HGST Hits 10-Nanometer Patterned-Bit Milestone

HGST's new discovery will double the bit density of today's disk drives by the end of the decade.

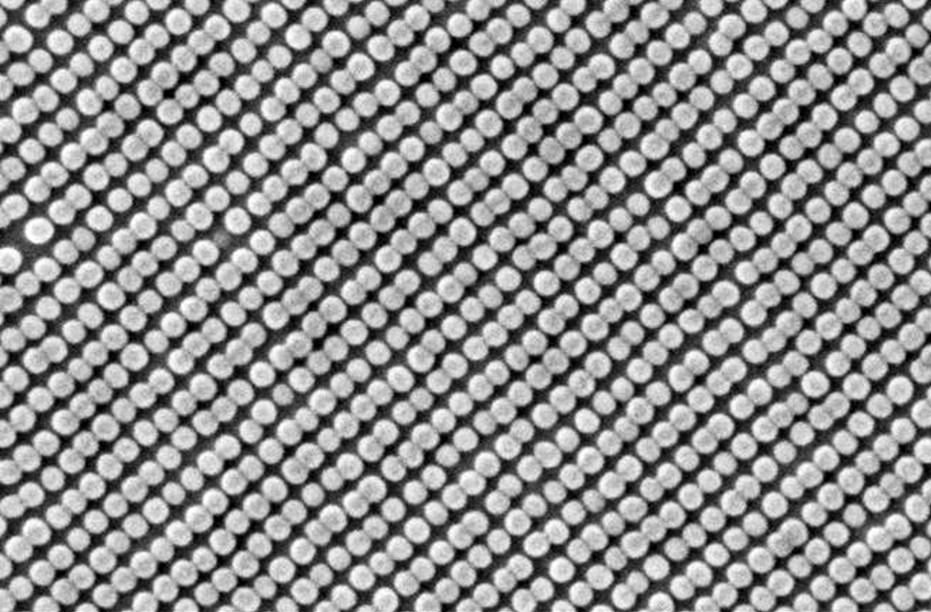

The company formerly known as Hitachi Global Storage Technologies, HGST, said that it has broken the 20-nm barrier associated with platter-based storage by combining self-assembling molecules and nanoimprinting. The result is the creation of large areas of dense patterns of magnetic islands only 10-nm wide. These islands are only about 50 atoms wide, and some 100,000 times thinner than a human hair.

HGST, now a Western Digital subsidiary, said on Thursday that the bit density of its new 10-nm pattern is double that of today's disk drives, and currently shows excellent initial read/write and data retention in tests. Once expanded to an entire disk, the nanoimprinting process is expected to create more than a trillion discrete magnetic islands.

"Self-assembling molecules use hybrid polymers, called block copolymers, composed of segments that repel each other," the company explained. "Coated as a thin film on a properly prepared surface, the segments line up into perfect rows. The size of the polymer segments determines the row spacing."

Once the polymer patterns are created, a chip-industry process called "line doubling" makes the tiny features even smaller, creating two separate lines where one existed before, the company said. The patterns are then converted into templates for nanoimprinting, a precision stamping process that transfers the nanometer-scale pattern onto a chip or disk substrate.

"A key challenge proved to be preparing the original surface so the block copolymers form their patterns in the radial and circular paths necessary for rotating disk storage," the company added. "HGST is the first to combine self-assembling molecules, line doubling and nanoimprinting to make rectangular features as small as 10 nanometers in such a circular arrangement."

HGST's new nanolithography achievements arrives at a critical time for HDDs as solid state drives become more prominent in the PC sector. Unfortunately, they come with high cost for consumers despite their speed, especially in larger capacities. As it stands now, the ideal setup is to have a small SSD for the OS, and a large HDD for media storage and other data.

