Japan Chip Supply Chain Fully Recovered by Q3

While the disastrous earthquake in Japan will remain in our memory for years to come, it appears that businesses in Japan have made astonishing progress to bring back their production.

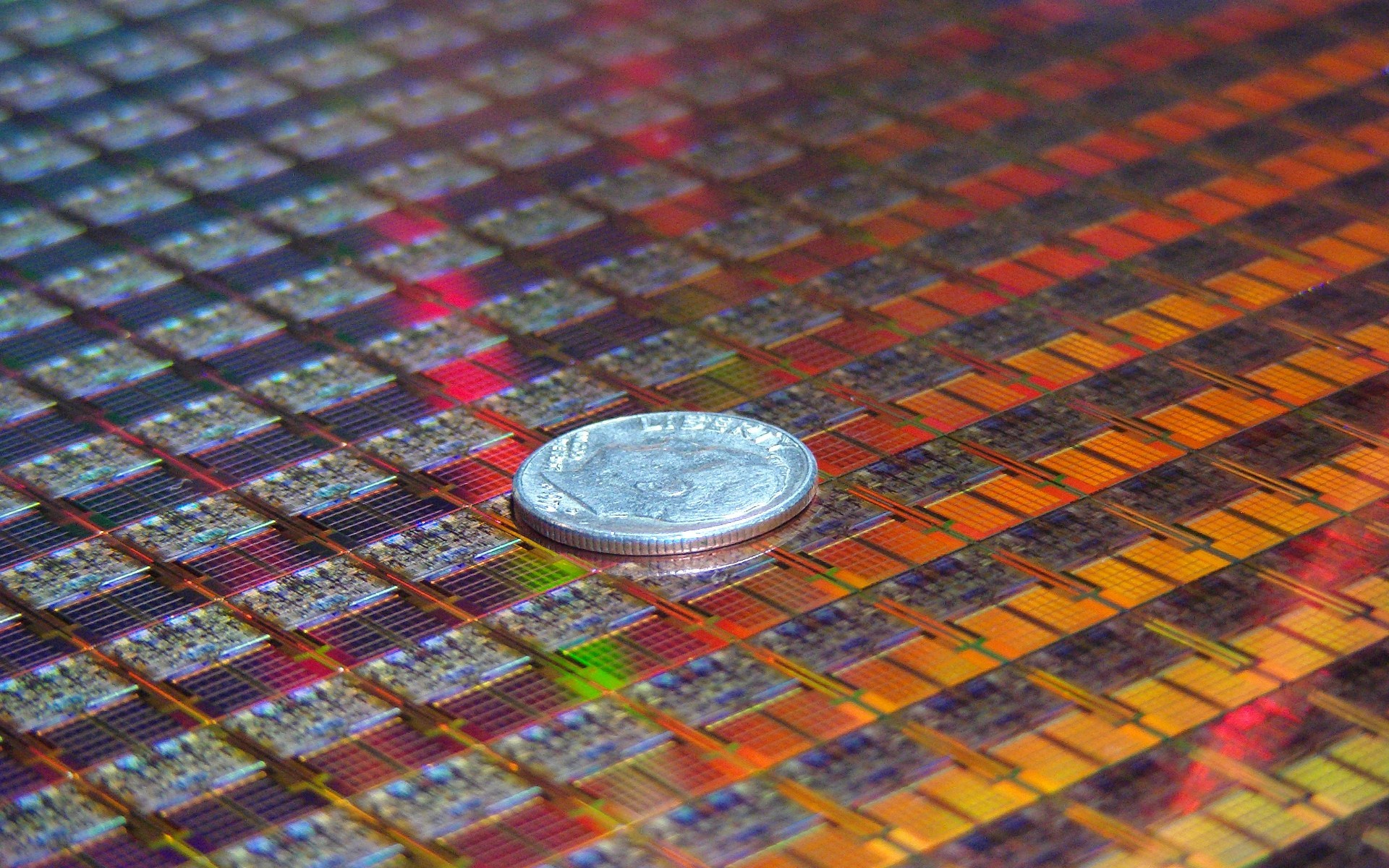

IHS iSuppli said that electronics companies, even those who were located at the epicenter of the quake, will have fully restored their operations and will resume full shipments by early September. Japan supplies about 45% of semiconductors for the global consumer electronics production. The earthquake hit Japan on March 11.

