Intel Demos Its First 400GbE Silicon Photonics Transceiver, Outlines Design

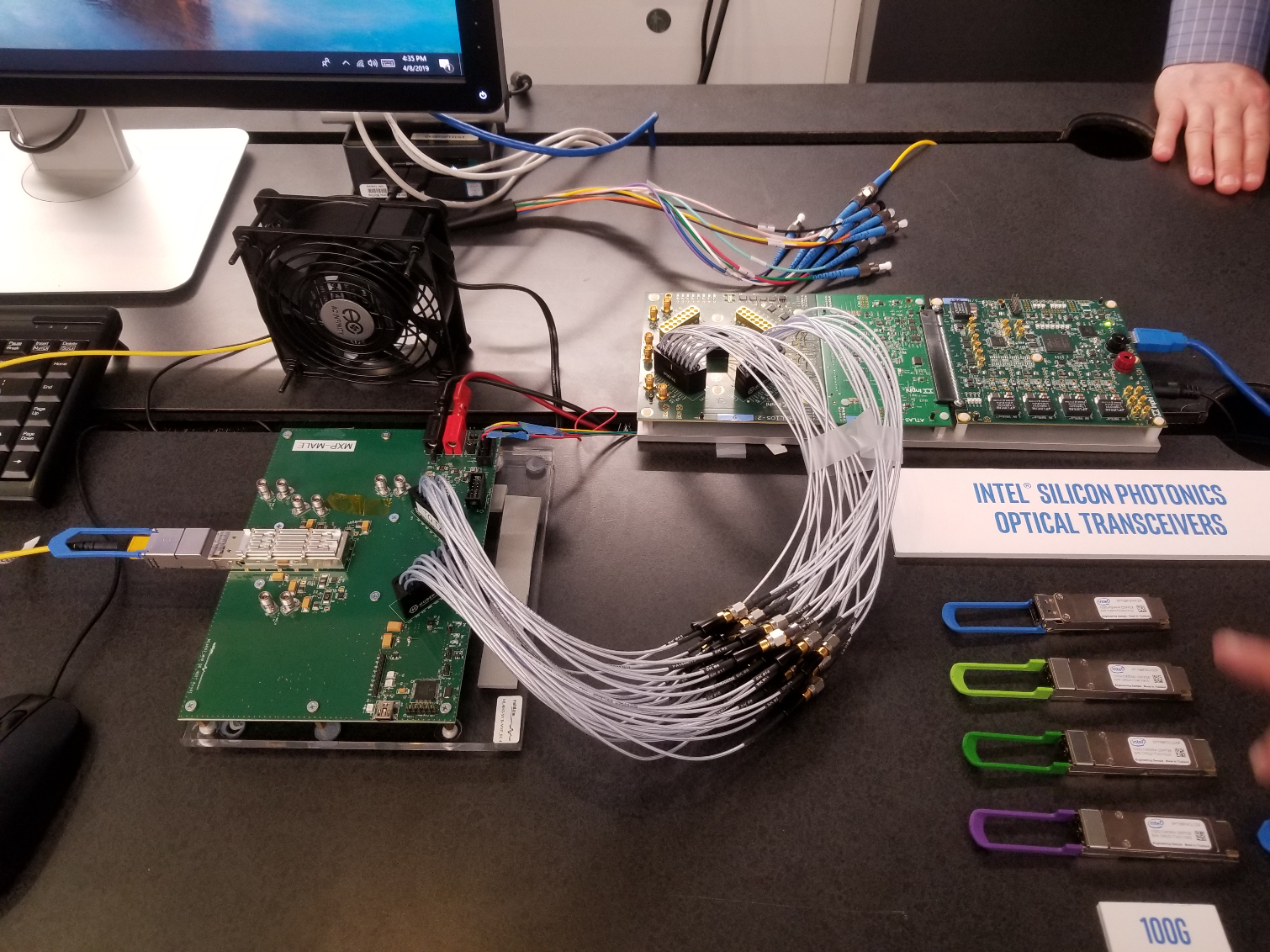

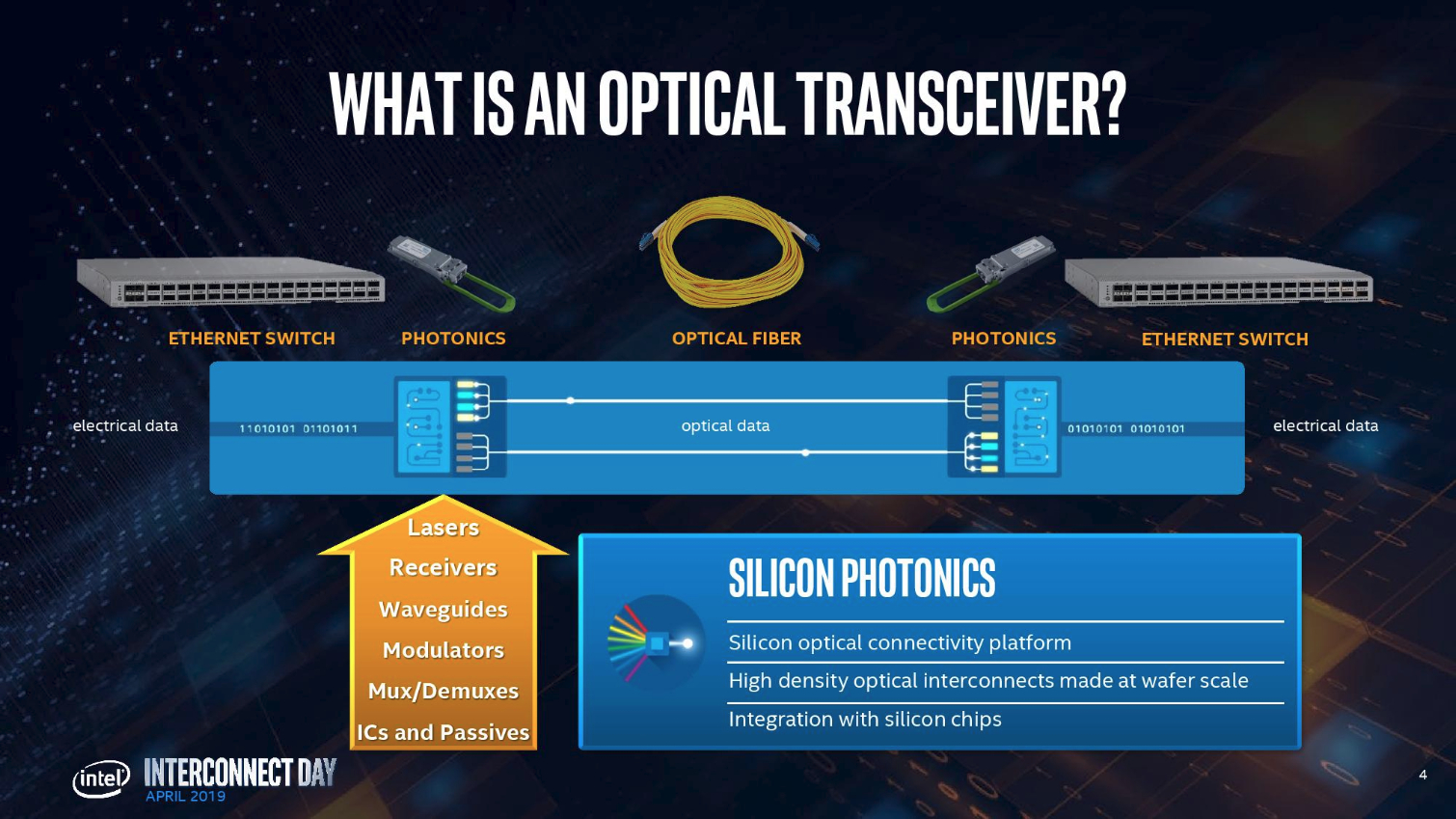

Intel provided its first demo of its 400G silicon photonics transceiver at its recent Interconnect Day event. These new silicon photonics transceivers blend an integrated circuit with semiconductor lasers to provide blindingly-fast data transfers with Ethernet, InfiniBand and OmniPath protocols over longer distances than traditional copper networking cabling.

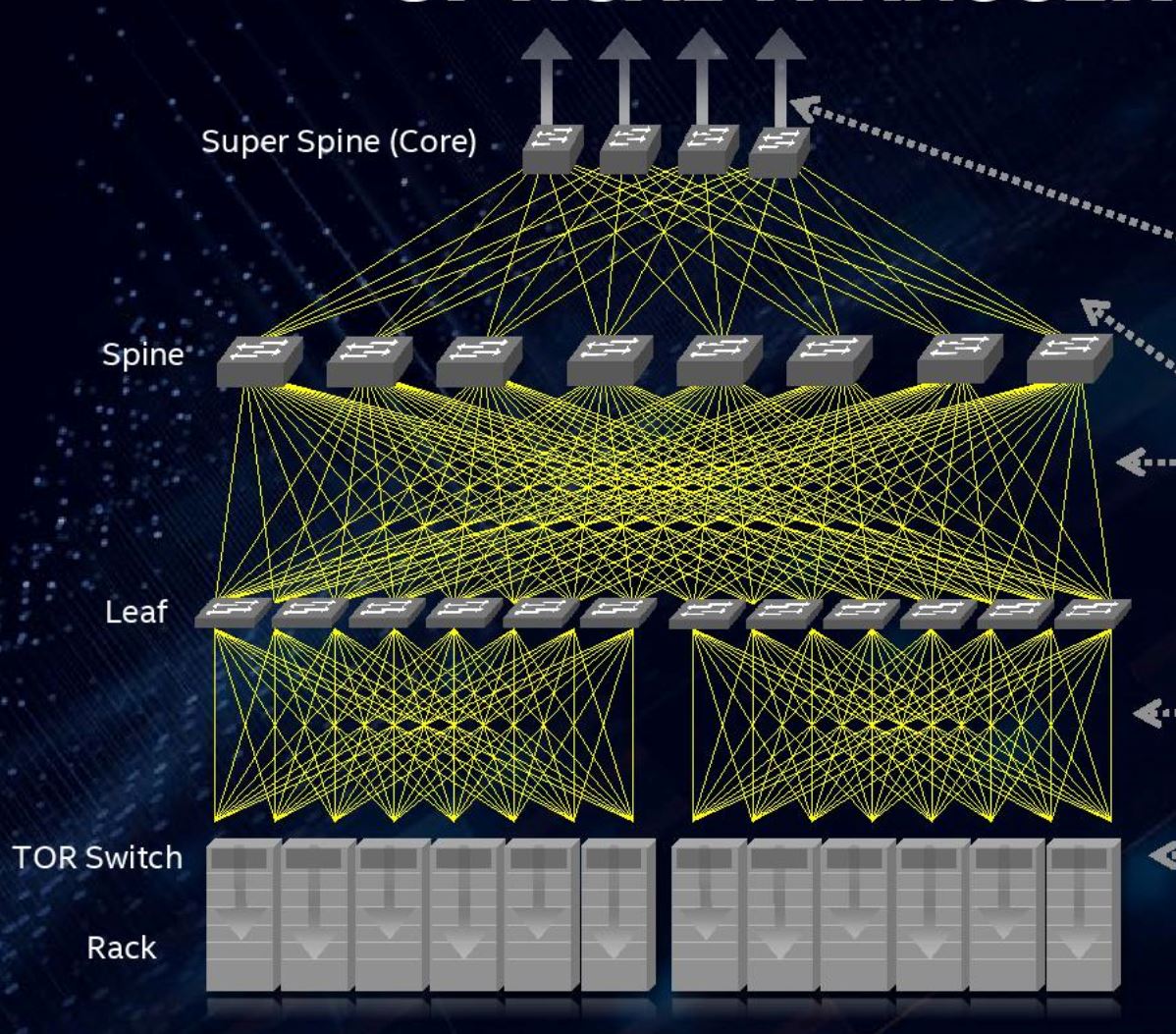

The modern data center consists of multiple layers of complex networking that span the length of several football fields, so high-bandwidth, low latency, and long reach are all key requirements for networking solutions.

Traditional copper networking cables are stretched to the limits with today's fastest networking speeds, with each progressive jump in performance leading to shorter transmission lengths that hinder long-reach capabilities. The increased power requirements also lead to thicker shielding inside the cabling, which presents its own challenges.

