Today's heavy GPUs continue to be plagued with cracking around PCIe slots — 19 damaged Nvidia RTX 4090s, most with cracked PCBs, arrive at NorthridgeFix repair

The big question is whether there is a PCB design defect or the damage comes from user error.

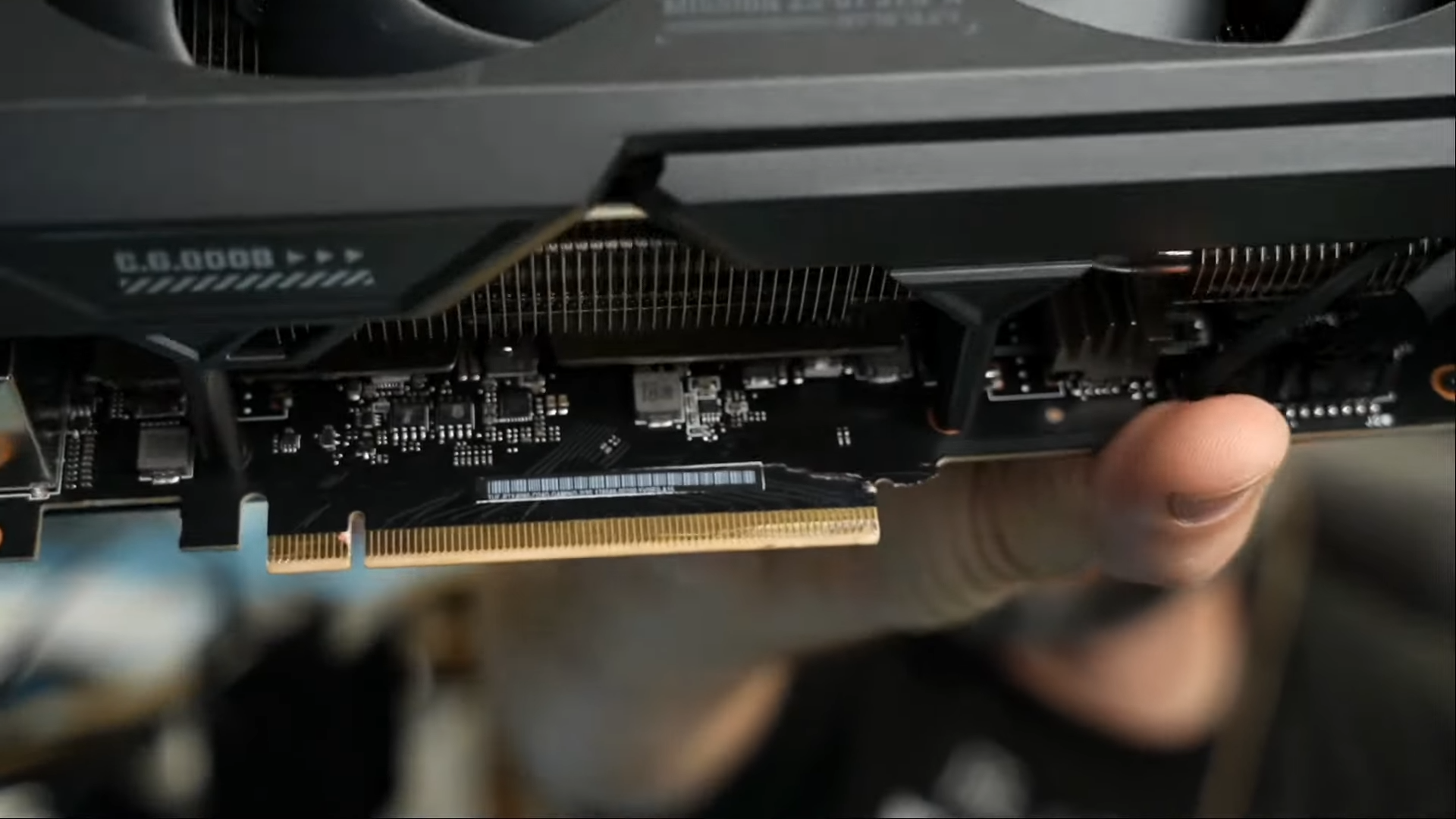

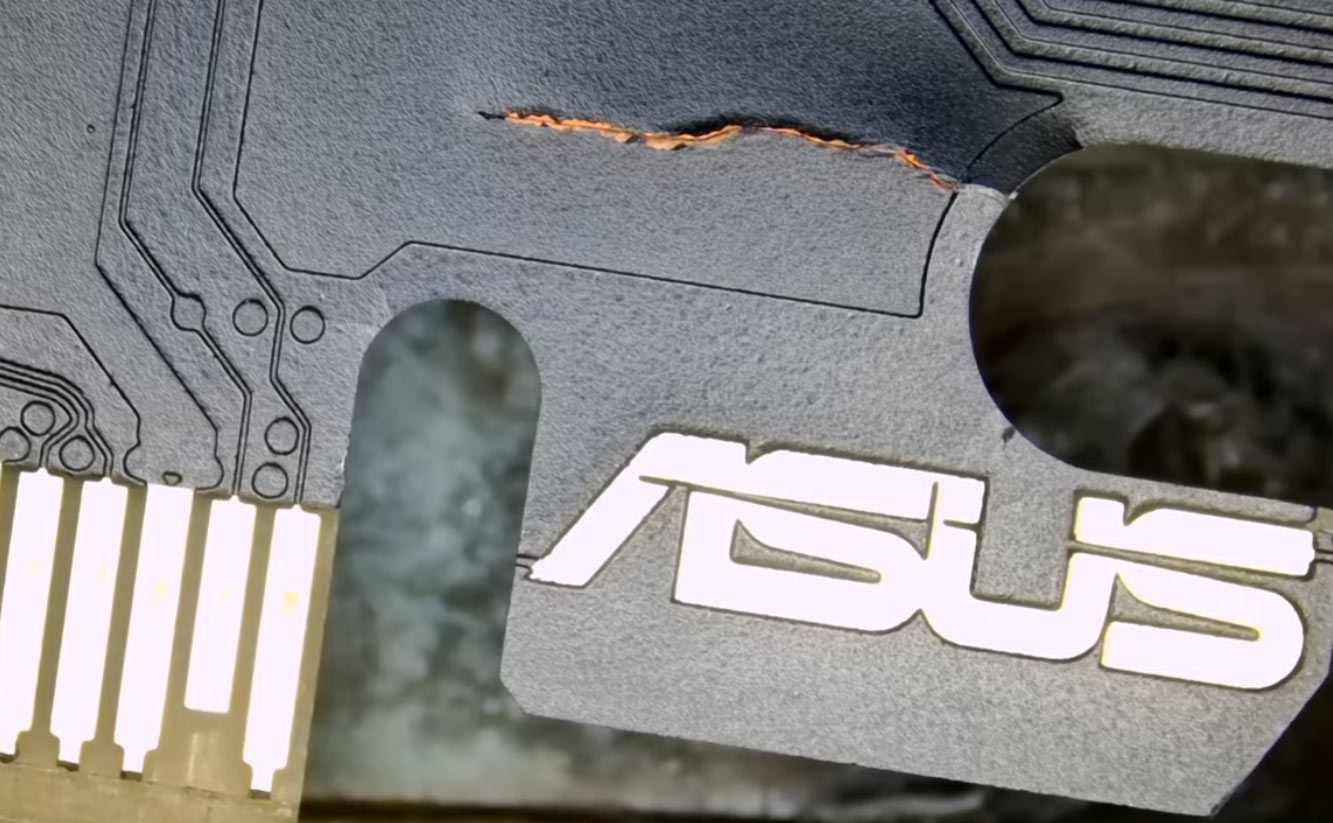

Prolific repair professional and YouTuber NorthridgeFix received 19 GeForce RTX 4090 graphics cards from a single customer. In the ensuing video, he outlines that most of the graphics cards have cracked PCBs near the PCIe card's retention finger. Although the source of the damage with these specific cards isn't readily apparent, the issue with PCB cracking on new, heavy GPUs has become more widespread.