“In the history of the electronics supply chain, nothing has had such a broad impact as the Japan earthquake, tsunami and nuclear disaster,” said Dale Ford, senior vice president for semiconductor market intelligence at IHS, speaking at the IHS Design & Supply Chain Global Summit last week in San Jose, Calif. “The worldwide repercussions of the catastrophe illustrated the global and interconnected nature of the electronics industry, with the impact of the disaster reverberating through the materials, components and equipment segments of the supply chain. However, even the semiconductor companies suffering the most direct damage from the quake, full production will resume near the end of the third quarter.”

According to IHS iSuppli, 14 semiconductor suppliers and four silicon wafer makers in Japan were impacted by the quake. The company highlighted Fujitsu as a supplier with the most rapid and efficient recovery effort among all Japanese semiconductor suppliers. Fujitsu claimed that its production was fully restored by June 9. According to IHS iSuppli, Fujitsu leveraged different production facilities around the globe, a pre-existing plan how to restore electricity in the event of a disaster as well as pre-installed equipment that could seismically isolate damage to semiconductor wafers to mitigate the impact of the earthquake.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Douglas Perry was a freelance writer for Tom's Hardware covering semiconductors, storage technology, quantum computing, and processor power delivery. He has authored several books and is currently an editor for The Oregonian/OregonLive.

-

legendkiller Why are the US helping Japan? I do not see a point in helping them... I don't know if you all forgot what they did and what happened in December 7, 1941 but they attack "Pearl Harbor"... That's what they should get for what they done and nearly 90% of the people in the US still helps... You all helps Japan for nothin, Soon there will be a WAR, Fight for Water!!!Reply -

banthracis Yes, because clearly we should base all current relationship upon historical conflicts....so clearly we should be bombing the Brits right now for what they did to us back in the 1700's, or did you forget?Reply

It's because of idiots with a mindset like yours that entirely pointless conflicts over insignificant details persist throughout the world. -

sykozis LegendKillerWhy are the US helping Japan? I do not see a point in helping them... I don't know if you all forgot what they did and what happened in December 7, 1941 but they attack "Pearl Harbor"... That's what they should get for what they done and nearly 90% of the people in the US still helps... You all helps Japan for nothin, Soon there will be a WAR, Fight for Water!!!Reply

Please don't post such stupid shit. Yes, they attacked Pearl Harbor.....we dropped Atomic Bombs on Hiroshima and Nagasaki in retaliation.....which, at the time, were heavily populated cities in Japan. Also, that was 70 years ago....and btw, at least half the electronics in every car on the road comes from Japan.... -

neokaer LegendKillerWhy are the US helping Japan? I do not see a point in helping them... I don't know if you all forgot what they did and what happened in December 7, 1941 but they attack "Pearl Harbor"... That's what they should get for what they done and nearly 90% of the people in the US still helps... You all helps Japan for nothin, Soon there will be a WAR, Fight for Water!!!August 6 1945Reply -

house70 Good for them, it shows what true resilience is. And very civilized/common sense people: not a single incident of looting or other anti-social behavior. Elsewhere, even after a local event like a tornado strike, looting and theft were common occurrence. Maybe we all need to learn from them.Reply

@Legendkiller: you, sir/madam, are a prime example of what's wrong with mankind. -

bobusboy LegendKillerWhy are the US helping Japan? I do not see a point in helping them... I don't know if you all forgot what they did and what happened in December 7, 1941 but they attack "Pearl Harbor"... That's what they should get for what they done and nearly 90% of the people in the US still helps... You all helps Japan for nothin, Soon there will be a WAR, Fight for Water!!!Reply

TRolololOLOLololol -

rubix_1011 ReplyWhy are the US helping Japan? I do not see a point in helping them... I don't know if you all forgot what they did and what happened in December 7, 1941 but they attack "Pearl Harbor"... That's what they should get for what they done and nearly 90% of the people in the US still helps... You all helps Japan for nothin, Soon there will be a WAR, Fight for Water!!!

...As you are being an insolent imbecile with no regards to any rational though, you submit this message using semiconductors, processors, memory, LCD display screen either developed in Japan or developed based off of R&D from Japan...as well as simply read and understand the news from Japan delivered digitally (via technologies mentioned above) so you CAN EVEN READ AND COMPLAIN ABOUT THIS.

Moron. -

clonazepam Japan deserves all the respect in the world. When you compare their pre world war 2 culture to today you see progress on a scale you'd be hard pressed to find comparisons to. On a lighter note, they feed beer to their cattle, how cool is that? Hopefully, their whaling will end soon.Reply

Their ability to recover from this horrific tragedy is nothing short of amazing. I wish them all a speedy recovery. -

clonazepam Hopefully, their whaling will end soon.Reply

Why should it? They have every right to whale, and they're following their quota. Don't tell me that you support that pathetic and lying bastard known as Paul Watson.