Solidigm Introduces Industry-First PLC NAND for Higher Storage Densities

Penta-level-cell has nothing to do with Doom, and all to do with density.

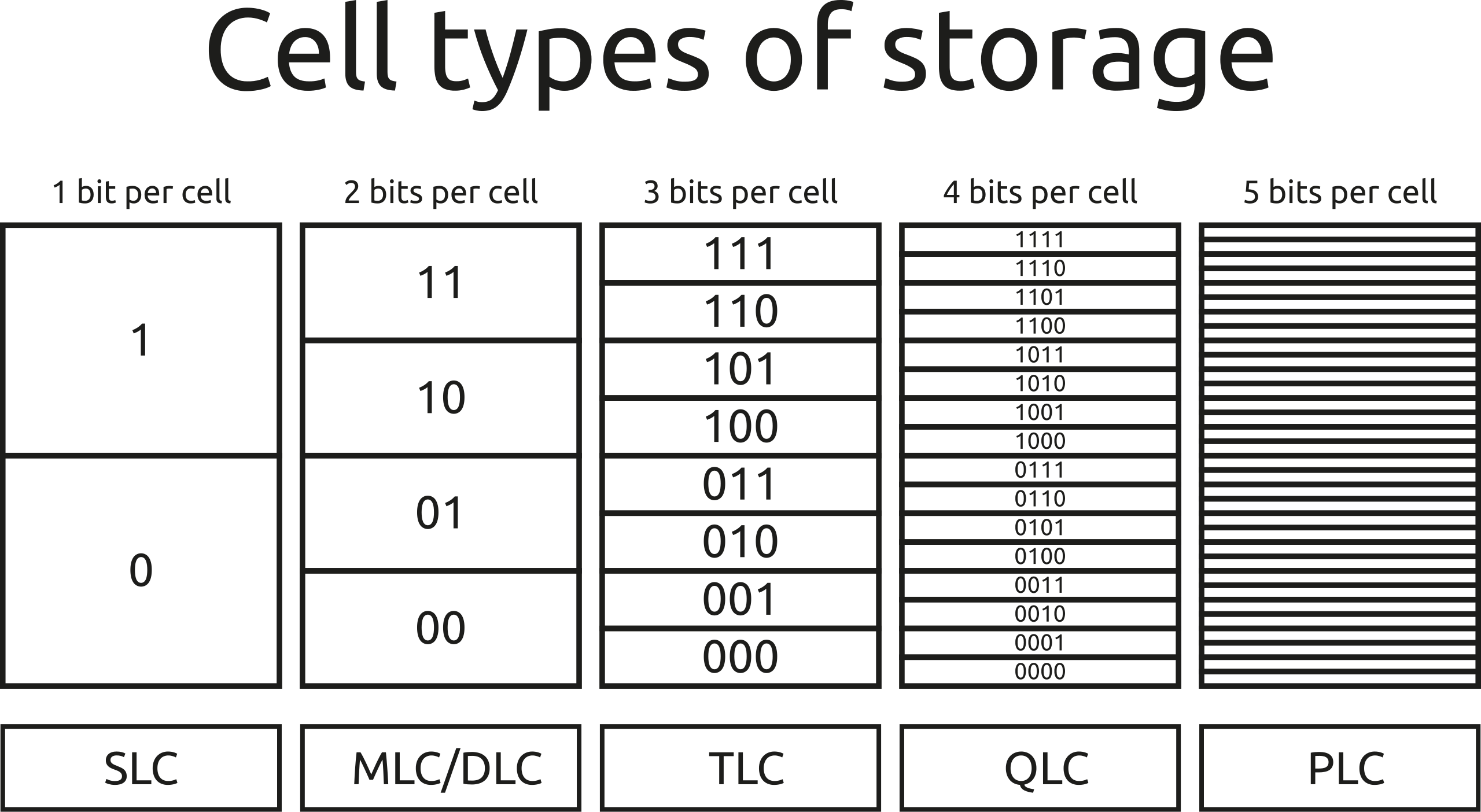

Solidigm, the NAND research and manufacturing arm sold by Intel to SK hynix, took to the Flash Memory Summit 2022 to showcase a finished and working SSD prototype carrying the company's latest NAND technology: Penta-Level Cell (PLC). PLC builds upon NAND density by adding the capability for a single cell to store up to 5 bits of data (up from QLC's four bits per cell), increasing the amount of available space in each NAND flash chip.

