Researchers develop new metamaterials that pave the way to bendy, stretchable computer chips

You can apply this tech to chips and semiconductors to build a bendy processor.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

You are now subscribed

Your newsletter sign-up was successful

Researchers at MIT have developed a new technique for fabricating materials, allowing them to become flexible while also staying strong and somewhat stiff.

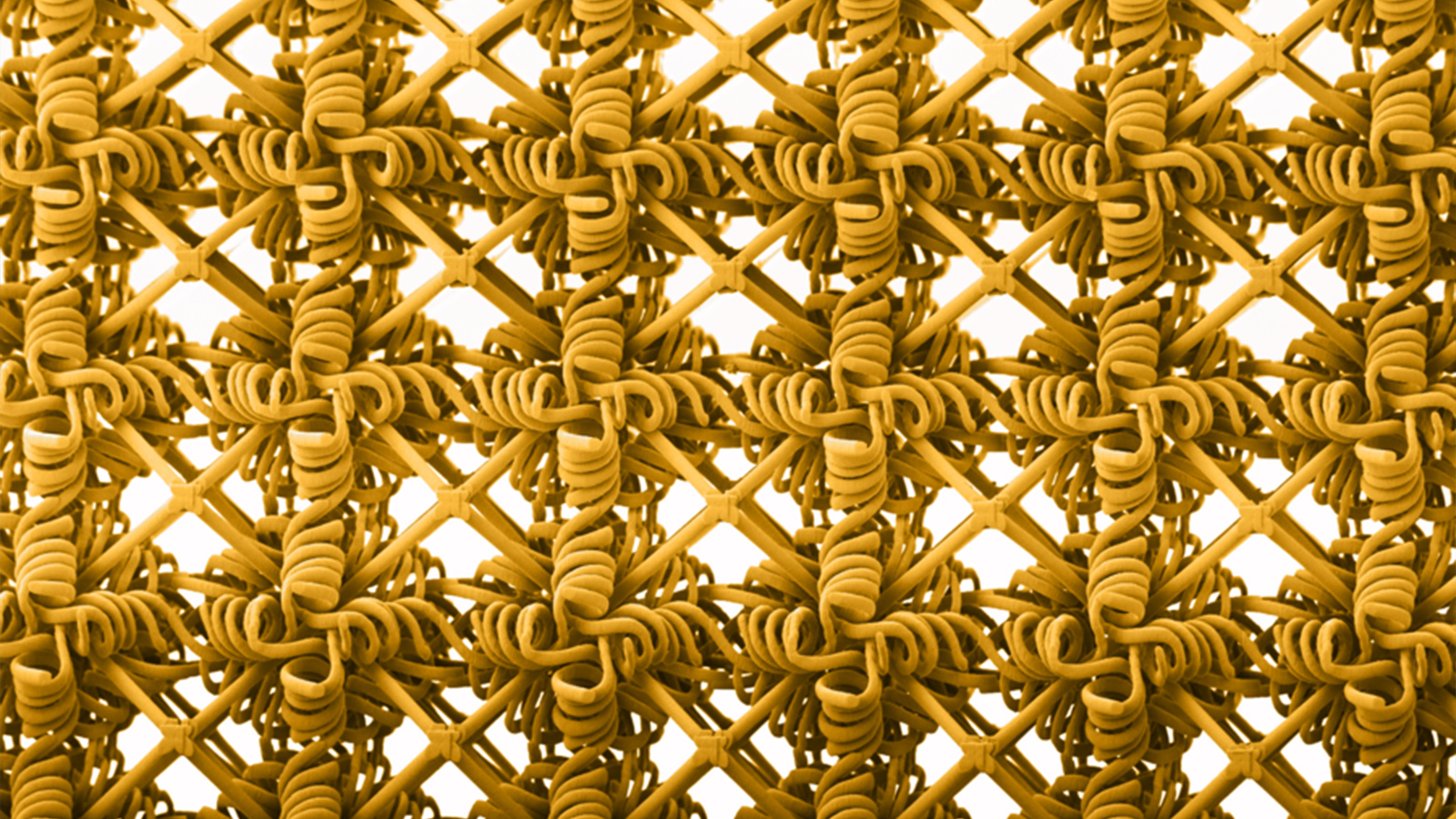

According to the MIT News report, the research team achieved this by using a microscopic double-network design that combines microscopic struts and a woven architecture. This combination was first tested on a plexiglass-like polymer, which allowed it to stretch four times its size before breaking. However, the same technique could be applied to other materials, like glass, ceramics, and metals, extending its possibilities to other industries, like semiconductors.

This metamaterial design gets its strength from microscopic struts and trusses, making it rigid but brittle. However, by adding a thread-like structure made of coils that wrap around the linear support structure, the polymer material was able to stretch three times its size before failing, some ten times more than a material just using the basic lattice structure.

“We are opening up this new territory for metamaterials,” says MIT Associate Professor Carlos Portela, who is part of the team behind this research. “You could print a double-network metal or ceramic, and you could get a lot of these benefits, in that it would take more energy to break them, and they would be significantly more stretchable.”

The secret to its added flexibility comes from the knots and entanglements of the thread structure within the lattice frame. This allows it to absorb more stress, and when a crack appears on a strut, it’s unlikely to propagate through because of how the energy is spread unevenly through the material.

“Think of this woven network as a mess of spaghetti tangled around a lattice. As we break the monolithic lattice network, those broken parts come along for the ride, and now all this spaghetti gets entangled with the lattice pieces,” Portela told MIT News. “That promotes more entanglement between woven fibers, which means you have more friction and more energy dissipation.”

