Enthusiast demos motherboard socket pin replacement — hot air, tweezers, and a steady hand

Simple tools, intricate skills.

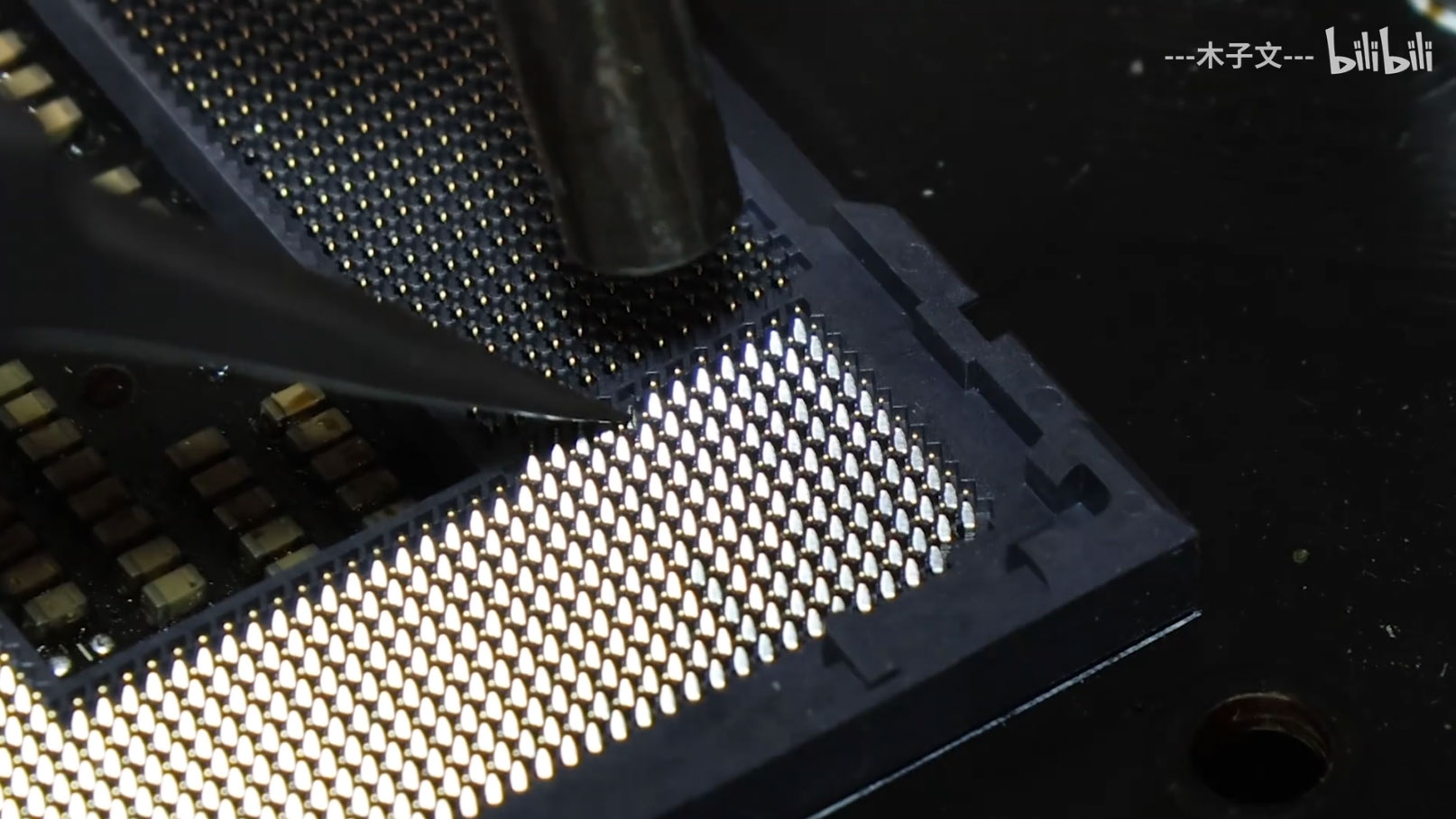

A tech enthusiast in China has demonstrated the skillful replacement of one of the ‘pins’ located in a CPU socket. Bilibili user and motherboard repair guru Mu Ziwen takes us step-by-step through the intricate process, demonstrating the success of their handiwork at the end of the brief video.

