Intel's Six-Core i5-9400F Skips Solder TIM, for Now (Updated)

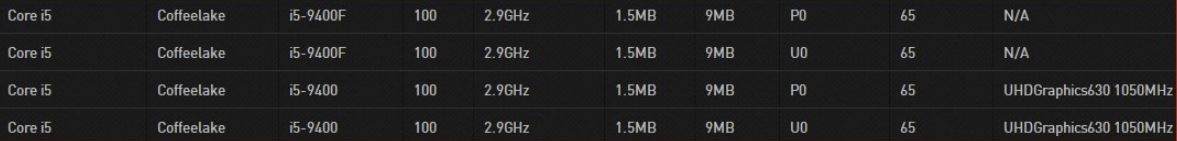

Update 2/6/2019: Intel confirmed to us that some Core i5-9400F processors do come with pTIM (polymer TIM - a.k.a. thermal grease), but that can vary based on the location of manufacturing.

Sources close to the matter also tell us that the company will transition the Core i5-9400F and Core i5-9400 models to solder TIM (sTIM) entirely in the near future. Naturally, that means there will be no need to differentiate between the two products on the packaging. All "K" series models in the Core i9 and i7 series will continue to come with sTIM, as well. We also learned that the company will use pTIM for all Core i3 "F" series models indefinitely.

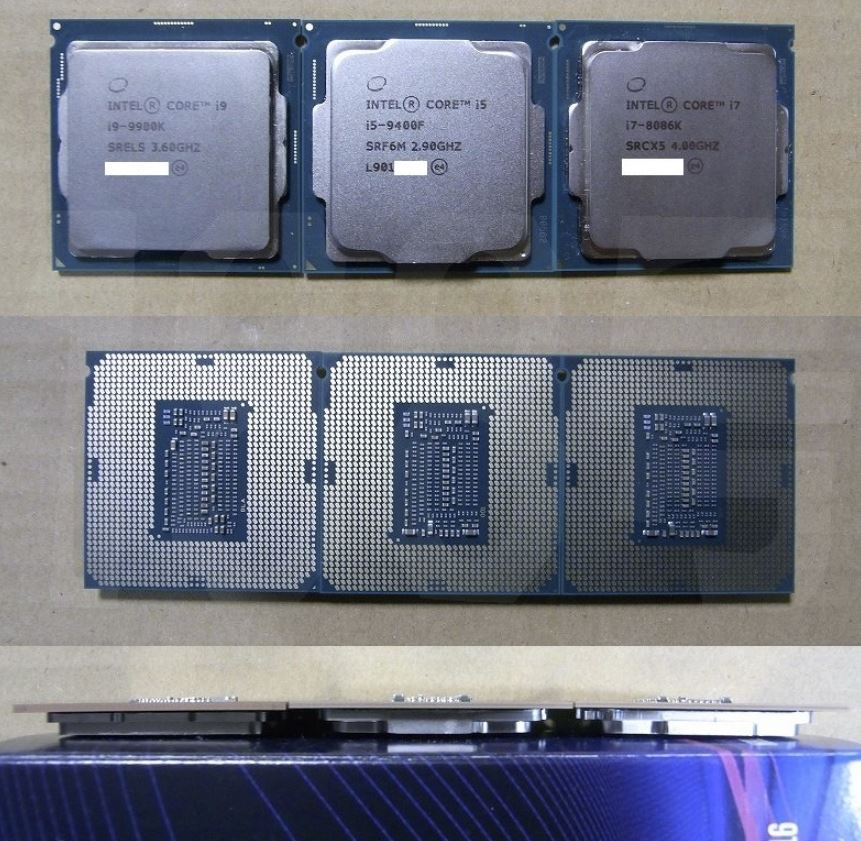

On another note, our resident overclocking expert Allen "Splave" Golibersuch has a Core i9-9900KF in hand for liquid nitrogen overclocking. As you can see from the images above, in contrast to the Core i5-9400F pictured below, this processor comes with the standard 9th-gen integrated heat spreader design.

Original Article:

Intel's new "F" series processors have spurred plenty of criticism from the enthusiast community because even though the processors come with a disabled graphics unit, Intel still assigns the same recommended price points as their fully-operational counterparts. Now it turns out the company is also discarding Solder TIM (sTIM) on the new models, instead returning to its oft-maligned thermal grease.

