Nvidia CEO says the US will take 20 years to achieve chipmaking independence from China and Taiwan, despite booming fab construction and subsidies

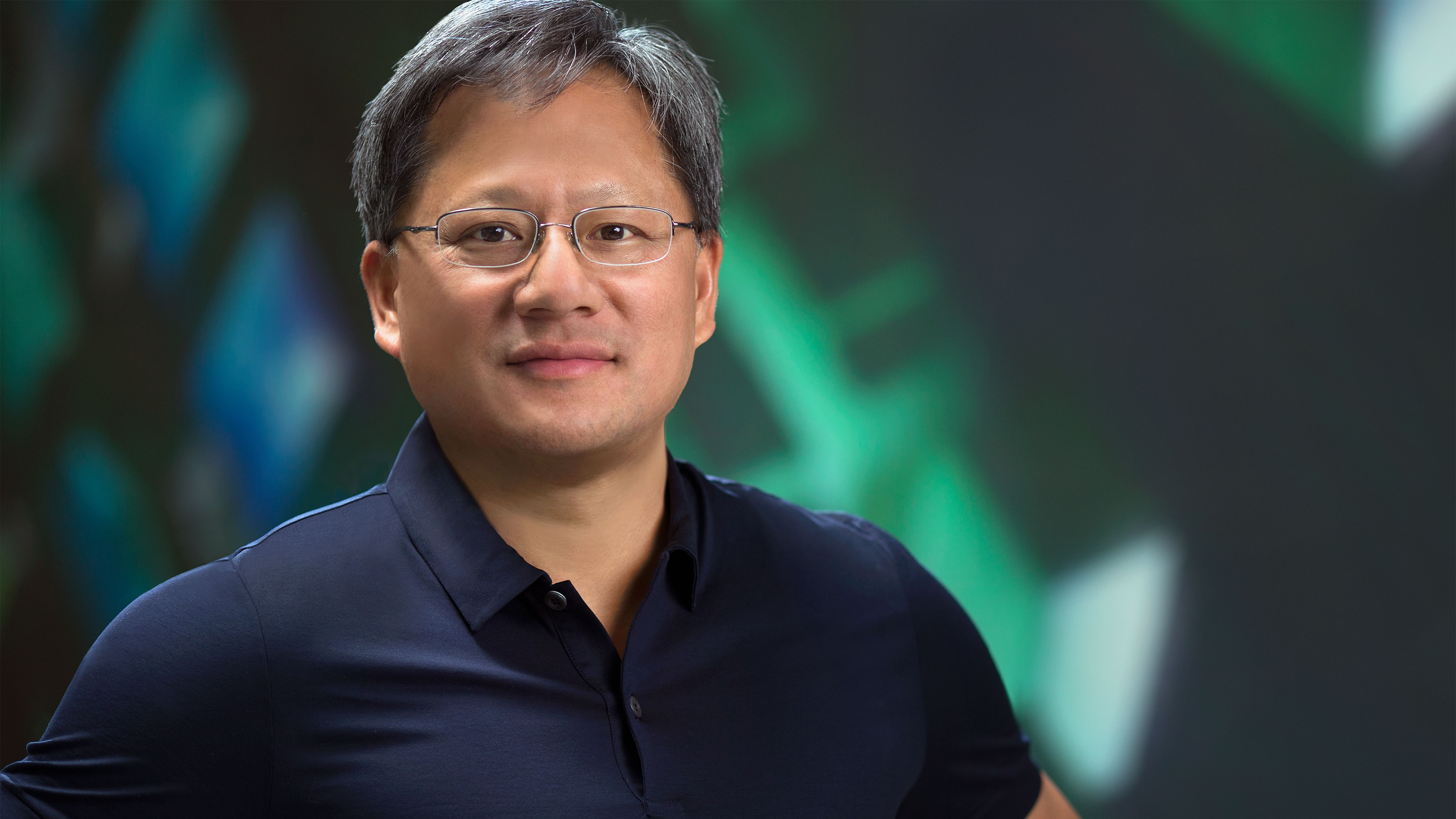

Jen-Hsun Huang doubts that the U.S. could live without chips from elsewhere.

