Battery Binding Material Swap Delivers 10% Endurance Boost Say Researchers

The swap from PET to PP tape was also found to reduce self-discharge by 70%.

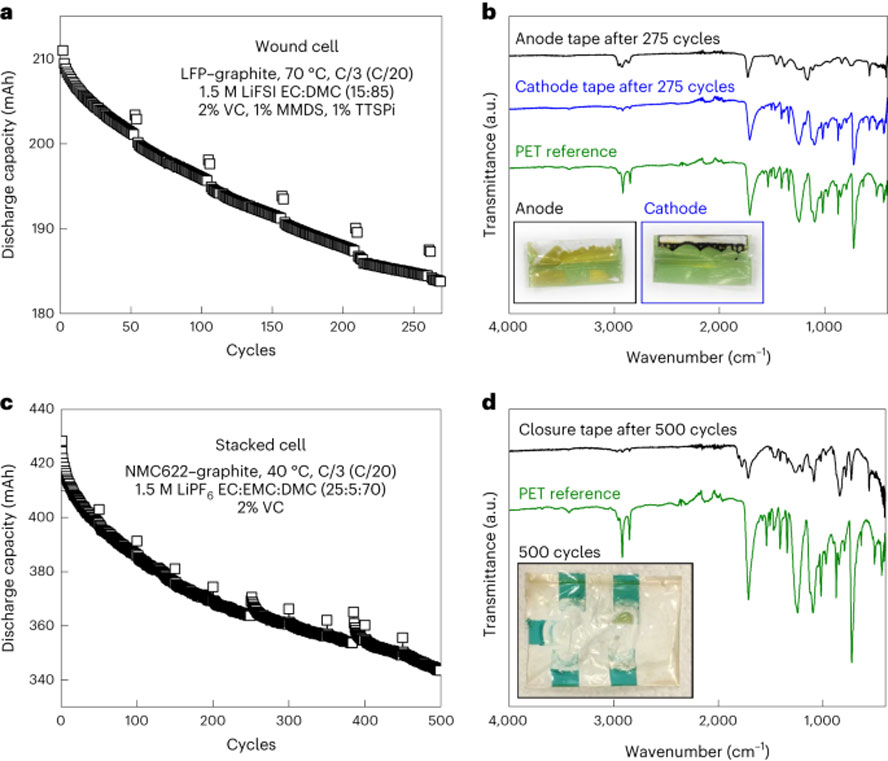

Swapping lithium-ion battery binding material can deliver a 10% increase in battery life and a reduction of 70% in self-discharge, according to a Canadian research team.