This multitude of cracked graphics card PCBs is puzzling. NorthridgeFix has seen this kind of issue in this area before, but getting so many in a batch raised questions. Who was to blame? NorthridgeFix said it could be the user, manufacturer, designer, or materials. He also pondered whether this batch of faulty Asus and Gigabyte cards (cracks present on Asus boards only) could be from a system maker who didn't include a GPU support. Another possibility was that PC systems shipped with installed RTX 4090 graphics cards and were treated roughly in transit.

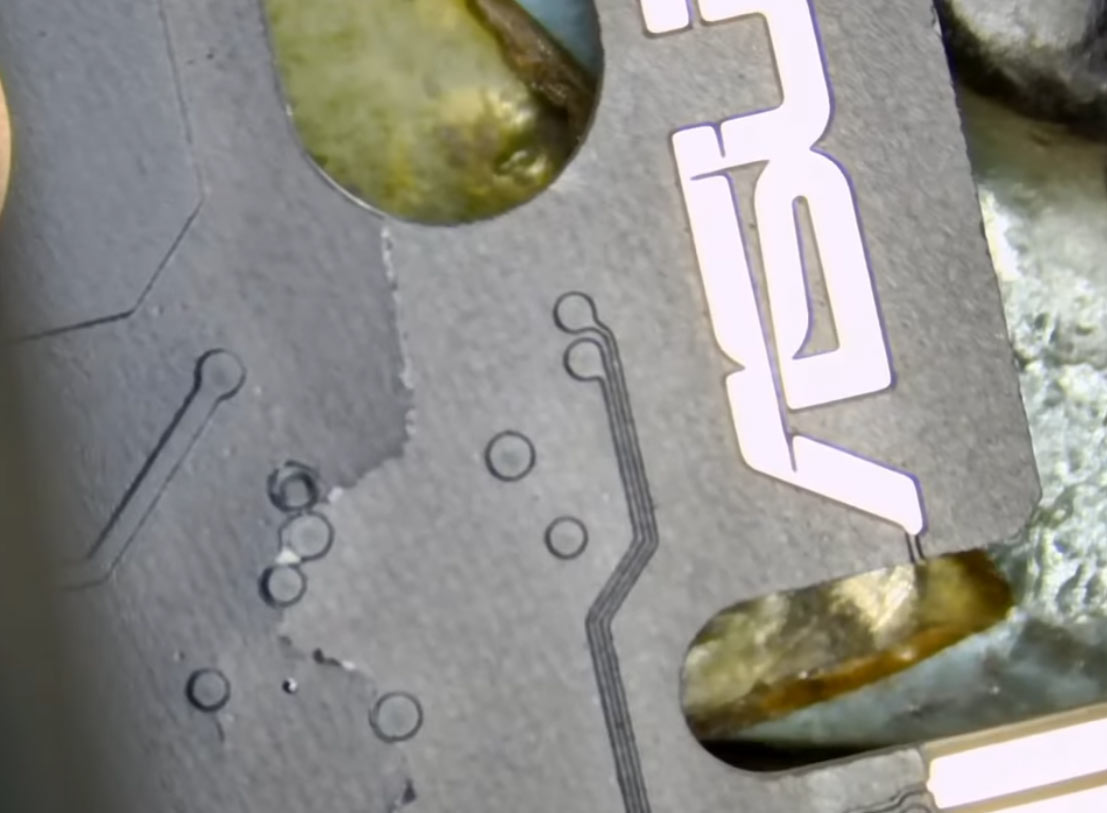

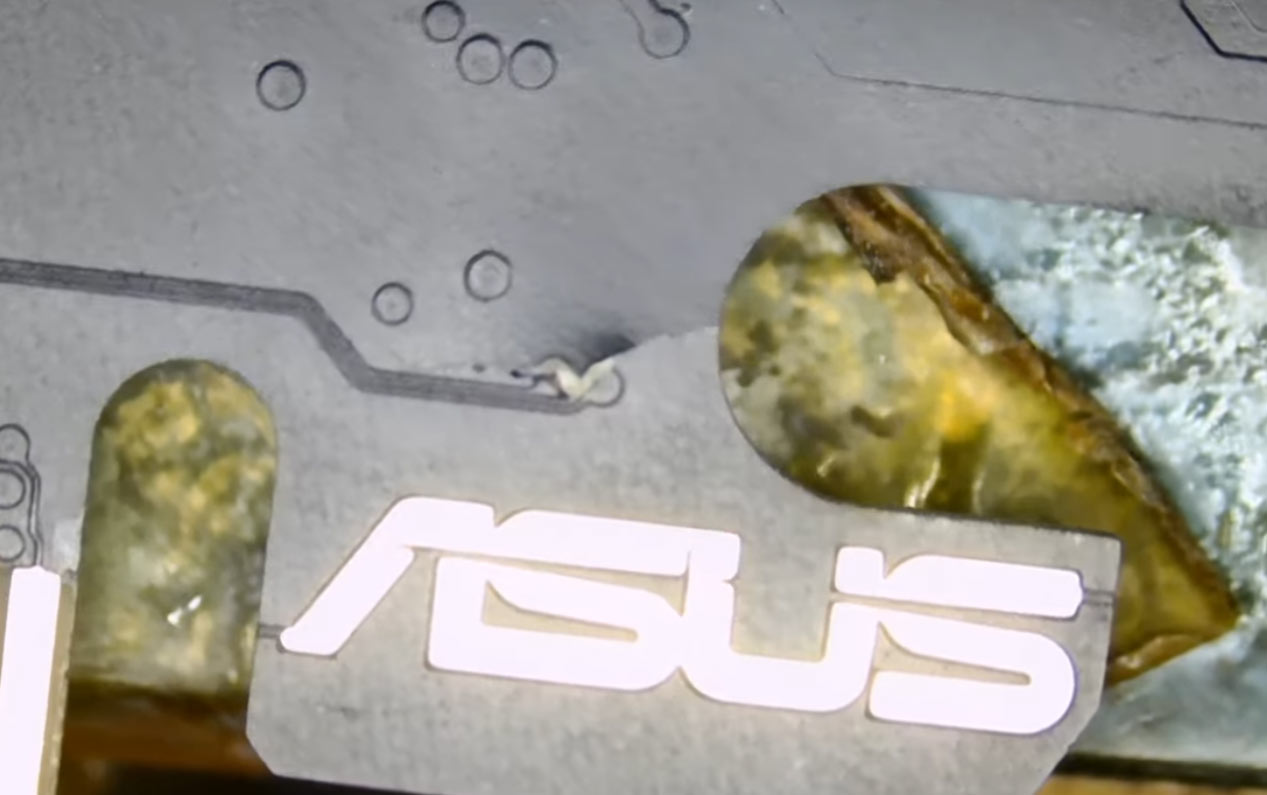

