Tom's Hardware Visits PCPartner In Dongguan, China

Have you ever wondered where your graphics card came from? There's a good chance it’s made by PCPartner in China. Zotac, PCPartner’s in-house brand, invited us on a tour of its factory in Dongguan, China, right after Computex, and we couldn't pass it up.

Freshly-Baked Cards

Once they’ve been baked, the cards leave the oven and are then whisked away to a visual inspection.

Eyeball, Mark I

Using a stencil, workers check that all the components are in the right place. They also remove superfluous solder and other residue. To complete this check, all cards are additionally subjected to a quick laser scan.

X-ray Vision, Now In 3D

To ensure the quality of the solder points, spot checks of card batches are conducted in this 3D X-ray machine. PCPartner boasts that the entire plant has a defect rate of fewer than 100 cards per million, or 0.01 percent. Of course, it's to PCPartner's benefit to keep defects as rare as possible. More failures would certainly lead to costly returns, and possibly a loss of confidence among the customers that PCPartner supplies. By the way, that failure rate does not apply to board components, since PCPartner can’t influence their quality.

Of Separation And New Connections

We continued our tour at another assembly line, which was incidentally also producing a different model of card. Since the procedure is the same, we’ll just continue our commentary and act as if nothing’s changed. Front-left, you can see the twin boards were just separated into two individual cards, their edges getting smoothed off in this snapshot. Meanwhile, assembly continues on other cards in the background. That takes us to our next step…

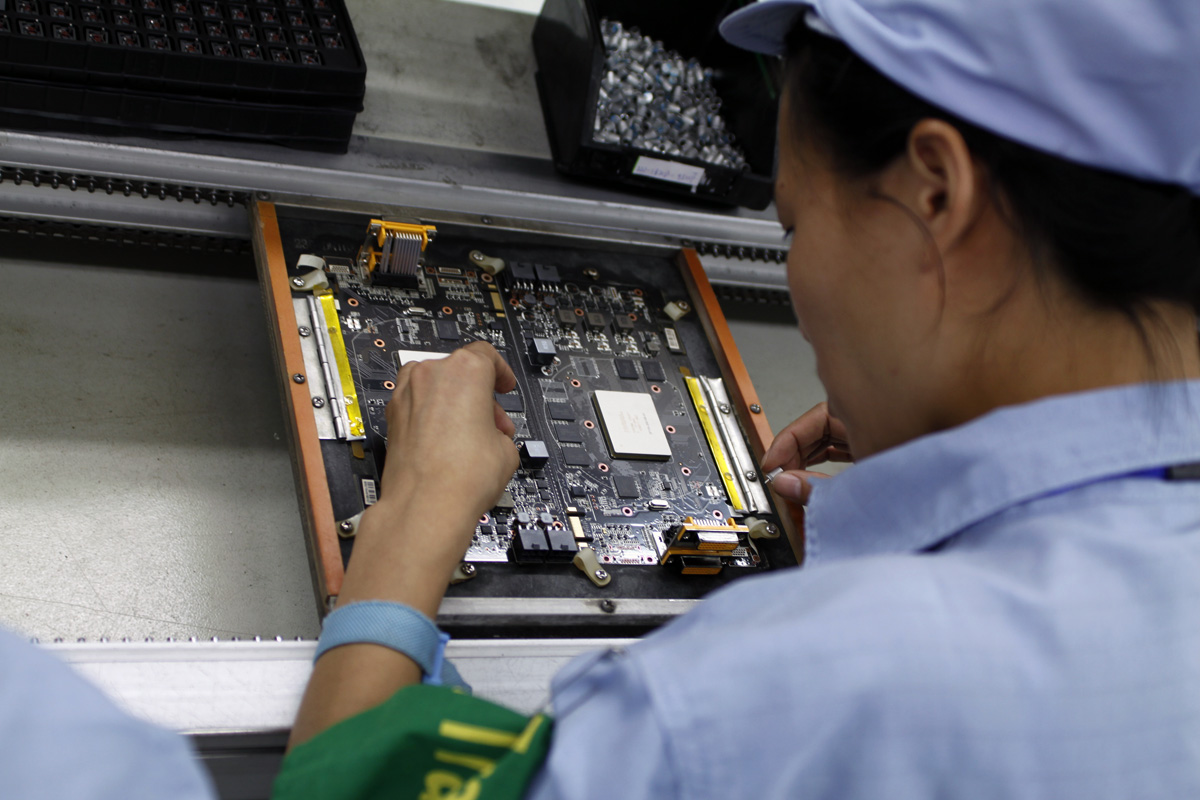

A Puzzle Called PCB

…which consists of workers mounting capacitors, PCIe power connectors, display outputs and, of course, the GPU itself. This is the epitome of assembly line work, where every station repeats the same steps over and over and over, always placing the same components in the same space.