The new technology thus paves the way for even cheaper $/GB ratios on PLC-based SSDs than what's currently possible with Quad-Level Cell (QLC) technology (let alone MLC and SLC tech, which have been mostly relegated to enterprise, datacenter, and other critical environments). Even as the amount of data produced by humanity increases at an astonishing pace (with predictions placing daily data creation sitting at 463 exabytes daily by 2025), storage technology will also need to evolve to accommodate this avalanche. With the increasing investments in supercomputing, the dawn of 5G and AI, all with deep data storage requirements of their own, Solidigm sees PLC as a way to scale while keeping costs in check.

We believe in the increasing benefits of QLC and PLC #NAND to meet the data-intensive needs of AI, machine learning, big data analytics, and to support 5G. We’re energized for the future and committed to seizing this moment. #TheNewParadigm #FMS2022 #SSD https://t.co/184jvKPGDE pic.twitter.com/AsKWjYujOTAugust 8, 2022

PLC works by adding additional voltage states, which represent the information bits in the cell. While SLC only had to deal with two voltage states (a bit was either written or not), MLC doubled that number to four voltage states (so each cell could contain any combination of both a 0 and a 1). PLC NAND technology ends up requiring 32 distinct voltage states to differentiate between all possible combinations of ones and zeros the cell can hold. This places additional strain on the cells and at the controller level, which has to account for the increased chance of voltage states being incorrectly written, corrupting the data. More powerful error correction algorithms thus have to be implemented at the controller level.

Each additional bit per cell requires a doubling of the voltage states, which has its own implications in the cell's life expectancy and requires much more fine-tuned reading and writing capabilities to deal with the increasingly smaller differences between states. This reduction in life expectancy for NAND cells as their bit storage capacity increases is part of the reason why QLC SSDs are generally considered to be less reliable (with cell "death" occurring earlier) compared to lower numbers of bits.

The laws of diminishing returns are pretty clear in scaling NAND density through additional bits per cell. Essentially, each additional bit of information on a single NAND cell leads to an increase of 100% in required voltage states (adding to its complexity), while the storage capacity increase itself is reduced in half.

| Row 0 - Cell 0 | SLC (1 Bit) | MLC (2 Bits) | TLC (3 Bits) | QLC (4 Bits) | PLC (5 Bits) | HLC (6 Bits, theoretical) |

| Delta Storage Capacity | Baseline | +100% | +75% | +50% | +25% | +12,5% |

| Delta Complexity Increase | Baseline | +100% | +100% | +100% | +100% | +100% |

"We are excited to show the industry's first PLC SSD in action today, " said Sanjay Talreja, SVP and General Manager of Solidigm's Client Storage Group. "It is an important milestone for Solidigm as a new company and an exciting moment for the future of storage technology with far-reaching implications."

Since Solidigm's PLC NAND is based on Intel technology, it uses a different type of cell than what other major NAND players - such as Micron - have been focusing on. Intel's NAND was based on floating gate transistors, which Solidigm says was suited to increasing bits per cell to enable the creation of PLC. Micron - alongside most of the NAND industry - has instead focused its manufacturing on charge trap technology, which has its own strengths and weaknesses.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

It's currently unclear when exactly PLC-based drives will hit the market. Western Digital has gone on record saying they wouldn't hit the market before 2025 - yet here we are in 2022 with Solidigm's working prototype. But when they arrive, customers can look forward to NAND drives that have better $/GB ratios than what the cheapest QLC drives can ever hope to provide. And if you think Solidigm should be relegated to the $/GB equation, think again. One of the most efficient and fastest SSDs we ever tested, the SK hynix Platinum P41, belongs to Solidigms' parent company. PLC SSDs will likely have a hard time fighting on performance, but as controllers and buses mature, we'd expect them to provide great performance at a more affordable price.

Francisco Pires is a freelance news writer for Tom's Hardware with a soft side for quantum computing.

-

bit_user I'm still wondering who's the idiot responsible for the "L" in "xLC". Should be a xBC for "x Bits per Cell".Reply

For a few years, I was operating under the assumption that TLC meant storing 1.5 bits per cell, rather than 3.