Jensen Huang, CEO of Nvidia, believes it might take the U.S. up to two decades to become self-reliant in chip manufacturing. This statement comes from the head of the company that has historically relied on chip production in Taiwan, and significant efforts by the U.S. and Europe to localize the crucial industry. However, the chip industry is clearly expanding in America at a rate unseen in decades, so he might be too skeptical.

"We are somewhere between a decade and two decades away from supply chain independence," said Jensen Huang, speaking at the New York Times's DealBook conference in New York, reports Bloomberg. "It is not a really practical thing for a decade or two."

The U.S. government is actively pursuing policies to increase chip manufacturing within its borders. This initiative has garnered bipartisan support, focusing on establishing more manufacturing facilities stateside. The goal is to mitigate reliance on external sources and strengthen national technology infrastructure.

So far, the plan has been a success as Intel, TSMC, and Samsung Foundry are building their advanced and leading-edge fabs in the USA. Furthermore, Micron is set to bring advanced 3D NAND and DRAM memory production to America for the first time in decades. Intel is also building advanced chip packaging facilities in America. There are also companies, such as GlobalFoundries, that produce chips on specialty and mature process technologies in the U.S.

Huang noted that Nvidia's products rely on plenty of components that come from different parts of the world, and he does not see all of them produced in the U.S. any time soon. Therefore, his assessments highlight the company's current reliance on international supply chains and the complexity and extent of the global chip industry.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.

-

PEnns "The U.S. government is actively pursuing policies to increase chip manufacturing within its borders.Reply

So far, the plan has been a success as Intel, TSMC, and Samsung Foundry are building their advanced and leading-edge fabs in the USA. Furthermore, Micron is set to bring advanced 3D NAND and DRAM memory production to America for the first time in decades. Intel is also building advanced chip packaging facilities in America. There are also companies, such as GlobalFoundries, that produce chips on specialty and mature process technologies in the U.S. "

Someone should send Mr. Jen-Hsun Huang a link to this article.

Or at least tell him to read some tech news occasionally. -

edzieba Reply

The supply chain constitutes more than just fabs. You need Silicon mines, refineries, and casters. Wafer producers. Sources and refiners of all support gasses and fluids. Mines and refiners of metals used during doping and FEoL and BEoL processed. Manufacturers of not jsut support ICs but also passives. Miners and refiners of the materials used in those passives (e.,g. who manufacturers the chemicals doped onto the substrates sandwiched between the electrodes wrapped into an electrolytic cap?), Manufactuters of FRP and simialr PCB sunstrate materials. Manufacturers of PCBAs.PEnns said:"The U.S. government is actively pursuing policies to increase chip manufacturing within its borders.

So far, the plan has been a success as Intel, TSMC, and Samsung Foundry are building their advanced and leading-edge fabs in the USA. Furthermore, Micron is set to bring advanced 3D NAND and DRAM memory production to America for the first time in decades. Intel is also building advanced chip packaging facilities in America. There are also companies, such as GlobalFoundries, that produce chips on specialty and mature process technologies in the U.S. "

Someone should send Mr. Jen-Hsun Huang a link to this article.

Or at least tell him to read some tech news occasionally.

And so on and so forth. The supply chain is deep for electronics (even ignoring cases or other packaging), just having a fab does not onshore much of that supply chain alone.

Maybe you should read some tech news occasionally? -

thisisaname Reply

True but if you do not build the fabs there is no reason for anyone to do the other things locally either.edzieba said:The supply chain constitutes more than just fabs. You need Silicon mines, refineries, and casters. Wafer producers. Sources and refiners of all support gasses and fluids. Mines and refiners of metals used during doping and FEoL and BEoL processed. Manufacturers of not jsut support ICs but also passives. Miners and refiners of the materials used in those passives (e.,g. who manufacturers the chemicals doped onto the substrates sandwiched between the electrodes wrapped into an electrolytic cap?), Manufactuters of FRP and simialr PCB sunstrate materials. Manufacturers of PCBAs.

