Showa Denko To Boost Output of Hard Drive Media

SDK to produce 30% more HDD platters.

Showa Denko K.K. (SDK), the world's largest independent maker of platters for hard drives, has announced plans to expand aluminum HDD media production capacities. The company intends to build a new facility that will increase its current output by about one third starting from the first part of 2022.

Unit sales of hard drives had been declining in the recent years, but demand for high-capacity multi-platter nearline HDDs is on the rise, which is why aluminum platters for drives are in high demand too. To meet demand for HDD media, Showa Denko plans to increase production of platters in the coming year by 30%.

Right now, Showa Denko produces its aluminum platters for HDDs in Malaysia, Taiwan and Japan. Most of SDK's aluminum platters are made in Malaysia, where some of its clients used to build their hard drives. In a bid to diversify its supply chain and because the Japanese Ministry of Economy, Trade and Industry plans to subsidize building SDK's additional capacity, Showa Denko's new production capacities will be built in the Land of the Rising Sun.

SDK's new production will be operated by its Showa Denko HD Yamagata K.K. (SHDY) subsidiary. Installation of the new equipment will begin in February, 2021, and the company plans to start using the new production capacities in the first half of 2022.

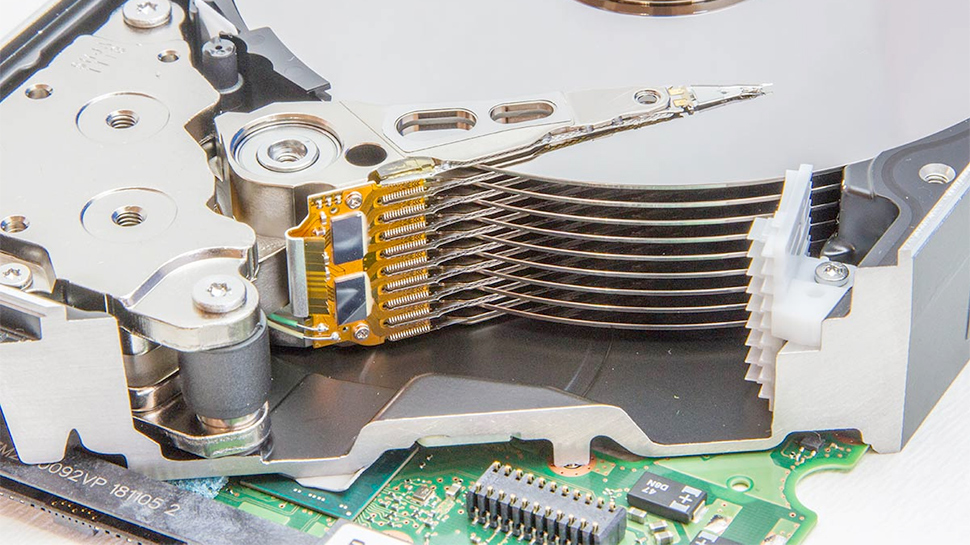

Showa Denko uses aluminum HDD platters for drives that rely on perpendicular magnetic recording (PMR), shingled magnetic recording (SMR) (as well as their energy-assisted variants), and microwave assisted magnetic recording (MAMR) technologies). By contrast, HDDs that use heat-assisted magnetic recording (HAMR) technology — the one that will enable hard drives with up to 80TB capacities — will use glass platters because of their superior heat resistance.

Increasing production of aluminum platters indicates that either Showa Denko and/or its partners have found a way to use them with HAMR HDDs, or the Japanese company expects aluminum platters as well as PMR and MAMR technologies (with or without shingling) to be used for years to come even for higher-end nearline hard drives that.

One of the companies that will benefit from Showa Denko's expansion the most is Toshiba. Unlike its rivals Seagate and Western Digital, Toshiba does not have its own platter manufacturing, so with more media available from SDK, Toshiba will be able to expand production of its hard drives starting from 2022.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.