Monster PowerCenter HT 800G Tear-Down

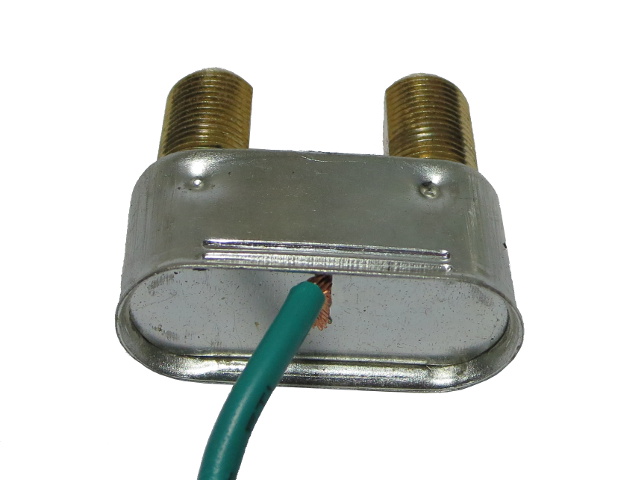

Coax Protection

Without a tracking generator-equipped spectrum analyzer, I cannot verify Monster's claim of low-loss RF surge suppression. But the HT800G does at least have a fully shielded RF unit instead of the naked-bottom PCBs found in APC's fancier models.

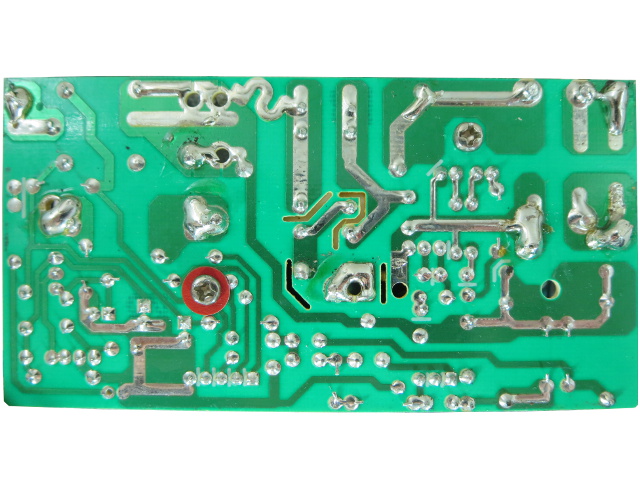

The Mystery PCB

Here's the component side of that small “mystery” PCB. It features one generously-sized 1µF X-cap for EMI filtering connected directly across the load-side metal strips, along with support components for Monster's surge protection buzzer that lets you know when the surge protection either kicked in or failed.

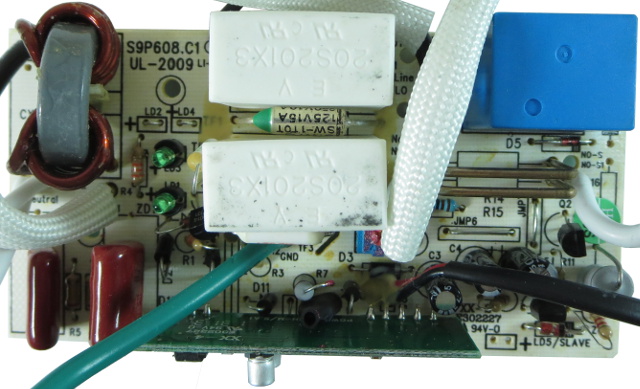

The Main PCB

Soldering on the main board looks a little blobular, similar to most PCBs with large through-hole leads. But it does not appear to have any obvious issues electrons would complain about. If you are wondering what the six extra holes are for, my guess is they serve other products reusing this PCB.

Going Top-Side

It's looking a little crowded. So crowded, in fact, that extra circuitry has to be relocated to a small daughterboard. In the top-left corner, we have the input choke and status LEDs. Below them are two film caps whose function is unclear. Occupying most of the middle of the board are Monster's two ceramic-encased MOVs with the usual thermal shut-offs in-between. Below and to the left (and along the right edge), we have the relay controlling power-saving and “dual protect” outlets, current-sensing shunts and likely bits of support circuitry.