Mechanical drives, on the other hand, continue to be the cheaper route while also offering tons of space for a growing amount of stored user content like movies, TV shows and music. On a cloud-based level, this achievement could have a huge impact, allowing companies to store more data both internally and externally. Cloud-based storage services could boom, or the could bomb, depending on HDD consumer-based prices.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

"We made our ultra-small features without using any conventional photolithography," said HGST's Tom Albrecht said. "With the proper chemistry and surface preparations, we believe this work is extendible to ever-smaller dimensions."

HGST is aiming to have the process ready for wide-scale commercial production by the end of the current decade.

Kevin Parrish has over a decade of experience as a writer, editor, and product tester. His work focused on computer hardware, networking equipment, smartphones, tablets, gaming consoles, and other internet-connected devices. His work has appeared in Tom's Hardware, Tom's Guide, Maximum PC, Digital Trends, Android Authority, How-To Geek, Lifewire, and others.

-

JeBuSBrian phate1337imagine what this will do for processors 5 years down the line. jeeeeeesusI don't think it will do anything. The specific process shown here is not applicable to processors.Reply -

CaedenV pretty cool! I doubt many people understand just how amazing this new tech really is!Reply

The problem is that is will be coming out 10 years too late.

Currently we have ~1TB of space per platter, and up to 5 platters to a drive, which means that this new tech could bring 10TB drives to the market some time before 2023. Meanwhile in the flash space we are looking at 2TB laptop sized flash drives being released some time late 2013 or early 2014 (1TB native, 2TB with some form of onboard RAID scheme), and you can easily fit the volume of 5 laptop drives in the volume of a single desktop drive. That means that if SSD controllers could address the area then you could have a 10TB desktop HDD purely made from flash memory this year rather than 10 years from now (granted it would cost a TON of money!!!). In more specialized spaces you have products like the OCZ R5 which was released last year and can be custom ordered with up to 12TB of storage (granted, using last years tech it takes a fair amount more space than a single drive, but next year they could do it). So by the time HDDs are doing 10TB, flash will have already far out-stripped that number.

Another issue is performance. HDD performance is largely a function of areal density. Current drives with 1TB platters have a sequential throughput of ~200MB/s, and doubling the density 10 years from now should roughly double the throughput to ~400MB/s, which is roughly where mid-level SSDs perform today. The problem is that hardly any workloads are sequential, and the non-sequential throughput on a HDD is ~1/4 of the sequential workload (obviously a gross over-simplification, but go with me on this). So in 10 years if you have a 10TB HDD, and you are only getting a throughput of ~100MB/s on a normal workload, and you set it up next to an SSD in 10 years that is ~1/2 the size (or less) and can max out the SATA 4 throughput of 1.5GB/s (or potentially SATA 5 at 3GB/s), then I think I know what people are going to purchase. Even with a 5x price difference the SSD will have something like 15x the performance. Going again to the R5 released last year which is a PCIe solution you get 7.2GB/s... compare that to a future drive getting 100-400MB/s (depending on workload) and that becomes pretty depressing.

All of the growing markets are using flash based storage already (phones, tablets, and ultrabooks), all of the traditional cash-cow HDD markets are converting to SSDs (servers and enthusiasts), leaving the slowly contracting laptop and desktop markets for HDD sales, and even those will dry up when decent cheap SSDs hit the market over the next 2-5 years.

In my own home we are already making the switch (granted I suppose we are in the 'enthusiast' camp). 2 years ago I had 2 HDDs in my wife's system, 5 in mine, and 1 in each of our netbooks. Fast forward to today and our netbooks have been replaced by our smartphones with flash storage, my wife's PC has a single 120GB SSD with no HDD in her box, and my box has 2 SSDs in RAID0 for all of my stuff and 2 HDDs in RAID1 for images, backups, and bulk storage. So we have moved from 9 HDDs down to 2, and those 2 drives (which I just purchased) will probably be the last HDDs we ever purchase. In 5 years when my HDDs are ready to be replaced I am sure I will be able to get a set of 2-4TB SSDs at an affordable price and set up some sort of RAID5 to meet my storage requirements. And then, because SSDs wear mostly by usage, they ought to last a really long time because they will mostly be used for storage and not writing.

