I built a PC With MSI's Project Zero Motherboard: Moving all the ports to the back for a cleaner, quicker build with better airflow

Hiding all your cables looks great, and is easier than fishing things through to the front. But there's some room for refinement here.

In case you haven't heard, multiple motherboard makers have been busy designing boards that move all of the typical data, power, fan and RGB headers and connectors to the back of the motherboard, making for an ultra-clean PC interior. Theoretically, at least, it should also allow for better airflow because there are no cables in the case to cause turbulence.

Maingear holds the patent for this layout in the United States. But Asus is partnering with Lian Li and XPG (among others) and seems to have settled on the name BTF (Back to Future). Gigabyte, partnering with Maingear, launched its Project Stealth in 2022. And now MSI (also in partnership with Maingear) is offering up its own take, dubbed Project Zero, which encompasses a few motherboard models and a Pano M100R PZ case.

In advance of CES next week, MSI sent us its B650M Project Zero AMD motherboard $229, the previously mentioned Pano M100R PZ case ($109), its MAG CoreLiquid 240R V2 AIO cooler, and an A850GL PCIE5 power supply ($119 for the black model, though the white model we were sent isn't yet available in the US). I used these parts, along with some others, to build a mostly white system. The nearly cable-free system interior looks great once the system is built. And in many ways, having all the connections at the back makes plugging things in easier. But moving all the cables at the back introduces its own complications. Plus, having a board with a bunch of easily bent pins on the back makes it awkward to handle until you get it in the case, and will likely change the order of the steps you take to build a PC. As you might expect given this is still essentially a first-generation product, there's plenty of room for refinement.

