Intel Docs Confirm Dual-Core Cannon Lake CPUs With And Without iGPUs

It seems Intel did, technically, ship 10nm parts in 2017. The existence of in-production dual-core Cannon Lake CPUs with and without integrated graphics has been confirmed by a publicly released Intel document.

Intel chose not to mention Cannon Lake or its long-in-development 10nm process at its CES 2018 keynote. Instead, it quietly confirmed at a press-only event the following morning that Cannon Lake CPUs had actually been shipped in 2017. Rumors suggested that these were low-power, dual-core parts that were possibly lacking integrated graphics.

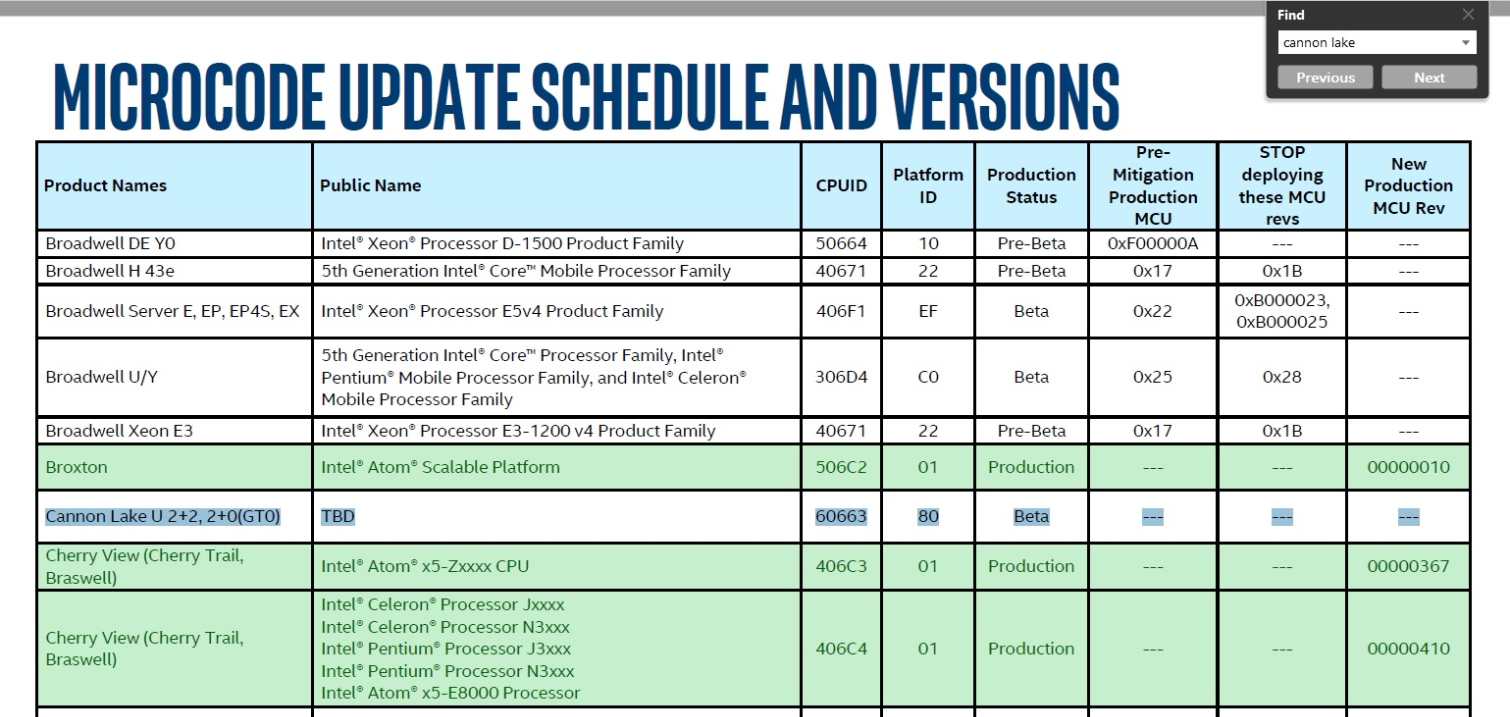

Those rumors have been seemingly confirmed by Intel’s Spectre microcode guidance document (pictured above), which was released on February 8 with Intel’s Spectre patching update (the document was updated on February 12 and the above has been removed). Two Cannon Lake “U” CPUs have been listed. The “U” designation, which has been used for mobile Core CPUs with a 15W TDP since at least the 5th generation, suggests that these parts are also low-power mobile parts. The “2+2” denotes that one CPU has two CPU cores and a GT2 iGPU. This would put the chip in the same market segment as mobile Core i3 CPUs, such as the i3-8130U.

The “2+0(GT0)” denotes that the second CPU has two CPU cores and no iGPU. This is interesting because it means that the CPU can’t function as a notebook part. In theory, it could be paired with a low-power discrete GPU, such as an Nvidia MX130, but that would negate much of the power savings from the CPU while not offering anything for applications without GPU acceleration. Even most embedded devices, like NASes and Intel NUCs, need graphics, so it’s difficult to think of an application for this chip.

Intel has been talking about 10nm for a very long time, but it always seems to be perpetually on the horizon. There were even rumors that Cannon Lake isn’t production-worthy, so it wouldn’t be productized. A pair of small CPUs, one of which might have a disabled (as opposed to unfabricated) GPU section, doesn’t inspire confidence in Intel’s 10nm process’ early yield, even if it does confirm Intel’s promise of shipping 10nm parts in 2017. The most recent update we got on the process was in the company’s Q4 2017 financial report. Krzanich said that low-volume 10nm production would continue for the first half of 2018, before shifting to high-volume production.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

-

RCaron Due to physics, and the complicated fabrication process. It's harder to fabricate a CPU at a smaller node. The problem is complicated by the size of the CPU you're trying to fabricate because errors pop-up more often at smaller nodes.Reply

So a smaller CPU, as TSMC has already printed several at 7nm, is easier to print than Intel's massive monolithic CPU's.

