Modder builds a totally fanless 'retro-futuristic' mini PC — attached to a USB4-powered bank of SSDs

Fanless Mini PC from whichever fragment of time "retro-future" resides within

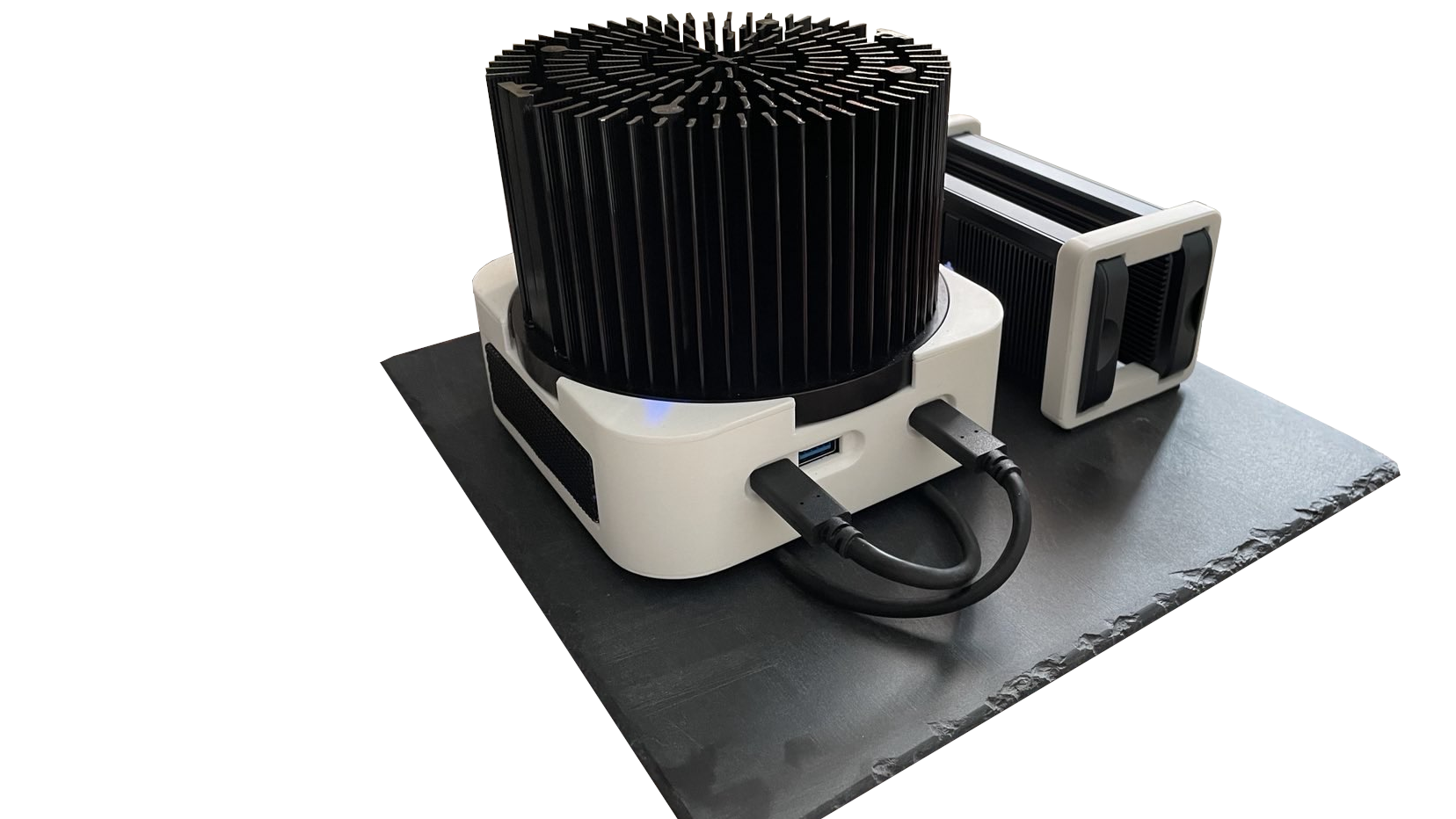

Part of our coverage of Mini PCs here at Tom's Hardware often includes fanless PCs— but rarely ones as custom as this build from Reddit user TheJiral, which features a suitably beefy heatsink and an external SSD enclosure running over two USB 4 ports. The heart of this build is the ASRock Industrial Box-7640U Mini PC, which previously used a fanless cooler with a much smaller heatsink. The replacement heatsink, which can be seen as the tallest point of the new build, is the Wakefield-Vette PADLED-13080, which TheJiral acquired from DigiKey.