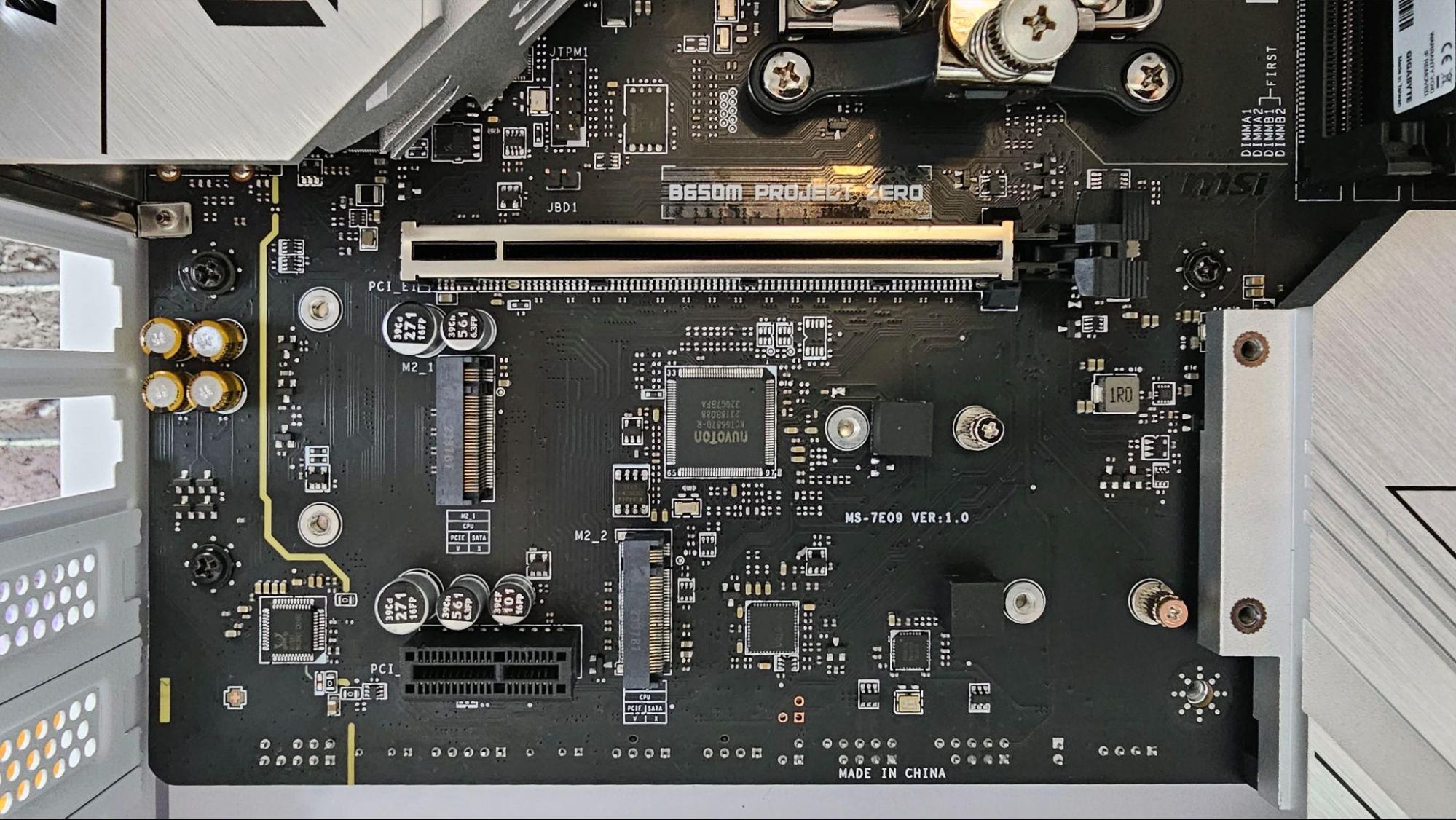

B650M Project Zero Motherboard

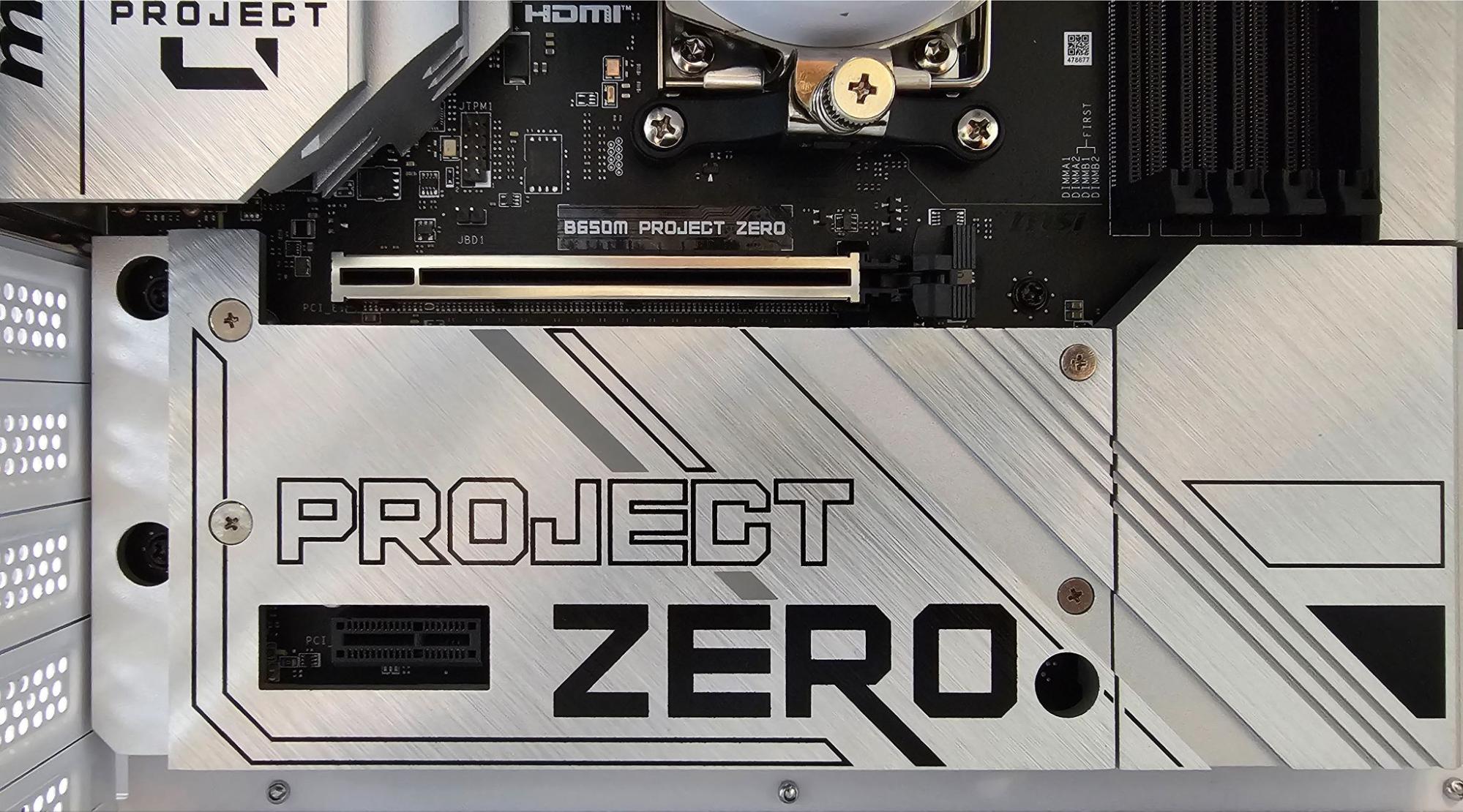

The B650M Project Zero is a Micro ATX motherboard that's slathered in metal heatsinks and shrouds. The four DDR5 RAM slots, the CPU socket, and the x1 and x16 PCIe slots are accessible, but to get to the two PCIe 4.0 M.2 slots, you'll need a screwdriver to remove the plate that houses the Project Zero lettering.