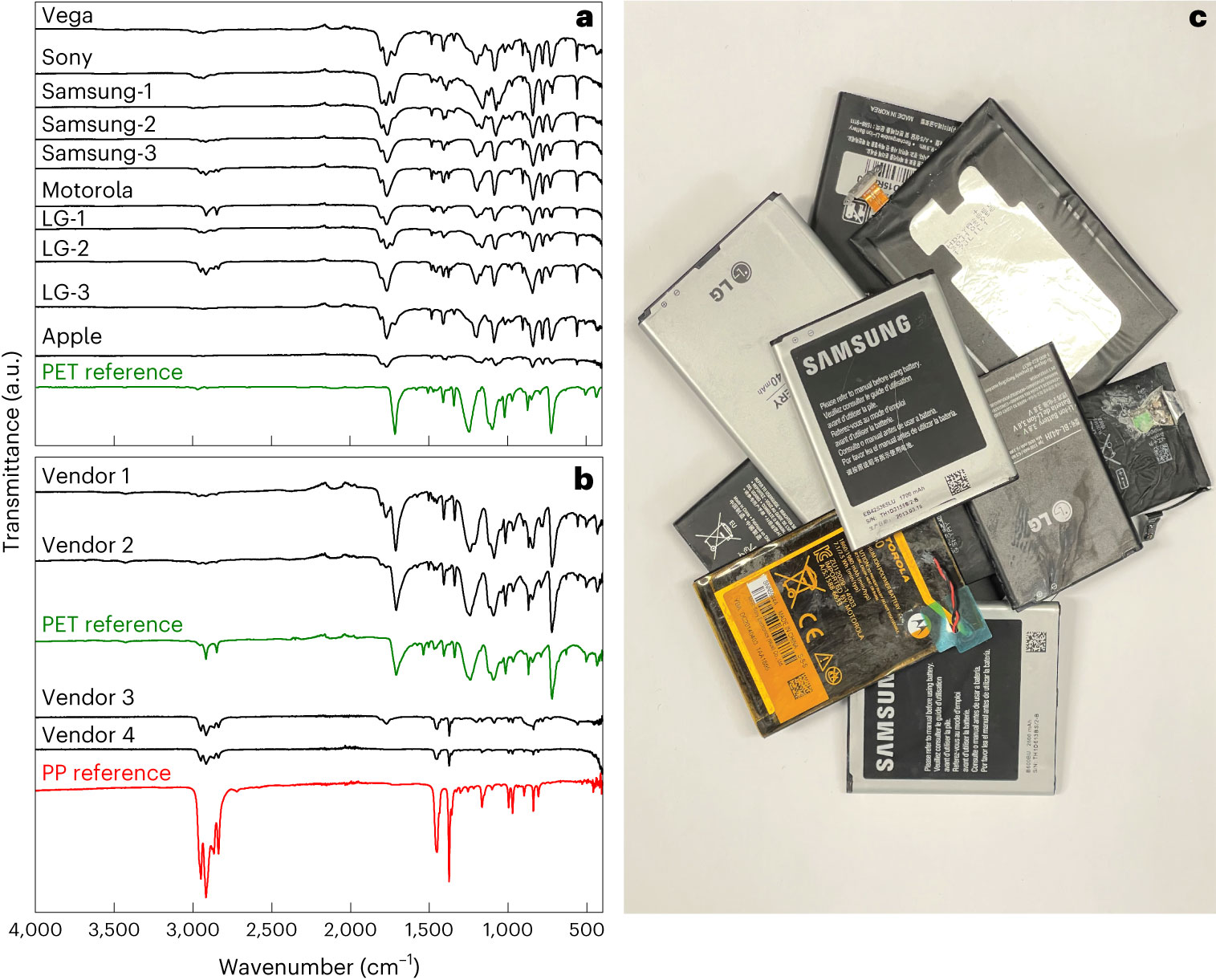

The specific finding of the researchers was that swapping from polyethylene terephthalate (PET) tape to polypropylene (PP) tape battery cell binding appears to be highly worthwhile, delivering the noticeable benefits outlined above. If the industry heed this research, it could mean laptops, tablets, and smartphones with improved battery life. Importantly, PP tape is roughly the same price as PET tape, so there should be little to no impact on costs/prices.

Ph.D. student Anu Adamson led the research team at Dalhousie University in Halifax, Canada. Nature published her paper, “Improving lithium-ion cells by replacing polyethylene terephthalate jellyroll tape,” earlier this month.

“Cells made with PP tape demonstrated significantly decreased self-discharge (up to 70%) and increased cycle life (up to 10%).”

Anu Adamson

The reason for the improvement in battery performance when changing tape material is due to a "largely overlooked" interaction between PET tape and Li-ion battery chemistry. Adamson and team noticed PET tape can depolymerize into its monomer dimethyl terephthalate, inducing substantial self-discharge in a lithium-ion cell.

"Nobody, I think, thought that it could be the tape," said Adamson in an interview with CBC Radio news. As people see battery self-discharge as inevitable, mused Adamson, no one thought of checking if there was a simple fix. "This is really the first time we've seen that something that is generally regarded as very inactive in batteries, is essentially anything but," Adamson explained.

Jeff Dahn, professor emeritus in the university’s physics, atmospheric science and chemistry departments, characterized Adamson’s findings as “incredibly nice chemical detective work,” praising the Ph.D. student for her talent and recognizing the extent of connections in lithium-ion battery chemistry.

Dahn was not involved with the research project but agreed switching to polypropylene (PP tape) would make a huge difference to battery cells. The professor reckoned “most manufacturers will make the change” going forward, as it is a simple switch that makes a noticeable difference.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Mark Tyson is a news editor at Tom's Hardware. He enjoys covering the full breadth of PC tech; from business and semiconductor design to products approaching the edge of reason.

-

Brian28 Reply

Apple has the same peaks and valleys, just the vertical scale is different. Maybe it's a thicker tape, but it's still PET. (Not PP)Co BIY said:In those graphs it appears Apple was already doing something different. -

bit_user It amazes me that it's taken this long to make these kinds of discoveries, given how enormous and highly-competitive the battery industry is. I get that it's non-obvious, but I'd have expected someone to think of characterizing all of the different materials involved, or perhaps to investigate the discrepancies between the behavior of a manufactured cell vs. the same materials under experimental conditions.Reply