UMC to Deliver 20 nm Chips in H2 2013

He expects a "structural shift", according to Digitimes, that will lead to a gradual change in market leadership.

Sun sees UMC well-positioned with new 300 mm production capacities coming online in 2013. The company is investing about $2 billion into its fabs this year, which mainly will be used to grow 28 nm capacity. Sun estimated that about 5 percent of UMC's 2012 revenues will be derived from 28 nm products.

20nm FinFET is scheduled for a 2014 volume production and the company said that it has an agreement with IBM to develop a 20 nm 3D FinFET production technology. Low-volume 20 nm chips will be coming off the production lines in H2 2013, Sun said.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Douglas Perry was a freelance writer for Tom's Hardware covering semiconductors, storage technology, quantum computing, and processor power delivery. He has authored several books and is currently an editor for The Oregonian/OregonLive.

-

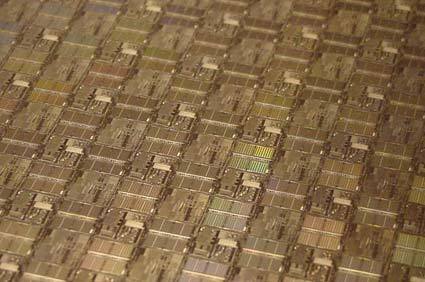

shin0bi272 I have to ask... why they are still using round wafers to make square chips? You'd think that someone would have come up with a way to mass produce chips 1 at a time via some sort of assembly line process. If it works for food, light bulbs, cars, dishware, etc., etc., it should work for chips too. Eh anyway Im sure someone will figure it out some day.Reply -

blazorthon shin0bi272I have to ask... why they are still using round wafers to make square chips? You'd think that someone would have come up with a way to mass produce chips 1 at a time via some sort of assembly line process. If it works for food, light bulbs, cars, dishware, etc., etc., it should work for chips too. Eh anyway Im sure someone will figure it out some day.Reply

Making larger wafers are generally cheaper per chip produced than making smaller wafers if I remember correctly. Round ones are probably much easier to make than square ones. -

gilgamex I think it's because the wafer is spun through all sorts of production phases, the circular shape of it allows the aerodynamics of it to be consistent leaving little margin for error.Reply -

gilgamex gilgamexI think it's because the wafer is spun through all sorts of production phases, the circular shape of it allows the aerodynamics of it to be consistent leaving little margin for error.Reply

Ignore this is completely wrong, and honestly a guess, "Silicon wafers are grown by using the Czochralski, in which a 'seed crystal' is rotated in a bath of hot molten silicon. As the seed crystal rotates, silicon atoms stick to crystal with a specific orientation that forms a crystal lattice. Eventually, this crystal becomes significantly large and forms a ingot weighing several tons. Because the crystal was rotating, the edges appear form a circle, not unlike spinning a popsicle stick in a thick syrup." found this on a website -

rantoc blazorthonMaking larger wafers are generally cheaper per chip produced than making smaller wafers if I remember correctly. Round ones are probably much easier to make than square ones.Reply

You are correct, bigger wafers produces more chips per cycle and also a bit less waste in the cutting process (square chips on a circular wafer = unused parts). -

If you bake a casserole or brownies in a square baking dish, the corners come out overcooked because they are, to put it simply, more exposed to the oven environment than the mid-sides areas and therefore heat up more quickly. That kind of non-uniformity is unacceptable in wafer processing, where temperatures and time-at-temperature needs to be precisely controlled.Reply

-

blazorthon Reply9385175 said:You are correct, bigger wafers produces more chips per cycle and also a bit less waste in the cutting process (square chips on a circular wafer = unused parts).

pcgeekesqIf you bake a casserole or brownies in a square baking dish, the corners come out overcooked because they are, to put it simply, more exposed to the oven environment than the mid-sides areas and therefore heat up more quickly. That kind of non-uniformity is unacceptable in wafer processing, where temperatures and time-at-temperature needs to be precisely controlled.

Thank you for the clarification. -

shin0bi272 pcgeekesqIf you bake a casserole or brownies in a square baking dish, the corners come out overcooked because they are, to put it simply, more exposed to the oven environment than the mid-sides areas and therefore heat up more quickly. That kind of non-uniformity is unacceptable in wafer processing, where temperatures and time-at-temperature needs to be precisely controlled.I was thinking more along the lines of cooling rather than baking. check out how they make glass dinner ware (I think its called vitrelle)... using a process similar to that could work for making chips.Reply

http://science.discovery.com/videos/how-its-made-vitrelle-dishware.html

You have molten silicon and you put it in a contraption that looks like a square waffle iron except its a cooling grid where each of the squares are the right size for the cpu die. The silicon goes in liquid and is spread out evenly then cooled on all sides by the waffle iron like device. Then you open the waffle iron and invert it and shake it and the chips fall out. Its not perfect no but if you could figure out a way to make the chips cool perfectly and get them out of the grid without breaking you'd have the ability to mass produce chips like lightbulbs ... Plus any waste could just be melted back down and repoured. -

f-14 shin0bi272I have to ask... why they are still using round wafers to make square chips? You'd think that someone would have come up with a way to mass produce chips 1 at a time via some sort of assembly line process. If it works for food, light bulbs, cars, dishware, etc., etc., it should work for chips too. Eh anyway Im sure someone will figure it out some day.watch on you tube at about 1:50 http://www.youtube.com/watch?v=aWVywhzuHnQReply

Mr Perry who is this "he" you are referring to at the beginning of your article? plagiarise much?

He expects a "structural shift", according to Digitimes, that will lead to a gradual change in market leadership. -

shin0bi272 f-14watch on you tube at about 1:50 http://www.youtube.com/watch?v=aWVywhzuHnQReply

saw that a couple of years ago actually. One of the things that they cut out of that youtube clip (or was on the "how its made" version of the same video) was that only 3 or 4 out of 10 wafers actually make it without shattering. Id also like to point out that the only reason that the crystal in that video is circular is because the thing they put it in is circular. if the seed crystal is put in the middle it should be possible to do the same thing with a square retort.

it should still be possible to take a smaller amount of silicon and put it in a mold with a grid on it and spin it while it cools and make a single crystal just square instead of circular.