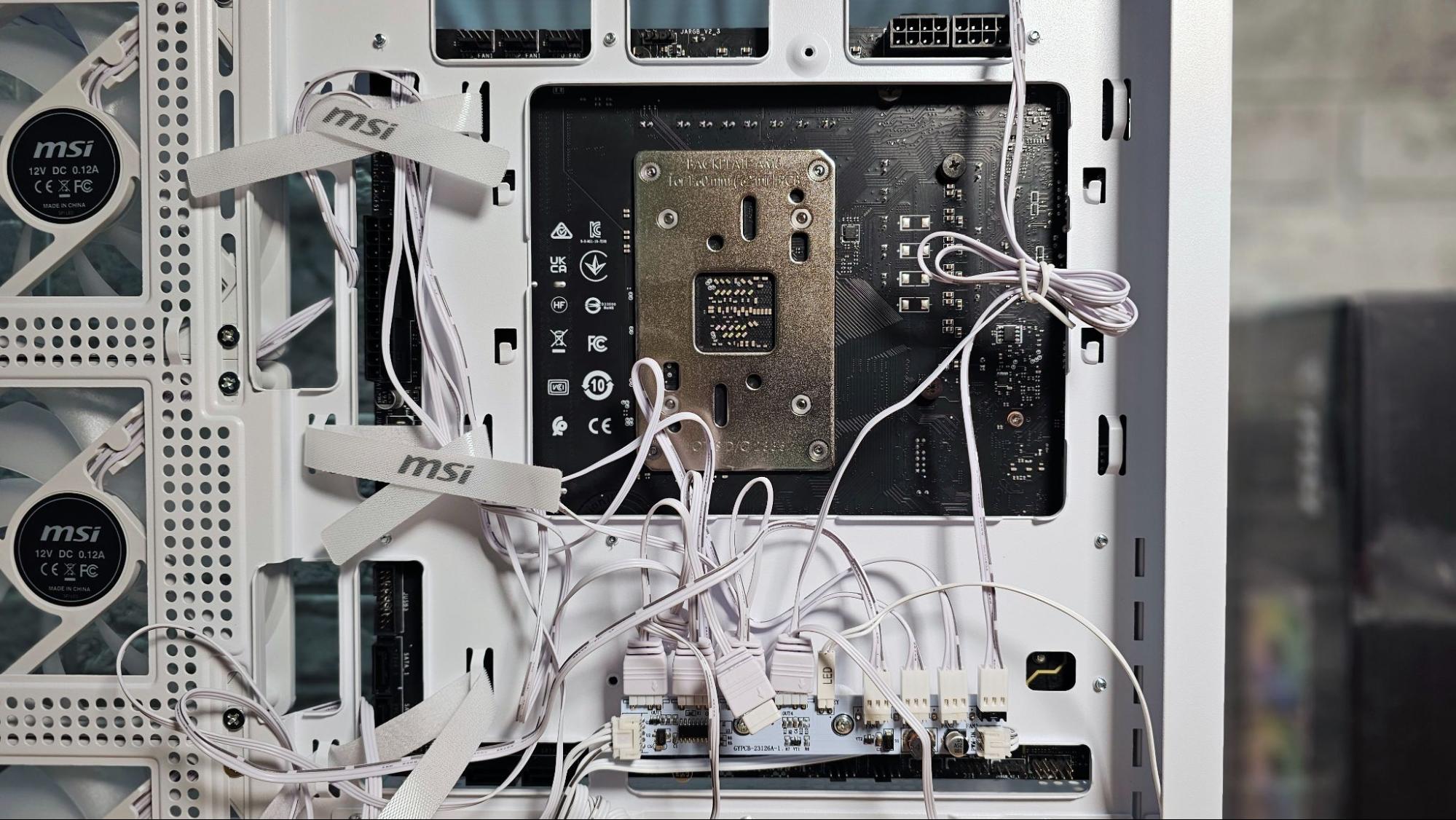

On the back side is where you'll find every other connector on the board, distributed around three of the four outer edges. I didn't have any major issues with the connector locations. But having a bunch of exposed fan, header, and RGB pins meant I mostly didn't feel comfortable placing the board on a table or anti-static bag with its backside down.

And I definitely wouldn't feel comfortable installing the CPU, RAM, or cooler (which entails pushing down on the board with some force) without this motherboard installed in the case for fear of bending or breaking pins. So if you're in the habit of doing that when building a system, expect that order to change.

The one thing I would potentially consider doing before installing one of these boards in the case is installing the SSD first. But on this board, that involves loosening two screws and removing a large metal plate, so you may want to do this after putting the board in the case.

That's what I did, but mostly because I forgot about the SSD specifically because the plate with the Project Zero logo hid the drive slots so well.

The MSI Pano M100R PZ Case

One of the biggest issues with any of these backside-oriented motherboards is going to be the limited number of cases that they will work with, at least for now. Because a case needs to have lots of extra cutouts on the motherboard tray for ports, no standard case will work. You'll need a case specifically designed for these boards, and the Pano M100R PZ (Project Zero) case that MSI sent our way is the first standalone retail case we've seen.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

As its name implies, the Pano is a Micro ATX / Mini ITX case with three glass sides so you can get a panoramic view of your Project Zero interior in all of its cable-free (or nearly, more on that soon) interior. The case is reminiscent of the Hyte Y60, with a bit more of an aggressive look thanks to a front glass face that bulges out at an angle, rather than a straight 90 degrees.

The Pano also comes with four RGB fans, three in front of the motherboard area for intake and one at the back for exhaust. None of these glass-happy cases are going to be the best in terms of airflow, but the inclusion of three intake fans is a nice touch, especially given the case's $110 price. There's also an included fan and RGB hub behind the motherboard that lets you control the lighting via a button on the front / side ports.On the foot of the case, you'll find the usual couple of USB ports and an audio jack.

So Many Cables, but So Easy to Hide

Much of the build process with the Project Zero board and Pano case, like installing the core components, felt pretty much like any other build. Installing MSI's 240mm AIO cooler was made easier by the fact that the top of the case slides off after you loosen two thumb screws.

You will want to be extra careful not to bend any pins when placing the motherboard into the case. But so long as you get the board close to the case's pre-installed standoffs, board installation should also feel pretty familiar if you've built any desktop before. All the rear connectors will just slot into their cutouts on the case.

When I got the board installed and took a look at the backside, I was worried at first that I'd have a problem installing the cooler.

But it turns out there's a removable panel that serves as a mount for two 2.5-inch drives or a single 3.5-inch drive. Also, the AIO mounting mechanism for the board's AM5 socket doesn't require adding a backplate anyway.