And so on and so forth. The supply chain is deep for electronics (even ignoring cases or other packaging), just having a fab does not onshore much of that supply chain alone.

Maybe you should read some tech news occasionally?

It will be a lot longer than 20 years if you never try. -

JamesJones44 Manufacturing and self reliance for the supply chain are two very different things. For supply chain self reliance I agree that we are decades away. You can't replace those resources especially hard resources like metals and material refinement overnight. Start with importing them, building local sources, then switch, but all that takes time.Reply -

PEnns Reply

Well of course, nobody said it'll happen overnight!edzieba said:The supply chain constitutes more than just fabs. You need Silicon mines, refineries, and casters. Wafer producers. Sources and refiners of all support gasses and fluids. Mines and refiners of metals used during doping and FEoL and BEoL processed. Manufacturers of not jsut support ICs but also passives. Miners and refiners of the materials used in those passives (e.,g. who manufacturers the chemicals doped onto the substrates sandwiched between the electrodes wrapped into an electrolytic cap?), Manufactuters of FRP and simialr PCB sunstrate materials. Manufacturers of PCBAs.

And so on and so forth. The supply chain is deep for electronics (even ignoring cases or other packaging), just having a fab does not onshore much of that supply chain alone.

Maybe you should read some tech news occasionally?

there are tons of logistics involved. But to blissfully claim / agree with Jen, it will take more than 20 years is beyond absurd.

This is 2023 not the 18th century.!! Heck, Planning and going to the moon didn't take 20 years of preparation. -

evdjj3j "It is not a really practical thing for a decade or two."Reply

Please update the title to reflect what he really said. He didn't say it will take 20 years, he said it will take 10-20 years. -

parkerthon I think he’s probably right. 10-20 years to reverse 60+ years of APAC region semiconductor manufacturing dominance seems reasonable assuming we don’t lose interest or change course along the way which I feel is far more likely to happen. If China retracts its claws we might abandon this quickly simply due to pressure from capitalism to resume globalization in the name of world peace and prosperity(and also bigger profits). I think what we’re doing is necessary but at the same time it wreaks of protectionism even if it’s justified for national security. I am just wondering if we will be able to onshore everything in supply chain long term without subsidies. I sure hope so as the alternative is being at China’s mercy.Reply -

watzupken Having fabs onshore is only a fraction of the equation and does not equate to success. And to be fair, fab is probably one of the easiest part to solve as long as you throw money at it. This is not a game where fabs will magically churn out chips with no other resources required. Key to the challenge will be training a suitable workforce and obtaining raw materials. While it is possible to diversify where they source raw material, onshoring every aspect of it is not possible.Reply -

kjfatl This problem is 'easily' resolved by US government policy.Reply

Step 1, insist that all parts by the US military are 100% sourced by at least 3 distinct manufacturing sources, possibly owned by the same corporation. Financial penalties for failure to comply increase each year based on the amount of sourcing from non-friendly nations. (If Intel builds a part in Germany and Israel and can also builds it here, we don't care which source is used). For the military, exceptions could be made for unique items such as an LCD panels for a low volume aircraft when 20 years of parts are procured and stored in multiple secure locations.

Step 2. Apply the same rules for all items procured by fungible federal tax dollars. For example, purchasing a PC at Best Buy using Federal Student Loans or for use in a state government agency that accepts any Federal funds would not be be permitted unless it was fully US(or friendly nation) sourced. -

rabbit4me2 Sorry this guy is the enemy they would sell their stuff to China and a heartbeat for the money. Who wouldn't It's the American way? Chinese still our patents all the time we can't do anything. We try to copy our product and we get sued beyond belief. No foreign companies should own American land treat us like they treat them It's only fair. Discover reminds me of the musk dude both complete idiots they have money and people listen.Reply