Cool Cooling: Jumping Droplets Whisk Away Hotspots In Electronics

Engineers from Duke University, backed by Intel and the National Science Foundation, have developed a new technology to cool hotspots in high-performance electronics by using technology that was developed by mimicking the natural process that cicadas use to clean their wings.

Yes, you read that right, the very same process that allows a bug to clean its wings is now being used to cool hot spots in electronics. The super-hydrophobic surface of cicadas’ wings naturally repels water. This is possible because as two or more tiny water drops collide on the surface of the bug's wing, it creates a small amount of energy that in turn self-propels the newly formed water droplet into the air, taking trapped dirt and dust with it in the process.

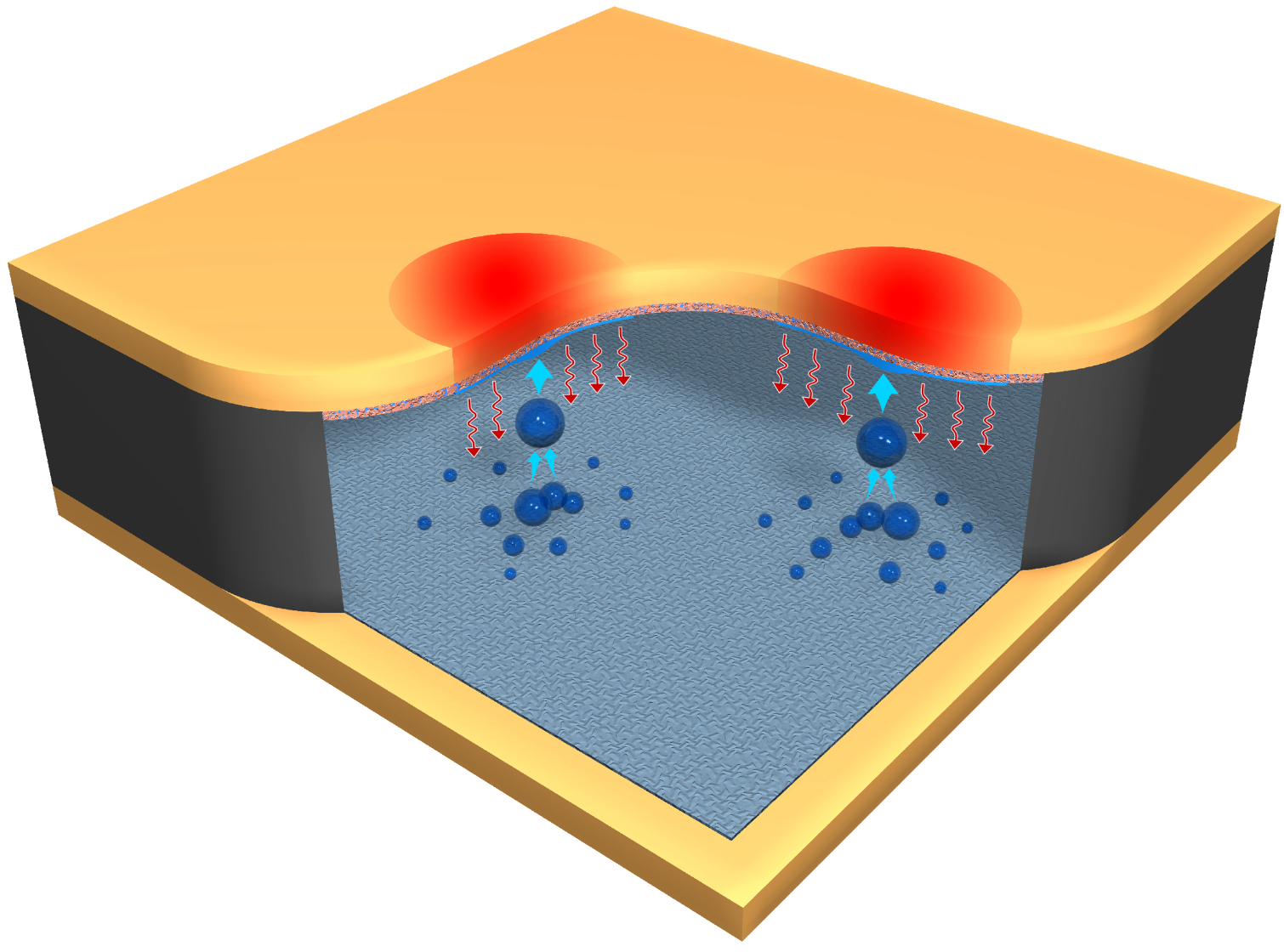

Researchers, believing that this very same process could be utilized to remove waste heat from electronics, built a special vapor chamber with a super-hydrophobic floor and a sponge-like ceiling. As the chamber absorbs heat, condensation occurs in the areas directly under the hot spots, which, in turn forms tiny water droplets that fall to the super-hydrophobic surface of the chamber floor, forming larger drops.

