BiCS FLASH Preview With Toshiba XG5 NVMe SSD

Features & Specifications

Despite Toshiba's troubles with regulatory agencies, bankers, governments, and partner Western Digital, the company has a new advanced flash poised to change the storage landscape. For the last year, analysts have placed the NAND market's recovery on the shoulders of Toshiba's BiCS flash production. IMFT, Samsung, and Sk Hynix play a role, but Toshiba is the linchpin because 3D BiCS is the uncertain piece of the puzzle.

Toshiba originally said to expect BiCS in Q3 2017, essentially now, but many analysts predicted we wouldn't see volume production until early 2018. Most of the speculation stems from Toshiba's financial troubles that are leading to the sale, in whole or in part, of its flash manufacturing outfit. Analyst predictions are valuable to us, but only in context. Both Toshiba and partner Western Digital have announced products with third generation 3D NAND, but neither company has products in retail. We can now say that BiCS-powered SSDs are coming and we won't have to wait until 2018.

The new flash utilizes 64 stacked layers and comes in 256Gbit (32GB) and 512Gbit (64GB) die, but vendors will use different die for different applications. SSD's are fast because they read and write to several die simultaneously in a RAID array-like arrangement. Large and small die capacities are nothing new, but as NAND technology progresses, the vendors increasingly use targeted sizes for different applications. Low capacity models use the smaller die for increased parallelization, which boosts performance, while larger die are used for SSDs with more capacity.

Without the larger die, though, controller technology becomes very expensive because the controller has to address more die simultaneously. That adds traces, more complex algorithms, and requires more processing power in the form of higher clock speeds and faster processors. In most cases, the larger die will drop right in and the same controller can take advantage of the extra capacity without a significant redesign. At that point, the high capacity products hinge on the amount of DRAM the controller can address to cache the LBA map.

The XG5 is the first SSD featuring Toshiba's new BiCS flash. It's an OEM model that follows the XG3 and XG4 OEM NVMe SSDs. Toshiba doesn't disclose design wins, but we know Dell, MSI, and other high-performance notebooks used the XG series through 2016 and 2017. Toshiba displayed the new XG5 model at Dell World just days prior to Computex, so we assume Dell will use the drive in back-to-school models this year. We're also told OCZ will use the XG5 as the base for the next generation RD series.

There were subtle differences between the OEM XG3 and retail RD400. OCZ tuned the RD400 for enthusiasts and included a custom NVMe driver for Windows. The driver makes a big difference. Some OEMs provide custom drivers, but the base XG5 we're testing today uses the standard Windows 10 NVMe driver. Some features are not optimized with the standard driver, so the XG5 performance you see today should only be used as a reference point for the next OCZ RD product.

Specifications

OEM partners will purchase the XG5 in three capacities that range from 256GB to 1TB. All drives in this series use the M.2 2280 single-sided form factor. Toshiba is coy about the XG5's specifications because ultimately the performance of final products varies by OEM. Performance is also dependent on firmware, which companies can adjust based on their thermal and power requirements. For instance, if a company reduces the 3,000 MB/s sequential read performance to 2,800, it might gain an extra 60 minutes of battery life. Then they could market a model with nine hours of battery life instead of eight.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Toshiba provided sequential performance specifications for the XG5 reference design, but not random performance. The XG5 reference design is capable of 3,000/2,100 MB/s of sequential read/write throughput.