So again; This is a truly monumental feat that HGST has accomplished, and it is absolutely mind-blowing that they can pull something like this off. But by the time it is publicly available it will be far too late to be useful. -

realibrad @CaedenVReply

I think you are looking at this from the wrong view point. True that for PCs that the HD will be too little too late, but that is not true for all storage. Most companies need volume over current speed. Higher density means they can save rack space, and heat. True, SSDs will improve, and already used much less power, but they are coming up to their limits on what they can do pretty qucik.

HDs will be around for a very long time, just not in home PCs. -

photonboy While hard drives will be around for many years, there will be a crossover point where SSD's even for Servers are cheaper. It's a function of the cost of hardware AND, reliability and power .Reply

SSD's cost more now but they are also dropping more rapidly in price. Reliability and power will be in their favor so the clock's ticking for Hard Drives.

I'd say the Server market might buy only SSD's starting around 2020. -

alidan CaedenVpretty cool! I doubt many people understand just how amazing this new tech really is!The problem is that is will be coming out 10 years too late.Currently we have ~1TB of space per platter, and up to 5 platters to a drive, which means that this new tech could bring 10TB drives to the market some time before 2023. Meanwhile in the flash space we are looking at 2TB laptop sized flash drives being released some time late 2013 or early 2014 (1TB native, 2TB with some form of onboard RAID scheme), and you can easily fit the volume of 5 laptop drives in the volume of a single desktop drive. That means that if SSD controllers could address the area then you could have a 10TB desktop HDD purely made from flash memory this year rather than 10 years from now (granted it would cost a TON of money!!!). In more specialized spaces you have products like the OCZ R5 which was released last year and can be custom ordered with up to 12TB of storage (granted, using last years tech it takes a fair amount more space than a single drive, but next year they could do it). So by the time HDDs are doing 10TB, flash will have already far out-stripped that number.Another issue is performance. HDD performance is largely a function of areal density. Current drives with 1TB platters have a sequential throughput of ~200MB/s, and doubling the density 10 years from now should roughly double the throughput to ~400MB/s, which is roughly where mid-level SSDs perform today. The problem is that hardly any workloads are sequential, and the non-sequential throughput on a HDD is ~1/4 of the sequential workload (obviously a gross over-simplification, but go with me on this). So in 10 years if you have a 10TB HDD, and you are only getting a throughput of ~100MB/s on a normal workload, and you set it up next to an SSD in 10 years that is ~1/2 the size (or less) and can max out the SATA 4 throughput of 1.5GB/s (or potentially SATA 5 at 3GB/s), then I think I know what people are going to purchase. Even with a 5x price difference the SSD will have something like 15x the performance. Going again to the R5 released last year which is a PCIe solution you get 7.2GB/s... compare that to a future drive getting 100-400MB/s (depending on workload) and that becomes pretty depressing.All of the growing markets are using flash based storage already (phones, tablets, and ultrabooks), all of the traditional cash-cow HDD markets are converting to SSDs (servers and enthusiasts), leaving the slowly contracting laptop and desktop markets for HDD sales, and even those will dry up when decent cheap SSDs hit the market over the next 2-5 years.In my own home we are already making the switch (granted I suppose we are in the 'enthusiast' camp). 2 years ago I had 2 HDDs in my wife's system, 5 in mine, and 1 in each of our netbooks. Fast forward to today and our netbooks have been replaced by our smartphones with flash storage, my wife's PC has a single 120GB SSD with no HDD in her box, and my box has 2 SSDs in RAID0 for all of my stuff and 2 HDDs in RAID1 for images, backups, and bulk storage. So we have moved from 9 HDDs down to 2, and those 2 drives (which I just purchased) will probably be the last HDDs we ever purchase. In 5 years when my HDDs are ready to be replaced I am sure I will be able to get a set of 2-4TB SSDs at an affordable price and set up some sort of RAID5 to meet my storage requirements. And then, because SSDs wear mostly by usage, they ought to last a really long time because they will mostly be used for storage and not writing.So again; This is a truly monumental feat that HGST has accomplished, and it is absolutely mind-blowing that they can pull something like this off. But by the time it is publicly available it will be far too late to be useful.Reply

there is a bare minimum cost for a ssd, because its on silicon wafers, while a hdd, doesnt have the same problem.