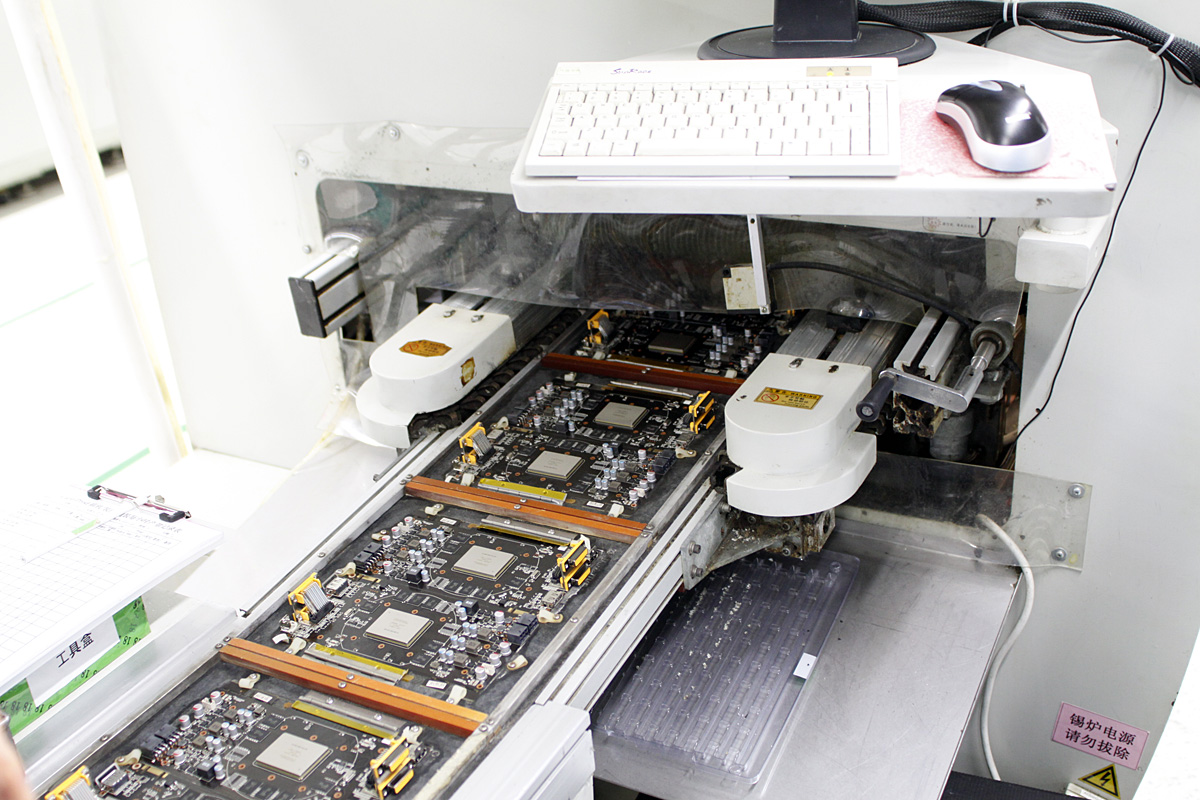

Need Solder? Apply Within!

So far, the components have only been snapped onto the PCB. The next machine down the line solders them in place.

Snappy Solder

Solder applied, the PCBs leave the automatic soldering machine. All parts are not fixed firmly in place, and the cards are theoretically ready for duty. Granted, running them without a cooler wouldn’t exactly be a good idea.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Look, Clean, Stack, Cart

Robots may be good at doing certain jobs, but it still takes a human eye to check the final result. Was the solder applied too thinly? Is there a dab of paste where it doesn’t belong? Workers check every single card for those issues and correct them as needed. After all, you wouldn’t want your new $500 board to short out the first time you fire it up just because some errant solder was crossing a couple of wires. Finally, the cards are stacked into carts once more and then wheeled to the next assembly line for finishing touches and some testing.

Keeping Cool And Connected

Once more, we switch to a different production line, which means we are now tracking the progress of a third type of card. Step by step, the bare board is turning into something recognizable as a finished graphics card, as its cooler and I/O panel are added.

Flash? Check!

Physically, the card is now complete. It still needs a current firmware, though. After it’s flashed to the current release, each card also has to pass a battery of quality assurance tests. But we’ll get to that in a moment. Here, we can see three workers supplying up to three cards at a time with a new BIOS. According to Zotac, each card spends less than a minute at this stop. Again, this is repetitious assembly work at its finest.

-

soccerdocks Get rid of the "read more" button and just make the text appear all the time and I'll consider actually reading this article.Reply -

jestersage It's pretty fair wage over here (not exactly in Dongguan) especially if you are single. For comparison, thing of $2 Big Macs. I figure those on campus can write off rent, electricity and water (yes, we pay for tap) from their monthly bills as well.Reply -

steelbox "We were told that if PCPartner didn’t let them work overtime, most would actually quit and look for other employment."Reply

Right... let me correct that.

"We were told that if the employee didn’t accept working overtime, most would actually be fired and forced to look for other employment."