New chip crunch looming? Booming demand from Chinese chipmakers causing shortage of critical photomask element

Toppan, Photronics, and Dai Nippon Printing are struggling to meet the demand for photomasks.

Over the past few quarters, the global semiconductor industry has faced shortages of chip packaging components and advanced chip packaging capacity. Now, despite an overall economic slowdown, it faces a persistent shortage of photomasks -- a critical and complex component key to the chipmaking process. This situation is primarily fueled by the robust demand from a growing number of Chinese chip designers as US sanctions have fueled a chip production boom in China.

Leading photomask producers, including Toppan, Photronics, and Dai Nippon Printing, are operating at full capacity to meet demand from various Chinese companies. However, supply has still fallen short, leading to rushed orders at higher prices and an anticipated increase in photomask prices in the near future, reports The Elec. Additionally, in their financial reports, Toppan and Dai Nippon Printing have acknowledged the challenges.

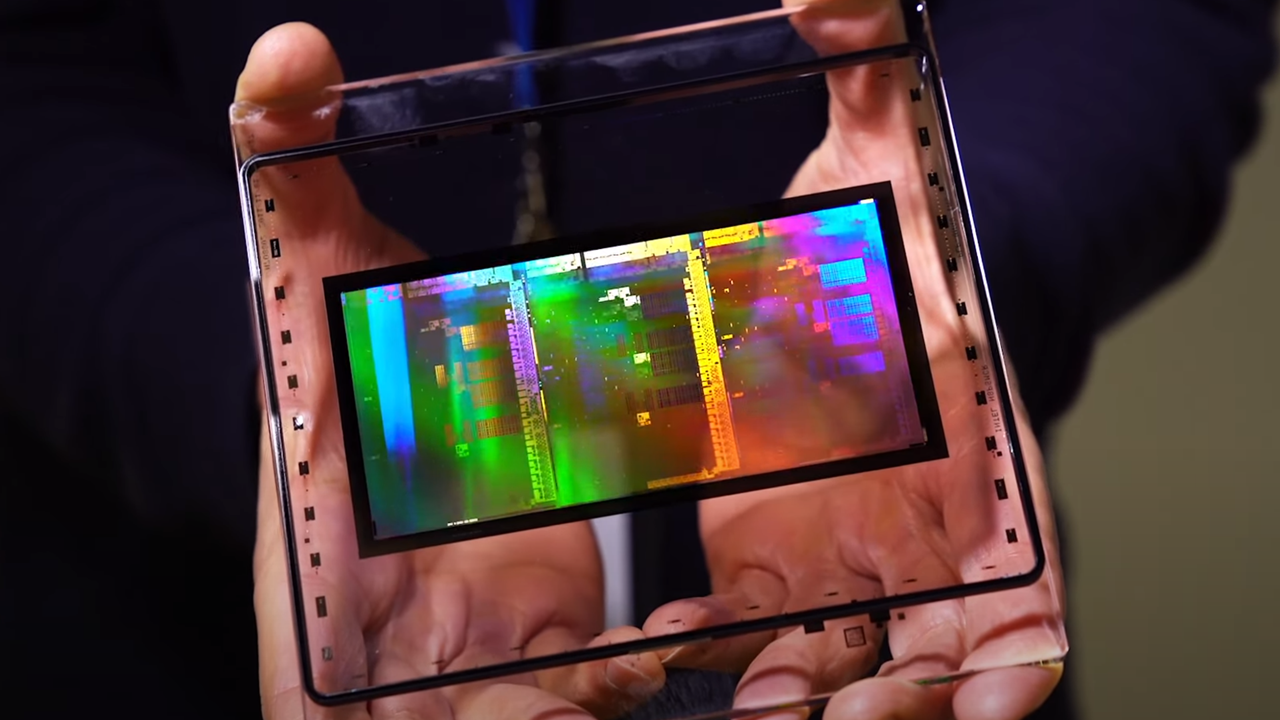

Photomasks are used to transfer circuit patterns onto silicon wafers during the lithography process, and they are an essential component of the chipmaking process. Photomasks are transparent chunks of quartz that have an imprinted pattern of a chip design and work much like a stencil — shining a light through the mask etches the design onto the wafer, thus creating the billions of 3D transistors and wire structures that comprise a modern chip.

The complexity of newer nodes and the advancement of chip technology directly impact the number of photomasks required. Each chip design requires multiple exposures to build up the chip's design in layers, but the number of photomasks used during the chipmaking process varies based on the chip. While older chip manufacturing processes might need around 30 photomasks to print intricate chip designs on wafers, the latest and most sophisticated ones often require between 70 and 80 photomasks. For instance, Nvidia says it takes 89 masks to create the H100 GPU, and some chip designs can even exceed 100 masks.

According to the report, the surge in photomask demand is primarily attributed to the rapid growth of Chinese semiconductor companies. In the past year, the number of fabless chip companies in China has skyrocketed to 3,243, largely due to the impact of U.S. sanctions. This growth has put additional pressure on the already strained photomask supply chain.

Recent technological advancements in the chip manufacturing process are contributing to the shortage. Chinese fab SMIC's introduction of the second-gen deep ultraviolet (DUV) 7nm process has intensified the demand for photomasks, as the process heavily relies on multi-patterning, which involves repeatedly exposing a single layer in order to create the finest of elements on the wafer. Naturally, this process requires more photomasks due to the increased number of exposures.

SMIC produces sophisticated processors, such as Huawei's HiSilicon Kirin 9000S, using its 7nm technology, with complicated designs requiring dozens of photomasks. Yet another factor affecting the shortage of photomasks is the adoption of extreme ultraviolet lithography by Intel, which used to rely solely on DUV in recent years.

Photomasks are also becoming more complicated as semiconductors progress to smaller nodes, with advanced methods like curvilinear lithography becoming more common with newer nodes. This technique addresses issues with diffraction, which essentially 'blurs' the design being printed onto the silicon. These photomasks counteract the impact of diffraction through complex mathematical operations that optimize the mask layout.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Despite efforts by manufacturers like Toppan to expand their global production capabilities, industry experts predict that the increased capacity will not be sufficient to meet the soaring demand. This imbalance between supply and demand is expected to lead to a price hike for photomasks in the coming year. In their financial reports, Toppan and Dai Nippon Printing have acknowledged the ongoing strong demand and the challenges it poses for the industry.

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.

-

evdjj3j "Photomasks are transparent chunks of quartz"Reply

Was this article written by a technology reporter or a local county newspaper reporter? I quit reading right there. -

bit_user Reply

Why so picky? I had no idea what they were made from. This is a general audience tech site, not tailored to engineers or covering just semiconductor production.evdjj3j said:"Photomasks are transparent chunks of quartz"

Was this article written by a technology reporter or a local county newspaper reporter? I quit reading right there.

Anton has been covering the semiconductor business for at least a decade, here and at Anandtech (and possibly elsewhere). It's possible he's gotten feedback to try and make his articles more approachable, as they can often be dense with jargon.