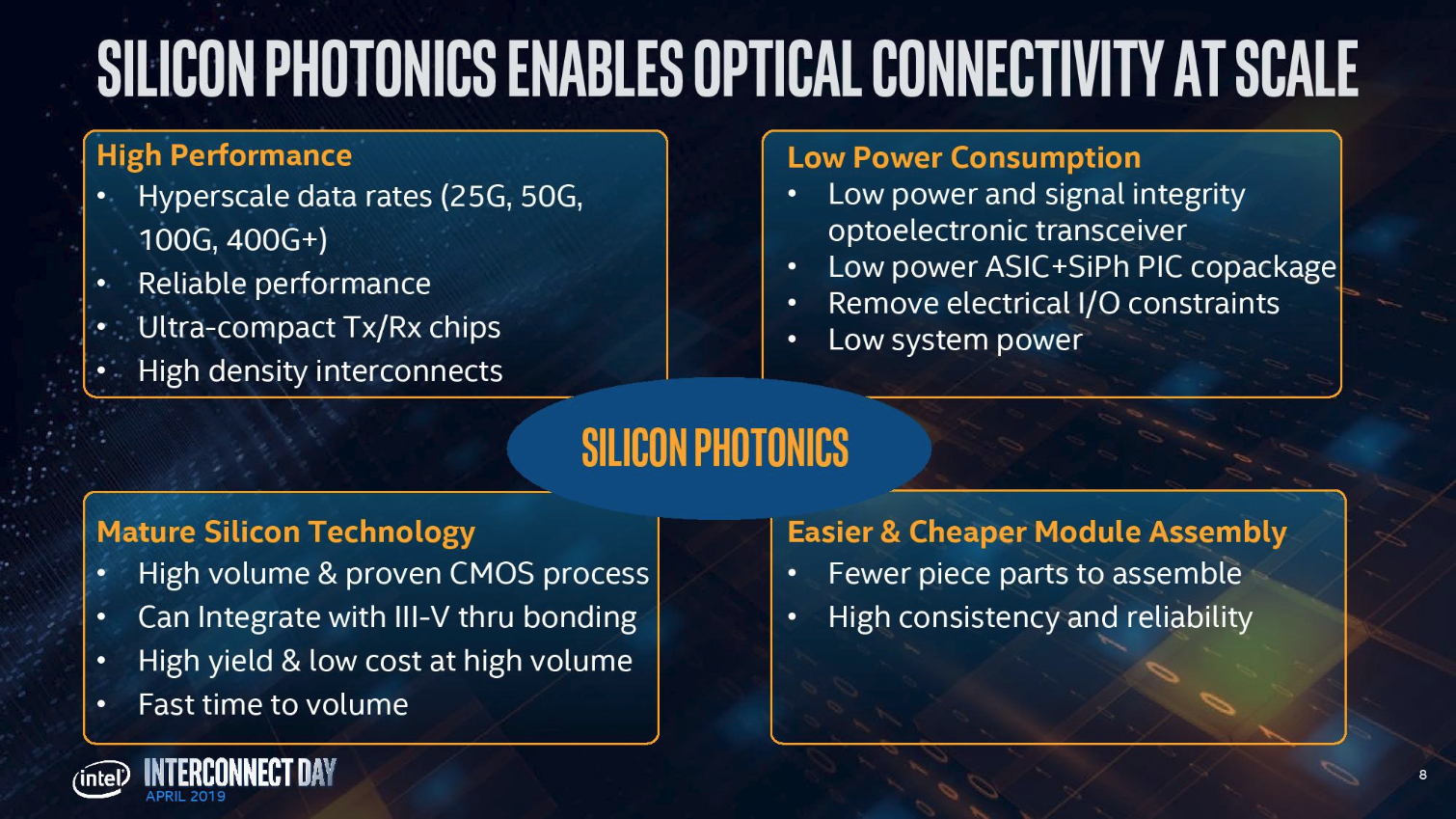

The key advantages of using lasers for data transmission are density and transmission distance. Photonics allows transmission of light streams in closer proximity to each other, which increases cabling density. Intel also touts the power savings, in the range of 3X less power-per-Gbps than copper, as another key advantage.

