Here’s a behind the scenes look at how a CPU air cooler is made — DeepCool gives a start-to-finish tour of its main production facility

You’ll never take cooling for granted after seeing how complex the making is.

If you own a gaming rig, there’s without a doubt a big chunky fan in the middle of your computer just sitting there blowing air. That’s attached to what's called a CPU air cooler, and while even the most rookie of PC enthusiasts know that its job is to cool down your CPU and keep temperatures in check, the majority of us have never really given much thought to how that massive block of cooling hardware actually comes together behind the scenes.

Well, it seems like today’s the day. Over on the YouTube channel SatisFactory Process, which is all about China’s top manufacturing facilities, a video has been uploaded showcasing DeepCool’s main production facility in Beijing. It gives complete insight into how some of their premium CPU air coolers are put together, and shows how raw materials, precision machinery, and the human touch all come together to help bring your CPU temps down.

The manufacturing process starts with copper tubes, which form the backbone of today’s coolers, whether for a CPU or a graphics card. Often called 'heatpipes,' these are made from scratch entirely on site, and it’s the part of the process that involves the most significant use of machinery. And that’s just step one. There are over 15 different steps, including automated filling, precision cutting, multi-stage cleaning, and packaging, each one as intricate and complex as the next.

Manufacturing a top-end CPU air cooler takes more than just machines

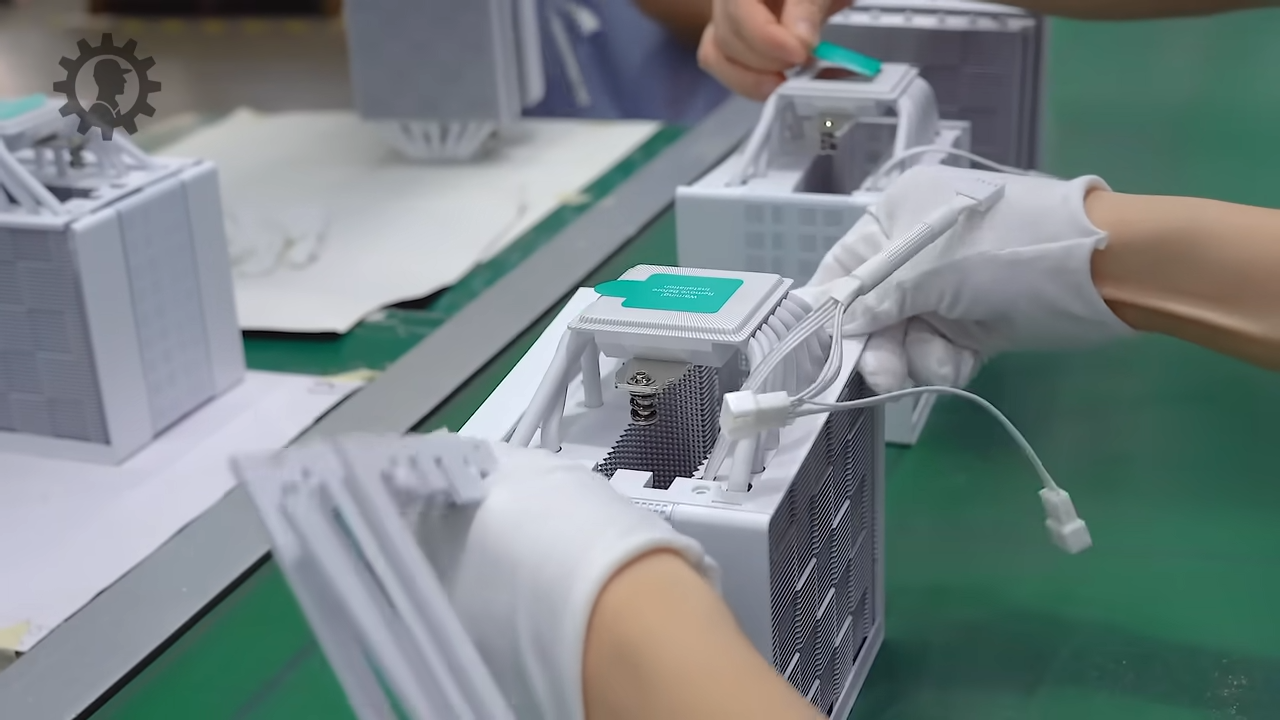

Not all the manufacturing process is robots and machines. In fact, when it comes to the stage where the vapor chamber plate is prepared for bonding to the heat pipes, the human hand is the preferred choice. This is because it’s a laborious, manual process that involves applying protective film and solder paste before the plate is passed on to be attached, where even a 0.1mm misalignment could potentially impact performance.

So, as much as there are machines out there churning out hundreds of motors for the fans, there’s also a long line of workers connecting wires to them, testing, sticking, fixing, and packaging it all together. And this doesn’t just apply to air coolers but pretty much every component inside your gaming PC, handheld, console, and so on.

That being said, the entire video runs for about half an hour, but one thing to admit is that it’s surprisingly relaxing to watch. There’s something soothing about seeing everything unfold in harmony, without any loud narration or background music blaring in your ears.

Follow Tom's Hardware on Google News to get our up-to-date news, analysis, and reviews in your feeds. Make sure to click the Follow button.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Hassam Nasir is a die-hard hardware enthusiast with years of experience as a tech editor and writer, focusing on detailed CPU comparisons and general hardware news. When he’s not working, you’ll find him bending tubes for his ever-evolving custom water-loop gaming rig or benchmarking the latest CPUs and GPUs just for fun.

-

Jabberwocky79 Wow, that's incredible to see. Isn't DeepCool one of those brands that can't sell to the US anymore? Or did I miss an update?Reply