Amkor Builds $1.6 Billion Advanced Chip Packaging Factory

Amkor unveils its most advanced chip packaging fab in Vietnam.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

You are now subscribed

Your newsletter sign-up was successful

Amkor, the world’s second-largest outsourced semiconductor assembly and test (OSAT) service provider, is set to open its new advanced packaging facility in Vietnam this week. The company is established to spend about $1.6 billion on the first two phases of the plant, which will focus on producing advanced multi-chiplet system-in-packages with HBM memory.

The advanced chip packaging facility spans 57 acres within the Yen Phong 2C Industrial Park. The fab will feature 200,000 m2 of specialized cleanroom space, quite an immense production capacity. To put it into context, GlobalFoundries’s Fab 1 in Dresden had a cleanroom space of around 52,000 m2 as of 2021, and the total cleanroom space owned by the foundry was 255,000 m2 as of 2021. Such a sizable area is designed to satisfy the growing demands of the semiconductor industry for advanced packaging methods that involve silicon interposers. Meanwhile, the company does not disclose the production capacity of the facility in terms of wafers per month/year and million hours of testing per month/year.

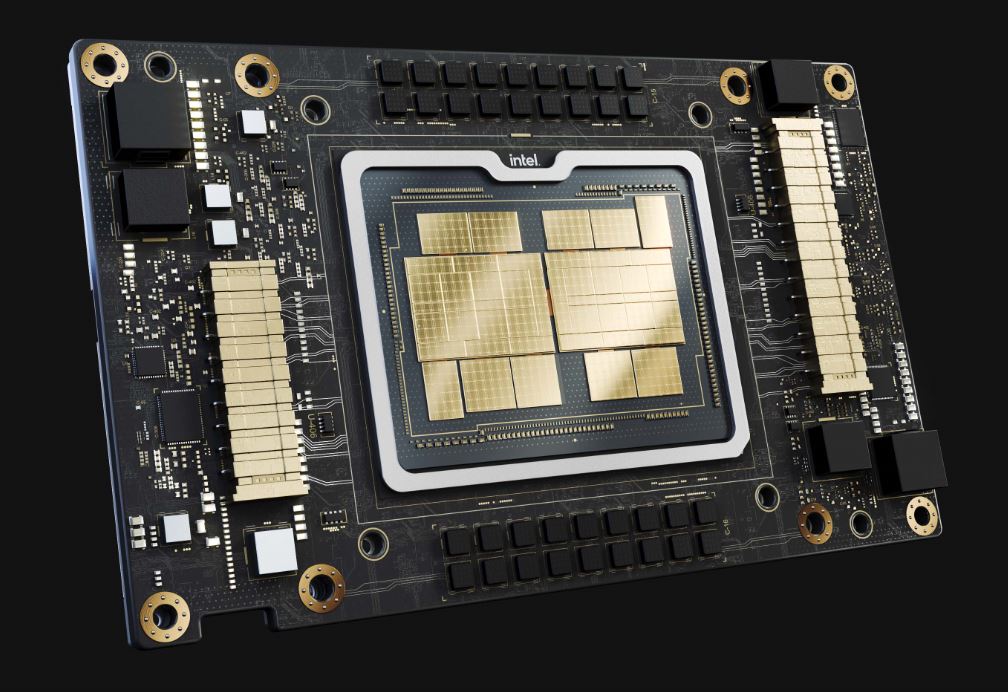

Companies like AMD, Apple, Intel, Nvidia, and Google use advanced packaging technologies, such as TSMC’s CoWoS, to build their most advanced processors aimed at artificial intelligence (AI), high-performance computing (HPC), and workstation applications. TSMC’s CoWoS capacity is reportedly sold out for quarters, so Amkor’s facility promises to be quite busy in the coming quarters and years.

As noted above, the new test and packaging facility will focus on advanced system-in-package (SiP) and HBM memory integration and will offer turnkey solutions from design to electrical test, the company said without emphasizing any particular packaging method. Amkor will need many sophisticated tools since we are dealing with advanced packaging technologies and vast cleanroom space.

Meanwhile, the sheer scale of the investment, particularly the $1.6 billion allocated for the project’s initial two phases, underscores the company’s ambition. However, establishing this plant has far-reaching implications beyond Amkor’s business ambitions. Its presence significantly boosts Vietnam’s economic trajectory, positioning it as a growing semiconductor supply chain hub. The ripple effects of such a vast investment will undoubtedly be felt across the Vietnamese industrial sector, leading to potential job creation and technological advancements.

“This state-of-the-art factory in Vietnam will help Amkor provide an unrivaled geographic footprint to our customers, supporting global but also enabling regional supply chains,” said Giel Rutten, Amkor’s president and chief executive officer. “It is the kind of secure and reliable supply chain our customers need — in communications, automotive, high-performance computing, and other key industries. A large and skilled workforce, a strategic location, and support from government authorities made it an ideal location for Amkor’s continued growth. We are proud of what we have accomplished together with Vietnam and look forward to a long and mutually beneficial relationship.”

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.

-

HaninTH Good bye my sweetheart, hello Vietnam?Reply

Anything that could help productions ramp up and hopefully drive down consumer pricing is welcomed!