Some analysts believe Intel won't build out its German fab due to financial woes: Report

Or will it?

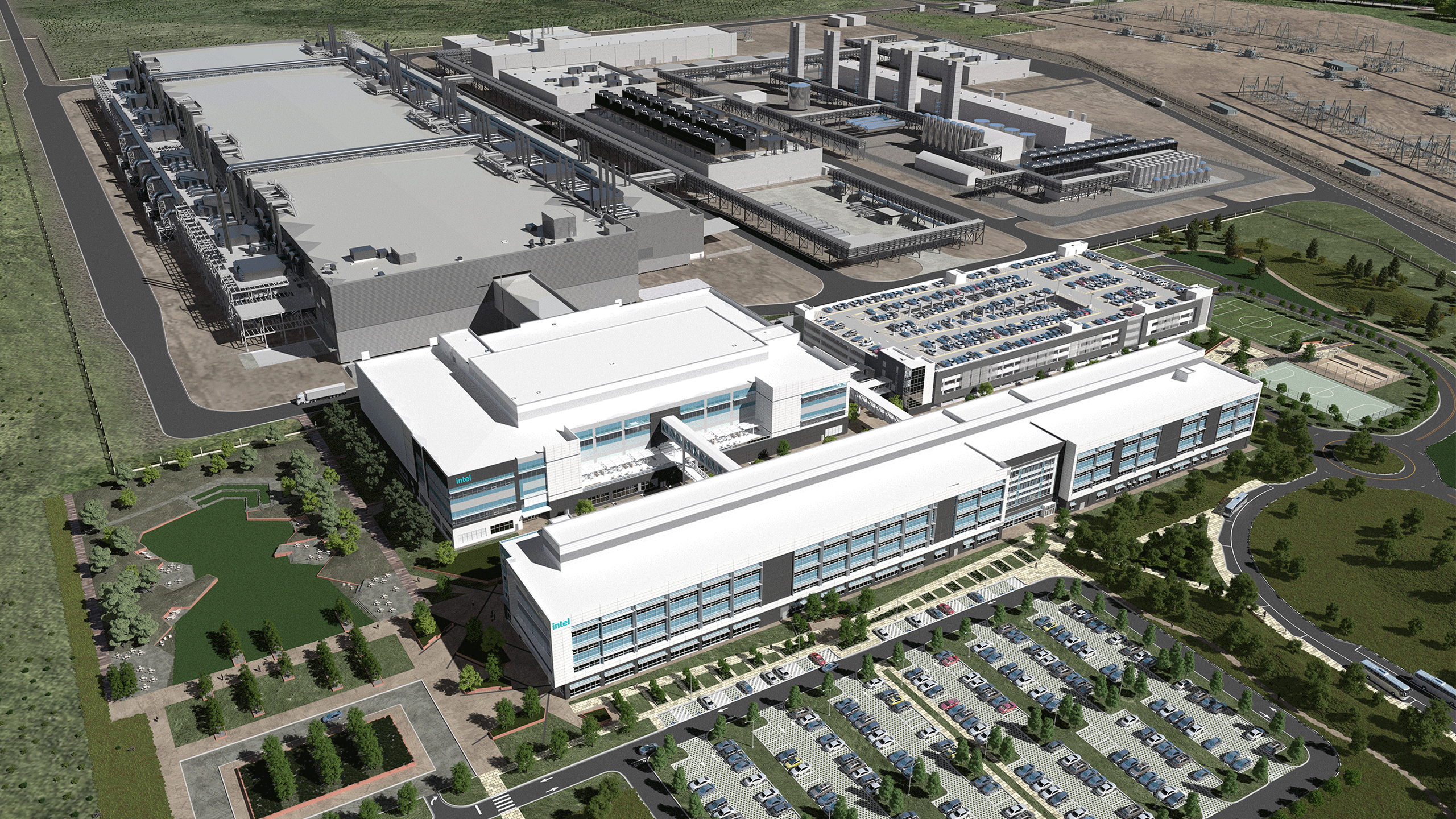

After Intel postponed a $30 billion investment in its fab near Magdeburg, Germany, to reduce its spending amid financial difficulties, the company could abandon the project entirely, reports Deutsche Welle. The development would be a major setback for Germany, which, like many other countries, wants to become a leading producer of semiconductors.

Alexander Schiersch of the German Institute for Economic Research (DIW) told Deutsche Welle that given Intel's current financial struggles, chances that it will come back to the Magdeburg project were no more than 50%. In an interview with DW, he highlighted several crucial components for Intel's future success.