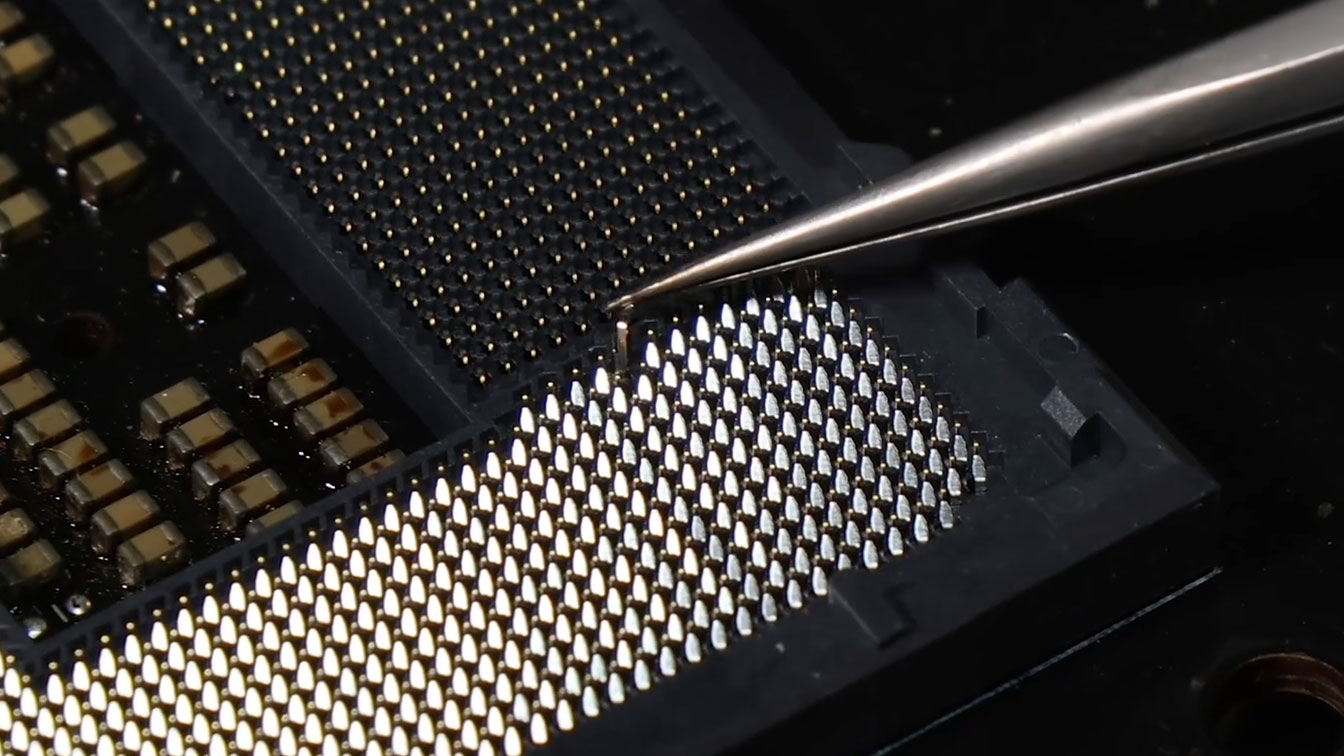

Current-gen Intel and AMD systems locate contact pins in the socket. While this makes processors more robust, we have to be more careful with motherboard sockets. Modern CPU socket ‘pins’ aren’t rigid, though. They have a thin kinked copper leaf at their business end, which exerts spring-like pressure for good contact on the corresponding CPU pad.

Damaged motherboard pins can sometimes be carefully, very carefully, pushed back into alignment with precision tools. However, there is a real danger that it can break if flexed too many times, or too strongly, because of metal fatigue. If the pin is too far gone to be prodded back into position or it breaks, as described, then most people would write off the motherboard. However, Mu Ziwen shows a full pin replacement process using a pretty basic toolset, seemingly completed pretty swiftly, too.