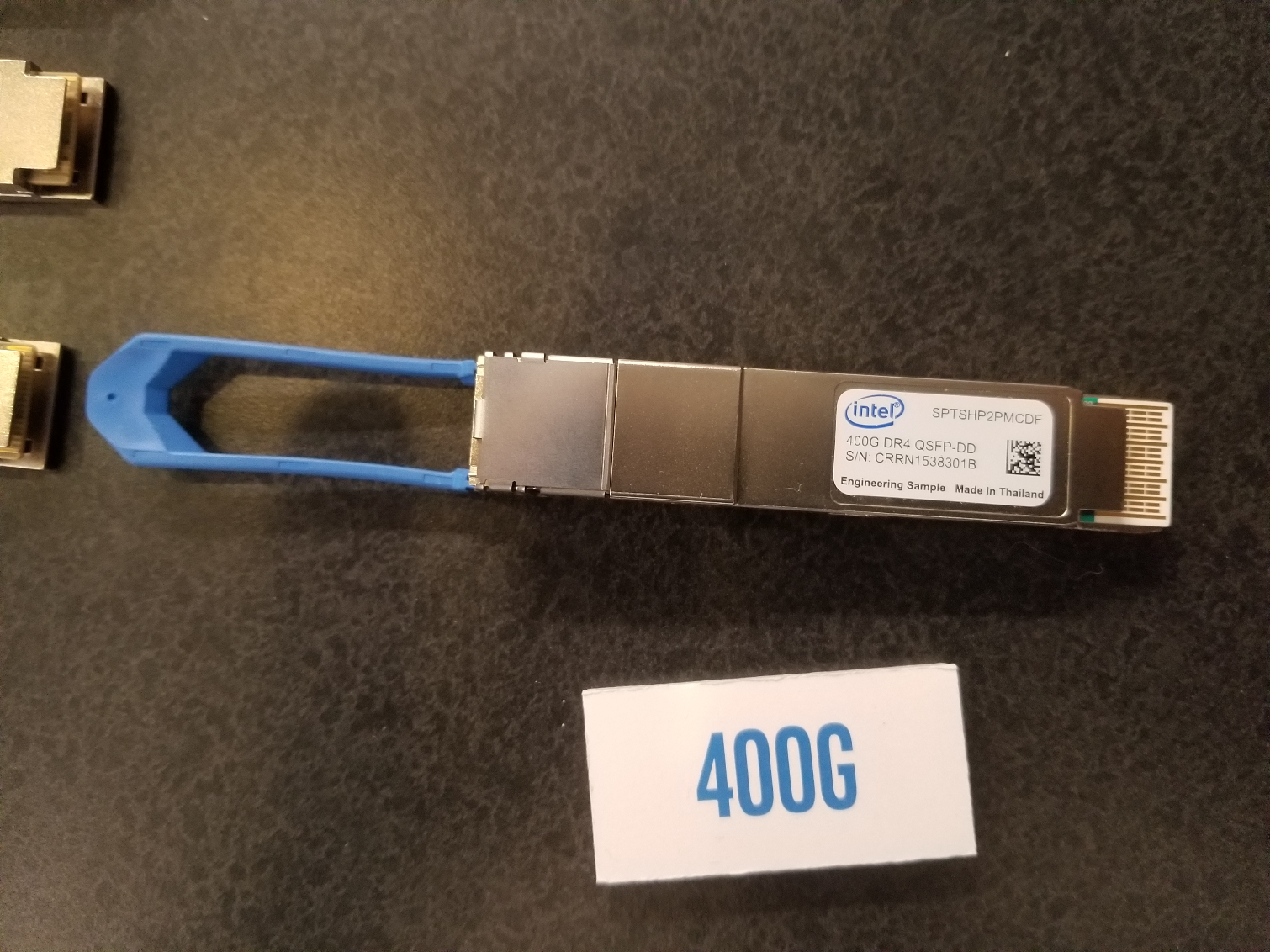

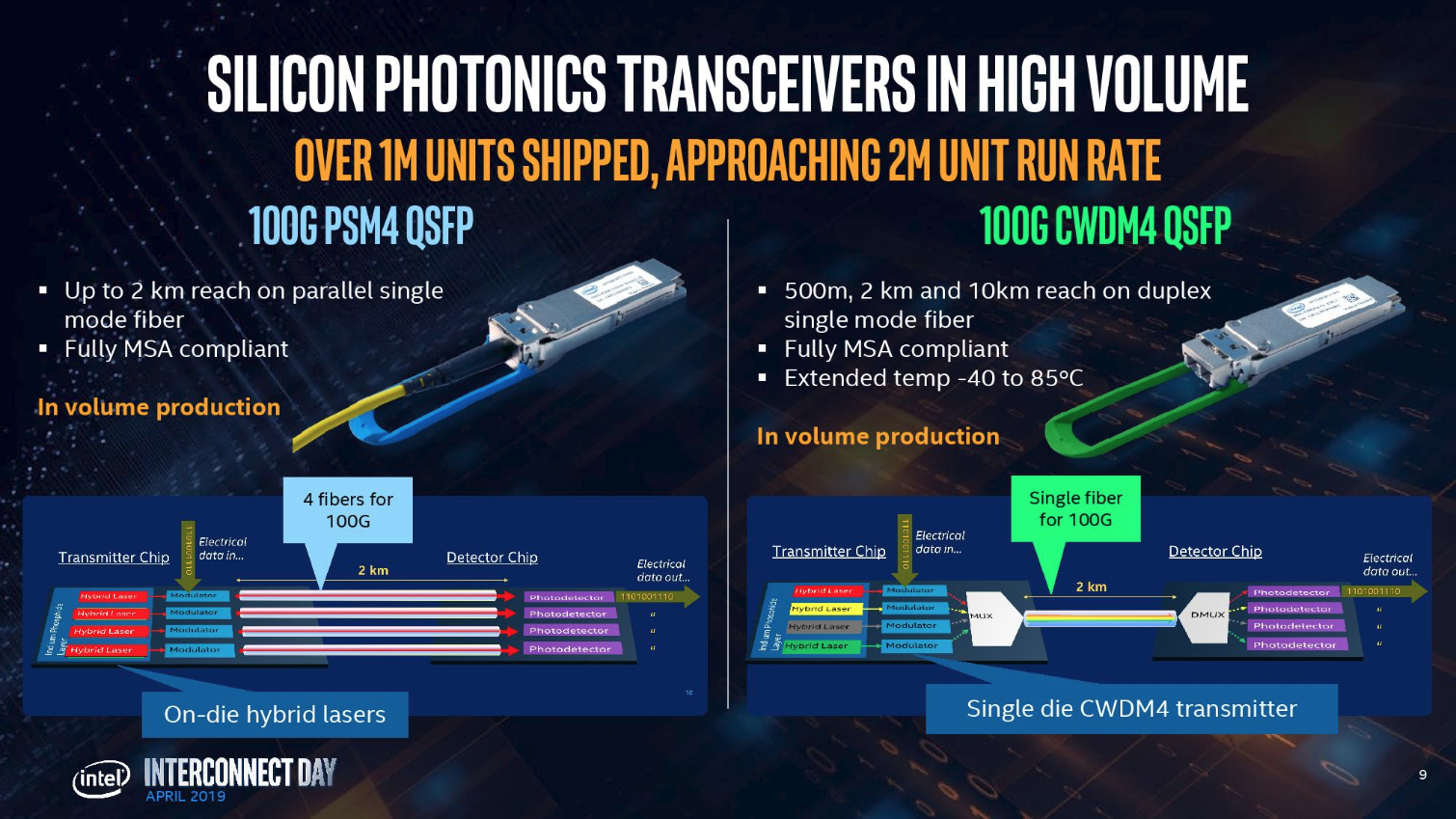

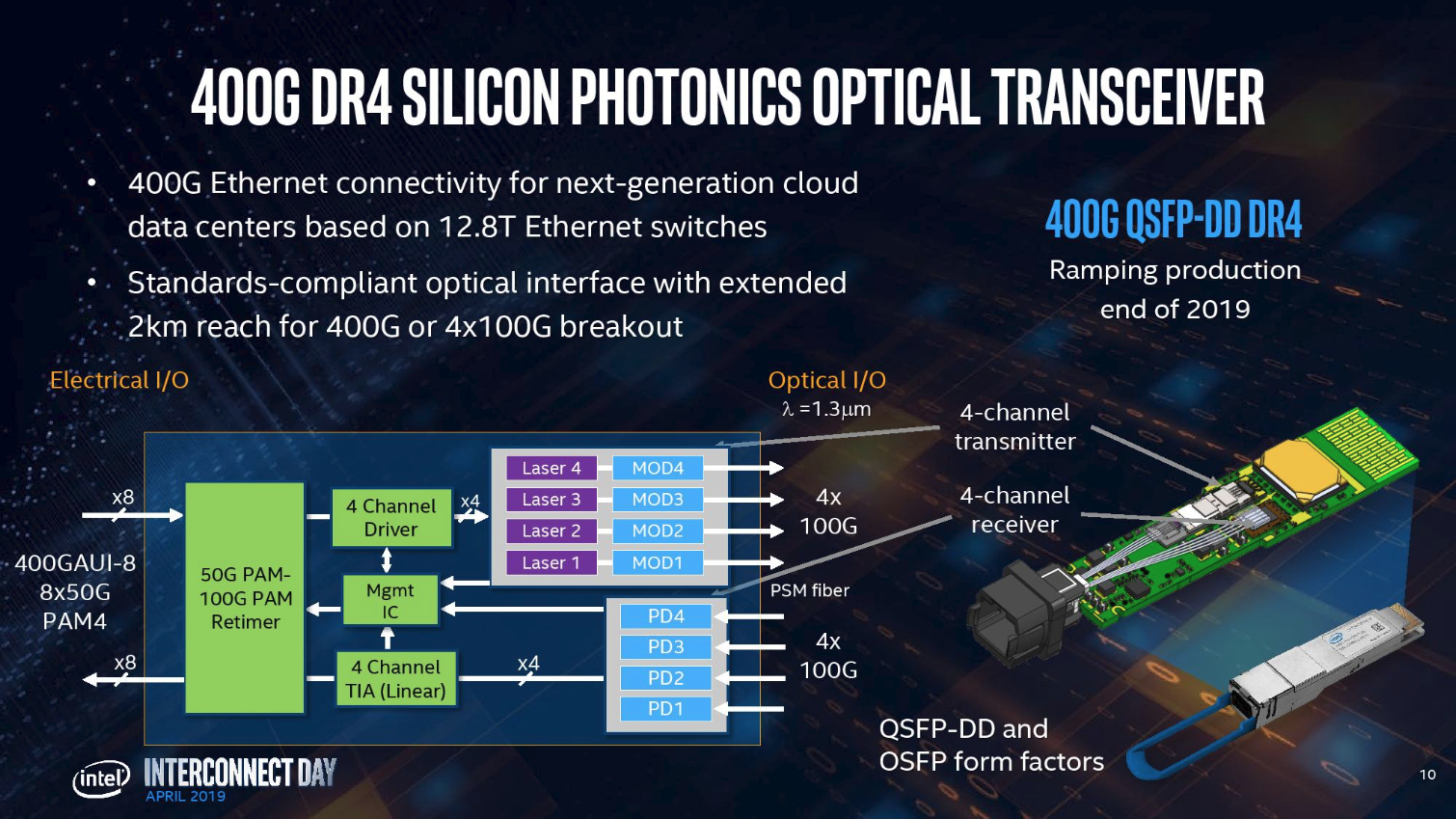

These small devices are mindbogglingly complex, with four lasers operating at 100Gb/s each inside of the 400G transceivers, but Intel has been developing silicon photonics technology for nearly 20 years and has invented several key new manufacturing and testing techniques that it claims provide advantages for mass-scale production.