You can potentially apply this new technique in semiconductors, allowing manufacturers to build flexible chips that you can install on garments and other wearable accessories. Furthermore, the research team is exploring the use of two different materials for the structure. One example is to use polymers that react differently to temperature, so that the material becomes softer and more compliant in cold environments, while harder and more rigid in hot temperatures.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

While we’re unlikely to see this being applied to wearable tech within the next year, these advancements give us a glimpse of the possibilities of tomorrow. Perhaps we’d see smart clothing or advanced wearables powered by chips using this technology in the future.

Follow Tom's Hardware on Google News to get our up-to-date news, analysis, and reviews in your feeds. Make sure to click the Follow button.

Jowi Morales is a tech enthusiast with years of experience working in the industry. He’s been writing with several tech publications since 2021, where he’s been interested in tech hardware and consumer electronics.

-

Grobe I can guess one big disadvantage with this kind of material that needs to be addressed before putting in use every public space and in the skies.Reply

When the material are cyclically stretched or being wearing from rubbing against other surfaces, it will shed microscopical particles to the air. Most materials, like glass, metals etc. are possible health hazards when it turns to fine dust that may find its way into our lungs. -

husker I'm trying to imagine stretchy glass, but it might as well be a 4 dimensional klein bottle. :confused:Reply -

bit_user Reply

Well, there are already cases where trillions of times more length of glass fibers are used, such as in fiberglass insulation.Grobe said:I can guess one big disadvantage with this kind of material that needs to be addressed before putting in use every public space and in the skies.

When the material are cyclically stretched or being wearing from rubbing against other surfaces, it will shed microscopical particles to the air. Most materials, like glass, metals etc. are possible health hazards when it turns to fine dust that may find its way into our lungs.

As for microscopic shards of metal, have you ever been in a machine shop or seen autobody repair? Some people are grinding away at metal all the time. -

bit_user Reply

Fiberglass composites are made by weaving glass fibers into a fabric that can be sculpted and then set by saturating it in a plastic resin.husker said:I'm trying to imagine stretchy glass, but it might as well be a 4 dimensional klein bottle. :confused:

We also have fiberoptic cables, as another example of flexible glass. Now, if you have coils instead of fibers, the flexibility is multiplied.