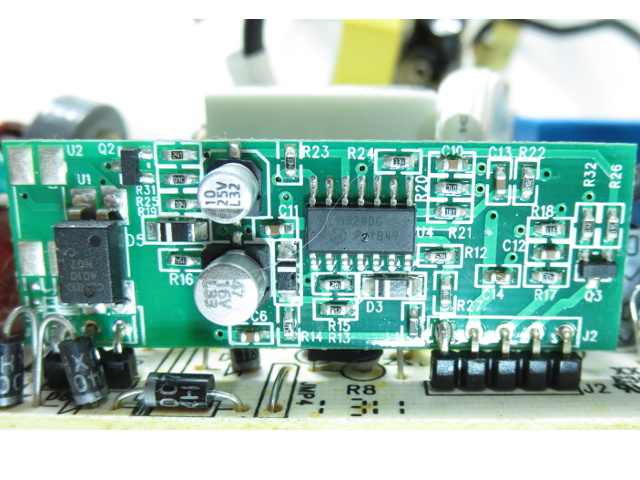

Daughter Dearest

If you were expecting anything fancy on this little PCB, you might be disappointed. It's only hosts a humble LM324DG quad operational amplifier, likely acting as a comparator for the dual-mode surge protection and detection amplifier for the GreenPower master current sensing.

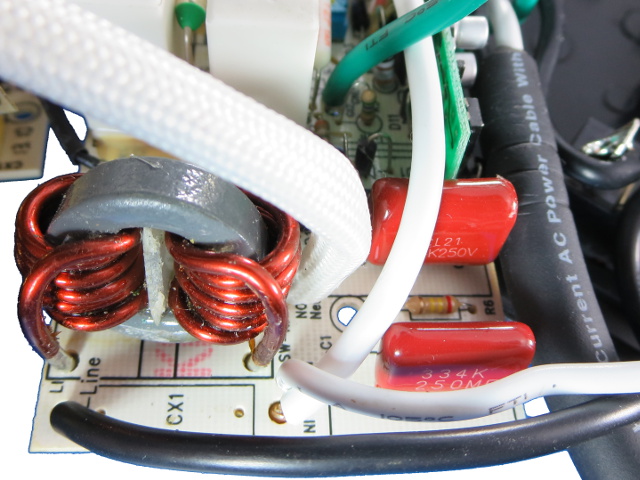

At The Input

On the left, we have a chunky common-mode choke to filter out high-frequency noise and soften edges on incoming surges to spare other components, such as the MOVs and X2 cap - at least in cases of common-mode events. The 330nF (front) and 680nF (back) film capacitors on the right form capacitive voltage dividers with the remainder of circuitry connected downstream from them. The larger capacitor powers the daughterboard, while the smaller one appears to be powering the relay's circuitry.

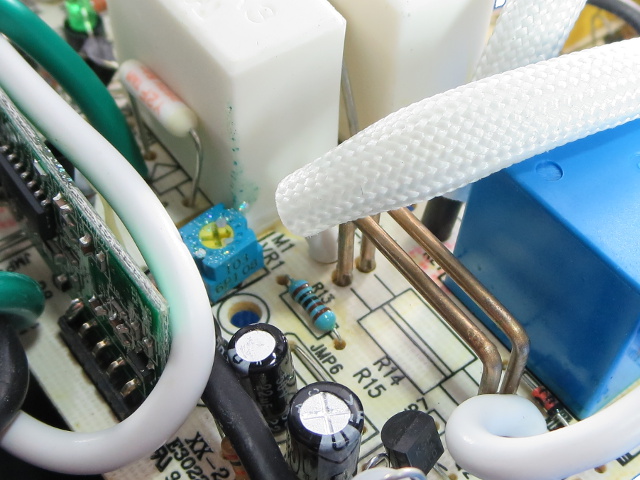

On And Off

The HT800G's GreenPower function needs to measure the “Master” device's current to determine whether it is turned on or off, and does so using a pair of metal shunts on the master's neutral side. You can see the master's neutral (covered in fire-resistant fabric near the MOVs) connect to the PCB on one side of the shunts and the normal outlet strips' neutral at the other end. The small potentiometer just below the MOV most likely provides trimming for the GreenPower on/off threshold and is covered in glitter-glue to prevent accidental changes after factory calibration.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