"A second reason for the slowdown is that it’s simply getting harder to design, inspect and test chips at advanced nodes. Physical effects such as heat, electrostatic discharge and electromagnetic interference are more pronounced at 7nm than at 28nm. It also takes more power to drive signals through skinny wires, and circuits are more sensitive to test and inspection, as well as to thermal migration across a chip. All of that needs to be accounted for and simulated using multi-physics simulation, emulation and prototyping." https://semiengineering.com/7nm-last-major-node/

But, using EMIB Intel could stitch 14nm+++ parts with 10nm parts creating hybrid CPU's until they've perfected the 10nm process to print their entire CPU's on 10nm in a competitive cost effective manner.

The question is, can they do this before AMD prints Ryzen on 7nm? AMD has an advantage here, Ryzen is 1/3rd the size of Intel's Coffee Lake.

Regardless I heard a rumor that Intel is switching to modular CPU's in 2020, to compete with AMD, although I have no idea if this was a joke or not. -

InvalidError Reply

Coffee Lake is 151sqmm while Zeppelin and Raven Ridge are both over 200sqmm. Intel is the one with a 33% die size advantage there.20703830 said:The question is, can they do this before AMD prints Ryzen on 7nm? AMD has an advantage here, Ryzen is 1/3rd the size of Intel's Coffee Lake.

-

AgentLozen ReplyRCARON said:Due to physics, and the complicated fabrication process. It's harder to fabricate a CPU at a smaller node. The problem is complicated by the size of the CPU you're trying to fabricate because errors pop-up more often at smaller nodes.

Intel has been fighting with this for a long time. I remember hearing about all of the quantum physics problems they ran into with the 22nm node. I bet 14nm had it's own unique challenges.

I wonder what the rate of producing fully functional 14nm chips is for Intel. How do you think it compares you the 65nm Core 2 Duo Conroe chips? Was Conroe coming out right more frequently than Coffee Lake or Kaby Lake? Do you think that 10nm Cannon Lake and Ice Lake chips will be fully functional more or less often than this current generation?

I'm asking because I wonder if it would make sense to focus on architecture improvements instead of die shrinks in the future. Think about what Intel has done with 14nm.

Broadwell was just Haswell @ 14nm.

Skylake was a real architectural improvement over Broadwell.

Kaby Lake is Skylake with 14nm+ transistors.

Coffee Lake is Kaby Lake with 14nm++ and 2 more cores.

How much radical innovation really happened over this last node generation? Skylake was the single biggest architectural change in the last 4 years. Instead of dumping all of your time and resources into the 10nm node that has a lower success rate of fully functional chips, why not focus on innovating at the current node size?

edit: typo, clarification

Also Skylake X featured a lot of new ideas for scaling. That should have been mentioned. What would Skylake X have been if they used solder instead of thermal paste? There wouldn't be much of a conversation about Threadripper today. -

jimmysmitty Reply20703830 said:Due to physics, and the complicated fabrication process. It's harder to fabricate a CPU at a smaller node. The problem is complicated by the size of the CPU you're trying to fabricate because errors pop-up more often at smaller nodes.

So a smaller CPU, as TSMC has already printed several at 7nm, is easier to print than Intel's massive monolithic CPU's.

"A second reason for the slowdown is that it’s simply getting harder to design, inspect and test chips at advanced nodes. Physical effects such as heat, electrostatic discharge and electromagnetic interference are more pronounced at 7nm than at 28nm. It also takes more power to drive signals through skinny wires, and circuits are more sensitive to test and inspection, as well as to thermal migration across a chip. All of that needs to be accounted for and simulated using multi-physics simulation, emulation and prototyping." https://semiengineering.com/7nm-last-major-node/

But, using EMIB Intel could stitch 14nm+++ parts with 10nm parts creating hybrid CPU's until they've perfected the 10nm process to print their entire CPU's on 10nm in a competitive cost effective manner.

The question is, can they do this before AMD prints Ryzen on 7nm? AMD has an advantage here, Ryzen is 1/3rd the size of Intel's Coffee Lake.

Regardless I heard a rumor that Intel is switching to modular CPU's in 2020, to compete with AMD, although I have no idea if this was a joke or not.

I don't see AMD getting to 7nm ( well GF as AMD doesn't do anything for fabrication anymore) before Intel hits 10nm. Beyond the fact that their 7nm isn't even a "true" 7nm, I doubt they somehow figured it all out and are not running into any issues on a true 7nm platform while the company that consistently lead the industry is somehow, with all their money in R&D (remember Intel typically goes it alone) somehow couldn't even manage to get 10nm to work. -

InvalidError Reply

GloFo began taking 7nm orders in June 2017 with the first production shipments expected around mid-2018. We'll see if its schedule slips to late-2018 soon enough. If things remain on track though, GloFo's customers may be first to market with 7-10nm products.20704595 said:I don't see AMD getting to 7nm ( well GF as AMD doesn't do anything for fabrication anymore) before Intel hits 10nm.

With GloFo's top priority going into 2019 being "improve yields on 7nm, reduce use of triple/quad-patterning", yields in mid-2018 might not be expected to be particularly good. I doubt that would surprise anyone. -

wownwow Meltdown inside?Reply

Does the current Windows update have them covered, both Meltdown and Spectre? -

AgentLozen Replyhannibal said:

No...

How mysterious. I wonder what context he's disagreeing with. I bet it's REALLY cool.