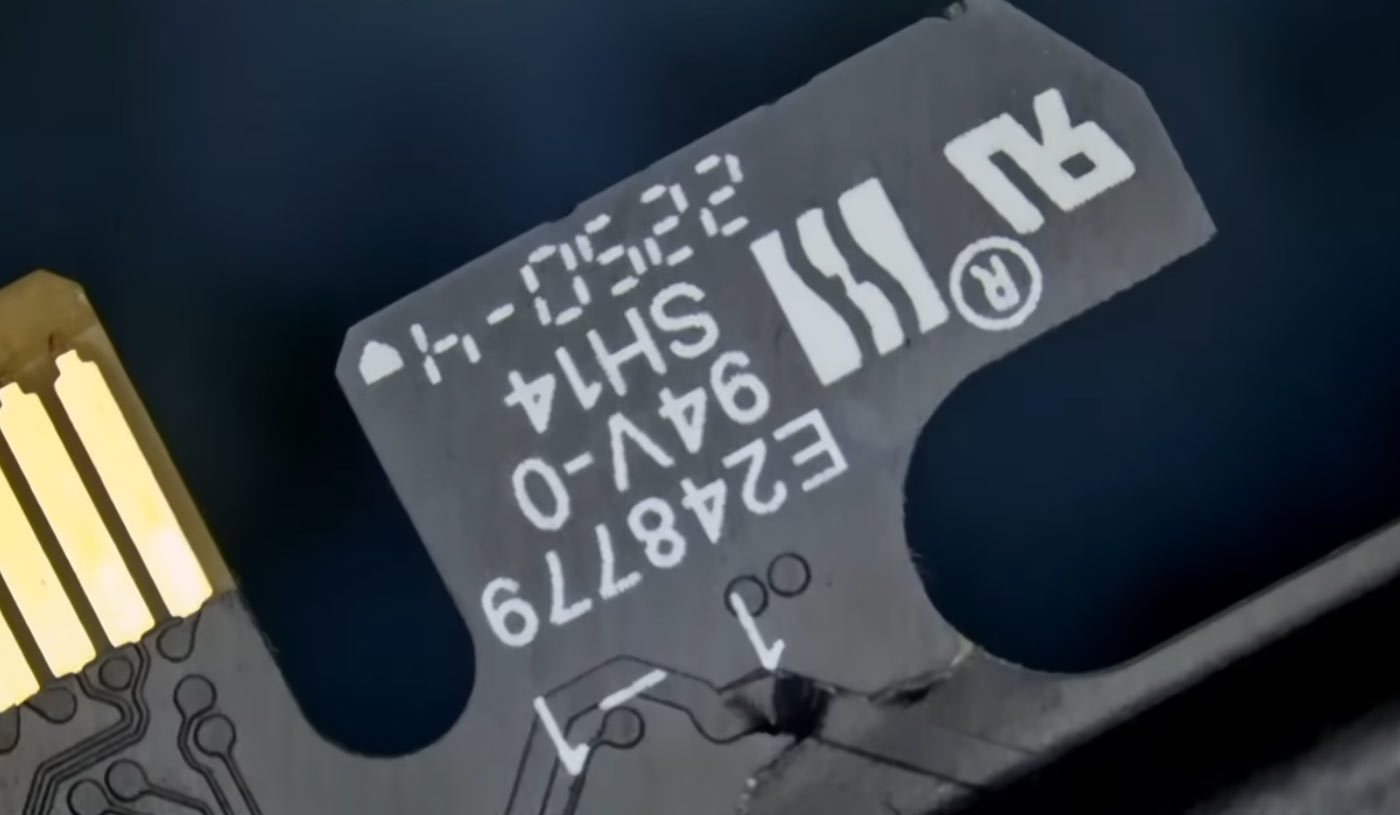

The GeForce RTX 4090 is a beefy and complicated graphics card. Typically, its PCB is made with 12-15 layers, each hosting a complex array of electrical traces. As Alex went through the 19 boxes one by one, as soon as he spotted a crack in the PCB, he referred to it as a "no fix" and put it to one side. Cracked PCBs with so many layers are possible to repair, but doing so isn't practical in terms of cost. Customers submitting these cards will be charged a bench fee (for handling) plus postage and packing.

Naturally, Alex wondered about the source of these 19 GPUs and how a single customer had acquired them. NorthridgeFix assumed the buyer may have bought them on eBay, hoping for an easy repair, and then to sell on at profit.

To the credit of the owner of the 19 broken GPUs, none had other visible damage or burn marks, which can be a regular issue with RTX 4090's 12VHPWR connectors across brands.

There isn't anything wrong with selling graphics cards that have damaged PCBs, like those tossed into the 'no fix' pile by NorthridgeFix, as long as the description of the problem is clear to the potential buyer. These 'dead cards' can still be used as donor boards for various parts: shrouds, fans, VRAM, GPUs, and more. It is good to recycle where possible.

Can These PCB Cracks Be Fixed?

