Taiwan's New Economy is Sink or Swim

Cut Through Motherboards: Cross Section Test

The manufacturer cuts parts out of working products to analyze their cross section.

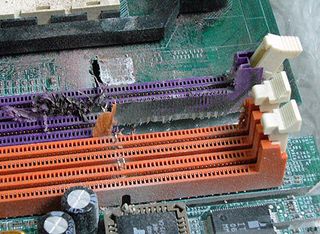

The cross section test is not very common for motherboard or graphics cards builders, but it is an important tool to verify product quality. The manufacturer cuts parts out of fully workable components to analyze their cross section: Especially the welding quality of solder points is of high interest, as it is something that has become very difficult to inspect in the case of BGA (Ball Grid Array) packages, as these feature hundreds of solder balls that cannot be inspected optically. After cutting parts out of a PCB product using a metallographic cutter, these are inspected using optical microscopes.

Any part of a PCB product can be used - depending on what you would like to analyze.

The cut is placed into a transparent medium for long-term storage.

Optical microscopes are used to analyze cross sections of solder balls, IC pins or pass-through holes.

This is a cross section microscope image of a BGA solder point.

Stay on the Cutting Edge

Join the experts who read Tom's Hardware for the inside track on enthusiast PC tech news — and have for over 25 years. We'll send breaking news and in-depth reviews of CPUs, GPUs, AI, maker hardware and more straight to your inbox.

Current page: Cut Through Motherboards: Cross Section Test

Prev Page Optical Inspection Next Page Shoot At Your ProductsMost Popular