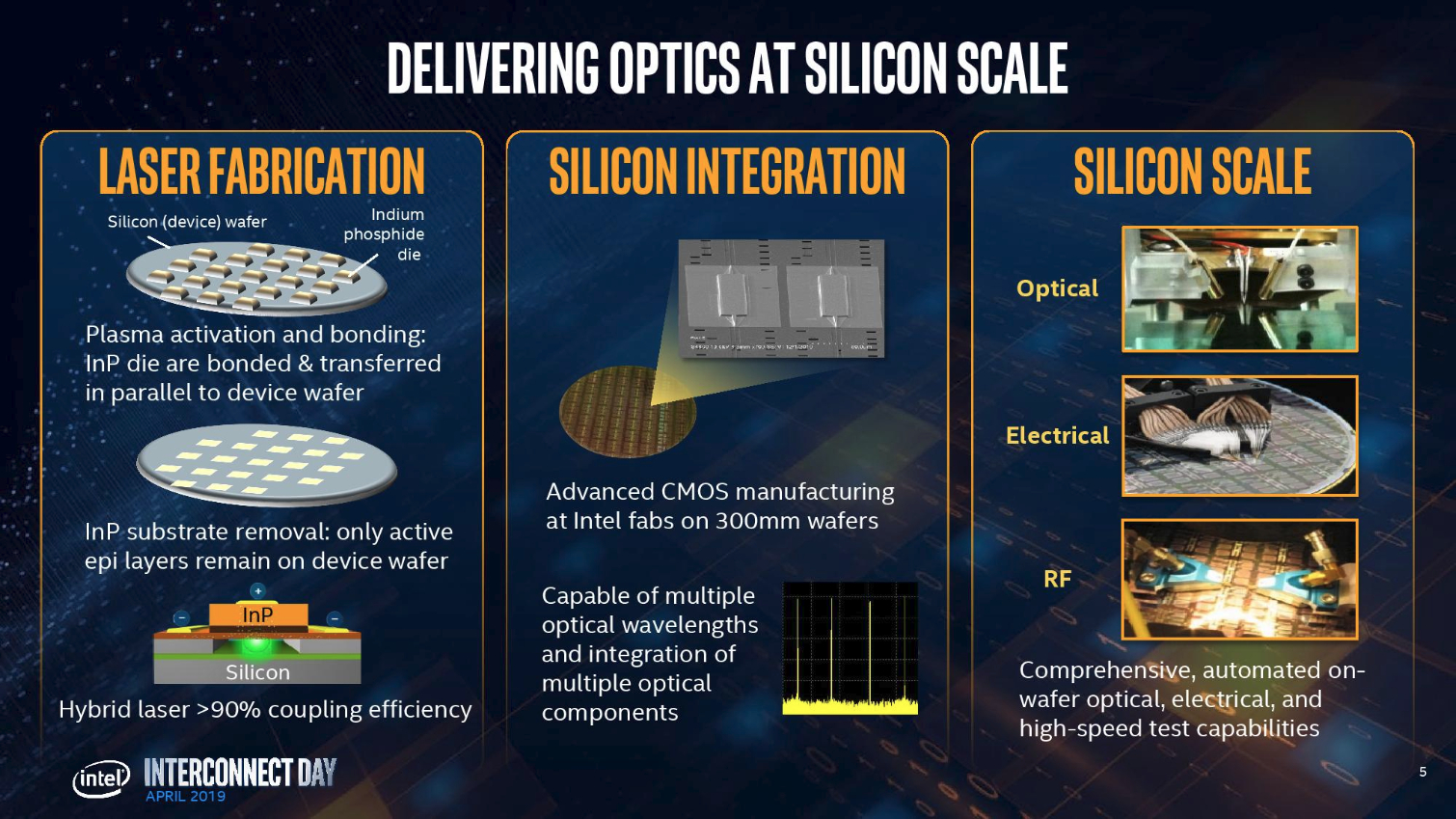

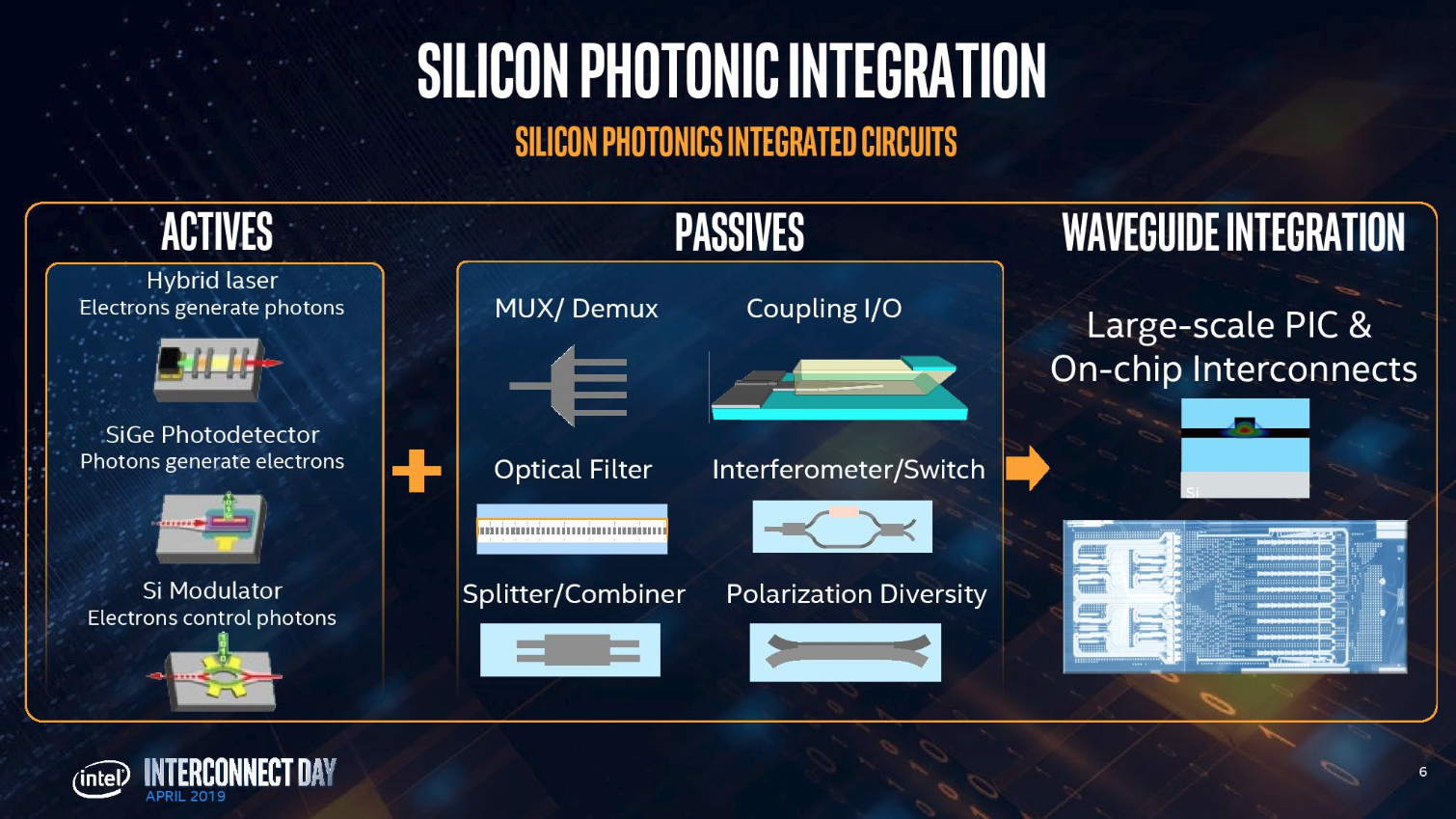

The company fabs its silicon photonics transceivers on a 24nm node with 300mm wafers using a standard CMOS process. Intel begins by creating waveguides, modulators, muxes, and other control circuitry on the wafers with photo-lithography techniques, then the company bonds hybrid Indium Phosphate lasers on top of the die. The lasers transmit light into the silicon, which then travels through the waveguides and is manipulated by various passive elements, like optical filters and splitters/combiners, to control the data flow.

