Silicon Price Spike Is Latest Terrible News for Tech Prices

A lack of coal in China has led to a cut in production of the highly refined silicon used in transistors.

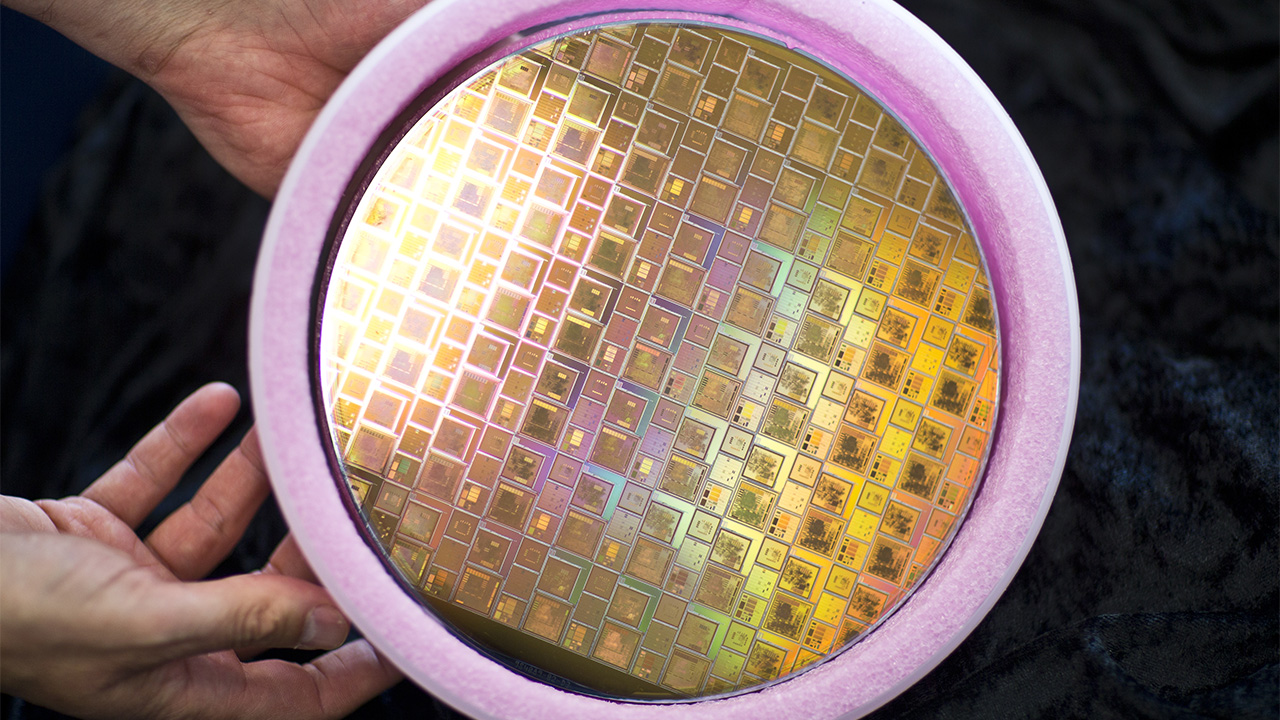

The semiconductor of choice for the transistors we rely on in just about every electronic product available today, silicon, is the latest metal to suffer a production shortage, according to Bloomberg and mining.com, despite being the second most abundant element in the Earth’s crust.

You can’t just go grinding up sand to let the MOSFETs out, however, which is why 20% of the silicon produced worldwide is refined to metallurgical-grade purity, and 15% of that is further refined to be used in semiconductors, at a purity of over 99%.

And that’s what we’re going short of. Thanks to a reduction in production in China, the world’s largest producer of silicon metal, the price of the shiny stuff has risen 300% in less than two months, leading plants in Scandinavia to cut production of chips.

This is bad news not only for the microchip sector, but other large users of silicon such as car manufacturers, who alloy silicon with aluminum to make engine blocks and other parts, and the solar energy industry, where refined monocrystalline silicon is used in panels. It also makes up the basic building blocks of many medical implants.

The production cut appears to be linked to electricity supply, with Reuters explaining that shortages of coal, combined with increased demand from industry, has led to curbs in the amount of electricity that can be used. China’s power system prevents increases in the price of coal being passed on to consumers, so the power companies themselves are left to either absorb financial losses or reduce output.

The news of a silicon shortage comes as Japanese silicon wafer maker Sumco announces it will be spending over $2 billion to increase its production of 300mm silicon wafers at its plant in Japan’s Saga prefecture, scheduled to be in full operation by 2025.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Ian Evenden is a UK-based news writer for Tom’s Hardware US. He’ll write about anything, but stories about Raspberry Pi and DIY robots seem to find their way to him.

-

InvalidError The good news just keep coming.Reply

The joys of supply mono-culture where nearly everything passes through a single country going through a mid-life crisis. -

jasonf2 If I remember right from high school chemistry silicon is a metalloid and on the periodic chart falls to a non metal group, not a metal.Reply -

jasonf2 Reply

Or better yet a society that has become so fixated on the lowest price that they failed to recognize that outsourcing your entire supply chain on a just in time model leaves you completely helpless when the single vendor who ran everyone out of business via government subsidies and currency exchange manipulation tells you that they can't deliver the product you ordered. Better yet when that vendor is in a country that is willing to profit from capitalism and democracy, but is actually exactly the opposite in stated ideology.InvalidError said:The good news just keep coming.

The joys of supply mono-culture where nearly everything passes through a single country going through a mid-life crisis. -

ConfusedCounsel So as the world grapples with a supply chain shortage, forcing production to lines to close, Congress keeps fighting over how much 3.5 trillion it can spend on some undisclosed plans and to be paid for with some undisclosed framework. How exactly is that helping people?Reply -

ConfusedCounsel Replyjasonf2 said:Or better yet a society that has become so fixated on the lowest price that they failed to recognize that outsourcing your entire supply chain on a just in time model leaves you completely helpless when the single vendor who ran everyone out of business via government subsidies and currency exchange manipulation tells you that they can't deliver the product you ordered. Better yet when that vendor is in a country that is willing to profit from capitalism and democracy, but is actually exactly the opposite in stated ideology.

But this gave us the green economy we wanted. Consumption without production is so environmentally friendly. Just don't look across the Pacific.

In hindsight, maybe it would have been more economically sustainable to develop technology allowing for eco-friendly production, rather than exporting our pollution producing production over seas.