With the four RGB fans pre-wired to the internal hub, though, there are a lot of cables here even before you start adding anything else. And the cable clutter quickly starts to feel like it's out of control once you start plugging everything into the back of the board.

Plugging pretty much every single cable save for GPU power into the back of the motherboard is, perhaps unsurprisingly, the strangest part of building with this board and case. It saves a fair bit of time and effort not having to feed things through holes from one side to the other, but the back of the board quickly becomes very busy with cables snaking all over the place. But the Pano case has three pre-installed cable straps that you can pretty easily jam most of the wires into to keep them under control. And at least with the R850GL power supply, there is enough room to shove what amounts to a lot of power supply cable slack in front of the PSU. If you were installing a large power supply, this might become an issue. After a few minutes of hasty bunching, stuffing, and wrapping, what looked like a nightmare of cable clutter was at least reasonably under control. There were still a couple of pain points, though.

The case's USB 3.0 connector, seen at the bottom of the image above, is smartly angled, so its stiff cable doesn't get in the way of closing the side panel. But for some reason (probably to do with power), MSI didn't do the same with the USB 3.2 front panel connector, which sits above the 3.0 connector. It protrudes straight out from the back of the board enough that, while it doesn't keep the side panel from closing, the plugged-in cable makes for a bulge in the side panel when the case is closed. And it also means the side panel presses up against the cable for that 3.2 connector in a way that probably isn't great. But an MSI rep told me this was a design oversight that the company will rectify in the short term with a right-angle adapter, and by mid-2024 it should have the case's cable replaced with a right-angle connector.

Final Assembly and Thoughts

For what amounts to a first-generation attempt by MSI, the Project Zero motherboard and Pano M100R PZ get a lot right. All the cutouts on the case are in the right places and large enough for the cables and headers that plug into them (which is more than I can say for the Gigabyte Stealth system that launched in 2022). And the three-sided glass is ideal for showing off that ultra-clean case interior.

That being said, there is plenty of room for improvements, both big and small. For instance, the PCB of the motherboard is black, and one of the few cables you do have to snake from the font of the case to the back comes off the AIO's cooler plate. Since MSI shipped a white AIO cooler, that cable is white. This actually makes that cable far more visible than if it were black. I suppose if I were building this system for my personal rig, I could color it black with a marker.

The main design issue I had with the case was the vertical USB 3.2 connector, which makes the back of the case bulge a bit. Thankfully, it seems like MSI has owned up to that issue and will be offering a free right-angle connector to buyers for a few months, before replacing the cable with one with a native right-angle connector by the middle of the year.

Shorter power supply cables, preferably also with right-angle connectors, would also be nice to have for a motherboard like this. Companies could offer them as an extra for modular power supplies. Or if the whole rear connector thing truly takes off, perhaps we'll see power supplies and other components specifically designed for builds like this.

Clearly, the necessity for at least some custom parts is the biggest hurdle for this whole connector- and cable-hiding endeavor, whatever it eventually gets called. Because you'll need a case designed for these kinds of boards, and while MSI's Pano M100R PZ is nice enough, it's certainly not going to appeal to everyone. If you're the type of builder who wants to go out of their way and spend extra money to get an ultra-clean case interior, you're probably also going to have strong opinions on what the outside of your case looks like, as well.

It will be interesting to see what other case makers bring to the table – I expect to see at least a few chassis designed for these kinds of boards at CES. But even with a couple dozen case options, those choices are still going to pale in comparison to the hundreds of more traditional cases already available. And motherboard options are also likely to remain at least somewhat limited, as well.

Who knows how mainstream this board layout will become? But if there is one thing that the popularity of the Hyte Y60 (and its many copycats) has taught me, not to mention the whole RGB explosion over the last decade, it's that there are millions of PC builders who are happy to spend lots of money making the inside of their cases more eye-catching. And MSI's Project Zero definitely accomplishes that.

After a rough start with the Mattel Aquarius as a child, Matt built his first PC in the late 1990s and ventured into mild PC modding in the early 2000s. He’s spent the last 15 years covering emerging technology for Smithsonian, Popular Science, and Consumer Reports, while testing components and PCs for Computer Shopper, PCMag and Digital Trends.

