Gigabyte GPU Design Details Emerge About PCB Cracking

An unusual and alarming amount of Gigabyte owners have experienced PCB cracking on their graphics cards. The preliminary cases appear to be limited to the GeForce RTX 30 series (Ampere); however, there are claims that the issue also extends to the latest GeForce RTX 40 series (Ada Lovelace), which encompasses some of the best graphics cards on the market. Twitter user 0xcats, who reportedly has experience with PCB design, shares a theory on the existing issue.

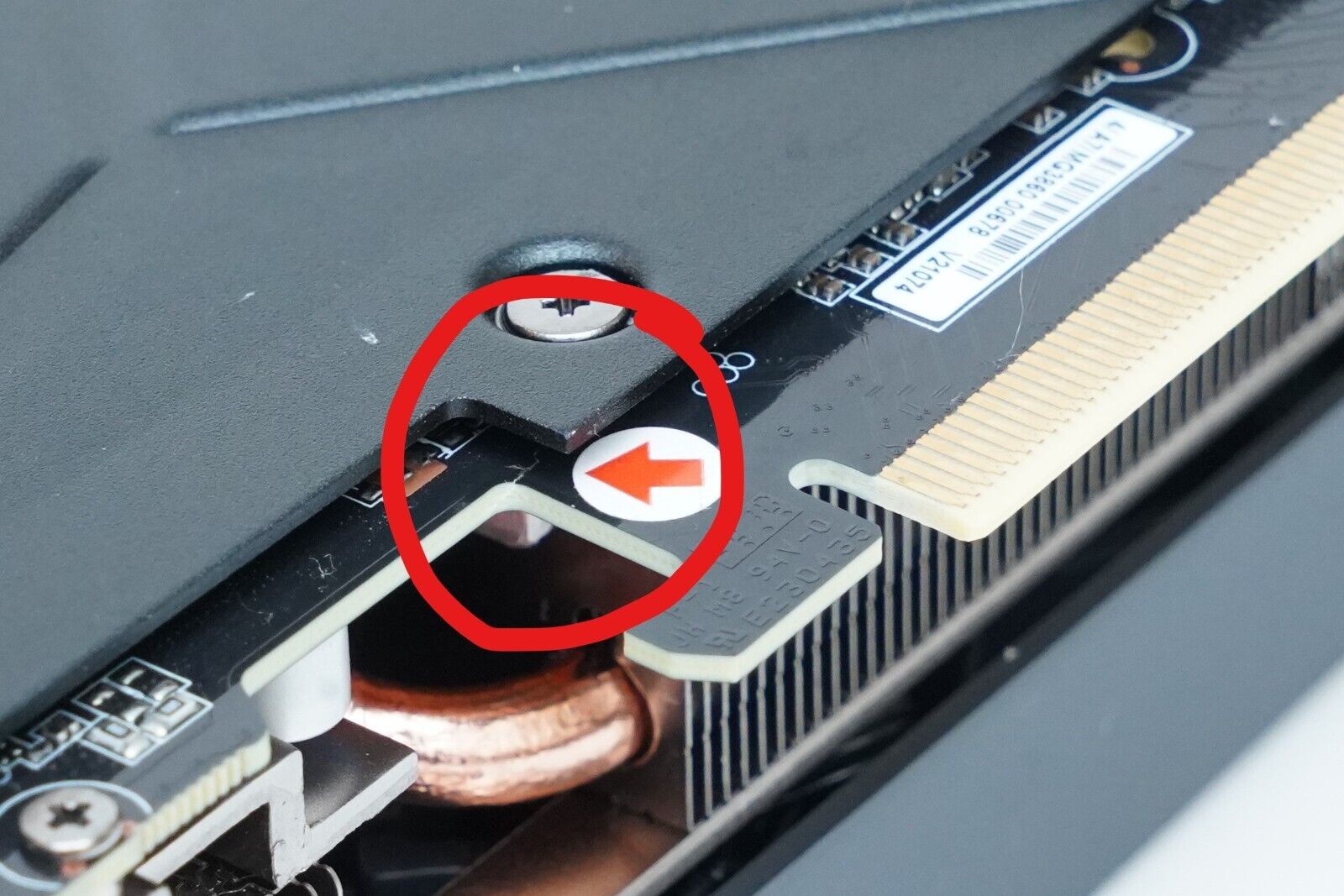

User feedback, photographs, and eBay listings have confirmed that the Gigabyte graphics cards primarily exhibited cracking near the PCIe locking tab. With how long and big modern graphics cards have become, there is a significant strain on that area of the PCB. It’s more than evident when you look at the graphics card, where a considerable portion of the heatsink extends beyond the PCIe connector. However, that’s only one part of what’s causing the problem. 0xcats has a hypothesis on the problem, and we agree with the person’s analysis.

As 0xcats pointed out, Gigabyte used a higher cutout at the PCB edge tab, turning the tiny area into the minor pivot point on the graphics card’s PCB. The 0xcats’ diagram evidences the highest strain zone on the PCB, which encompasses the section along the PTH (Plating Through Hole) and the cutout. 0xcats admitted that it’s not some revolutionary revelation since it’s a well-documented issue that PCB designers have known about for years.

Why Gigabyte chose a higher cutout than the standard measurement remains a mystery. According to 0xcats, one potential explanation is that the manufacturer may have gone with the design to compensate for the taller PCIe latches on the connector. All the user-provided photographs have one thing in common: the cracking manifests near the mounting hole for the memory cooler frame plate and the backplate. 0xcats assessed that this is the product of overstress at the narrowest part of the PCB.