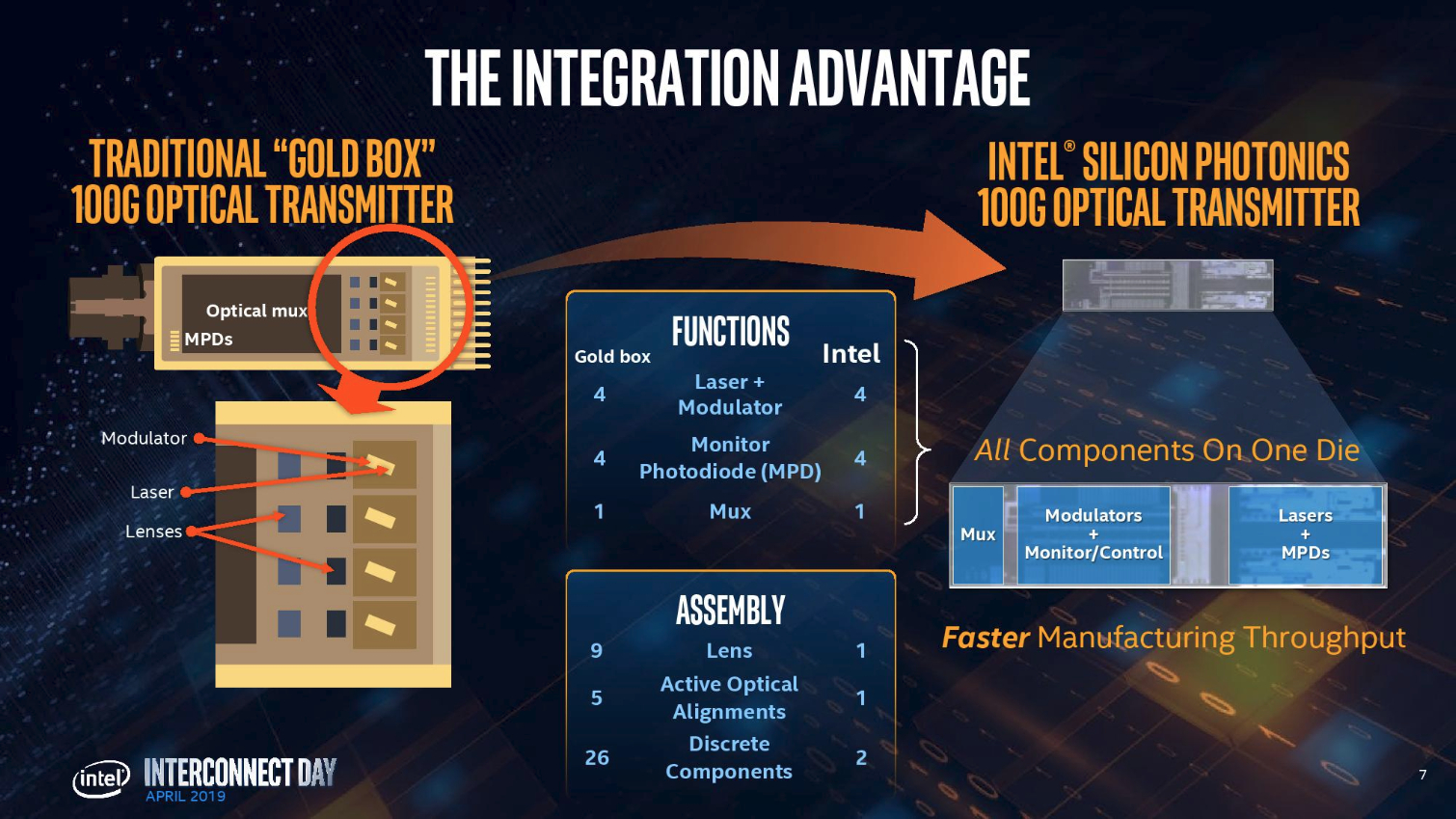

The single-chip approach affords power and reliability advantages over competing devices that consist of 40 separate components that are often manually assembled and tested and require hermetic sealing, compared to four components assembled and tested in an automated fashion for Intel's completed transceiver, which doesn't require sealing. This ultimately reduces production costs.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