The reduction in surface area causes the release of a small amount of energy that propels the larger drop into the air, taking heat energy with it. The heated "jumping" water drop is then absorbed into the sponge-like ceiling of the vapor chamber, and the cycle repeats itself. According to the article, this process happens regardless of orientation, even if the device is upside-down.

Researchers claim that the benefits of this type of cooling system has many advantages over existing cooling techniques. Thermoelectric cooling modules that use the Peltier effect are popular but are unable to target heat spots and are not particularly efficient. Although there are other cooling techniques capable of targeting hot spots, they require additional power inputs, which leads to inefficiencies.

This video from Duke University demonstrates how the entire process works:

Even though the engineers in charge of this project are optimistic, they freely admit there is still much work to be done before these jumping droplets can compete with today’s cooling technologies.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

"It has taken us a few years to work the system to a point where it's at least comparable to a copper heat spreader, the most popular cooling solution," said Chuan-Hua Chen, associate professor of mechanical engineering and materials science at Duke. "But now, for the first time, I see a pathway to beating the industry standards."

Steven Lynch is a contributor for Tom’s Hardware, primarily covering case reviews and news.

-

Giroro This could be the best cooling in the world, but Intel would still use a cheap thermal paste that dries out in a year, forcing you to 'upgrade' your entire platform to get a similarly performing model.Reply -

Virtual_Singularity But is it as cool as this novec immersion based idea that's been around for years but is usually only implemented in datacenters? No residue left on components, efficient operation, evaporates on surface e.g. radiator & falls back into tank. It'd be cool to see a desktop made with this, but smaller than the one in the vid =P.Reply -

InvalidError Reply

The solid components of thermal paste account for 90-95% of the heat conduction - zinc oxide powder has a thermal condictivity near 50W/mK while silicone oil is only ~2W/mK. The silicone oil is only there to make application manageable and keep the fine metal oxide, graphite or other powder which does the bulk of the actual heat transfer from becoming airborne. The paste only seems "dry" because excess oil got squeezed out by thermal cycling over time but the thermal performance remains as long as the packed particle bond remains unbroken. Most of the times where people complain about sudden cooling performance loss is after swapping RAM, cleaning heatsinks, moving a PC, etc. where an impact on the PC or heatsink broke the paste bond.19531922 said:This could be the best cooling in the world, but Intel would still use a cheap thermal paste that dries out in a year -

JacFlasche The first time I saw this done was with a liquid named Floristate or something like that, by some Australians who were experiencing problems running it through a coil cooled by acetone and dry ice because it kept gelling up. Problem is that the stuff cost hundreds of dollars a gallon. Later we saw that the same thing could be done with a variety of different mineral oils, even vegetable oil. That had it's own problems, but a pure transparent mineral oil seemed to work OK for a while. Like the mineral oil that is used for high vacuum pumps. I don't know how much 3m Novic costs, apparently it is a unique synthesized fluid, but I do know that there are any number of corporations that will sell you what is essentially mineral oil for huge bucks, like the fluids used to cool the old types of transformers on power poles. The ones that explode every once in a while with a beautiful deep orange fireball. I guess the problem for all such systems is cost and maintenance per performance gain. I suppose if you are the kind of person who loves to tinker around and that in itself is mostly what you enjoy, then there is all kinds of stuff you can do that doesn't really make sense for a gamer in the real world.Reply

Personally I think this cicada wing thing is gonna be great if it happens, maybe they can nanofacture it as a matrix that is deposited right on the silicon and eliminate the need for thermal paste inside the lid, by having the lid the top of such a little chamber where this effect takes place. Then the only grease would be what you put between the lid and the heat-sink on your cooler.

And after my recent experience with a LEPA 240 all in one watercooler destroying my computer by leaking, and the ill response of Enermax, I am back to air, and this new development seems like it would work really well with air.

I found this interesting:

http://www.overclock.net/t/1209583/3m-novec-7000-group -

JacFlasche I am wondering if a number of little chambers like this could be stacked on top of each other to good effect. I also wonder why the heat generated by the CPU could not be used to power a little sterling engine which in turn could be used to help power the computer.Reply -

RomeoReject Reply

My media PC uses immersion cooling! It's cool, but immovable. Awesome for stuff like datacenters and servers, awful for stuff like cellphones and laptops.19535265 said:But is it as cool as this novec immersion based idea that's been around for years but is usually only implemented in datacenters? No residue left on components, efficient operation, evaporates on surface e.g. radiator & falls back into tank. It'd be cool to see a desktop made with this, but smaller than the one in the vid =P.

This solution I could see being useful on devices where energy consumption is key, namely: Laptops, tablets and phones. -

RomeoReject Reply

Scale and heat, would be my guess. Hard to make a motor that small efficient. And if it isn't efficient, it's generating heat. On top of that, the better the cooling half of the equation, the worse any heat-based generator would perform.19540535 said:I also wonder why the heat generated by the CPU could not be used to power a little sterling engine which in turn could be used to help power the computer.