correct me if im wrong, but heat assissted is suppose to give us 10 times the space we currently have on a hdd, and this is going to take the scale down too... both applied to each other would that mean a 100tb drive is possible?

see there is a bare minimum price for ssd, and from my math, it comes to about (1 or 2 cents less) than pre flood 2tb cost for the same amount of space, but that is also taking into account the 6nm ceiling (about the theoretical minimum)

so unless we start printing these things 3d, and its cheaper than 1 layer to do that, you wont see ssd over take hdd space wise ever. you will see them as a viable option, and possibly in some computers the only drive, but there will always be a demand for hdd, even if its just for backup purposes. -

CaedenV realibrad@CaedenVI think you are looking at this from the wrong view point. True that for PCs that the HD will be too little too late, but that is not true for all storage. Most companies need volume over current speed. Higher density means they can save rack space, and heat. True, SSDs will improve, and already used much less power, but they are coming up to their limits on what they can do pretty qucik. HDs will be around for a very long time, just not in home PCs.I don't know about that.Reply

We already have seen the death of the sub 500GB HDD because it was cheaper for HDD manufacturers to stop making smaller platter sizes than to support that market. So if you need a HDD in your computer then you are looking at either a large HDD, or a smallish SSD. In ~2 years SSDs will start being competitive in the 500GB market, so then HDDs will have a smallest size of 1TB, but the simple fact is that only power users and gamers need more than 500GB, and while that will change eventuially, it will not be in the next 5 years.

Meanwhile, over the next few years (less than 5 I think) we are going to be seeing more explosive growth in mobile devices with limited storage that heavily rely on servers for content. These dockable phones and tablets will replace laptops to a point of near extinction (though laptops will still be around for road wariors who need more of a portable desktop), and will replace desktops for light PC users who just browse the web. It will not be the 'death of the PC' that everyone likes to tout, but the PC will move from an enduser role, to a server role. At any rate, they will require high bandwidth storage from both home and corporate servers which can only really be addressed by SSDs.

So, the questions in my mind for the survival of the HDD is this:

1) Will user created content and game size grow to a point where HDDs are simply the only medium that can be mass produced fast enough to store it all? Or will this explosion of new user data and program sizes grow and then plateau out like it did up until a few years ago before the advent of cheap HD cameras?

2) Will server throughput requirements by all of the drive-limited devices on the market be so great that SSDs become the only things fast enough per GB of storage that HDDs disappear? Or do mobile devices start having large usable drive sizes (120+GB) so that people can fit their most used documents and media collections on the device so that servers can continue to get by on HDDs?

Surely reality will lie somewhere between the two, but I think that the 1080p video explosion is beginning to level off a bit, and while we are going to see a program size explosion over the next few years with the next gen of games and consoles, I do not think that will be so monumental that it will be a big game changer for most users.

What I do not see changing much (to my annoyance) is a change in drive size of portable devices. I think that software companies like MS, Amazon, and Google have a lot more money to be made by pushing people to cloud services, and they dictate the storage available on portable devices. But the data served (music, movies, and programs especially) are easy to consolidate, meaning one copy on a server can be downloaded millions of times to end users. If this is the case then it makes a lot more sense to have the fewest number of highest performing servers available, which is the ultimate case for SSD storage. The vast bulk of network and internet usage is exactly this; a relative few number of files accessed by huge numbers of people. Netflix is well over 50% of internet traffic, and it is their set of movies streamed to millions of users. Another large portion of the internet is the streaming of porn and torrents, which is also easily consolidateable data. Very small portions of network usage are of end users accessing files... not because they do not do it, but because the size of the files are so small.