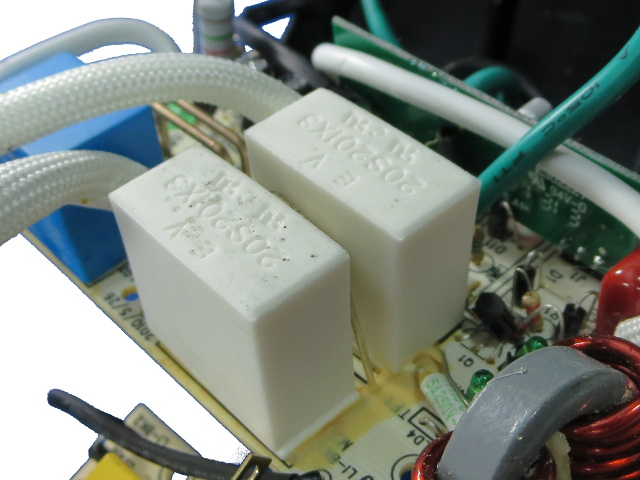

The Star Of Monster's Show

These are likely the main selling point for most people – they certainly were for me. I would expect manufacturers of ceramic-encased MOVs to put their brand on display, but these have no visible manufacturer markings on any side. Doing a search for the 20S201X3 part number returns a few hits on Chinese distributors, one of them with a matching pictures lists the manufacturer as Shenzhen Kangtai Song Long Electronics Co., Ltd. The corresponding website was not responding when I tried accessing it, and I was unable to find the specifications anywhere else.

From the part number and distributor descriptions, we can guess the ceramic casings contain three 20mm square MOVs with a varistor voltage of 200V connected in series with one of the four terminals bonded to each internal node.

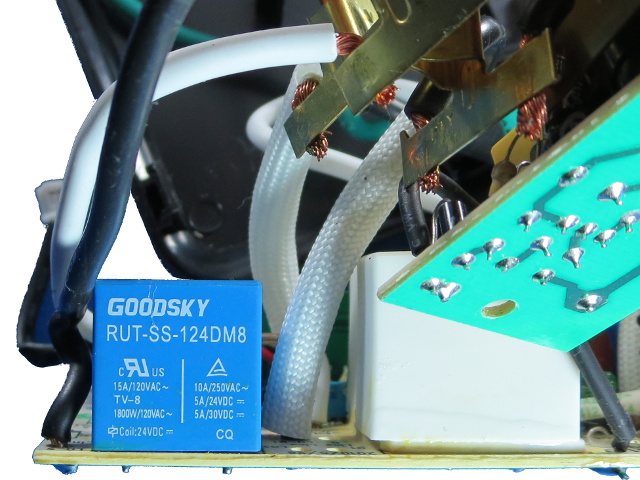

The Sidekick

After the fireproof MOVs, the HT800G's other main attraction is its GreenPower function that switches off controlled outlets when the “Master” device is off. The device responsible for switching those outlets is the blue Goodsky relay, which also performs double-duty as the “dual protection” output disconnect for those outlets.

Behind The Scene

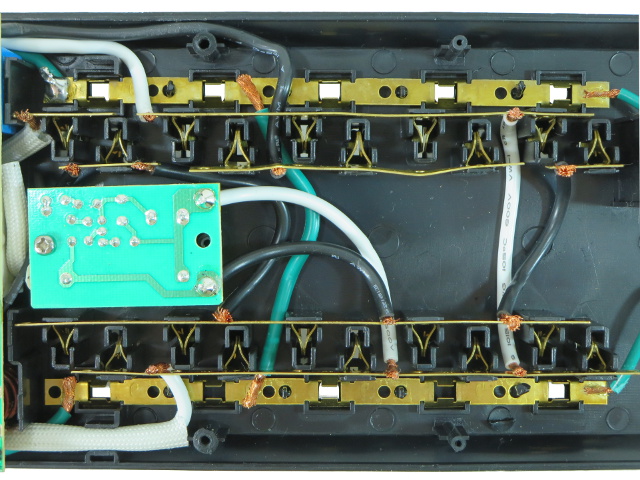

Remember earlier when I wished Monster had simply put five outlets on both sides? It turns out that all of the necessary metal and plastic work is already there; the only missing detail is holes and patented coordinated labels, I suppose, just to keep up with the theme. If someone really wanted the two additional outlets, all they would need to do is drill holes at the correct locations.