Much to the delight of enthusiasts, Intel's ninth-gen processors marked the return of solder interface material (sTIM), but prolific chip-detective momomo_US uncovered photos of a delidded Core i5-9400F processor without sTIM.

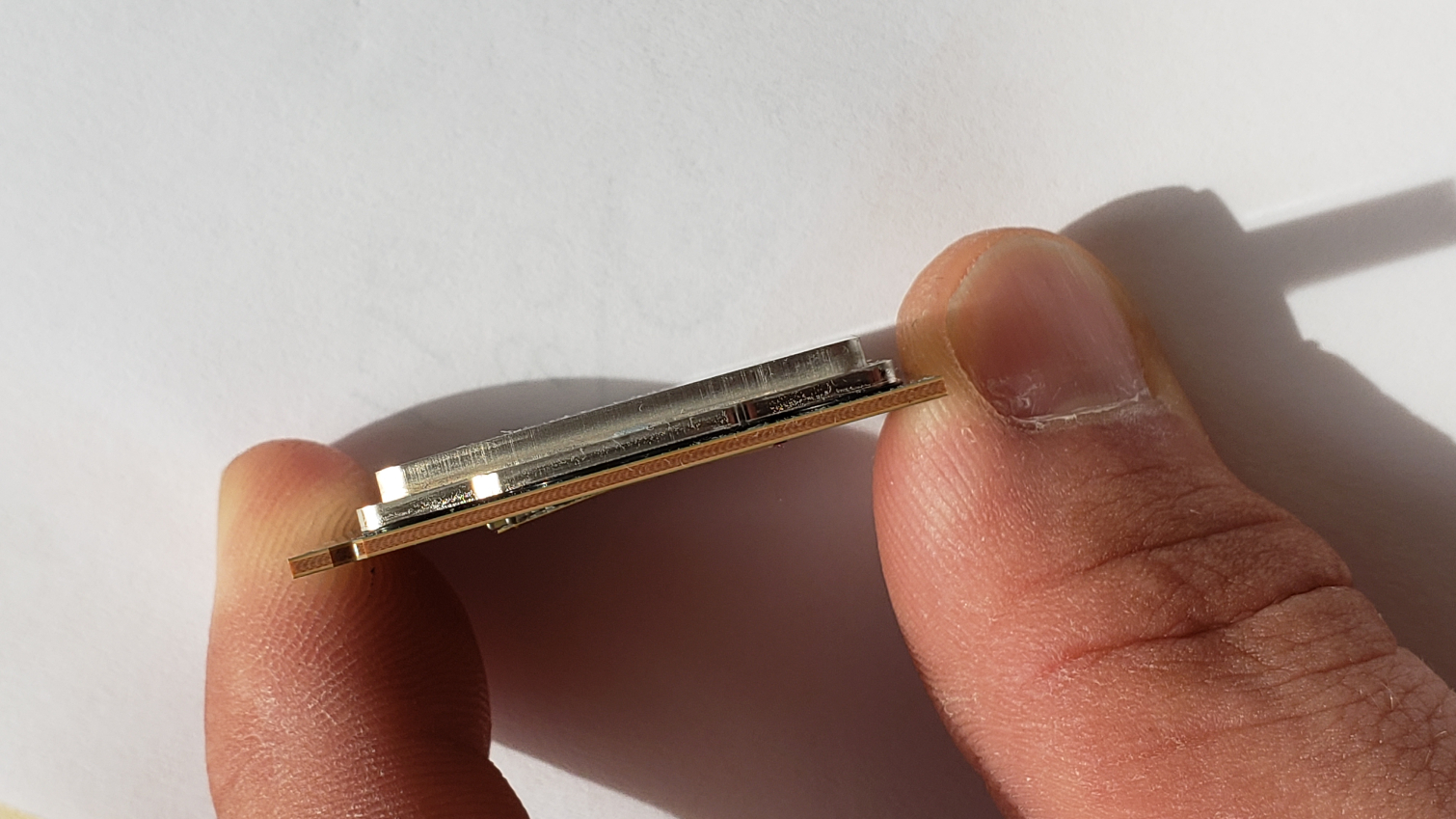

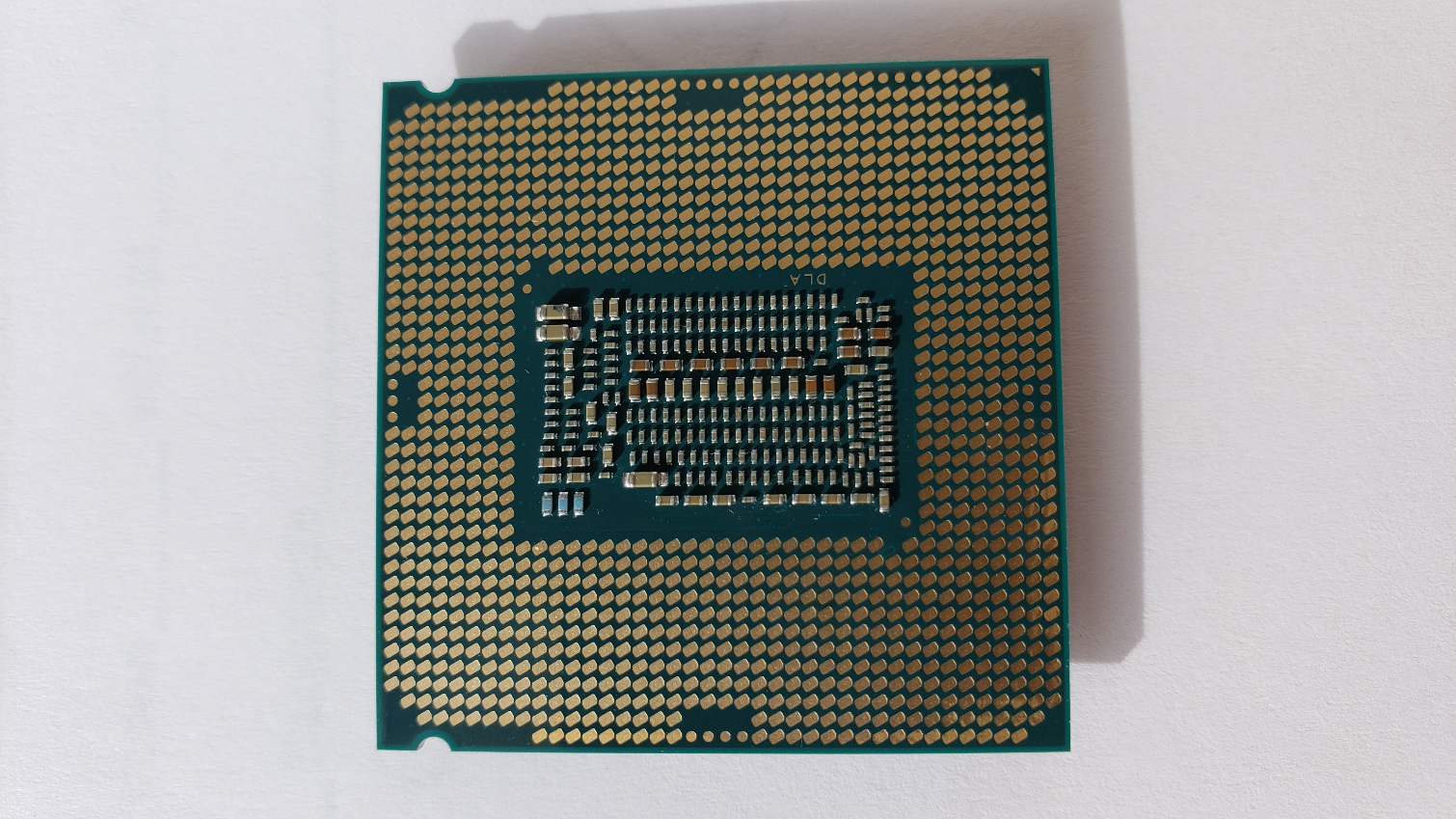

Recent motherboard firmware updates posted to MSI's website have confirmed support for two Core i5-9400F steppings. According to the recent findings, the P0 stepping denotes an eight-core die with sTIM and has two cores disabled, while the U0 stepping (pictured above) has a smaller six-core die that comes with standard thermal grease. The U0 stepping also comes with a thinner PCB and the same IHS (integrated heat spreader) design found on the eighth-gen chips, as you can see in the image below.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Solder TIM improves the thermal transfer efficiency between the die and heat spreader, which lowers operating temperature and often unlocks a higher overclocking ceiling. Lower temperatures also help during stock operation–they typically enable longer turbo boost durations. sTIM is more expensive than the standard thermal paste that Intel has used for several generations of its processors, so a return to the thermal grease is a cost-cutting measure that Intel may deem acceptable given the locked multiplier on the chips.

