Raspberry Pi Pico Uses 3D Printed Circuit In Mechanical Keypad

Making your own keyboard from scratch isn't usually this hands-on, but the results are totally worth it. This custom Raspberry Pi Pico keypad comes from a maker known on Reddit as Duzitbetter who decided to 3D print the circuit inside.

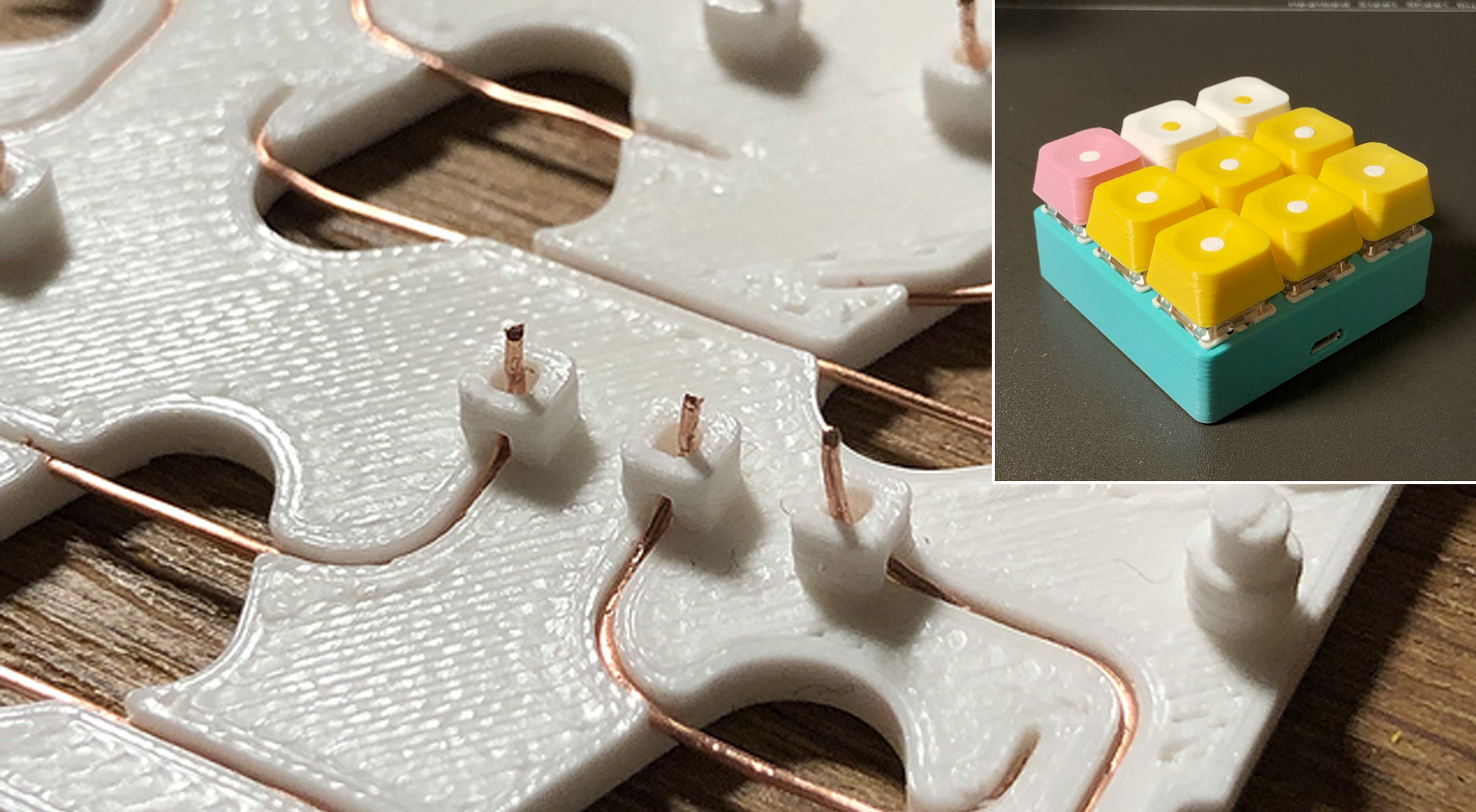

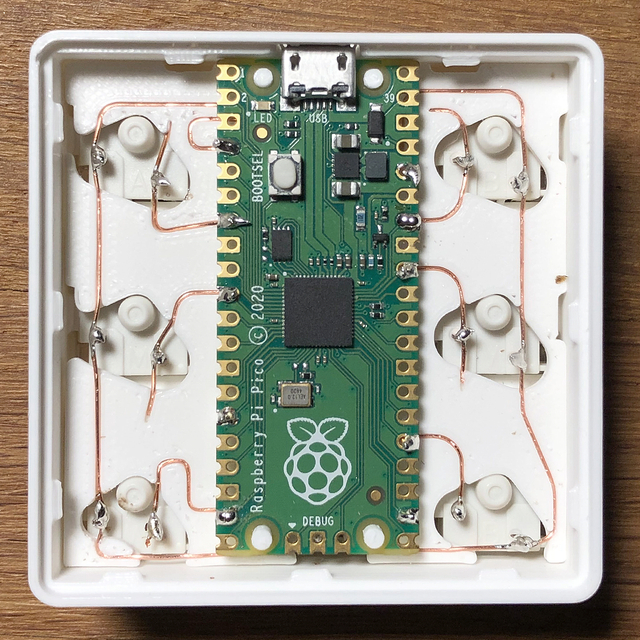

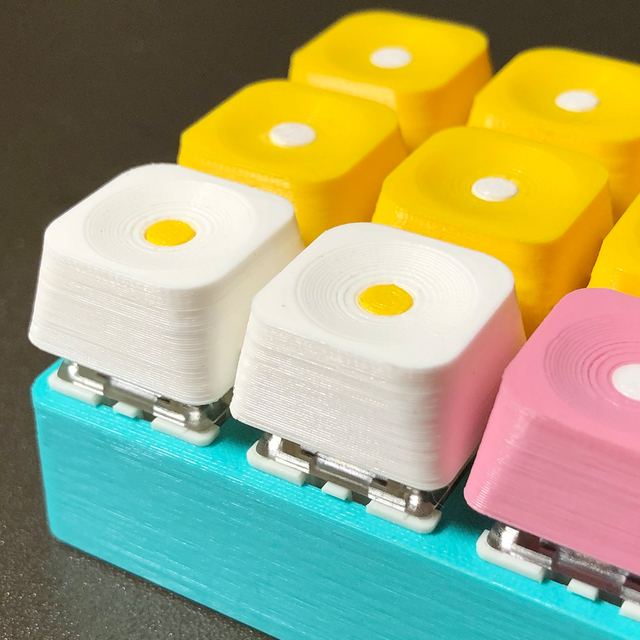

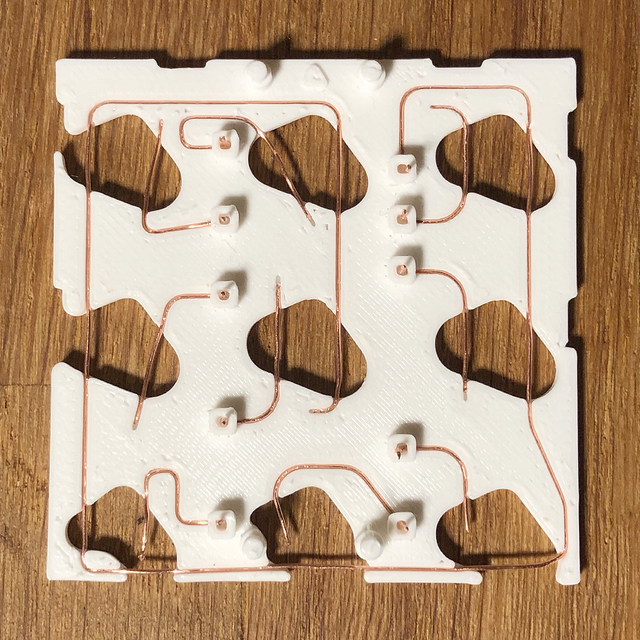

Where other makers would design their own PCB, Duzitbetter decided to 3D print custom channels to route copper wires from the keys to the Pico. The keypad has a 3 x 3 layout to support 3D printed keys fitted with Gateron switches.

According to Duzitbetter, the board, circuit, case and keycaps were designed just for this project and 3D-printed using a Prusa MK3S. The printed circuit board is essentially a series of grooves in which copper wires can be pressed into place.

The end result is a 9-key Pico-powered keypad that can be easily programmed with custom macros. Adjusting each key function is as easy as editing a file on the Pico which connects via micro USB.

If you're interested in recreating this project, Duzitbetter provides everything you need to get started on Cults3D. There are also plans in the works to create a full-sized keyboard with a similar, 3D-printed circuit. Check out our list of Best Raspberry Pi Projects for more cool creations from the maker community.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Ash Hill is a contributing writer for Tom's Hardware with a wealth of experience in the hobby electronics, 3D printing and PCs. She manages the Pi projects of the month and much of our daily Raspberry Pi reporting while also finding the best coupons and deals on all tech.

-

BillyBuerger That's a pretty impressive way to hand-wire a keyboard. Being a 9-key keyboard, you can wire each switch to it's own pin and remove the need for diodes and still have independant keys (N-key rollover). Expanding this to a larger keyboard would require making room to fit some diodes in there as well. And while hand-wired keyboards make a fun project, building a custom PCB isn't too difficult or very expensive either. Incorporating something like this into a Dactyl type ergonomic keyboard where PCBs are more difficult to use could be interesting though.Reply