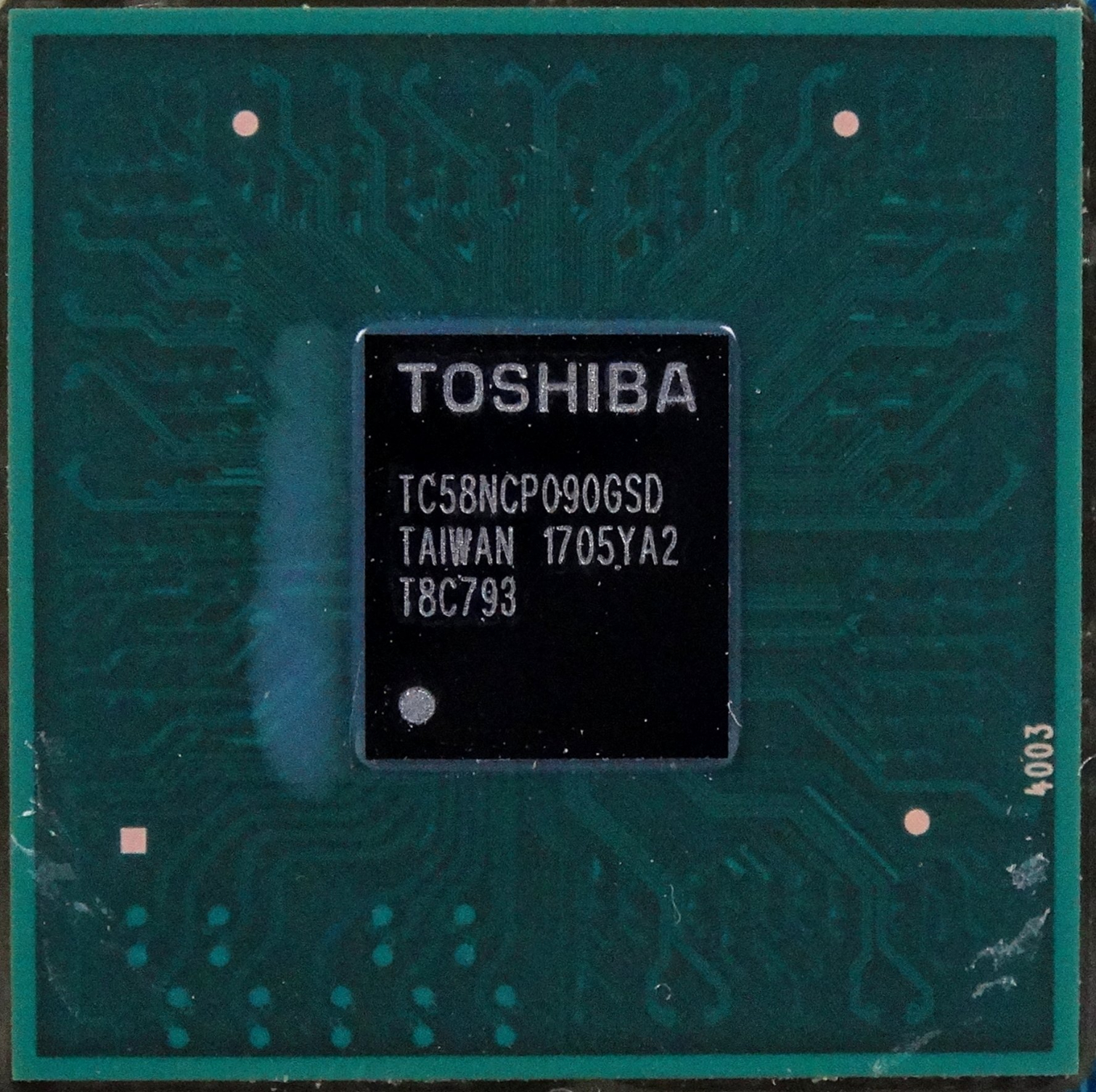

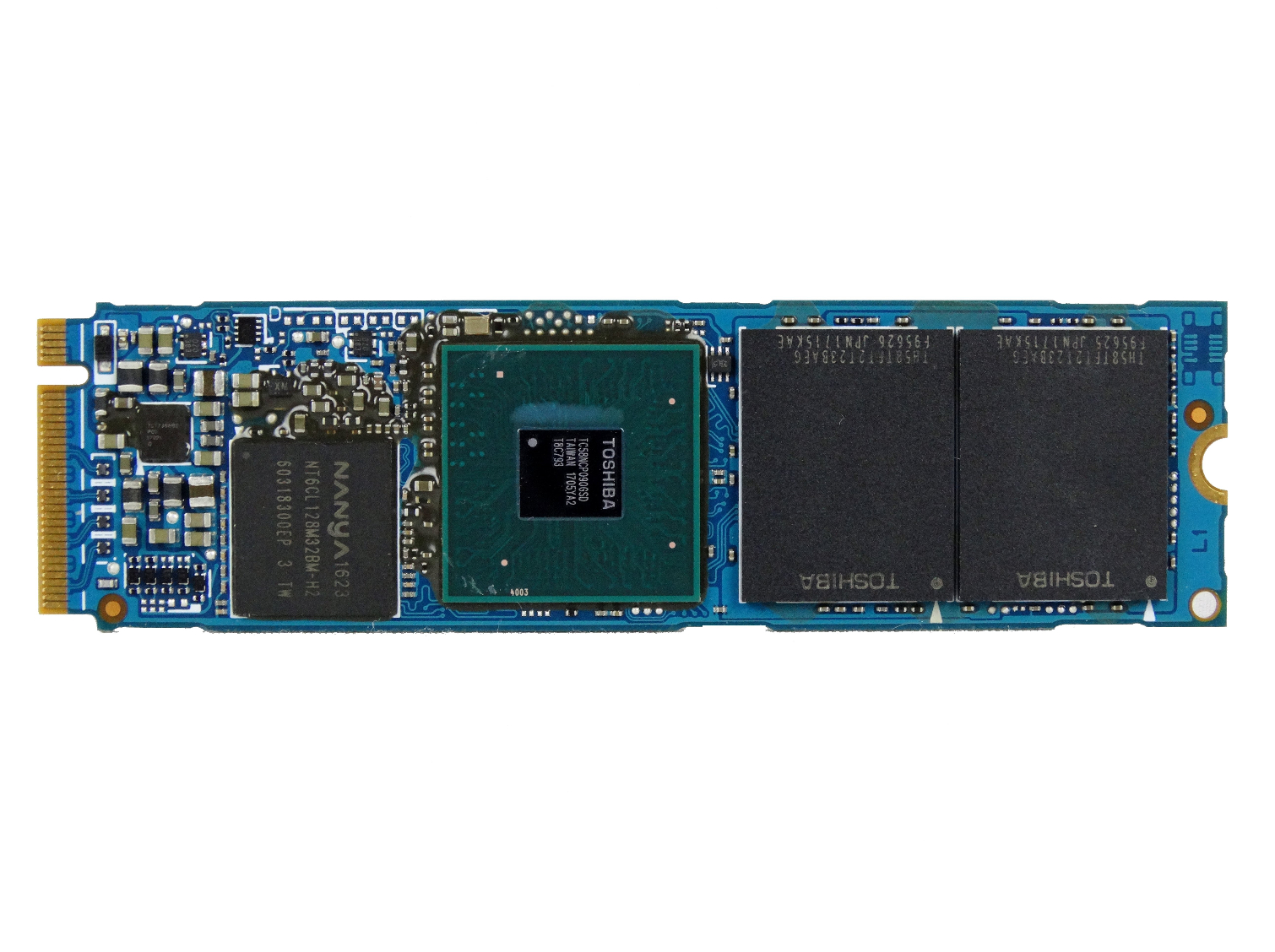

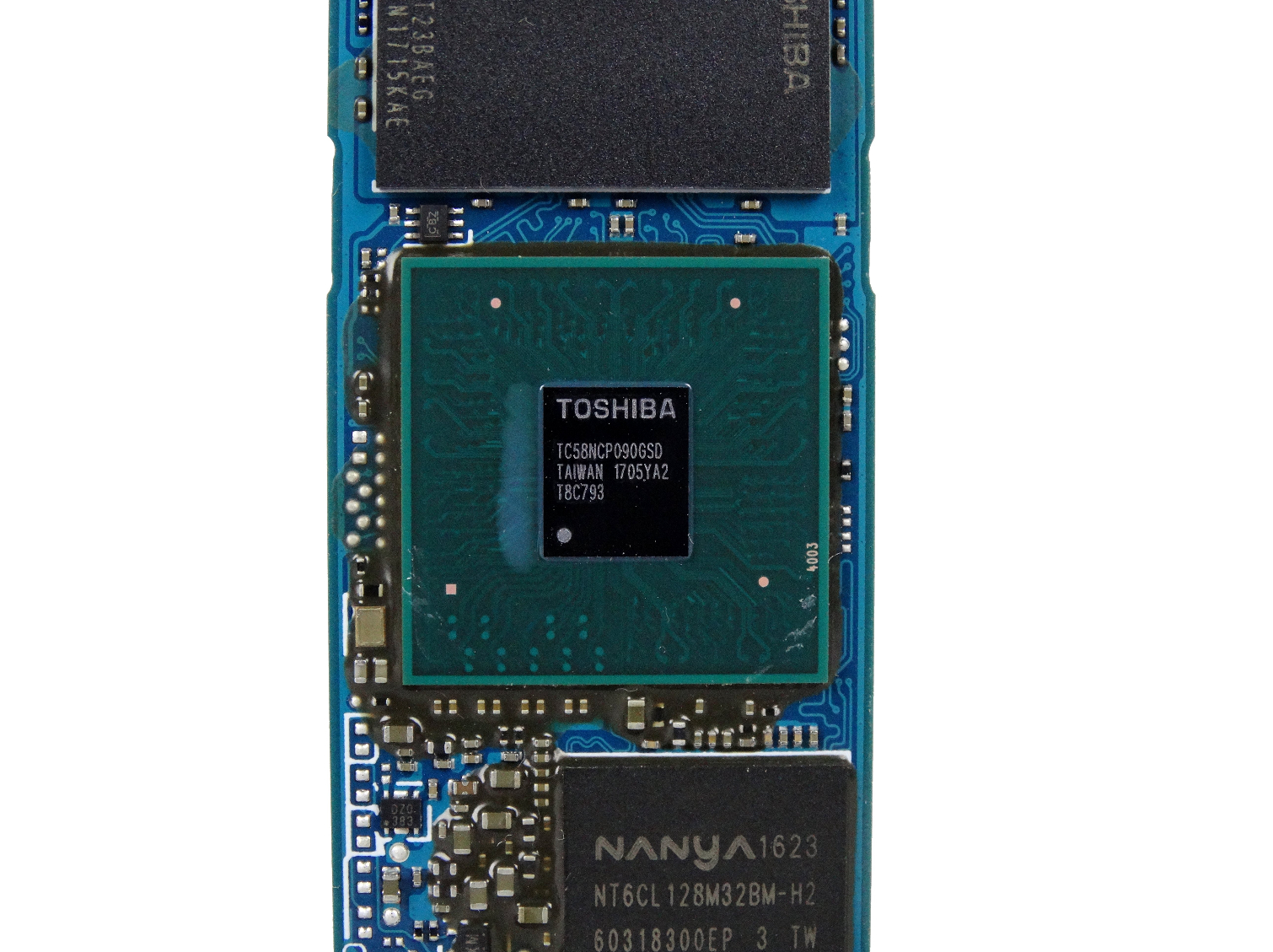

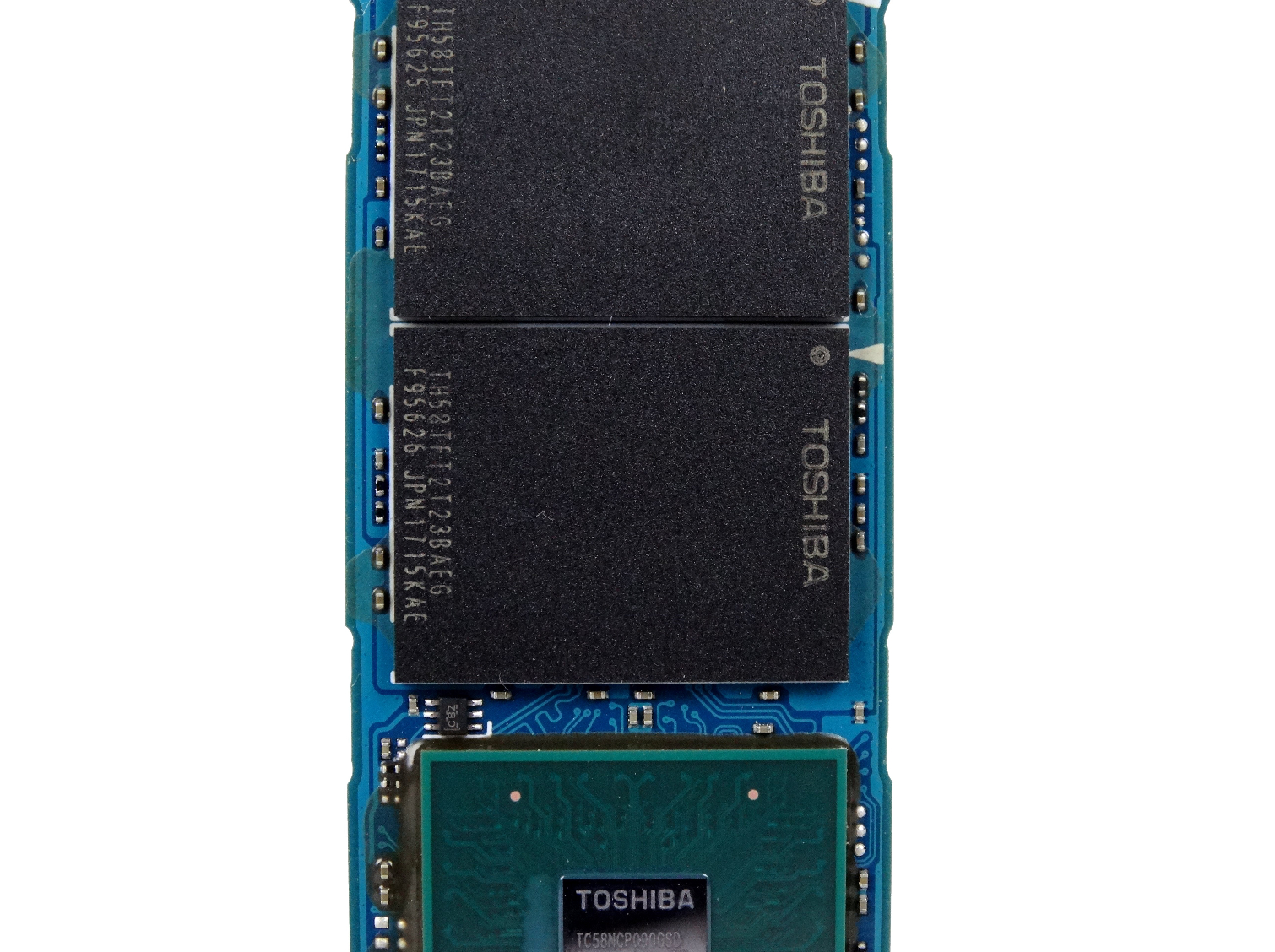

Toshiba isn't sharing information about the new TC58NCP090GSD controller, either. The company has always kept certain aspects of its technology secret. We could never get any solid answers about the controller in the XG3 / RD400. We do know the new controller uses a flip chip design, and that isn't the same design as the XG3. The performance characteristics lead us to believe the controller can utilize at least eight channels. We asked, but our questions went unanswered, again.