-

MiniITXEconomy Seemed like a cool idea to me, putting all those ports on the back. Then Paul from Paul's Hardware tried to convince us all otherwise, and I remember thinking, "what an out-of-touch man... he should get outta the tech game." Then just a few short months later, he did!Reply

But now that we know all about Paul, let's discuss this motherboard: I still think it's cool. -

hotaru251 Replywith better airflow

the few cables in a build don't effect airflow much at all...

especially with aio.

The concept is nice, but the main issue will always be case compat. -

Eximo I want to see a reverse PCIe x16 also at 90 degrees/or riser cable so you can actually use all the expansion slots on the front of the motherboard. Always compromising around these massive GPUs. Though that would be an even more disruptive change in case design, though there are plenty of the dual chamber chassis ready for it.Reply -

edzieba My main gripe is that if you're going to go to all the trouble of board redesigns and needing non-standard (or at the very least a new standard) chassis to put everything in, then why half-arse things by still having a bunch of loose cables dangling around the the back that you need to plug in manually?Reply

If you're already having to use a bunch of custom hardware and are already selecting new component locations, then instead do what OEM PC manufacturers do: use a fixed power distribution plane, and use the self-centring-insertion variants of the Molex Mini-Fit Jr connectors that already exist. That way, the act of installing and screwing down the motherboard itself ensures the motherboard is now fully connected to the power backplane.

You can even go one step further and integrate the front-panel header & USB headers this way, as well as fan and SATA breakouts. -

Notton Reply

My guesses:edzieba said:My main gripe is that if you're going to go to all the trouble of board redesigns and needing non-standard (or at the very least a new standard) chassis to put everything in, then why half-arse things by still having a bunch of loose cables dangling around the the back that you need to plug in manually?

If you're already having to use a bunch of custom hardware and are already selecting new component locations, then instead do what OEM PC manufacturers do: use a fixed power distribution plane, and use the self-centring-insertion variants of the Molex Mini-Fit Jr connectors that already exist. That way, the act of installing and screwing down the motherboard itself ensures the motherboard is now fully connected to the power backplane.

You can even go one step further and integrate the front-panel header & USB headers this way, as well as fan and SATA breakouts.

- Extra cost

- This new "standard" has multiple partners. It's quicker and easier to agree to where the punched out holes should go. Locking down the connectors to a specific spot is restrictive.

- It's marketed towards DIY enthusiast segment, not OEM "shove as many out the door as fast as possible" market. -

user7007 Reply

Agreed, they could make it easier (not just move it all to the back) without much effort.. They also didn't use the idea that Asus is floating around of not using the big external graphics card power connectors but having essentially another pci-e1 type connector for power. That build would look substantially better with a white gpu and no gpu power cables.edzieba said:My main gripe is that if you're going to go to all the trouble of board redesigns and needing non-standard (or at the very least a new standard) chassis to put everything in, then why half-arse things by still having a bunch of loose cables dangling around the the back that you need to plug in manually?

If you're already having to use a bunch of custom hardware and are already selecting new component locations, then instead do what OEM PC manufacturers do: use a fixed power distribution plane, and use the self-centring-insertion variants of the Molex Mini-Fit Jr connectors that already exist. That way, the act of installing and screwing down the motherboard itself ensures the motherboard is now fully connected to the power backplane.

You can even go one step further and integrate the front-panel header & USB headers this way, as well as fan and SATA breakouts. -

deesider Reply

Since graphics cards are so long and overhang the motherboard they could just put the power connector on the bottom.user7007 said:Agreed, they could make it easier (not just move it all to the back) without much effort.. They also didn't use the idea that Asus is floating around of not using the big external graphics card power connectors but having essentially another pci-e1 type connector for power. That build would look substantially better with a white gpu and no gpu power cables. -

vanadiel007 The idea is good, but they should just make a new PSU/motherboard standard with a single 100 PIN connector and have everything including GPU's powered from that.Reply

Should be a system where the PSU directly connects to the MB with a single 100 PIN non-wired connector. Super simply to install and never have to worry about what cables go where.