Intel has also long preached the perils of solder TIM, which can lead to shorter lifespans due to microcracks in the solder TIM that form during heat-induced expansion and contraction. That's more of a concern with smaller die, such as the six-core die on the -9400F.

These same effects also can break the solder bumps that connect the substrate and the PCB, leading to premature chip death. Intel has never officially disclosed solder-induced chip failure rates (to the authors' knowledge), but the increase in the failure rates is thought to be within a single percentage point. Of course, when you punch out north of a million die per day like Intel does, even a 1% increase in failure rates equates to a huge hit to the bottom line.

But enthusiasts still love solder TIM for its superior cooling effects, and AMD's adoption of the material has made it a must-have for enthusiast-class chips.

Whether Intel will stick with solder for the other F-series processors, such as the unlocked Core i9-9900KF, is an open question. It also remains to be seen if Intel will bring the P0 stepping to market (all known retail models carry the U0 stepping), or differentiate between the two different steppings on retail boxes. Currently, that doesn't appear to be the case. We've pinged Intel for more details and will update as necessary.

Paul Alcorn is the Editor-in-Chief for Tom's Hardware US. He also writes news and reviews on CPUs, storage, and enterprise hardware.

-

panathas Intel seems to be using solder TIM for all the new 8-core dies and it is still using thermal grease for the old 6-core (defective?) dies that has kept in stock.Reply -

seanmcc Is using thermal grease that significant a cost saving measure? I believe that it saves cash, but is the difference that significant? For all the r and d and fab complexity that goes into these chips, it seems like a rather small and petty way to save few bucks for such significant thermal benefits.Reply -

mischon123 Paste is expensive. Its 1/3 the price of a watercooler for your chip.Reply

Cheap paste and watercooler keeps your chip running at 40-45 Celsius. My R1800x does.

Hot running Intel chips developing cracks is a no go. Having to overamp your chips right out of the factory to compete is an engineering flaw, among others. -

photonboy Mischon123,Reply

Paste is 1/3 the price of a liquid cooler?

First off, we are talking about TIM in between the CPU chip and the heat spreader. You'd need to DELID to see it.

Anyway, nobody knows why Intel is avoiding solder. You can read this but really nobody knows: https://venturebeat.com/2018/10/08/intel-solder-9900k-i9/

I will say Intel Engineers aren't stupid. It's also not that costly in terms of profit margins. Micro-cracks don't seem like much of an issue as they solder Xeons for servers. So the above suggestion it's about conflict-free materials by the process of elimination may be true. So maybe they just used solder now temporarily for the worst offenders temperature wise and will stop using it again soon. -

photonboy "Of course, when you punch out north of a million die per day like Intel does, even a 1% increase in failure rates equates to a huge hit to the bottom line. "Reply

Uh... if they made a BILLION per day it would still be the same low failure rate. -

rantoc So a chip that's defective (gpu) slammed together with sub-pair thermal transfer vs the proper chip... and sold at the same price as the full "proper" chip.Reply

Yeah, if i bought that by mistake i knew what greedy company i would be avoiding! -

mischon123 @rantoc: You are definitely on to what constitutes a consumer grade Intel chip. Its most likley a yield problem of epic proportions. 3 out of 4 dies are defective...This is my conservative estimate.Reply -

justin.m.beauvais Those two dies are different sizes... whaaaaaaaaaat?Reply

Does this mean that the 9600K is a defective 9700K? Or does it mean that there is simply NO graphics (as in missing, not disabled) on the F chips? -

Olle P This was only to be expected for these lower TDP CPUs.Reply

Intel's claim (summarized): "Micro-cracks occur due to (repeated and) rapid variations in temperature."21739900 said:... Micro-cracks don't seem like much of an issue as they solder Xeons for servers. ...

How are Xeons run? Typically at stable loads and temperatures 24/7.