While it may not look like it, PCBs are thin, so even the slightest bend can affect the integrity. 0xcats noted that the strain is present alongside the GPU area and the heatsink PTHs, creating a shear zone in the corner. The user compared the effect to a scissor, where the further away it is from the hole, the larger the displacement.

There are ways to solve the issue occurring on Gigabyte’s graphics cards. For starters, 0xcats believes it’s crucial not to route critical traces through the affected area. Instead of extending the cutout area, vendors should reduce it to the most significant degree possible for two reasons: one, to increase the narrowest part of the PCB, and secondly, reinforcement, allowing the copper to fill on all the PCB layers.

Modern graphics cards have become bigger in comparison to the old days. Many of them arrive with support to prevent sagging. 0xcats thinks that vendors should bring back the rear-end graphics card brackets that secure them to the case. The gaudy graphics card holders that are available nowadays don't offer the same level of support as brackets. Gigabyte has a similar anti-sag bracket implementation on one of its revised GeForce RTX 4090 graphics cards that stick to the old-school design.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Unfortunately, the PCB cracking has only been present on the last-generation Gigabyte GeForce RTX 30-series graphics cards, so the issue may not receive the attention it deserves. The GeForce RTX 40-series models have grown in size substantially. Unless Gigabyte has resolved the flaw with the previous design, it may only be a matter of time before cases of the new Ada-based graphics cards start to pop up.

Zhiye Liu is a news editor, memory reviewer, and SSD tester at Tom’s Hardware. Although he loves everything that’s hardware, he has a soft spot for CPUs, GPUs, and RAM.

-

digitalgriffin Learned that the first year of engineering. Sharp corners equal high stress points. We then used a special type of plastic to show the differences in stress between sharp corners and rounded ones.Reply

https://en.m.wikipedia.org/wiki/Photoelasticity -

Alvar "Miles" Udell Imagine if there were a computer spec designed to mount GPUs vertically...Reply -

Amdlova With these mega sized gpu... it's normal to get something broken. Some time ago people complains about the size the air cooler bending or broking the mother board. But gigabyte make some crap products. Beware buyersReply -

g-unit1111 I'm seriously curious as to how much of this problem would be solved if the GPUs were mounted horizontally instead of vertically. Because I would imagine that those giant heat sinks and heavy fans can't be good for vertical mounting.Reply -

helper800 Reply

Never had a problem with a gigabyte product myself, but buyer beware of their customer service...Amdlova said:With these mega sized gpu... it's normal to get something broken. Some time ago people complains about the size the air cooler bending or broking the mother board. But gigabyte make some crap products. Beware buyers -

bit_user Reply

Totally! It's on there like peanut butter on a cracker!Plumet said:That one Heat Paste Hungry GPU

-

Reply

lol peanut butter on a cracker hahaha lol :ROFLMAO:bit_user said:Totally! It's on there like peanut butter on a cracker!

-

razor512 Reply

Pretty common for even factory applications since with a bare die, having more paste than needed has very little impact on cooling, but a single bare spot or less than 100% coverage can damage the chip, especially if the bare spot has no on-die thermal probe in that location.Plumet said:That one Heat Paste Hungry GPU -

Reply

(cues the music and wobbly lines)razor512 said:Pretty common for even factory applications since with a bare die, having more paste than needed has very little impact on cooling, but a single bare spot or less than 100% coverage can damage the chip, especially if the bare spot has no on-die thermal probe in that location.

I come from the days of ye olde CPU when it was common practice for amd and intel to sell CPU's with exposed die like my old althlon 1200mhz and intel P3 and my amd XP 1600 cpu etc

I also remember you were forced to go through the terrifying stress and almost vomit fear inducing install the heat sink process:sweat::sob:

praying to god I don't slip and destroy the motherboard with this totally inappropriate screw driver while forcing down trying to get the what seemed like an over the top sprung steel CPU Heat Sink retaining Clip to lock to the plastic CPU socket and all the time hoping I have not damaged/chipped the CPU Die and wondering how much heat sink paste will be left on the CPU?

Then I learned it was easier to fit the heatsink before I fitted the motherboard in the razor sharp should of came with a free box of plasters case with power supply included LOL

Those of us who come from the Ye Olde CPU Day's will know once one end of the CPU heatsink retaining Clip is attached to the CPU socket you had one hand trying your hardest to keep the heatsink flat and true on top of the exposed CPU Die

The force of the attached end of the retaining clip would be pulling the heatsink in an upward direction due to the sprung steel its made from

In the other hand you would be forcing down and with a forward motion trying to attach the other end of the heatsink retaining clip with with screw driver.

And Like a NOOB or mainly because I was just thick lol I would make it harder for myself by first installing the motherboard in to computer Case.

Which back in those days PC cases used to be made by or at least must of been sponsored by a well known ... lets just call them G-let razor's (for any legal reasons lol)

By the time I had finished the install my hands looked like I put them in cylinder lawn mower!

Do Not Try This At Home Or Anywhere Else!!!

EDIT

Ok I added the worrying bit about the heatsink paste but the rest of it is the truth honest lol

Only after the Build was complete and windows XP etc was installed (I didn't really get in to benchmarking until win XP) did I start to think of the heatsink paste but these CPU's never seemed to go much over 60C no matter how much was used because sure most if not nearly all of it was most likely squeezed out after the Battle of the CPU install.