AMD Ryzen 7 1800X CPU Review

Why you can trust Tom's Hardware

Results: Power Consumption And Temperatures

Power Consumption

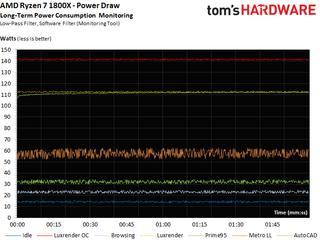

We measure voltages and currents directly on the motherboard using the existing sensors and calculate the power consumption based on them. To achieve valid results, we take the average of the two-minute measurements for each of our scenarios and use our low-pass filter and analysis software to get rid of any extreme peaks or valleys.

These aggregated results are a lot more telling than extremely short peaks due to the latter’s very brief nature. We took a look at a total of eight different scenarios.

Some of the applications consume more power over time. This is due to the CPU heating up. We found that the difference between a cold and fully warmed up CPU can be up to 3W. If these 3W are interpreted as leakage currents, then this is actually a very good result.

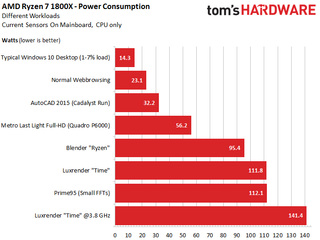

We took the average of the power consumption curves after the CPU had reached its full operating temperature and put the results in a bar graph to provide a summary.

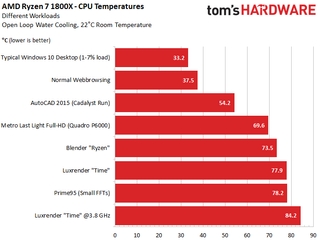

Temperatures

Keeping the processor cool is more important than ever due to AMD’s XFR and related technologies. Lower temperatures have the potential to translate to higher clock frequencies. This is why we used a custom water cooling loop, which was very much needed during the rendering benchmarks with all cores running at 3.8GHz.

The CPU diode that AMD uses should be closest to the Tpackage value, which is the part of the CPU that has to endure the most heat in the long run. Tcore doesn’t matter as much anymore due to the massive areas that the cache takes up these days.

Infrared Video and CPU Temperatures

We decided to make an infrared video and spare no expense. Shooting it also required a degree of bravery, since we had to take off the CPU cooler to record it. We installed the camera so that it was pointed downward directly facing the CPU’s heat spreader. The camera’s distance from the processor was a function of the camera’s focal length and efforts to avoid any reflections caused by the camera’s lens and the metallic surface of the heat spreader.

We also applied a total of six thin layers of special lacquer used in board manufacturing to the heat spreader. This is necessary because the pure metal’s temperatures can’t be measured accurately due to its emissivity changing along with its temperature. After the usual calibration, we recorded the following video.

It’s easy to locate the processor’s die this way. It appears to be long and narrow in shape. The heat spreader’s uniform heat distribution indicates that there’s sufficient contact between the die and the heat spreader, especially in light of the fact that we weren’t able to assert any pressure on the heat spreader while we were recording the video. We recently discovered that the die is soldered to the Integrated Heat Spreader (IHS), which is typically much more efficient than Intel's technique of using thermal paste.

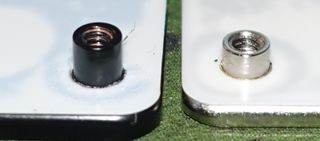

AM4 Kit Incompatibility

One of the hardware components that’s seen some changes is the AM4 motherboard’s backplate. It’s different in two very significant ways: The distance between the holes has changed and the threaded pins are longer. Even though AMD seems to have informed manufacturers of the first change, they apparently forgot about the second one.

We asked the manufacturers, and they confirmed that this is what happened. This means that if the original motherboard backplate’s used in conjunction with longer screws, then the cooler might not be held against the processor tightly enough.

The solution involves adding the needed millimeter by using either thick ring washers or suitable nuts. We’ll keep in touch with the manufacturers, since the problem doesn’t seem to affect all of the kits.

Current page: Results: Power Consumption And Temperatures

Prev Page Results: Scientific & Engineering Computations And HPC Next Page ConclusionStay On the Cutting Edge: Get the Tom's Hardware Newsletter

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Paul Alcorn is the Managing Editor: News and Emerging Tech for Tom's Hardware US. He also writes news and reviews on CPUs, storage, and enterprise hardware.

-

vrumor Well, at the very least, it is competition. Competition drives innovation and lower costs. Well done AMD.Reply -

kiniku Why did I feel AMD was hiding something? Understandably the "gamer market" is comparatively small. But couldn't AMD have designed a CPU that worked well in gaming/desktops and in data centers? Disappointing.Reply

(But I have a 5820K. The best Ryzen in the world would not have had me switch anyway.) -

xryanx123 Bias review as always. Most of your information is obviously screwed up. How do you get 4.0ghz at 1.45v. When that's not even an overclock for the chip (not really at least compared to stock) yet you're already pushing 1.45v? You're tailoring your articles for the uneducated. Duck off tomsReply -

captaincharisma in the end the best anyone can hope from AMD is that it spooked intel enough to lower its pricesReply -

ssdpro In a hurry to compare various site's gaming results, it appears differing sites are finding the same thing: gaming performance is acceptable but below 4c/8t Intel offerings. If you spend your day encoding or multi-thread benching this is a monster bargain.Reply

With the good and bad, I think we can all agree the good here is competition. There is some now. -

Pompompaihn All along AMD was claiming to equal/beat Broadwell-E in comparative tasks at half the price, and from another review that included Broadwell-E, it's done that. I don't recall ANY AMD press saying it was going to beat the 7700K in straight up gaming. So, target set, and hit. That's a win in my book. But now, need to see what they can do with the smaller core count chips and if they can scale frequency to be competitive in the gaming sector.Reply -

Dionisiatis Maybe i missed it but i would love to see a perf/dollar ratio comparison. Im sure Ryzen would occupy the top position, and it would also make it clear that AMD achieved extraordinary results in bringing such high performance to the average consumer that cant 700+ dollars for a CPU.Reply -

jackspeed @Dionisiatis the 7700K is cheaper then the 1800X so for gamers it currently is the best CPU. now games have yet to optimize for the new AMD architecture, so maybe soon it will be a different story.Reply -

Aspiring techie Your "Heating up AMD Ryzen" video on the Power and Temperatures tab is still private. I can't watch it.Reply -

Fails in gaming, and for multitasking stuff i got Xeon 14/28 who is doing all that encoding and other stuff for $300 on eBay.Reply

In my opinion AMD failed and they really pulled BS by fooling people into pre ordering but it turns out that in gaming sucks..