The actual die appears to be slightly larger than the Phison E7. The E7 also uses an exposed flip chip design. This led us to believe the two share some digital DNA, but the physical size difference takes that possibility off the table.

The label on our reference design XG5 has a PSID, so this model supports self-encrypting drive (SED) technology. We later found that TCG Opal encryption is an option for OEMs.

Things get interesting on the NAND side. Toshiba and manufacturing partner Western Digital have both stated that 2-bit per cell NAND (MLC) is dead for the consumer market. There will always be a young enterprising company that tries to make a name for itself with a few batches of MLC, but all of the fabs have similar plans for the consumer market.

The Toshiba XG5 will use both BiCS die capacities. It's easy to assume the 256GB model will use the 256Gbit die and the 1TB will use the 512Gbit die. The 512GB model could go either way. Toshiba wouldn't say if it uses the smaller or the larger die. The SSD would be faster with smaller die, but with the larger die it would be cheaper. In time, we'll get one and find out.

Toshiba armed the XG5 1TB reference design with 512Gbit die. The design uses two NAND packages with eight die each. Toshiba can, and eventually will, build 16-die packages. That could lead to a 2TB single-sided XG5 model in the future. If the controller can handle it, we could even see a 4TB model with components on both sides.

Pricing, Warranty & Endurance

We have it on good authority that this is the base for the next OCZ RD-series NVMe SSD, but Toshiba won't sell the XG5 into the channel. The same was also said about the XG3, but several sold as system pulls early in the product life cycle. Now that the XG3 with 15nm planar MLC is end of life, several them are available from different sellers. MyDigitalDiscount has 20,000 XG3 SSDs available in three capacities. The XG3 512GB currently sells for just $200 (Mydigitaldiscount.com) and $219.99 (Amazon). There's a good chance we will see the XG5 sell as a gray market product at some point, as well.

OEMs selling the Toshiba XG5 in pre-built systems will dictate warranty and endurance specifications. Most, if not all, systems don't list specific SSD performance or endurance specifications.

A Closer Look

Sadly, the XG5 doesn't come with the cool sticker used on the promotional images. The drive looks like any standard OEM SSD with a boring white label.

BiCS NAND is the star of this show. There is more to this story than meets the eye. With all consumer SSDs moving over to 3D TLC, the XG5 gives us our first look at what the new definition of "high-performance" is like.

MORE: Best SSDs

MORE: How We Test HDDs And SSDs

MORE: All SSD Content

Chris Ramseyer was a senior contributing editor for Tom's Hardware. He tested and reviewed consumer storage.

-

Giroro There's a lot of words padding out the Features and Specifications page ... but very little meaning or context.Reply

So flash manufacturers make flash in different die sizes ... is there anything noteworthy about the die sizes in the XG5? Is a 256Gbit die big or small?

Drive makers tune power consumptions and performance ... ok. Is the XG5 tuned for power or performance. Is the claimed 3,000/2,100 MB/s of sequential read/write particularly high or low compared to other drives?

What is a "flip chip design"? Is that different than other designs, or is there any particular reasons why a drive should/shouldn't use "flip chip design".

Most importantly, WTF is BiCS? What aspect of flash is it even trying to improve? Price? Density? Durability? -

mikewinddale "There were subtle differences between the OEM XG3 and retail RD400. OCZ tuned the RD400 for enthusiasts and included a custom NVMe driver for Windows. The driver makes a big difference."Reply

I had problems with the Windows NVME driver on my XG4, so I used the RD400 driver with the XG4, and it worked perfectly, with no problems.

See https://forums.lenovo.com/t5/ThinkPad-11e-Windows-13-E-and/E570-needs-better-NVMe-driver-support/td-p/3518940?clickid=whh1IG1svXPPQp90UK2rHzHXUkkXJgxNw11DxM0&PID=10451&acid=ww:affiliate:bv0as6&irgwc=1

and

https://www.youtube.com/watch?v=3SwvB_drcJE -

irish_adam Reply19976663 said:There's a lot of words padding out the Features and Specifications page ... but very little meaning or context.