First, the company needs to expand its customer base for its chips. Next, it must make its AI strategy work, which would help with the customer base. Lastly, Intel's cost-reduction measures must be effective to ensure its financial stability. If Intel fails to expand its customer base and its Intel Foundry unit fails to land orders from third-party clients, it won't need an additional fab in Germany. So far, the company has struggled to secure third-party clients for its foundry unit.

This delay is a significant setback for Germany. The project was expected to create 3,000 jobs, and the German government offered €9.9 billion in subsidies to support Intel's investment. It viewed this initiative as crucial for securing chips essential to industries undergoing digital transformation. For example, the fab could reduce Germany's reliance on Asian semiconductor manufacturers and bolster its automotive sector, which increasingly needs leading-edge processors. As a result, the delay adds to broader economic concerns in the country, as its industry faces increased challenges.

Intel's financial struggles are the reason for the delay. After the company lost $1.6 billion in the second quarter, it announced plans to cut 15,000 jobs, save $10 billion, and scale back other operations to regain profitability.

The delay in the Intel project has triggered a political debate in Germany over how to use the €10 billion earmarked for subsidies. Finance Minister Christian Lindner has suggested redirecting the funds to address a budget shortfall, while the Green party votes for investing it in climate initiatives. The German government has yet to settle on a decision.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.

-

Gururu In 2-3 years as postponed, sounds like it could go either way. AI bubble will have burst and there will only be 1 or 2 AI contenders at that point, one starts with A and the other with G. If Intel is still a dominant innovator in microprocessors at that point, then Germany will be fine.Reply -

DavidLejdar The automotive industry at large is actually quite slow in adopting lower nm and stuff. In particular, the in the media reported chip shortage came mostly down to a lack of chips from a specific wafer size, which has been last-gen for quite some time, didn't it? Like, the tech world moved on, and invested in entire new production chains, with larger wafers, while automotive companies were like: "Nah, we're good.", and didn't invest, what would have been a fraction of the yearly dividends paid out, to move on to the next gen of wafers. So they stuck behind, relying on the production of last-gen fabs, of which no new were build, while the production of e-cars increased (requiring more chips).Reply

Anyhow, as far as I am personally concerned, as head of state, Prussian that is, I would have keen interest in fine chips. In particular, there happens to be stuff like natural catastrophes, such as the particularly still ongoing floodings. And what I want to provide the emergency services with, is to be able to scan e.g. a flooded town, to create a virtual 3D map, on which there will be already marked if someone sits on a roof, for example, and to use the map also to coordinate rescue efforts, like giving a boat driver a route to that building. And that's quite some stuff needed in real-time, that comes with the need for data processing capability.

That in itself may perhaps not sound interesting at all, from a business point of view, and on a stock market, where it may seem that everyone tries to grab as much money as possible, to then have even more money! But there is more. Such as, that I would support production of medical equipment, to be used e.g. with hospitalship fleet (for humanitarian expeditions), and to supply hospitals e.g. in Africa with, for free like (I mean, free for them - but here it would be part of the budget, including argument for parliamentarian approval, that the money spent goes largely to employees here - like a subsidy basically, but with some actual result for it). -

thestryker Reply

Yeah the automotive industry seems to like all the separate controllers so most of the chips going into cars were using nodes exclusively on 200mm wafers. A lot of those either cannot be manufactured on smaller nodes or would simply cost too much relative to what they are. Due to the low margins on the old nodes it's quite literally not financially viable to spin up a new fab using those wafers. It's also not viable to make a new "old" node on 300mm wafers which meant the supply has a maximum that cannot be passed. This is one of the big reasons why Intel wanted to buy Tower Semiconductor as they have several active 200mm fabs.DavidLejdar said:The automotive industry at large is actually quite slow in adopting lower nm and stuff. In particular, the in the media reported chip shortage came mostly down to a lack of chips from a specific wafer size, which has been last-gen for quite some time, didn't it? Like, the tech world moved on, and invested in entire new production chains, with larger wafers, while automotive companies were like: "Nah, we're good.", and didn't invest, what would have been a fraction of the yearly dividends paid out, to move on to the next gen of wafers. So they stuck behind, relying on the production of last-gen fabs, of which no new were build, while the production of e-cars increased (requiring more chips).

It does seem like the shortage has pushed the automotive industry forward into a more centralized design with fewer overall chips but more performant ones. I want to say they're referring to these as "software-defined" cars. -

sjkpublic Given the turmoil in Ukraine and the Middle East it is no wonder that this article appears. Intel already stopped the fab in Israel. Germany is closing its borders. Intel building a fab in Germany at this time would just be another blunder in a long list of blunders.Reply -

newtechldtech It is not about Money , it is about the coming war with Russia ... If Ukraine turns bad , Germany will be the frontline. and investing in Germany now is a huge RISK , until Russia - Ukraine war ends or leads to greater war.Reply