For business servers;

For small to mid sized businesses it is a consideration of performance per user vs storage per user. Most businesses are dealing with relatively small documents where the price difference between SSD and HDD (especially server grade HDDs) are not very different to begin with, so I think that change will happen soon if it is not already happening.

For larger businesses with 50+ employees I am seeing more and more of them look at moving away from the whole server+desktop strategy that has dominated the industry for years, and moving to a server+terminal setup where the whole operating environment lives on the server (something win8 is made for by the way). In this setup you again have the same thing as the cloud example where a lot of similar data is downloaded several times, making overall space available very secondary to drive performance. This model will not only require SSD performance from servers, but may also require the use of something faster than plain old gigabit ethernet and finally pave the way for 4gbps or 10gbps ethernet. In this case SSDs become much cheaper than HDDs not because of $/GB, but because you need less drives and (more importantly) less servers overall in order to serve the same number of users. Where HDDs need more redundancy in other supporting hardware to achieve critical bandwidth mass, SSDs require less drives for performance, so you need less boxes and less (better utilized) servers to do the same work. The issue at the moment is a lack of available SSD space per drive. Sure there is the R4 or R5, but that is a rather expensive and exotic piece of equipment. Right now the 'big' SSDs are only in the 400-512GB range, where as late this year we will see more affordable 500GB drives, and more mainstream 1TB SSDs that do not rely on internal RAID schemes. When those come out then it will be a good replacement for current server drives which are typically less than 1TB anyways.

At any rate, the point is, if the home PC market dries up, the small to medium server market dries up, and if the web streaming market dries up, then you are talking about a monumental chunk of HDD sales converting to smaller, but higher performance SSDs. HDD makers cannot survive on the backup and cold storage industry alone, so they will have to raise their price per drive, which only makes SSDs even more attractive. The big question in my mind is if they will slowly wind down to a point where they do only support the backup industry, or if it will be more like floppy discs where the best year of sales was the last year they were made and Sony decided to pull the plug because while numbers were high there was simply no money in it.

But then again, I could be wrong :D -

CaedenV alidanthere is a bare minimum cost for a ssd, because its on silicon wafers, while a hdd, doesnt have the same problem. correct me if im wrong, but heat assissted is suppose to give us 10 times the space we currently have on a hdd, and this is going to take the scale down too... both applied to each other would that mean a 100tb drive is possible?Reply

see there is a bare minimum price for ssd, and from my math, it comes to about (1 or 2 cents less) than pre flood 2tb cost for the same amount of space, but that is also taking into account the 6nm ceiling (about the theoretical minimum) so unless we start printing these things 3d, and its cheaper than 1 layer to do that, you wont see ssd over take hdd space wise ever. you will see them as a viable option, and possibly in some computers the only drive, but there will always be a demand for hdd, even if its just for backup purposes.HAMR is neat tech, but it promised a 10x increase in density back in the day when 1TB drives were available, making for 10TB drives, not 100TB drives... even if it was true today then we would be talking about 40TB drives which is still less than 1/2 of a 100TB drive. Amazing does not equal Magic.

As for the rest of what you were saying... I am a bit confused as to what you are even saying. Current gen 1TB SSDs have multiple boards in them and are essentially 2 seperate SSD boards linked together via an internal SATA and RAID array. What makes them expensive is the inclusion of the RAID processing, and the duplication of things like the SSD controller which cost more than the actuial SSD nand units. There are nand units available to SSD manufacturers today that allow them to do 512GB drives with only 8 chips. The reason they do not go doubble-sided with these types of chips is because the current gen controllers max out at 512GB of flash on board.