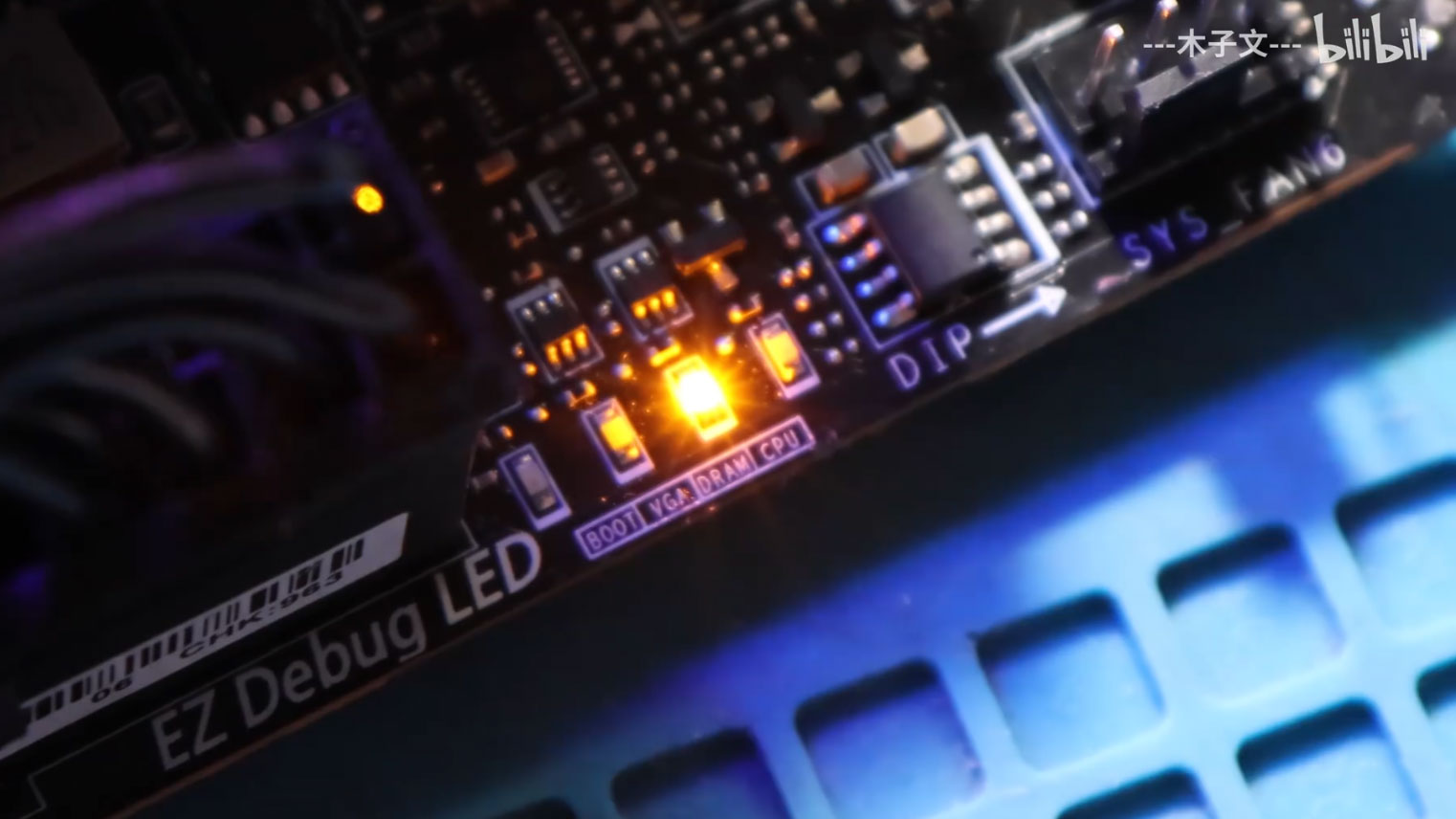

The damaged motherboard socket is causing the system to be unable to recognize the installed memory correctly - with just one pin out of action. That’s bad luck, as some pins aren’t needed, being functionally duplicated elsewhere, for example. The key symptom of the broken pin in this case was that one of the DIMM slots didn’t function.

