TSMC Asks Partners to Delay Fab Equipment Deliveries: Report

TSMC wants to slightly slowdown spending, asks partners to postpone delivery of wafer fab equipment.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

You are now subscribed

Your newsletter sign-up was successful

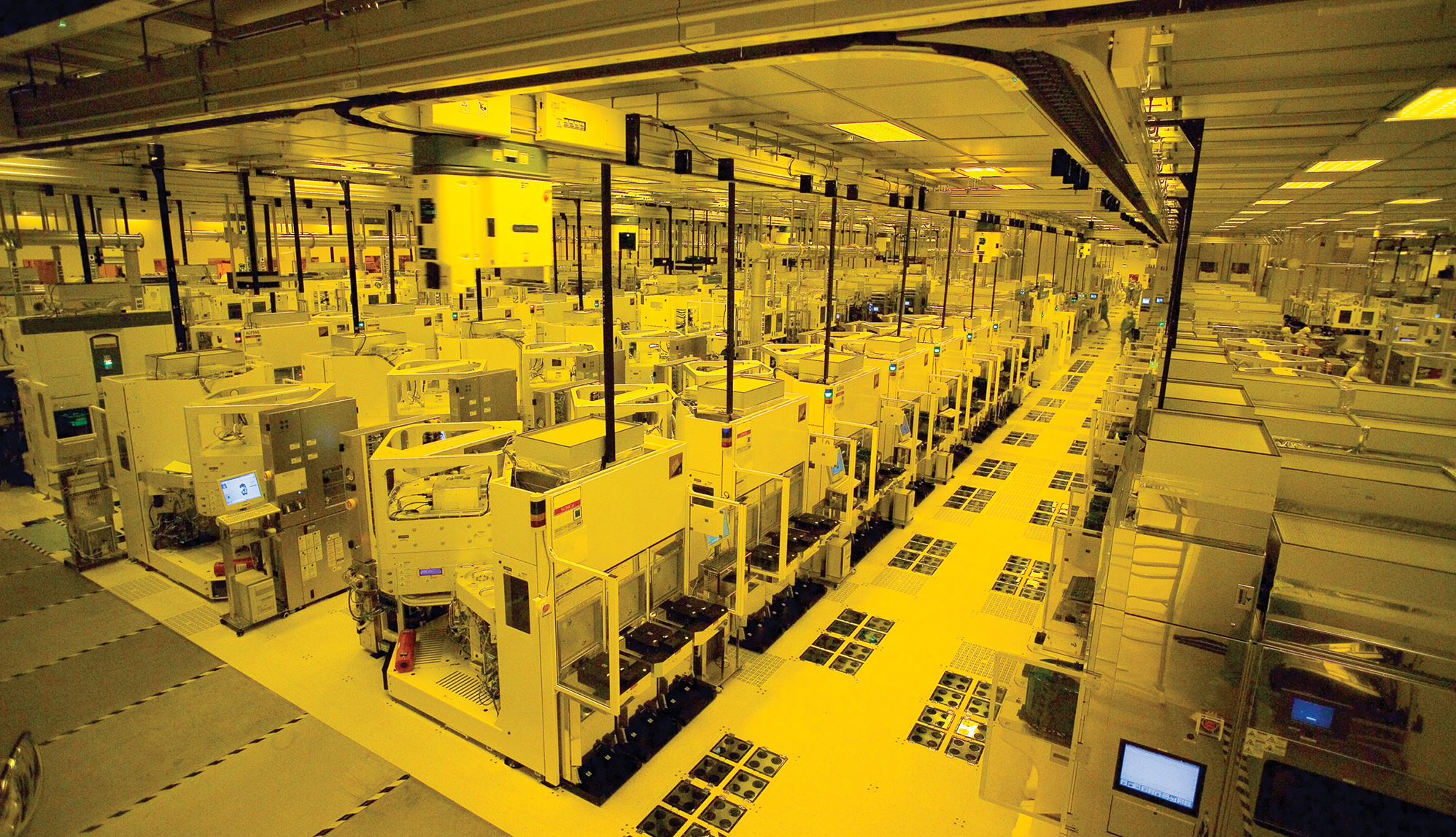

TSMC has reportedly asked its primary suppliers of chipmaking tools, including ASML, to hold off on delivering advanced wafer fab equipment due to uncertainties in customer demand and setbacks it faces with its Fab 21 in Arizona. The information comes to us courtesy of a Reuters report that cites two sources with knowledge of the matter.

The report does not explicitly disclose which tools are delayed. However, since it mentions ASML, we imagine that the world's largest contract maker of chips wanted its partner to push back the delivery of lithography scanners, which are among the most expensive tools installed in the fab.

TSMC is currently building several fabs, including two leading-edge facilities in Taiwan and one in the U.S. In addition, the company is constantly adding tools to existing fabs to boost their production capacity. We imagine that the company would slow delivery of new tools to Fab 21 in Arizona due to its setbacks and some of the scanners to existing fabs due to uncertainties with customer demand.

ASML, the world's largest maker of lithography scanners, has been directly impacted by TSMC's decision. Despite acknowledging some order delays in an interview with Reuters last week, ASML's CEO, Peter Wennink, remains optimistic, viewing the situation as a short-lived management challenge. Notably, ASML still projects a robust 30% sales growth for the year.

TSMC has chosen not to comment directly on the situation, instead pointing to previous remarks by its chief executive, C.C. Wei. Previously, Wei highlighted a weakening economic environment and a trend of customers becoming more conservative, factors that might have influenced the company's current stance.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.

-

TechieTwo Consumers that are struggling to buy food, gas and pay the rent due to high economic inflation and interest rates might be why demand is down.Reply -

InvalidError Fewer orders or delayed deliveries to TSMC on TSMC's request means more equipment sooner for everyone else still in the back-order queue.Reply -

ASMLHandler Reply

I have no idea where you get your info from but, TSMC North Phoenix has not slowed down on receiving ASML and Applied Materials equipment. I have been picking up directly at LAX and delivering the latest DUV systems since the beginning of Jan 2023. They actually have 2 more machines coming in this weekend LAX Saturday 7/16 and Sunday 7/17 at Mesa Phoenix Airport. I see what machines are going where and when. TSMC has been receiving almost monthly a new machine from Veldhoven, Netherlands. Texas Instruments Richardson TX is doing well. Their additions to their Sherman Fab are coming along with ASML delivering early next year. Samsung Taylor Texas is coming along too. TSMC is its own problem. Their not used to working with Unions and are creating problems that Intel Chandler just down the street is continuing to add another Fab with No issues. Between Phoenix and Texas both are busy the rest of the year getting product from ASML.Admin said:TSMC asks to delay delivery of chipmaking tools because of demand uncertainties and Fab 21 setback.

TSMC Asks Partners to Delay Fab Equipment Deliveries: Report : Read more -

exposureTruth The real reason is because American companies are disrespectful to the company's property. They vandalize the equipment that cost millions of dollars, they sleep on the ground an waste time, they don't follow clean room policy's. I'm not surprised why taiwan want more Taiwanese to be working there. They do the work without complain.Reply