Water-Soluble PCBs Are Major Step Towards Recyclable Electronics

You don't want any water close to your working electronics anyway, so why not take advantage of that?

If our technological evolution has one shadow, it's environmental sustainability. Every year, gigatons of deprecated electronic materials are incorrectly disposed of, leading to lost opportunities to recover rare precious metals while simultaneously risking ecological damage. To curb the rising amount of electronic waste, semiconductor and PCB expert Infineon partnered with Jiva Materials to explore the company's biodegradable, water-soluble PCB design. Soluboard - the board that can be dissolved - is here.

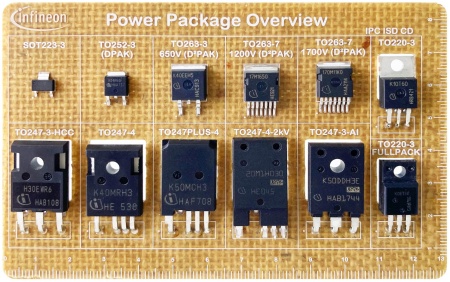

Instead of the traditional glass-based fibers and chemicals used in common PCB materials, Soluboard tech uses natural fibers that are naturally biodegradable. These fibers are then enveloped in a non-toxic polymer (which is to say, a spray-on plastic solution) that completely dissolves in hot water, allowing the environment to start composting the fibers that compose the PCB's structure itself. Besides the direct environmental sustainability gains from not building up Babel towers of disposed electronics, this degradable PCB also allows for the appended electronics to be later removed and recycled without the risk of secondary damage.

"For the first time, a recyclable, biodegradable PCB material is being used in the design of electronics for consumer and industrial applications – a milestone towards a greener future," said Andreas Kopp, Head of Product Management Discretes at Infineon's Green Industrial Power Division. "We are also actively researching the reusability of discrete power devices at the end of their service life, which would be an additional significant step towards promoting a circular economy in the electronics industry."

Circular economy, in this case, refers to the dream of a virtuous recycling, well, cycle, where components and materials used for new electronics are sourced from already-existing materials. Besides the obvious monetary advantage of this approach, the secondary benefits of reducing dependence on newly extracted raw materials are reduced - something that might help the Western chip manufacturing industry from being held at the throat by Chinese-imposed rare earth export restrictions. A circular data economy is precisely what AI companies such as OpenAI are attempting to solve with their research on recursive training. It is something most other industries are trying to get at as well.

Soluboard’s plant-based PCB material is made from natural fibers, which have a much lower carbon footprint than the traditional glass-based fibers. The organic structure is enclosed in a non-toxic polymer that dissolves when immersed in hot water, leaving only compostable organic material. This not only eliminates PCB waste, but also allows the electronic components soldered to the board to be recovered and recycled.

"Adopting a water-based recycling process could lead to higher yields in the recovery of valuable metals," said Jonathan Swanston, CEO and co-founder of Jiva Materials. "In addition, replacing FR-4 PCB materials with Soluboard would result in a 60 percent reduction in carbon emissions – more specifically, 10.5 kg of carbon and 620 g of plastic can be saved per square meter of PCB."

For now, Infineon is still testing the PCBs in non-critical deployments, such as in demo and evaluation boards - the rapid-fire yet materially costly iteration on prototyping. The company has already produced three PCB designs based on the material, which have resulted in more than 500 PCB boards being built on the technology, one of which is to be applied in refrigerator designs.

500 showcase PCBs built from only three base designs should give you an idea of the environmental benefits ingrained in the tech.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Infineon hopes to eventually scale the usage of Soluboard for its business lineup, representing another tick on its attempt to follow the European Commission's "Green Deal" program - which aims to achieve climate neutrality by 2050.

Francisco Pires is a freelance news writer for Tom's Hardware with a soft side for quantum computing.

-

brandonjclark Maybe if there was a removable film or something that made it soluable after use.Reply

I know there are some sweaty nerds out there breathing hard over their case trying to get a screw down, lol! -

rluker5 There's a lot of humidity in a lot of the world.Reply

Unexpected fires aren't environmentally friendly. -

USAFRet Brings a whole new meaning to the question:Reply

"I spilled some water on my PC. Is it going to be OK?" -

brandonjclark Wait, I got it!Reply

Why not water-FORMED PCB's?!?!?!

We could lend a few drops to a folded up mess and watch it expand into form like one of the Magic Grow Water Animals! -

Eximo I prefer IBMs water powered concept. Why use power traces when you can use conductive coolant lines?Reply

Still, first thing I thought of was, how hot this water has to be. Because a 95C CPU is really close to boiling... -

salgado18 Reply

Intel didn't like this...Eximo said:I prefer IBMs water powered concept. Why use power traces when you can use conductive coolant lines?

Still, first thing I thought of was, how hot this water has to be. Because a 95C CPU is really close to boiling... -

mac_angel yea, I see a lot of problems with this. Custom Water loops, sweating over it, as someone mentioned, humidity.Reply -

LabRat 891 This is dumber than PCW Cardboard Chassis/enclosures/cases.Reply

Honestly, I see more applications for this technology in espionage than consumer products. -'bout the only field 'self-destructing' devices are actually warranted. -

HyperMatrix It could work if they replaced the encasing polymer with one that isn’t water soluble but that requires liquid with a certain additive to break down. As it stands it’s completely useless and not worth a 60% carbon reduction.Reply -

InvalidError Making PCBs out of something that reacts with water sounds problematic when ultrasound washing is usually part of the manufacturing process to remove flux and other residue along the way.Reply

It would make more sense to search for polymers that are soluble in things that don't occur under normal operating and manufacturing conditions such as supercritical CO2.