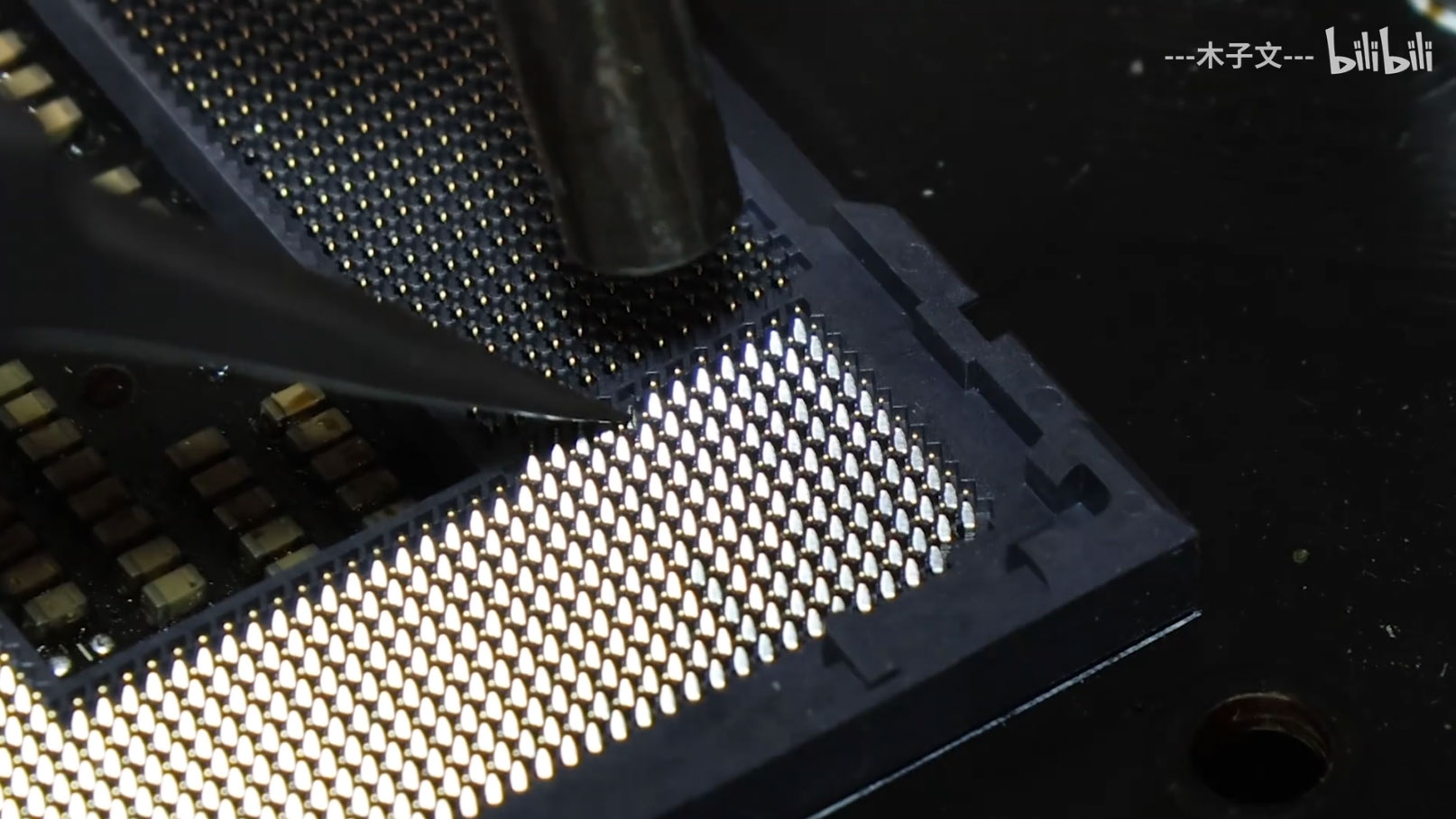

Mu Ziwen takes us through the following process:

