Asus Starts Industry's First Fully-Automated Graphics Card Production

Asus' new production method is an industry first, and it should deliver more reliable, higher quality graphics cards than before.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

You are now subscribed

Your newsletter sign-up was successful

Just a couple of days ago, Asus started a new production method for its graphics cards called Auto-Extreme. This is the industry's first fully-automated production process, according to Asus.

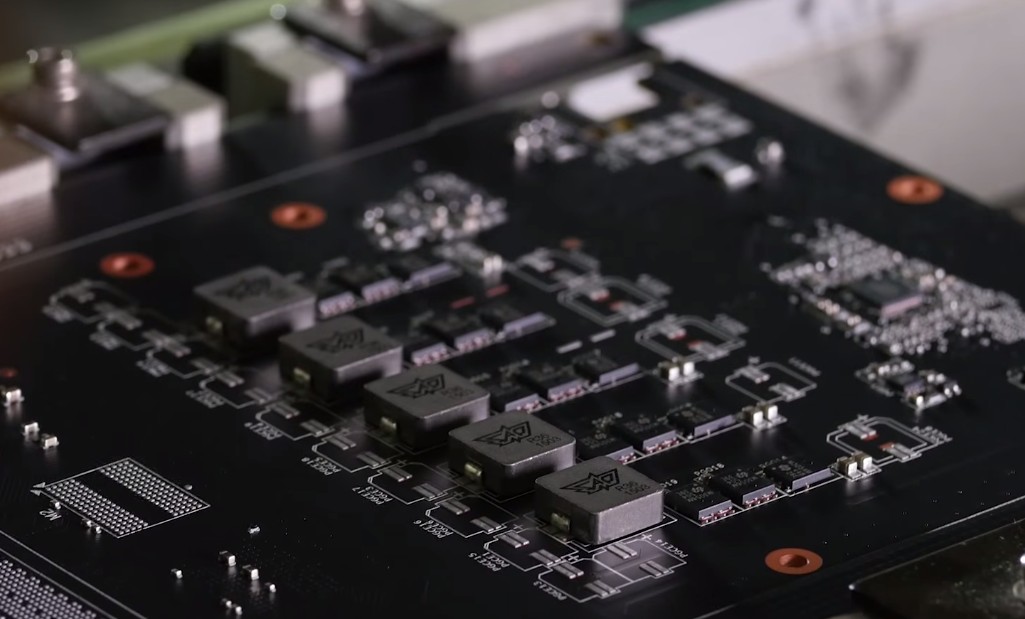

The idea behind Auto-Extreme is that when parts of graphics cards are built by hand, it introduces the chance of human error. The new production process fully automates all the steps of PCB manufacturing, which includes rolling the spools and manufacturing the MOSFETs. A handful of these PCB components used to be soldered to the PCB by hand, but now that everything is fully automated, it can be done with much more precision than before.

The process designs, which lead to smooth PCBs and neat component layouts, are optimized further due to the higher precision possible in manufacturing. And, because it is all automated, installation of the components can be accomplished without oxidation and in environments with less dust. The neater manufacturing also introduces the possibility of testing with tighter tolerances for component placement, enabling stricter quality inspection and control.

Such a manufacturing process brings benefits for both Asus and its customers. It reduces Asus' production costs due to a lower failure rate in the quality control phase, and the graphics cards will likely have a longer lifetime, reducing warranty claims.

Asus' first products to have been built using this new production line are the 20th anniversary graphics cards.

Follow Niels Broekhuijsen @NBroekhuijsen. Follow us @tomshardware, on Facebook and on Google+.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Niels Broekhuijsen is a Contributing Writer for Tom's Hardware US. He reviews cases, water cooling and pc builds.

-

John12w It helps reducing Asus costs by firing employers, great job Asus, I will move to Gigabyte.Reply -

derekullo ReplyIt helps reducing Asus costs by firing employers, great job Asus, I will move to Gigabyte.

To be fair they can also fire cpus and get a new one (Upgrade). -

RedJaron Reply

Asus is a business, and they're in the business of making money. Minimizing costs is one way to be more competitive in the market. Right now Asus products usually cost more than competitors strictly for a brand premium, particularly in the lower-cost mboards. If this allows them to bring pricing into line with the other GPU vendors, it helps them stay in business.15976602 said:It helps reducing Asus costs by firing employers, great job Asus, I will move to Gigabyte. -

skoalreaver ReplyIt helps reducing Asus costs by firing employers, great job Asus, I will move to Gigabyte.

Firing employers. Good job on that GED

-

Aspiring techie Excellent! This is capitalism and competition at its finest! This will definitely make folks migrate towards them.Reply -

Sprezzaa John12w then you should quite wearing clothes and drinking Coffey eating bananas ect ect. They all come from unfair conditions.Reply