Despite Intel's woes, the U.S. remains the revenue leader in the semiconductor industry

And will stay this way for years to come.

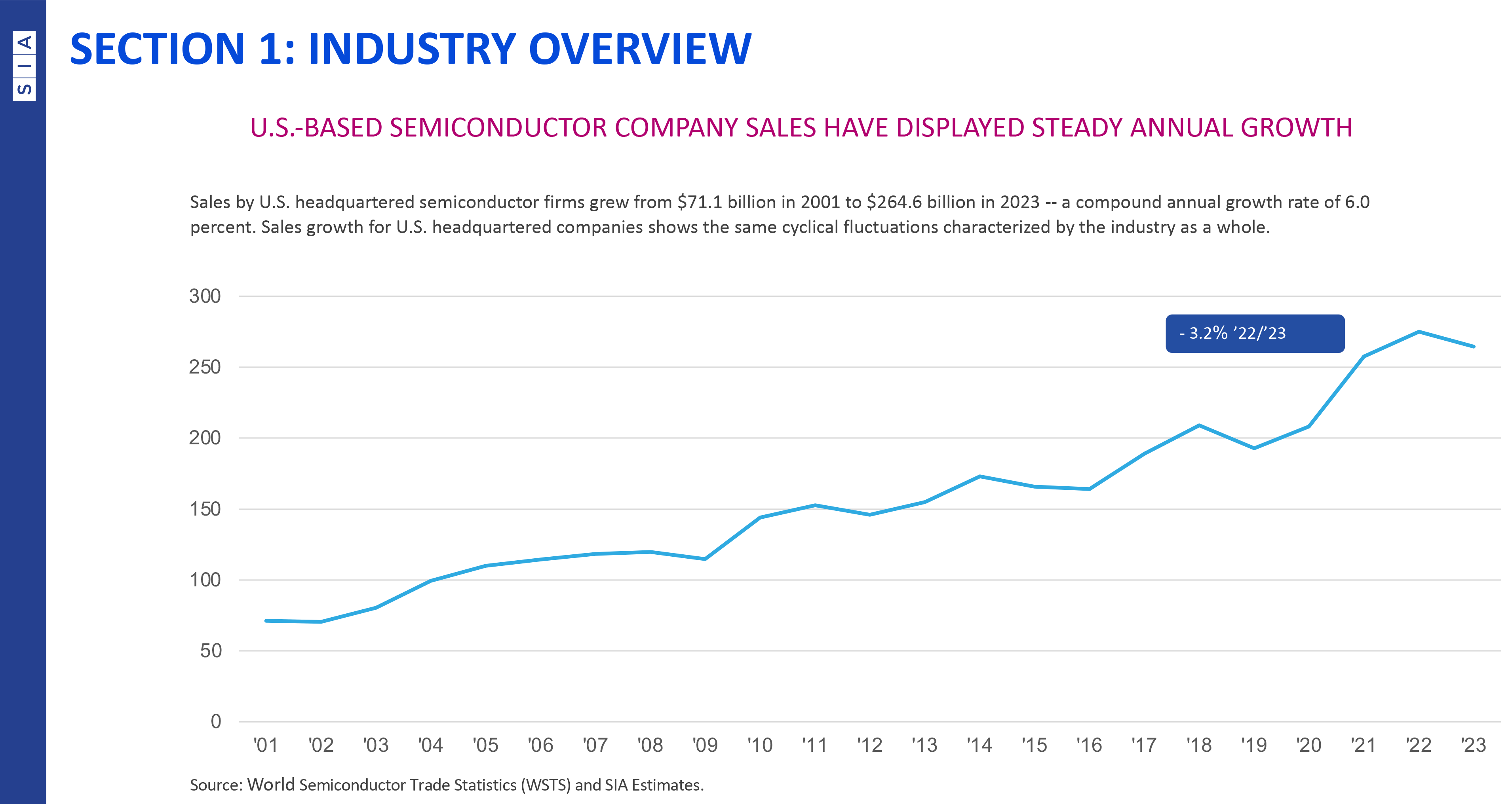

Nowadays, Intel is engaged in a high-risk, multi-year strategy to reclaim its leadership, with global ramifications that intertwine technology, national security, and geopolitics, believes Fortune writer Geoff Colvin. And even though Intel struggles, the U.S. remains the semiconductor industry leader, with $264.6 billion in revenue in 2023 alone, as noted by Dan Nystedt.