Fixing a broken pin affecting the memory bus

- Remove damaged pin – using hot air and tweezers

- Load new pin – heat gun temperature set to a little under 300 degrees Celsius

- Test pin adhesion - tweezers

- Test pin function - multimeter

- Power on test – with CPU back in place

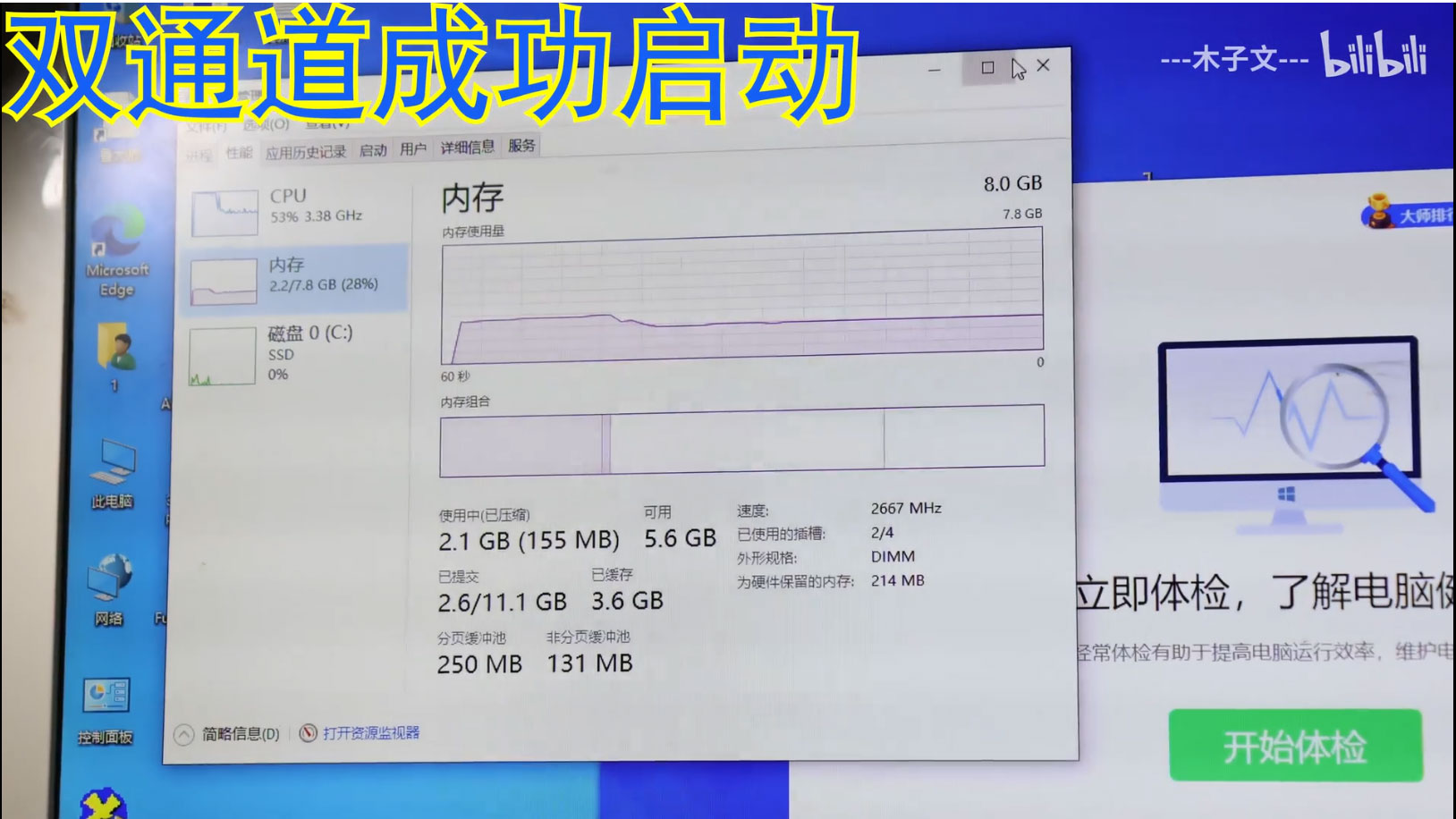

- Success – both memory channels test OK

So, the tech enthusiast only used three affordable tools throughout the repair process: a hot air gun, tweezers, and a multimeter. A hot air station temperature of a smidgeon under 300 degrees Celsius was just right for this delicate extraction and replacement job. The Bilibili user warned that anyone wielding hot air approaching 400 degrees Celsius would be in danger of melting the motherboard socket plastics.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

At the end of the video, we can see Windows Task Manager’s Process monitor confirm two of the motherboard’s DIMM slots are populated for a total of 8GB of DDR4-2666 RAM, running in dual-channel mode. This is a nice success story but be warned that skillful operators can sometimes make difficult jobs look very easy.

Mark Tyson is a news editor at Tom's Hardware. He enjoys covering the full breadth of PC tech; from business and semiconductor design to products approaching the edge of reason.