All wire connections except mains ground are spot-welded to metal strips, while the ground gets the solder blob treatment. Readers who have been following these tear-downs should be familiar with both connection strip styles by now, but we will still take a look at them next.

-

bit_user I long ago replaced my Monster Power A/V surge protection / power filtering product with a Panamax unit, which were peerless at the time. It would be nice to know how their quality rates, these days.Reply

Oh, and thanks for yet another excellent teardown. -

toddybody Not trying to be negative...but Tom's is really confusing me lately;Reply

Continued Power Strip Teardowns (admittedly boring, though technically interesting) juxtaposed against some goofy op eds (yes Im talking about you, Mr. Used Macbook)...with a considerable lag in reporting tech news behind it's peers (i.e., GTX 970 VRAM-Gate, recent AMD 3xx tweets).

Tom's, you ARE an AWESOME site because of your attention to:

PC Component Reviews (though a topical review of Apple Products wouldn't offend master race folks either)

Manufacturer Q&A Articles

System Builders and Benchmarks!

...anyhoo, please dont loose the spark that makes you a special site.

PS: How about a refreshed customer water loop guide?

-

bit_user Reply

Why not complain about this in the comments on those Op Eds and the late news articles, then?15254691 said:Not trying to be negative...but Tom's is really confusing me lately;

Continued Power Strip Teardowns (admittedly boring, though technically interesting) juxtaposed against some goofy op eds (yes Im talking about you, Mr. Used Macbook)...with a considerable lag in reporting tech news behind it's peers (i.e., GTX 970 VRAM-Gate, recent AMD 3xx tweets).

Or, better yet, perhaps the site feedback forum (might actually get some results):

http://www.tomshardware.com/forum/forum-9.html

-

Steelwing Now show us a tear-down of a professional level surge protector that doesn't use MOVs (is a non-sacrificial protector) but cancels the surges in another manner.Reply

I want to see something from SurgeX, Zero Surge, or Brick Wall. -

Daniel Sauvageau Reply

Send an email to SurgeX and try convincing them to contact me and send me a review sample. At $200 and up, those fancy units are far too expensive to tear down at my own expense.15255097 said:Now show us a tear-down of a professional level surge protector that doesn't use MOVs (is a non-sacrificial protector) but cancels the surges in another manner.

I want to see something from SurgeX, Zero Surge, or Brick Wall.

If I did receive one, I would also feel compelled to try giving its protection some sort of work-out to prove a few points based on what I read in their patents during a long argument with other forum posters about SurgeX many months ago.

(Hmm, looks like THG ate my signature and won't let me set it again.) -

babernet_1 I really hate these new horizontal windows. They usually don't work for me. I have Google Chrome and a cable modemReply -

Daniel Sauvageau Reply

Then you might be happy to read that my next tear-down won't be a power strip... and my next two stories after that might not be either, now that I have enough basic test equipment to start building my own and dig into more intricate stuff - THG has lent me an oscilloscope last month and the Eyeball + DFT power factor slides in this story were my first of likely many future uses of it in a story... a hint of on of the things I might end up using it for at least until I get a more convenient method of obtaining the same measurements.15254691 said:Not trying to be negative...but Tom's is really confusing me lately;

Continued Power Strip Teardowns (admittedly boring, though technically interesting) juxtaposed against some goofy op eds

I started doing power strips because it was something simple sparked by an unexpected failure that got more interest than expected from readers. The wild manufacturing quality variability helped keep things entertaining so I will probably continue doing them whenever I get something potentially different enough to turn into a story - you never know where the next shocking revelation will come from until you look and it jumps into your face!

-

tsumeone I personally love these teardowns. Goes to show you that money is not always quality, but sometimes it can be. I'd personally love to see a teardown of one of those highly regarded metal Tripp-Lite units, the ISOBAR Ultra ones. I wonder just how much quality is actually in those, but I don't want to bust mine open.Reply -

06yfz450ridr i have a few panamax pdus that we pulled from a job literally 20+ of them. I use one for my tv equipment and a panamax ups for my pc stuff.Reply

I could donate a pdu to disassemble if you would like here is the model #m4315-pro -

Daniel Sauvageau Reply

That would certainly be much appreciated.15258021 said:i have a few panamax pdus that we pulled from a job literally 20+ of them. I use one for my tv equipment and a panamax ups for my pc stuff.

I could donate a pdu to disassemble if you would like here is the model #m4315-pro