The time and effort (and thus expense) needed to repair the cracked traces in multiple PCB layers is not worthwhile. However, in another NorthridgeFix video from earlier this year, you see the arduous task of fixing an Asus GeForce graphics card that had broken near the retention finger.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Fiberglass is typically used as a filling and tends to be stronger than copper. However, any subsequent use, installation, and removal of this repaired card will need to be done with extreme care.

Has this problem been going on for long?

We have reported on this type of GPU PCB cracking, usually affecting big and heavy graphics cards, previously. Professional repair technicians like Louis Rossman, NorthridgeFix, and others have featured these faults and repairs for months. Another example in the news this year seemed to center on PCB design issues with Gigabyte cards.

Roshan Ashraf Shaikh has been in the Indian PC hardware community since the early 2000s and has been building PCs, contributing to many Indian tech forums, & blogs. He operated Hardware BBQ for 11 years and wrote news for eTeknix & TweakTown before joining Tom's Hardware team. Besides tech, he is interested in fighting games, movies, anime, and mechanical watches.

-

spoidz I hope to upgrade to 4090 or that level next year.Reply

I switched to a Cube Case a few years back - Thermaltake Level 20 XT - that has horizontal MB and Vertical GPU mounting so hopefully that is one issue I won't ever have to face.

Unless the sheer weight is still allowing the Card to flex the connector area to one side of the other? I don't think the connector is actually centered between the sides of the frame/shroud? -

CorrOzi0n_s0cZ This isn't a manufacturer defect, it's a harsh reality that can befall any particularly heavy GPU that is not vertically mounted and has no GPU support bracket installed as well.Reply

As someone who does warranty / refurbish / RMA related repairs for a number of large electronics and PC component manufacturers I've seen this over and over again first hand with larger GPUs across every single manufacturer including NVIDIA's Foxconn manufactured FE models. The number one cause of this type of crack near the PCIe slot retention bracket is a combination of the sheer weight of the cards, gravity, time, and no decent GPU support bracket being installed on top of it all.

At best, you don't wind up with a cracked PCB and instead the flexing of the PCB over time leads to solder joints under the VRAM or GPU Core breaking which will result in either artifacts / no video / no fan spin / etc. This is exacerbated when an individual or a prebuilt manufacturer ships the PC or moves the whole PC with said card installed in the system still.

Gigabyte is slightly more susceptible to this causing damage that leads to the card no longer functioning as intended for the simple fact that they manufacture their PCBs with several critical data and voltage traces running much closer to the retention hook then other manufacturers but it has nothing to do with PCB quality or defects.

This is the same reason no manufacturer will accept warranty repairs for this kind of damage because it's technically the fault of the user or the company that purchased the GPU to be installed into the prebuilt system.

Do I believe manufacturers should be more transparent about how critical a solid GPU support bracket is to the longevity of these larger GPUs? Yes. However, the damage that occurs from these combination of factors ultimately isn't the fault of the manufacturer.

Also, there is a typo in the heading. It's NorthRIDGE not Bridge. -

peachpuff Reply

Lay down the pipe, it is their fault.CorrOzi0n_s0cZ said:However, the damage that occurs from these combination of factors ultimately isn't the fault of the manufacturer.

-

aberkae A non issue for the hybrid solution like Suprim liquid, which by the way fits into an itx case with 240mm rad clearance and oc with 1 click to 3ghz. Take home message if you are going to purchase a 4 slot behemoth air cooled gpu, make sure it's secure at a minimum.Reply

and or make sure the client is aware of purchasing one to mitigate sag/leading to pcb cracks eventually.Dr3ams said:Maybe it's time for every GPU manufacturer to include a generic GPU support bracket. -

Alvar "Miles" Udell This is a problem a vertical GPU mounting system was supposed to solve, but that never really took off. Considering more high end systems these days are shipping with essentially one usable PCIe slot, with the rest being used for M.2 slots, it's about time to move on from the traditional ATX form factor and to something that makes more sense.Reply -

CorrOzi0n_s0cZ Reply

It's really not the manufacturers fault. Common sense dictates something as heavy as an air cooled 4090 / 4080 / 4070Ti / 7900 XTX / 7900 XT / etc. should have some sort of support to prevent the PCB from flexing if it's going to be installed in the traditional horizontal orientation.peachpuff said:Lay down the pipe, it is their fault.