For decades, Intel has been the symbol of the U.S. semiconductor prowess. But without a doubt, Intel today is not the company it was a decade ago. Intel no longer leads in process technology and has more viable competitors than ever.

One of the most important semiconductor companies

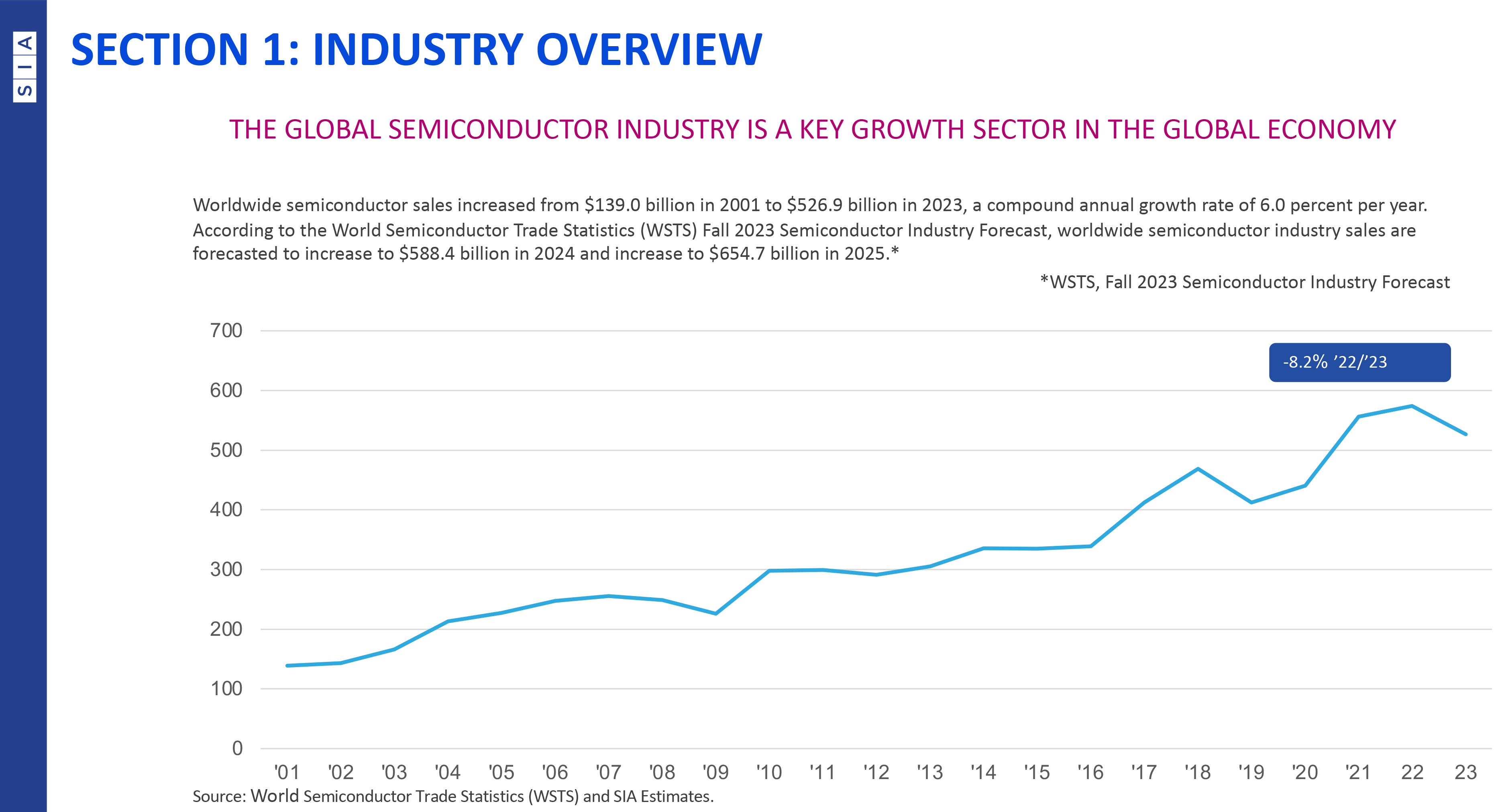

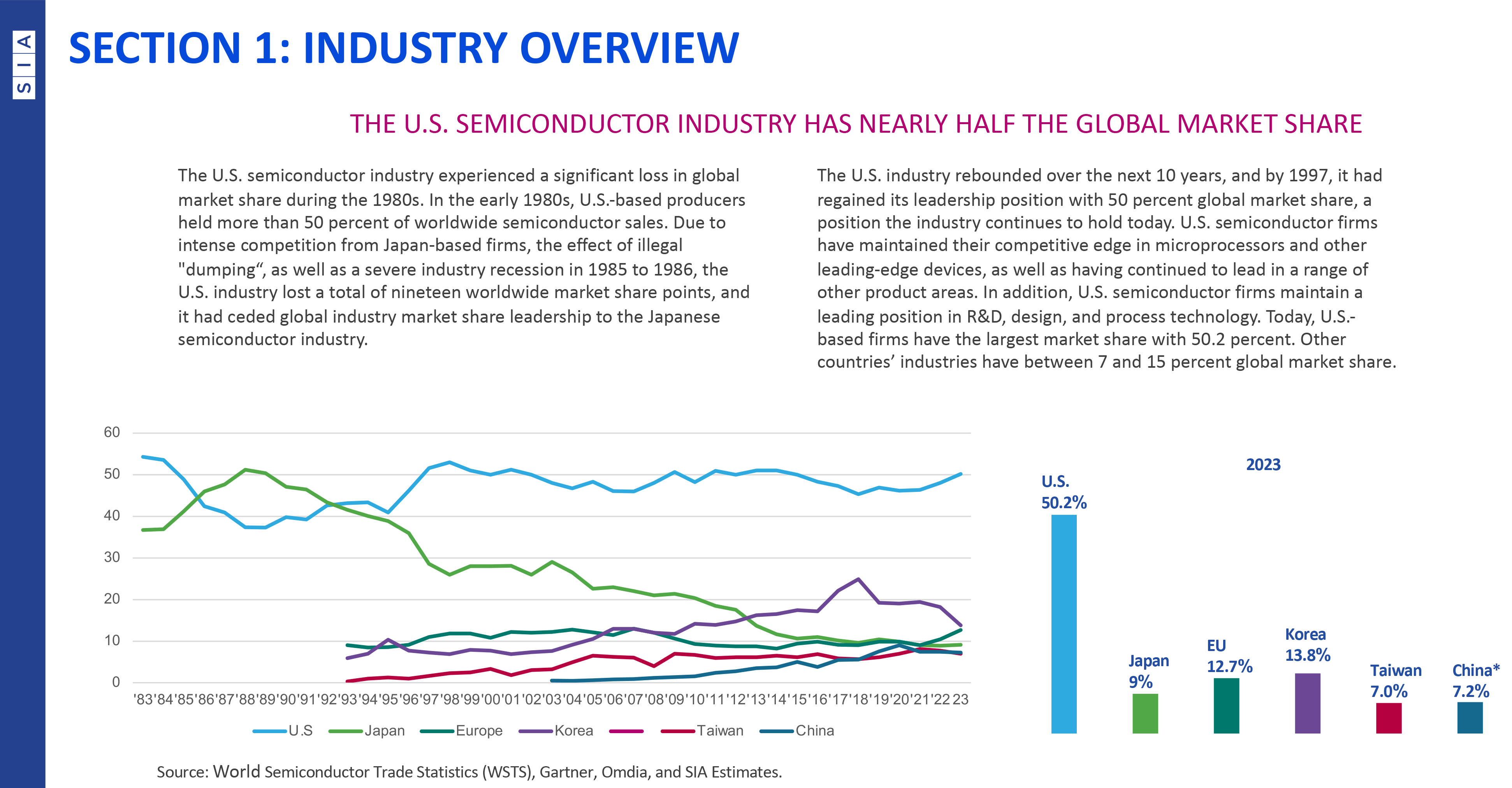

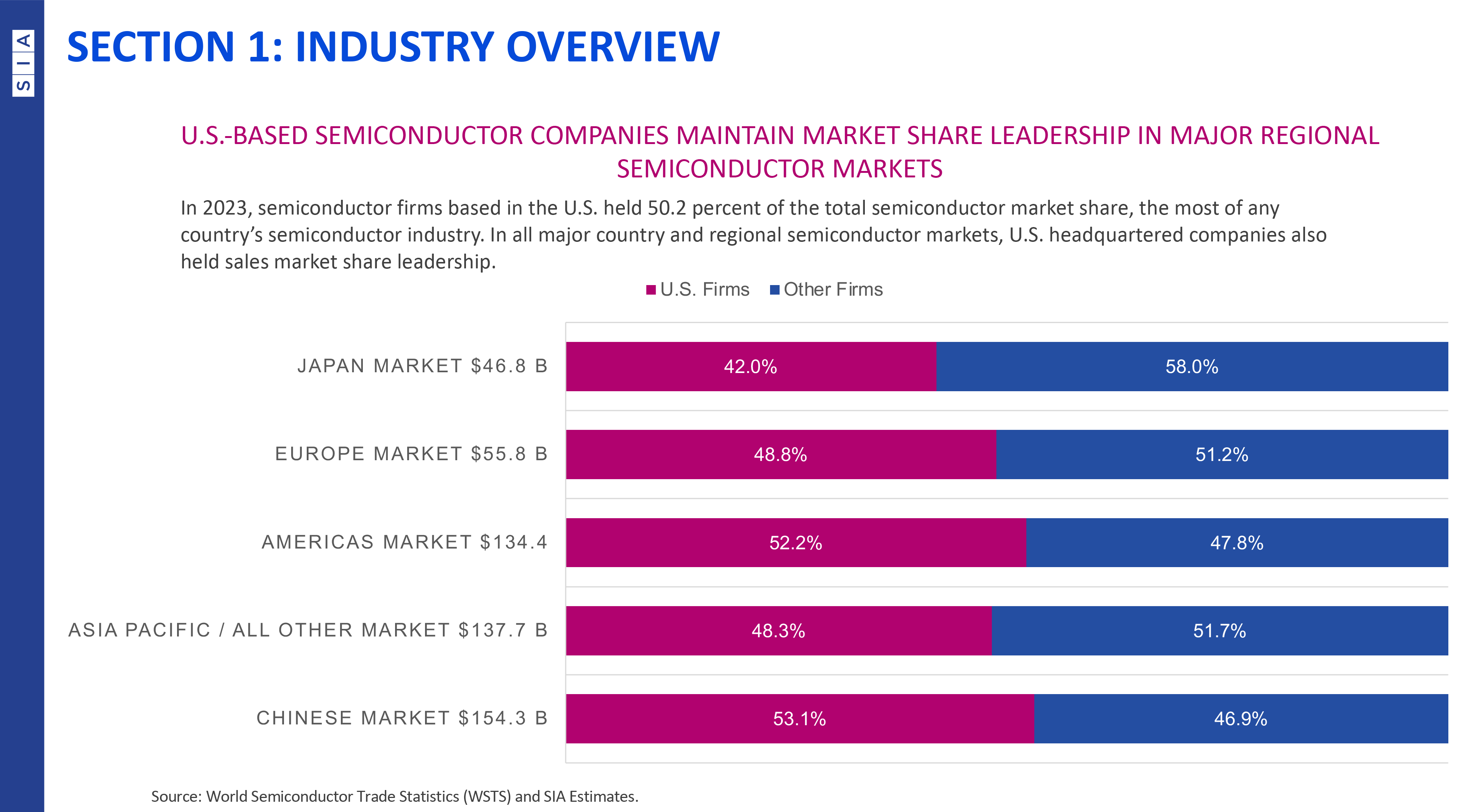

Global semiconductor sales increased from $139 billion in 2001 to $526.9 billion in 2023, according to World Semiconductor Trade Statistics (WSTS) and SIA Estimates. Revenue of U.S.-based semiconductor companies increased significantly, from $71.1 billion in 2001 to $264.6 billion in 2023. Therefore, U.S. semiconductor firms currently dominate the global market with a 50.2% share, according to the Semiconductor Industry Association (SIA). Competitors from other countries hold between 7% and 15% of the market, and this distribution is expected to remain stable for the foreseeable future.

