Japanese chipmaker aims to build fully automated 2-nm chip fab — Rapidus claims automation can slash delivery times by 66% versus TSMC and Samsung

Could a fully automated fab produce chips faster, cheaper, and better?

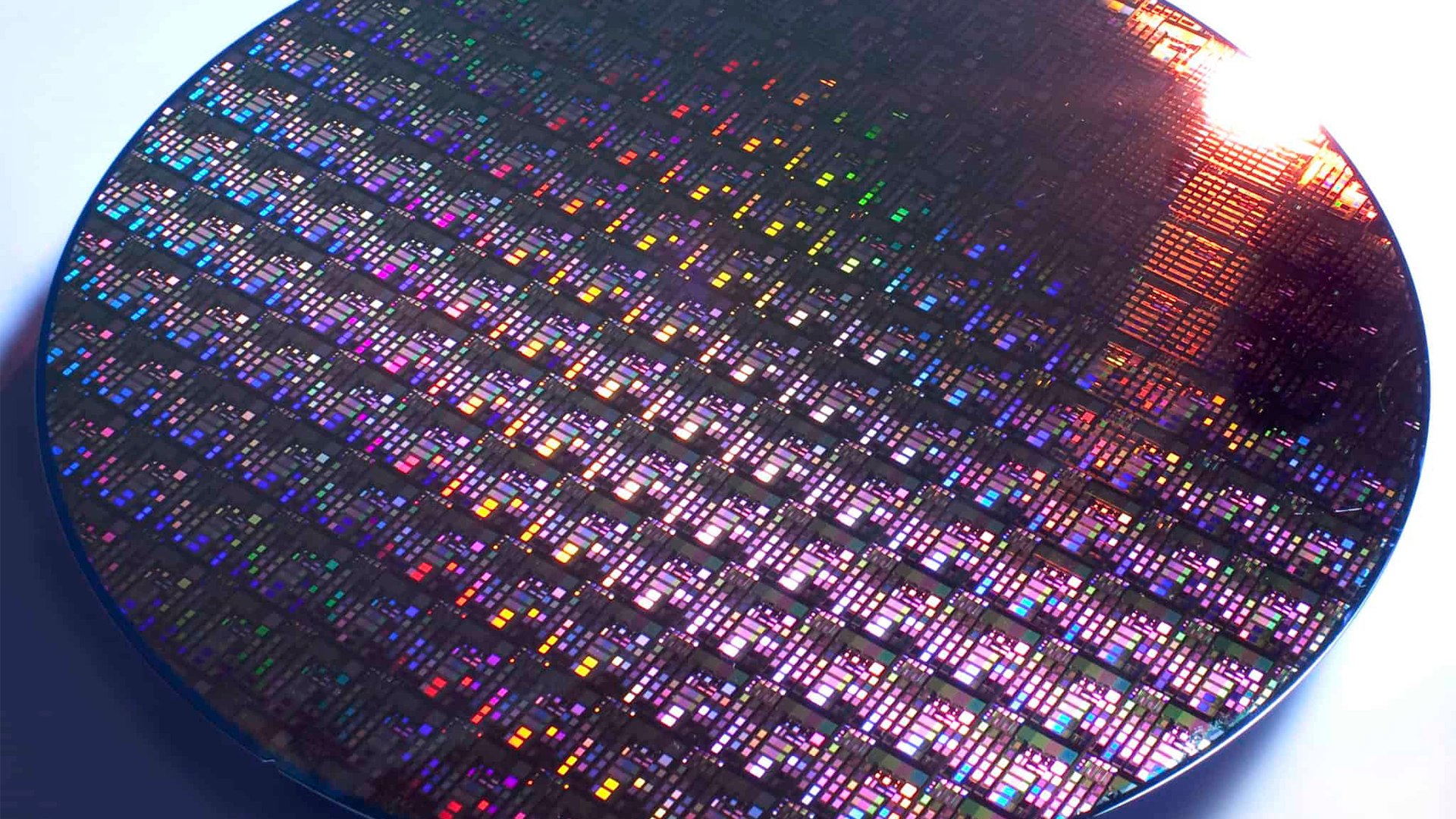

Rapidus Corporation, which is building a chip fab in Northern Japan, said it will use robots and artificial intelligence to create a fully automated line for producing 2-nm chips for advanced AI applications. Nikkei Asia reports that prototyping of its 2-nm chips should begin next year, but mass production will not begin until 2027 at the earliest.

The automation will supposedly speed up production times, allowing the company to deliver chips at just a third of the time compared to its rivals. The company's fab is expected to finish construction on the external structure by October this year, with EUV lithography tools scheduled to arrive in December.

This attempt at creating a fully automated factory should help Rapidus gain an advantage over other companies already established in the semiconductor fab business. Although front-end chipmaking processes, which include EUV lithography, are already highly automated at most production facilities, back-end processes like interconnection, packaging, and testing are still human labor-intensive.

Rapidus' move will completely automate all stages for higher efficiency. Atsuyoshi Koike, President of Rapidus Corporation, says that this "will offer higher performance and faster turnaround times than other companies on the same 2-nm products."

The company's ability to produce AI chips much faster is crucial, especially as it's two years behind its rivals—TSMC and Samsung—which are slated to start production in 2025. This is especially true given that the AI accelerator market is expected to grow by 250% this year.

If Rapidus can deliver chips much faster than its rivals without sacrificing price quality, it could gain a significant foothold in the market. The faster delivery time could allow data centers and other AI companies more flexibility in planning and deploying their massive computing systems.

However, despite this positive outlook, the company has a few hurdles before becoming fully operational. Rapidus says it needs 2 trillion yen ($14 billion) when it starts prototyping in 2025 and at least 3 trillion yen ($20 billion) to start mass production. It's already expecting 920 billion yen from the Japanese government, but the private sector is still hesitant to pick up the slack as Rapidus does not have a track record.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

"As things stand now, it is difficult for Rapidus to secure private financing." However, Koike adds, "Discussions are moving forward on making it easier to raise capital, such as a system for government loan guarantees."

Jowi Morales is a tech enthusiast with years of experience working in the industry. He’s been writing with several tech publications since 2021, where he’s been interested in tech hardware and consumer electronics.

-

jkflipflop98 All leading-edge fabs are already completely automated. Humans are just there for maintenance and correcting the screw-ups.Reply