So flash manufacturers make flash in different die sizes ... is there anything noteworthy about the die sizes in the XG5? Is a 256Gbit die big or small?

Drive makers tune power consumptions and performance ... ok. Is the XG5 tuned for power or performance. Is the claimed 3,000/2,100 MB/s of sequential read/write particularly high or low compared to other drives?

What is a "flip chip design"? Is that different than other designs, or is there any particular reasons why a drive should/shouldn't use "flip chip design".

Most importantly, WTF is BiCS? What aspect of flash is it even trying to improve? Price? Density? Durability?

There is this great new website called "Google" which has all the answers to your questions.

I honestly dont mean to be mean, you seem to be lacking in some basic understandings of flash and the flash market which would take someone a little time to explain to you, especially on a forum. You would be far better off just searching for the information yourself, theres plenty of it out there.

-

mikewinddale Reply19976663 said:So flash manufacturers make flash in different die sizes ... is there anything noteworthy about the die sizes in the XG5? Is a 256Gbit die big or small?

Basically, the smaller the die, the more dies it will take to make an SSD of a given capacity. And more dies means more parallelism, which makes the flash drive faster.

For example, suppose an SSD is 1 TB. Then it will take twice as many 256 Gbit dies as 512 Gbit dies to make that 1 TB SSD. And more dies means - as I said - more parallelism.

High-speed SSDs basically rely on internal RAID parallelism. Any given piece of data is read and written to and from multiple dies at once, with the data being split across dies. This way, the SSD can be multiple times faster than any given die.

Compare a high-speed SSD to a flash thumb drive, for example. Most thumb drives are single-channel and lack a sophisticated controller. While they have lower read latency than mechanical hard drives, because there's no mechanical seek, they are also very slow at sequential operations. A flash thumb drive will have virtually no seek latency, but it also has a peak sequential speed of about 20 MB/s, whereas a mechanical hard drive has a seek latency of about 8 milliseconds, but it can achieve about 500 MB/s in sequential operations.

So single-channel flash is actually quite slow in some ways. But a high-speed SSD, by splitting data across multiple dies, can increase its speed several-fold. If you write to every die at 20 MB/s, but the data is split across 50 dies, then you might get 1000 MB/s. (These numbers are just illustrative, and I haven't checked them against any actual SSD model.)

So again, die size matters because the smaller the die, the more dies it takes, and the more parallelism, and the faster the drive.

For this reason, for any given model of SSD, the larger drives are typically faster. The larger drive has more dies, so more parallelism. Sometimes, the smaller SSD cannot use all of its controller's channels. For example, you might find a 1 TB SSD with an 8 channels controller, and 32 dies, with 4 dies per channel. But the 128 GB model of the same brand, with the same 8 channel controller, might have only 4 dies, only has enough dies to use 4 channels. It's an 8 channel controller, but with only 4 dies, only 4 channels get used, so the 128 GB SSD might be half the speed of the 1 TB SSD. A larger SSD will be more able to utilize multiple channels, and similarly, an SSD with smaller dies will have a larger number of dies, so it will be able to utilize more channels.

Of course, smaller dies also make it harder to make a large-capacity drive. So there's a tradeoff. In general, dies are getting larger as drives get larger. This means that a brand-new 128 GB SSD today might be slower than one a few years ago, because a few years ago, the dies were smaller, and it took more of them to make a 128 GB SSD. SSDs are generally getting both faster and larger, so if you buy an SSD that is small by today's standards, it will be slower than a larger SSD.

-

Giroro @MikeWinddaleReply

That's all good and fine... but once again, a dissertation about the parallelism in flash dies doesn't actually tell me anything at all about the XG5 that is supposedly being previewed.