Large U.S.- companies, such as Intel ($54.22 billion revenue in FY2023), Nvidia ($60.9 billion revenue in FY2024), and Qualcomm ($35.82 billion revenue in FY2023) control the lion's share of American chip revenue (57%), so their prosperity is essential for the whole country. Still, where Intel loses, others gain.

In 2023, the U.S. exported $52.7 billion of chips, making it the sixth-largest export category, following refined oil, crude oil, aircraft, natural gas, and automobiles.

How Intel lost its leadership while Nvidia and Qualcomm gained theirs

Intel has historically dominated the market of processors and PCs and eventually gained ground in servers. It is still the world’s largest maker of CPUs for client computers and servers by volume. However, Intel has missed crucial market shifts, particularly in processors for smartphones and tablets in the late 2000s and early 2010s and then for artificial intelligence in the late 2010s and early 2020s. This allowed competitors like Nvidia, MediaTek, and Qualcomm to rise. Today, Nvidia and Qualcomm have higher market capitalization than Intel. Also, Intel lost process technology leadership to TSMC, which has a higher market capitalization and supplies companies like AMD, Apple, Nvidia, and Qualcomm.

In response to this crisis, Intel’s board reappointed Pat Gelsinger, a long-time veteran who had left the company in 2008, as CEO in 2021. Gelsinger initiated an ambitious and expensive recovery plan to restore Intel’s position at the forefront of the industry. His strategy was to develop advanced products, design leading-edge process technologies, and produce chips for third parties to pay for increasingly more expensive manufacturing processes and fabs. This required the company to invest massively, pouring tens of billions of dollars into fabs. Of course, the financial burden of this recovery is enormous. Intel spends nearly $16 billion annually for new manufacturing capacity without immediate returns.

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

But while Intel lost smartphone SoCs and AI processors, Qualcomm and Nvidia capitalized on the rise of smartphones and artificial intelligence, massively earning hundreds of billions of dollars over the years. So did Apple, Broadcom, and, to some degree, AMD. These are all fabless companies, and while TSMC makes the bulk of its chips in Taiwan, its profits come to the U.S. Most chips sold worldwide are designed in the U.S. The vast majority of high-performance, high-margin processors are also designed in America.

Another factor driving the American semiconductor industry is advanced fab tools produced by companies like Applied Materials, KLA, and Lam Research. No semiconductor fab in the world can be equipped without using tools from these three companies. Only this year has ASML managed to outsell Applied Materials, which used to be the world’s No.1 maker of chipmaking tools.