P.S. I'm still trying to avoid QLC as much as I can. This new development should be very unwelcome by anyone who values data retention and integrity. -

cyrusfox Amazing to see PLC out so early, nice work Intel/Solidigm (Crappy new name though...)Reply

Have you wore out a SSD yet through read/write cycles? I am still using a OCZ Vertex 4 that were notorious for dying early. I have a 660p QLC 512GB drive showing 80% life left which has been in service for 3 years now(It only boast 200cycles). PLC will work out fine, As long as it can do 100+ cycles, that coupled with the latest controllers and SLC cache to smooth out the experience, these will be great to put price pressure on the TLC charge trap everyone else is making in the consumer space. PLC should easily outlast the useful life of the laptops and are easy to swap out and use as a fast m.2 external storage drive if you want something more performant.bit_user said:This new development should be very unwelcome by anyone who values data retention and integrity.

For my heavy write/scratch drives, I use old server grade Intel and Samsung drives for pennies per GB(SATA drives with rated for 10-20k cycles). -

bit_user Reply

That's only one way to lose your data. The other is simply to leave it turned off for too long. As cells become smaller and packed with more bits, that power-off data retention time quickly dwindles.cyrusfox said:Have you wore out a SSD yet through read/write cycles?

Winning a race to the bottom is no victory for anyone.cyrusfox said:these will be great to put price pressure on the TLC charge trap everyone else is making in the consumer space.

You assume that will always be an option, but they're starting to use different form factors that are much less consumer-friendly and ship in capacities that limit us to buy heavily used drives pulled from decommissioned servers. Not a very attractive alternative.cyrusfox said:For my heavy write/scratch drives, I use old server grade Intel and Samsung drives for pennies per GB(SATA drives with rated for 10-20k cycles). -

edzieba Reply

We've seen the exact same proclamations of impending data-loss and drive-failure when MLC overtook SLC for the majority of drives sold, when TLC overtook MLC for the majority of drives sold, and when QLC overtook TLC for the majority of drives sold. The sky has resolutely refused to fall.bit_user said:P.S. I'm still trying to avoid QLC as much as I can. This new development should be very unwelcome by anyone who values data retention and integrity. -

AgentBirdnest I'm pretty excited about this (which seems like an unpopular opinion.) I'd love to have a cheaper, large capacity SSD for a media drive. Don't care about write speeds or endurance, since I'd probably only write to it once.Reply

I hope it comes before 2026... -

bit_user Reply

There are a few reasons for this. First, error correction schemes have gotten better. Second, cell designs have improved. However, both of those are not wells you can keep going back to. I'd guess both are beyond the point of diminishing returns.edzieba said:We've seen the exact same proclamations of impending data-loss and drive-failure when MLC overtook SLC for the majority of drives sold, when TLC overtook MLC for the majority of drives sold, and when QLC overtook TLC for the majority of drives sold. The sky has resolutely refused to fall.

The other thing you're ignoring is what I said about power-off data retention time. I have an ebook reader that I bought in 2019. I went maybe 4-6 months without using it and its storage was toast. I had to factory-reset it. I have > 10-year-old USB sticks which still have files I wrote when I got them. New USB sticks won't come anywhere close to such retention times.

For a device you use every day, QLC and even PLC is fine. However, such experiences don't translate to other usage models. -

bit_user Reply

Here's why it's a bad tradeoff. They're halving the voltage difference between two distinct values, for the benefit of only 25% more bits per cell. Your media drive is going to be a lot more failure-prone, for the benefit of only 25% more capacity. If you really care about what's on it, that's not a risk I'd take.AgentBirdnest said:I'm pretty excited about this (which seems like an unpopular opinion.) I'd love to have a cheaper, large capacity SSD for a media drive.

And unlike hard disk errors, you can't very well mitigate the issue of dwindling power-off data retention through RAID, because all of your SSDs are going to suffer charge decay at roughly the same rate. So, if one drive falls off the cliff, chances are the others will have, also. -

GoboII Bit of a typo in the article, TLC would provide 50% more data density compared to MLC, going from 2 to 3 layers per cell. Similarly, QLC would be a 33% increase over TLC, and PLC would be a 25% increase over QLC.Reply