What this means is that when the new controllers are released and start being used we will see 1TB SSDs fall in line with the pricing of normal SSDs rather than having the 'RAID tax' on them that make them so much more expensive. We will then see internally RAIDed 2TB SSDs wich will be ridiculously expensive until yet another set of die shrinks. But this means we will see 2TB SSDs that fit in the size of a traditional laptop HDD, which to my knowledge has only been done by WD on one drive so far. The other thing which can be done, if SSDs were ever to move to a full Desktop format, is that they could put multiple drives on a single long raided board. You could easily fit 4 double-sided boards inside of a traditional desktop HDD space. At 2 drives per board * 4 boards with 1TB each that would be an easy 8TB you could put in there, and if they played with he layout they could easily fit more. Obviously this would not be practical because you would essentially be RAIDing 8 drives together, which is a nightmare, and it would be insanely expensive... but the point is that it could be done using today's tech rather than needing to wait 10 years for them to figure out how to do it. And if someone where to make a controller that was designed for this type of application and could control more than 16 chips then it could go a lot easier and cheaper... but there is 0 demand for it, so it will not happen any time soon.

Another advancement in drive density that brings the price down is the movement from SLC, to MLC, to TLC. It is not so much that it makes the die smaller, but it allows multiple bits to be placed in the same location by allowing more values than a simple 0 or 1 to be used. TLC essentially says that the value can be a 0, 1 or 2, which is essentially a way to use trinary storage a compression for a binary signal. What it boils down to is that you get more storage density for the same amount of flash memory at the cost of more expensive voltage regulation, and a higher (but still acceptable) flash derogation rate. There is talk about doing this up to a base 8 at some point in the future, so once die shrinks hit the magic 6-8nm limit, they will still be able to increase density by increasing the number of different voltages each cell holds. It is a nice trick that electric storage can do that magnetic storage does not have access to.

The biggest issue with HDDs is not the sheer size they can hold, because they obviously have a plan to grow in that regard, but it is that ratio of size to throughput which makes them impractical after a certain point which will eventually hurt business. They will always be great for sheer bulk storage that does not need to be often accessed, and I do not argue that point. What I find unsustainable is the idea that they can run the whole HDD market (with all of it's R&D required to keep hitting their progress marks) entirely on the bulk archival storage market.

If SSDs take over slowly like they have been up to this point, then perhaps HDD makers will be able to slowly pair down their business appropriately. But if this next gen of SSDs hits that critical mass of space+performance+price that I think they will, then there is a real risk that the HDD market dries up very quickly and HDD manufacturers loose business literally overnight. If that happens then there is no way for a big business to cope with that kind of loss except to fold up and go home. It is not that I WANT HDD companies to fail. I just know what the addition of SSDs in my systems at home and work have done for me and I just sit here wondering why on earth they are not more popular than they are.

Yes, $/GB is important, but once you start seeing 240GB drives for ~$120 (which is what I paid for my 2nd 240GB drive last year) then $/GB doesn't matter anymore. It is merely a drive that is 'big enough' to be very useful and cheap enough where it is a nearly negligible amount of money for most individuals. And when a $120 drive upgrade creates more of a visible performance upgrade than building a new $3-500 PC that still uses HDD tech, then you really start to wonder why on earth SSDs are not more popular in new machines. Considering a HDD cannot even push a modern i3 processor (much less an i5 or i7), it drives me crazy that there is not simply more demand for them. Buying a modern computer (even a cheap i3) and putting a HDD in it as a system drive, is just plain nuts as most things that most users do on it will be limited to the HDD throughput which makes it no faster than a 5 year old Core2Duo system (and you can get those really cheap these days).

For server applications where you have multiple users accessing the same drive this effect is multiplied. For each concurrent user added on a HDD you are looking at a nearly 30% overall performance drop (meaning when 2 users are on you get 1/3 the performance of a single user going to each user), where as if you use SSDs instead then you get a negligible performance drop until you get a bunch of users, at which point performance falls of gracefully rather than catastrophically. I mean, at that point (other than a massive storage requirement) why wouldn't you move to SSDs? Yes, the SSD is more expensive, but you get to use the full performance of that SSD with a lot more load on it than a HDD. It really seems crazy not to at this point except for the use of backup servers.