Common sense further dictates that moving a system with something that heavy still installed in it with no additional support and thinking there is no possibility of something breaking is absurd. It would be the manufacturers fault if these damages were caused by a manufacturing defect, but they're not. They're caused due to damage from shipping or individuals either known or unknown negligence by not installing something as simple as a $5 GPU support for a exorbitantly more expensive piece of hardware that every warranty states will not be covered in the event of physical damages.

As I said before, manufacturers should advocate more in informing end users that they should install a support bracket for most cards that are 2 slots or more but that doesn't necessarily put the blame directly on them. If every PC case was designed so PCIe hardware was mounted in a vertical fashion these incidents would be almost unheard of. I don't see you blaming case manufacturers though.

There have been plenty of cards purchased that come with a support bracket for this exact reason and the end user opts not to install it anyways, how is that the fault of the manufacturer? There is only so much engineering that can be done to combat breaks like this when the GPU is mounted horizontally with zero additional support.

The only ones who need to put the pipe down are customers who feel they're entitled to warranty repairs or replacements for damages that were ultimately their fault. That's not how warranty works, it covers manufacturing defects and premature component failure, not cracked and broken layers of fiberglass epoxy filler and copper from customer negligence. -

plusev Reply

You're contradicting yourself.CorrOzi0n_s0cZ said:This isn't a manufacturer defect, it's a harsh reality that can befall any particularly heavy GPU that is not vertically mounted and has no GPU support bracket installed as well.

As someone who does warranty / refurbish / RMA related repairs for a number of large electronics and PC component manufacturers I've seen this over and over again first hand with larger GPUs across every single manufacturer including NVIDIA's Foxconn manufactured FE models. The number one cause of this type of crack near the PCIe slot retention bracket is a combination of the sheer weight of the cards, gravity, time, and no decent GPU support bracket being installed on top of it all.

At best, you don't wind up with a cracked PCB and instead the flexing of the PCB over time leads to solder joints under the VRAM or GPU Core breaking which will result in either artifacts / no video / no fan spin / etc. This is exacerbated when an individual or a prebuilt manufacturer ships the PC or moves the whole PC with said card installed in the system still.

Gigabyte is slightly more susceptible to this causing damage that leads to the card no longer functioning as intended for the simple fact that they manufacture their PCBs with several critical data and voltage traces running much closer to the retention hook then other manufacturers but it has nothing to do with PCB quality or defects.

This is the same reason no manufacturer will accept warranty repairs for this kind of damage because it's technically the fault of the user or the company that purchased the GPU to be installed into the prebuilt system.

Do I believe manufacturers should be more transparent about how critical a solid GPU support bracket is to the longevity of these larger GPUs? Yes. However, the damage that occurs from these combination of factors ultimately isn't the fault of the manufacturer.

Also, there is a typo in the heading. It's NorthRIDGE not Bridge.

Plenty of "CoD bros" - for lack of a better term, are completely oblivious to such problems. It's their fault for not being more transparent about potential issues that can surface. -

USAFRet Reply

It is a design flaw.CorrOzi0n_s0cZ said:It would be the manufacturers fault if these damages were caused by a manufacturing defect, but they're not.

If you make something so heavy that it flexes and breaks in normal use....that is a design flaw.

Stiffen the board, or provide an additional support. -

PEnns ReplyAlvar Miles Udell said:This is a problem a vertical GPU mounting system was supposed to solve, but that never really took off. Considering more high end systems these days are shipping with essentially one usable PCIe slot, with the rest being used for M.2 slots, it's about time to move on from the traditional ATX form factor and to something that makes more sense.

This ^^^^^

But don't expect the manufacturers to accept any blame while laughing all the way to the bank. Better blame the user, as usual.

A 2-3 lbs, 3-4 slot behemoth of a GPU still using the same flimsy PCI connector that was fist used with 1 slot, 1/2 lb GPU!!