Is the drive more parallel than a typical nvme drive, or is it less parallel? Because all the explanation implies that some aspect of this drive's die size and therefore parallelism is noteworthy ... but in what way? Is that supposed to be explaining why this drive has good sequential write speeds? Did the previewer start the test -expecting- those write speeds?

It's like if you had written 8 paragraphs about why some circuit boards are green and some are blue ... without actually saying what color of circuit board the drive uses. The detail might be interesting, but it doesn't say anything until you give it a point.

What makes this drive unique? Why is it being previewed? What's the thesis statement to any of this? -

CRamseyer The reason why that section is vague is because Toshiba will not tell us. Western Digital / SanDisk will not tell us either. Both companies are fighting like 1st graders on the playground right now. Toshiba just locked WD/SD out of the database files (again) after a judge said they couldn't. There are a few lawsuits on two continents.Reply

It's my guesstimate that the Toshiba factory is only making 256Gbit die right now on a large scale. That would explain why there is a delay in the 2TB XG5 and 2TB Blue 3D / Ultra 3D. Those capacity sizes would require the larger 512Gbit die with the controller WD/SanDisk used.

When I wrote the XG5 article I didn't know about the Blue 3D / Ultra 3D 2TB delay. Now I know and can give a better answer to your question.

So flash manufacturers make flash in different die sizes ... is there anything noteworthy about the die sizes in the XG5? Is a 256Gbit die big or small?

256Gbit is the small BiCS FLASH die and 512Gbit is the large die. 512Gbit is 64GB. Toshiba has the technology to stack NAND 16 die per package. They are not doing it now with BiCS but it's coming. That means with the 512Gbit die they can make a 1TB package. The package is the black thing on the PCB that hold the NAND, the stuff that holds the data.

Paired with the right controller Toshiba could put 8 1TB packages in a single SSD and make an 8TB SSD that resembles a consumer SSD. Some companies have very large SSDs already but they use custom controllers that are not "off-the-shelf". The controllers that support (for example) 32 packages are expensive and generate a lot of heat. It's not the sort of thing you want in your desktop or notebook. The new 512Gbit die size will make very high capacity products possible at reasonable price points.

Companies have used 256Gbit die in the past and Micron has even shipped a 384Gbit die. The odd 384Gbit die caused some other problems but that's not really important in this review other than the experiment was tried and was not as successful as some expected.

Drive makers tune power consumptions and performance ... ok. Is the XG5 tuned for power or performance. Is the claimed 3,000/2,100 MB/s of sequential read/write particularly high or low compared to other drives?

The SSD was tuned for both power consumption and performance. On consumer / client SSDs companies choose a balance. Enterprise products generally favor one or the other but most allow users to manually tune the drive to how you want it. For more information look at the Intel DC P3700 user manual or command line guide.

What is a "flip chip design"? Is that different than other designs, or is there any particular reasons why a drive should/shouldn't use "flip chip design".

This simply means an exposed chip that doesn't have a shell. Flip chips generally run a few degrees cooler but at the same time are exposed and susceptible to breaking if you put a heatsink on with pressure. The corners are fragile.

Most importantly, WTF is BiCS? What aspect of flash is it even trying to improve? Price? Density? Durability?

BiCS FLASH is simple a trademark name for Toshiba's 3D NAND flash. Samsung uses a "special" name too, V-NAND.

3D NAND gives companies two planes to increase density, horizontal and vertical. Planar (2D) NAND is usually 128Gbit (16GB) so we already see a capacity increase. Using less die to build the same capacity size SSD reduces power consumption. 3D also uses a larger lithography process (the switches inside are farther apart) so that also increases endurance.

I hope this information helps. I often forget that not everyone is so involved in the technology. I wrote articles that cover topics like these but that was many years ago. -

reghir I think you meant "making matters" instead ofReply

Western Digital isn't matters easier by trying to block to sale. -

SayNO2BS How come there is no temperature data? It would be really good to know if this thing runs too not for a 24/7 laptop application.Reply