Eco-friendly 3D-printed house uses soil, not cement — building still scores top earthquake resistance rating

The material reminds us of wattle and daub, a home building material harking back 6,000 years.

Japanese company Lib Work has outlined its 3D house building technology, which relies on soil as its primary constituent. The company’s Lib Earth House Construction (machine translation) process uses a massive 3D printing assembly, rather like others we have seen used for building coffee shops, bus stops, and so on. However, instead of relying on cement to create concrete, Lib Earth dwelling utilize a patent pending mix of earth, slaked lime, and natural fibers.

The materials mix outlined above reminds us somewhat of wattle and daub, a building material and technique that has been around perhaps 6,000 years. Wattle and daub buildings have been known to remain serviceable for as long as 700 years. So there should be no real worries about living in a ‘mud’ house, as long as the construction has been finished correctly. Actually, Lib Work notes that its structures “have a strength equivalent to earthquake resistance grade 3, making it a safe home to live in even in Japan, a country prone to earthquakes.” Indeed, grade 3 is the highest rating for such architectural durability in Japan.

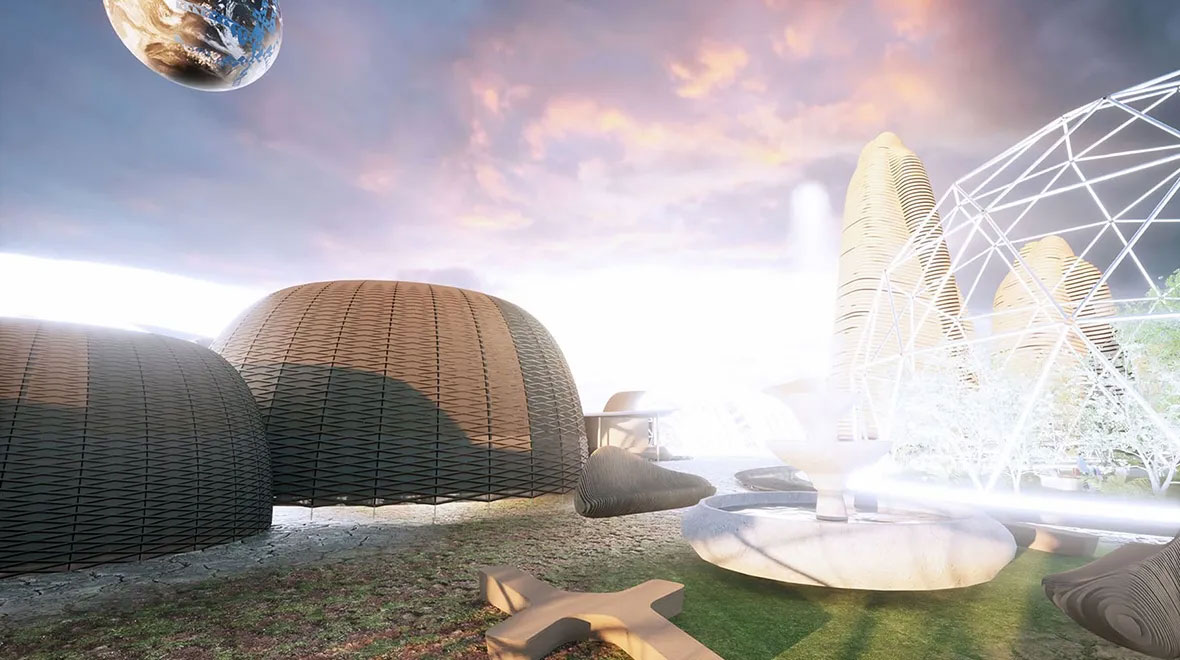

Another attraction of the 3D printed house is that it opens up the flexibility of free form design. Structures which would be a challenge to fabricate from traditional building sheet materials don’t phase 3D printers. Lib Work unveiled their first Lib Earth construction a year ago, but that was basically just a small hut. The Lib Earth model B, unveiled recently, with its cluster arrangement, is far more sophisticated and home-like, as you can see from the imagery.

A closer look at the materials and sustainability implications

Lib Work’s charts indicate that its 3D printing mix for homes is made from 65% soil and sand, the with the next largest chunk consisting of slaked lime binding material, finished off with a few percent of natural fibers and ‘other’ stuff.

The firm has done some CO2 emissions calculations / measurements. According to these figures, the new material’s reliance on “soil, lime, and natural fibers that are abundantly available on Earth,” and eschewing of cement, means far lower CO2 generated per residence.

The Lib Work figures show that building a typical house of this stature might cause about 45,000kg of CO2 emissions. This figure is reduced by more than half, to 22,434kg of CO2, when using the new 3D printing construction tech and sustainable materials. That’s even better than a ‘wooden house,’ it goes on to claim.

Lib Work Mars Project

If you think the above Lib Earth project is pretty ambitious, moving further down the linked page, you will find some eyebrow-raising information about the firm’s Mars Building Project.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Naturally, on Mars, the planned major component of buildings from Lib Work would be Martian dirt.

Soil balls

Soil and dirt are generally regarded as lowly materials, even extending to being insults. However, common earth's status might improve by becoming a valued building material for modern, sustainable 3D printed dwellings.

Soil is actually one of the key ingredients of Hikaru Dorodando shiny balls. Numerous YouTube videos provide evidence that it is possible to polish dirt. Whether this technique could be used in the finishing of your 3D printed soil house, for marble effect features, remains to be seen.

Follow Tom's Hardware on Google News to get our up-to-date news, analysis, and reviews in your feeds. Make sure to click the Follow button.

Mark Tyson is a news editor at Tom's Hardware. He enjoys covering the full breadth of PC tech; from business and semiconductor design to products approaching the edge of reason.

-

Alvar "Miles" Udell ReplyNumerous YouTube videos provide evidence that it is possible to polish dirt. Whether this technique could be used in the finishing of your 3D printed soil house, for marble effect features, remains to be seen.

Or just use Stucco. -

usertests Reply

The Hobbits were onto something.3tank said:So we're heading back towards mud huts....got it -

Sam Hobbs If a building constructed using a 3 D printer is subsequently damaged or needs improvement then is a 3D printer required to do the repair or improvement?Reply -

USAFRet Reply

I would expect No.Sam Hobbs said:If a building constructed using a 3 D printer is subsequently damaged or needs improvement then is a 3D printer required to do the repair or improvement? -

Notton A few thoughts.Reply

If they are going to use multiple small and repetitive segments like that, a prefab would be better.

It's a single floor house sitting on top of a concrete slab and a flat roof.

The extrusion looks like poo, literally.

Earthquakes aren't the only thing that hits Japan. There are typhoons, heavy torrential rain and flooding.

I know it's a demonstration, but single floor houses is exactly the opposite of what Japan needs.

That design is more like a cottage for the extremely wealthy. -

DonQuixoteIII Resembles adobe construction, somewhat. Minus the tia's and vigas. I (for one) would like to know the roof's composition. Loks like pre-stressed concrete to me.Reply -

Mr Majestyk Reply

No we do. not want to revive that 19070's style monstrosity.Alvar Miles Udell said:Or just use Stucco.

Anyway this is a modern twist on mud brick homes, just far more versatile.