The build saw the original case being replaced with a 3D printed case, one with vents to the side and lovely use of threaded inserts instead of self tapping screws. We're not sure what 3D printer was used, but it looks like an FDM (Fused Deposition Modeling) printer was used, perhaps one of the best 3D printers from our list.

As for performance, fortunately, most of the performance characteristics for this build can be determined with some accuracy at just a glance. Based on the specification of the original mini PC and even its name, we can tell this Mini PC is using the low-power Ryzen 5 7640U. This is a CPU aimed at laptops and is somewhat cut down from its big brother Ryzen 7 7840U, but it's still in the upper echelon of iGPU performance thanks to those RDNA3 Compute Units. Unlike 7840U's 12 RDNA3 CUs with the Radeon 780M iGPU, though, the Ryzen 5 7640U only has a Radeon 760M iGPU with 8 RDNA3 CUs.

According to TheJiral, their cooler of choice can handle the Ryzen 5 7640U operating at 28 Watts (near-full utilization) "pretty well".

TheJiral even toggled an overclock option on the ASRock motherboard that enabled a 45 Watt TDP "performance" mode, though this did result in the setup eventually overheating when stress testing CPU cores— thus, overclocking is definitely not happening with this mini PC build. However, the existing results do suggest that just adding a fan or two to this setup might be all it needs to be overclockable, though it's likely not worth sacrificing the aesthetic for a slight performance bump.

The original Reddit thread has some more detailed build information posted by TheJiral, but there unfortunately they doesn't share how the custom shell was made and what inspired it. However, considering their recent Settlers of Catan-themed 3D printing project, it stands to reason that this reportedly-unintentional "retro-futuristic" mini PC components were made the same way.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Christopher Harper has been a successful freelance tech writer specializing in PC hardware and gaming since 2015, and ghostwrote for various B2B clients in High School before that. Outside of work, Christopher is best known to friends and rivals as an active competitive player in various eSports (particularly fighting games and arena shooters) and a purveyor of music ranging from Jimi Hendrix to Killer Mike to the Sonic Adventure 2 soundtrack.

-

bit_user Reply

Note that the modder used the two fat heat pipes from the original solution to spread the heat into the base of the heatsink. They're being used sort of like a vapor chamber, which I was going to suggest.The article said:TheJiral even toggled an overclock option on the ASRock motherboard that enabled a 45 Watt TDP "performance" mode, though this did result in the setup eventually overheating when stress testing CPU cores

I think thermal performance could be improved if they filed and sanded the heat pipes flat and used a good heatsink compound, rather than using a thermal pad between them and the heatsink. -

8086 Aesthetically, his design looks a lot like the 1980s CRAY X1.Reply

Source: https://cray-history.net/cray-history-front/fom-home/fom-xmp/ -

bit_user Reply

Yeah, but I wonder if that's just happenstance?8086 said:Aesthetically, his design looks a lot like the 1980s CRAY X1.

Source: https://cray-history.net/cray-history-front/fom-home/fom-xmp/

If you follow the purchase link for the heatsink used, the bottom of the page shows lots of other heatsinks of a similar shape & style. I believe these are designed for LED lighting applications. The modder either knew this, or just searched for a large heatsink and happened to find/use one of these. Perhaps the Reddit thread covers this topic. I didn't read the whole thing.

BTW, I wonder how much the cooling would be improved if the system/board were oriented vertically and a heatsink were used that could better take advantage of such convection. There are some server heatsinks you can find that have a vapor chamber directly integrated into the base.

Another thought I have is how hot the RAM & SSD are getting. -

TheJiral The design is certainly "form follows function". I started with looking for easiliy available heat sink options. For compact heatsinks with higher convection based heat dissipation the options are more limited than some might think. LED heat sinks are the best suited option IMHO. They are not only designed to work in horizontal orientation and for high power dissipation and feature compact horizontal dimensions, but they also come with good surface finish as they are intended to be used where they can be seen and where looks often matter. I designed the case to integrate both, the board and the heat sink.Reply

The looks that remind of the Cray or maybe works from Dieter Rams were a happy accident but part of the reason I stuck with this design and also with this colour scheme. -

TheJiral Replybit_user said:Note that the modder used the two fat heat pipes from the original solution to spread the heat into the base of the heatsink. They're being used sort of like a vapor chamber, which I was going to suggest.

I think thermal performance could be improved if they filed and sanded the heat pipes flat and used a good heatsink compound, rather than using a thermal pad between them and the heatsink.

Indeed. Using a good heat sink compound on a sanded flat heat pipe would probably be more efficient in the heat transfer but also a lot less forgiving regarding tolerances. I really did not want to sand the heat pipe as I have no experience with how much one can get away with, without damaging the integrity of the heat pipes internals. More importantly though, I expect the rate limiting step not at that interface of heat pipe to heat sink but rather at the heat transfer from heat sink to air.

