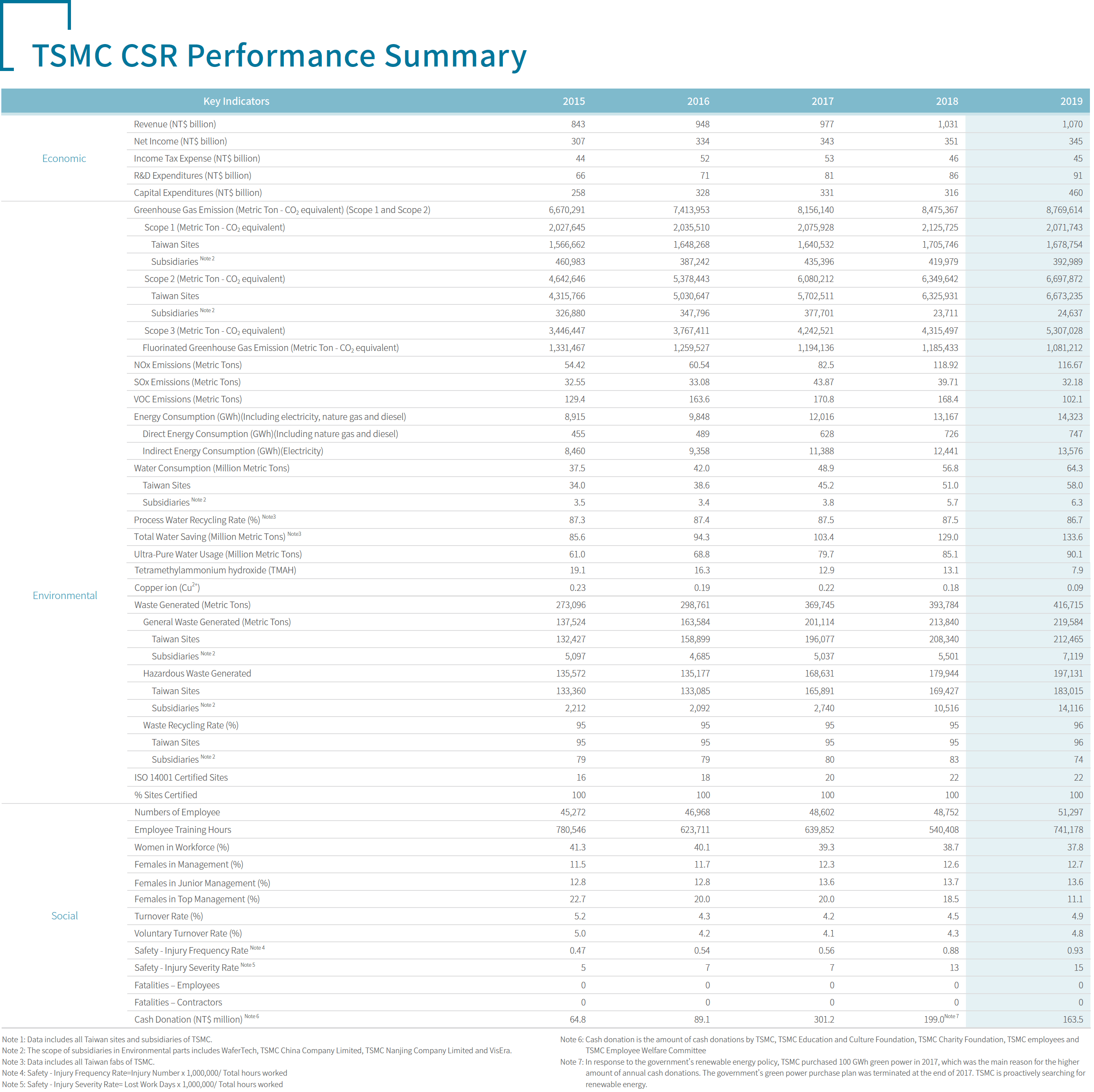

Back in 2019, all of TSMC's facilities consumed 64.3 million metric tons of water (176.16 thousand metric tons a day) as well as 90.1 million metric tons of ultra-pure water (246.85 thousand metric tons a day), according to the company's 2019 Social Responsibility Report. The company recycled 86.7% of water it used and therefore saved 133.6 million metric tons of water (366.03 thousand metric tons a day) in 2019.

Chip production requires different kinds of water — some steps require ultra-pure water, others need clean water. It was unclear from the report whether the plant can produce ultra-pure water from industrial wastewater, but the numbers that TSMC is talking about may imply on both.

"It will gradually ramp up the treatment capacity of industrial wastewater and by 2024 will be able to generate 67,000 tons of water daily that can go back into to the chipmaking process," said Lora Ho, senior vice president of Europe & Asia sales as well as chair of TSMC's corporate social responsibility committee.

The ongoing drought in Taiwan has already made authorities start rationing water supply to the populace and divert water supply from farmers to chipmakers, whereas TSMC and UMC had to start purchasing water by the truckload to lower regional water consumption. TSMC already re-uses more than 3/4 of the water it consumes, but this is not enough to reduce the foundry's dependence on water supply, so the company is building an advanced wastewater treatment plant.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.

-

targetdrone How about reporting on the difference between Ultra-pure water, clean water, Spring water, and good old chlorinated unfiltered tap water.Reply

23 million gallons/day is a lot of water but that much ultra-pure might be even more impressive -

Co BIY This is why all the factories are in Taiwan! They aren't afraid to just engineer their way out of the problem and keep advancing.Reply

I can't imagine how long it would take to get this approved in California even if the "wastewater" coming out of the fab and into the treatment plant was already clean enough to mix with infant formula. -

hannibal If this leads to more environmental friendly production in the long run... i almost hope that the draugh would last longer for even better results...Reply

It would help the situation in the future.

As for ansver above: Super clean, is most likely distilled water. And normal clean water is what you would consider good enough to drink. In this case i am not 100% sure, but that is what most likely is used in here.