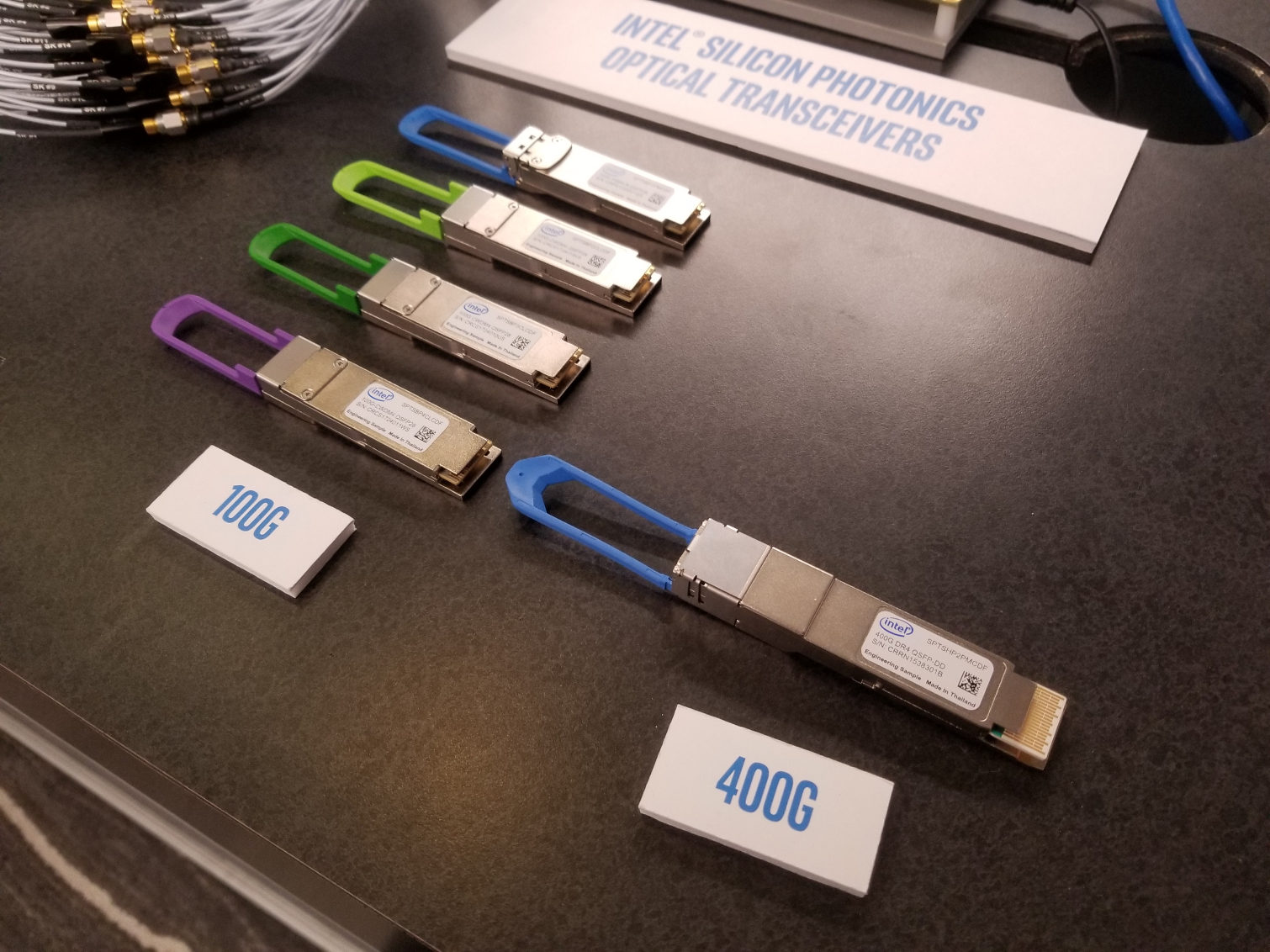

Here we can see Intel's inaugural 400G silicon photonics transceiver next to several of its 100G transceivers. These transceivers adhere to the QFSP28 form factor and are split into different categories based on transmission length, with the light green transceiver capable of pushing data 500 meters while the dark green model reaches up to 2 kilometers. The purple transceiver extends the range to 10 kilometers for communication between data centers. The 400G transceiver can push data out to 500 meters, with more models to follow.

Intel projects that data centers currently spend 60% of their networking budget on optical solutions, with that mix projected to increase in the coming years. A single hyperscale data center can require up to 1.5 million transceivers, and for reference, Facebook alone operates 15 data centers and continues to build more.

That presents a huge revenue opportunity for Intel, especially as the industry is moving towards 1.6Tb links that feed into 25.6Tbps switches that require close proximity to the central switch ASIC to accommodate the faster transmissions speeds. That means that typical copper networking cable will not be able to satisfy the density and power requirements. Instead, the transceivers will be co-packaged with the switch itself, potentially representing a huge captive market for silicon photonics transceivers. Intel is already well down the development path on this next iteration of the tech, with demos planned for the first half of 2020.

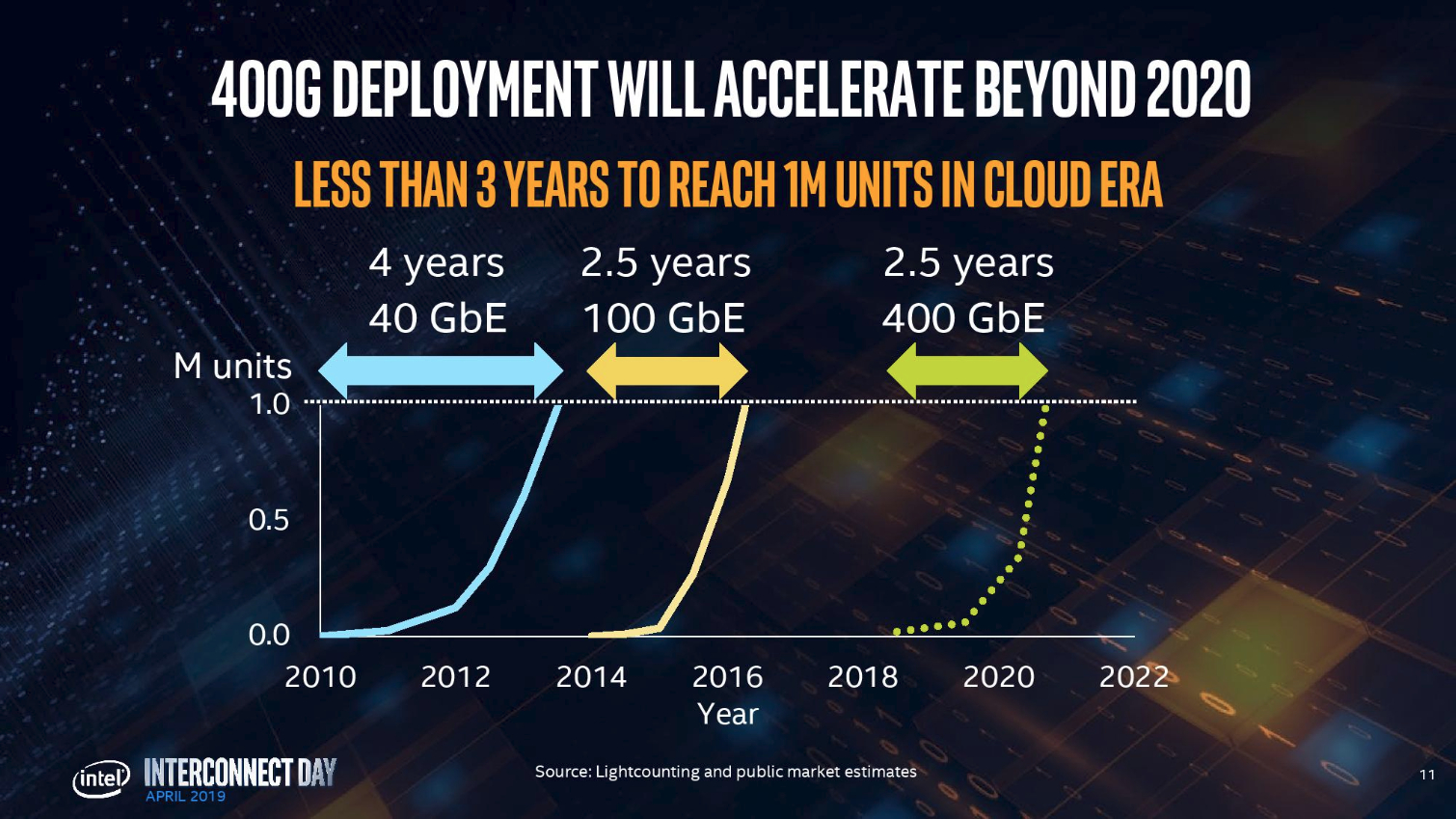

Intel claims it has mastered mass-producing the transceivers and has sold more than one million 100G transceivers over the course of two years. The company's production capabilities are increasing, as it has reached a two-million-unit-per-year run rate.

Intel says it will reach volume production of its 400G transceivers in Q4 2019.

Paul Alcorn is the Editor-in-Chief for Tom's Hardware US. He also writes news and reviews on CPUs, storage, and enterprise hardware.