My experience with it so far seems to confirm that, as under long lasting stress tests, the heat sink is probably reaching an equilibrium between 60 and 70°C. That is pretty much where I want the max Temp to be. -

TheJiral One small correction to the article. The original ASRock Industrial Box 4x4 7640U is not a fanless MiniPC but a regular fan based mini PC. I do have a spare radial fan now indeed ;)Reply

Because the question was asked in the article. The white case was printed with my custom built Voron 2.4 in Formfutura ABSpro which is a flame redartant ABS/PC blend. Rather challenging to print actually but it has good heat resistancy and is self extinguishing. I designed it in the open source program FreeCAD. -

bit_user Thanks for stopping by!Reply

: )

I'd need to see how much material is being removed, but I'd probably risk it with also some judicious use of pliers and a file to work down the high spots.TheJiral said:Indeed. Using a good heat sink compound on a sanded flat heat pipe would probably be more efficient in the heat transfer but also a lot less forgiving regarding tolerances. I really did not want to sand the heat pipe as I have no experience with how much one can get away with, without damaging the integrity of the heat pipes internals.

It can be tough to go on intuition. What if your 0.5 mm thermal pad is only making good contact at a few spots?TheJiral said:More importantly though, I expect the rate limiting step not at that interface of heat pipe to heat sink but rather at the heat transfer from heat sink to air.

Anyway, regarding thermal pads, which did you use? I've had a good experience with ARCTIC TP-3. It comes in 0.5, 1.0, and 1.5 mm, in case you find the surface variations are bigger than you expected.

https://www.amazon.com/ARCTIC-TP-3-Performance-Conduction-Installation/dp/B09V53W559

What heatsink compound did you use between the heat pipes and the die? The paste I've used for a similar direct-die application is ARCTIC MX-6. -

Notton That is an interesting heatsink choice.Reply

Since the APU is <30W, I would have used a regular C-shaped heatsink, like a thermalright SI-100, without the fan and called it a day. The exposed base plate makes it easy to fashion a DIY bracket for the mini-PC's mounting holes.

But I like the look from the vertical fin heatsink better.

It reminds me of Alpha and Swiftech pin fin heatsinks of the Pentium 3/4 era, before heatpipes were invented. -

TheJiral Reply

I did not check how the base plate aligns with the location of the mobile CPU, but from a first look it would be probably off centre along one axis. That is not a problem technically of course, merely a design question. It would be interesting though how it would compare in terms of performance. Convection based cooling is helped by larger plate spacing which goes against what is needed for heat sinks intended exclusively for use with fans. Still, C-shaped heat sinks allow for vertical pass through, which would be a plus.Notton said:That is an interesting heatsink choice.

Since the APU is <30W, I would have used a regular C-shaped heatsink, like a thermalright SI-100, without the fan and called it a day. The exposed base plate makes it easy to fashion a DIY bracket for the mini-PC's mounting holes.

But I like the look from the vertical fin heatsink better.

It reminds me of Alpha and Swiftech pin fin heatsinks of the Pentium 3/4 era, before heatpipes were invented.

Creating some metal bracket is beyond my capabilities and I wouldn't want to use a plastic bracket for that job even if polycarbonate for example could probably handle the temperatures.

In the end I would have chosen the LED heat sink anyway I suppose, I just think it makes the whole thing look more interesting and unique. -

TheJiral Reply

I chose "Iceberg Thermal DRIFTIce" which claims pretty good heat transfer (no idea if it is true) and is just the best value, by far, where I live. I think it was 3,33 EUR per piece. I did reseat the heat sink a few times, without using new pads. The pad did appear to be nicely compressed along the whole length. Initially I planned to replace it with fresh ones but as the thermal performance of the setup looked just fine as it was I kept it as it was. I can still change it when need arises.bit_user said:It can be tough to go on intuition. What if your 0.5 mm thermal pad is only making good contact at a few spots?

Anyway, regarding thermal pads, which did you use? I've had a good experience with ARCTIC TP-3. It comes in 0.5, 1.0, and 1.5 mm, in case you find the surface variations are bigger than you expected.

https://www.amazon.com/ARCTIC-TP-3-Performance-Conduction-Installation/dp/B09V53W559

What heatsink compound did you use between the heat pipes and the die? The paste I've used for a similar direct-die application is ARCTIC MX-6.

The heatsink compound I used above the die was Noctua NT-H1, simply because I still had some lying around and I would expect it to be decent enough for the job.

www.iceberg-thermal.com/product/thermal-pad/driftice/www.noctua.at/en/nt-h1-3-5g