Why advanced chipmaking is important

There is a big catch, of course. This is producing chips on leading-edge nodes. Nowadays, only three companies produce chips using leading-edge process technologies: Intel, Samsung Foundry, and TSMC. These production nodes make sophisticated chips like Apple's A17 Pro or Nvidia's H100. While some may argue that Apple's processors are used in consumer devices, they are vital for Apple's economy, and Apple is necessary for the U.S. economy. As for Nvidia's H100 GPU for AI and supercomputers, such processors are essential for the economy and national security.

Recognizing the strategic importance of semiconductor production in general and making chips on leading-edge nodes in particular, the U.S. passed the CHIPS Act in 2022 to reduce reliance on foreign-made chips and strengthen domestic production. Intel received the largest subsidy package of grants and loan guarantees, around $20 billion, to build new fabs in Arizona and Ohio. Samsung Foundry and TSMC also got support to build new fabs in the U.S.

One reason the Biden administration decided to propose the CHIPS & Science Act is to boost the domestic semiconductor production industry. The decision also has geopolitical components.

Under President Xi Jinping, China aims to become self-sufficient in semiconductor manufacturing by 2027 (though this will not happen) while also considering the possibility of a military takeover of Taiwan, home to TSMC. Such a move would disrupt the global supply of chips and potentially bring the U.S. and China into direct conflict over Taiwan's semiconductor assets, as noted in the Fortune coverage, as U.S.-based AMD, Apple, Broadcom, Nvidia, and Qualcomm all depend on TSMC's leading-edge manufacturing capacity located in Taiwan.

Intel's plan includes starting production of chips on its leading-edge 18A process technology (1.8nm-class) in 2025, months before TSMC starts making products on its 2nm fabrication process, thereby reclaiming formal process technology leadership. In the meantime, Intel faces stiff competition from TSMC and Samsung, which are also expanding their U.S. operations.

What happens if Intel fails?

Will the U.S. semiconductor industry remain successful if something happens to Intel and Pat Gelsinger's turnaround plan does not work? Yes, provided that American companies can produce chips in Taiwan and sell equipment to TSMC, UMC, Vanguard, and other chipmakers. Given the risks, the U.S. government must ensure Intel's long-term success.

The company's future is uncertain for now, as its success will depend on technological innovation and support from the U.S. government and the broader geopolitical landscape. For example, when the Chinese government orders its agencies to cease using PCs based on processors from foreign companies (e.g., AMD and Intel), this is a direct hit for American chipmakers in general and Intel in particular.

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.

-

vanadiel007 Part of the issue in my opinion is trade sanctions. They end up hurting both the consumer and the companies. I think this is a good example of that, that put countries like China and Russia into a frenzy of chip development, all state sponsored.Reply

This will result in them taking over other well established chip designers like Intel, since Intel has to put their own money into it as opposed to Chinese companies who are basically getting access to unlimited R&D funds.

Keep your friends close, but your enemies closer. -

ottonis I don't think that Intel will actually fall. Intel is spending literally tons of money in new technology and production capacity and in the long run, this is money well spent. and will most certainly pay for itself: There is exponentially increasing demand for production capacities on all technological levels: nowadays, virtually every device has a microporcessor: cameras, audio devices, alarm bells, doors, heck, even lihgt bulbs, screens, TVs, cars and even the friggin refridgerator and what not. And the fabs Intel is currently building will employ state of the art tools and technology and not some 10 generations old tech .Reply

So, what Intel needs is to stay on track and just do their thing.

Although I really despise Intel's malpractices of the past, they are still a relevant player in the x86 world and what we need as many great players as possible as competition drives innovation and the users usually beenfit from better products at lower prices. -

svengollie Its a copy of the auto industry sadly. We have a chips act in US, but the fabs getting money are mostly foreign so....we may increase wager starts from 8% and grow to 20% from the chips act but the money these fabs generate will not stay in US. A bmw built in USA keeps 6% of the sale price example of 75k and the rest is sent to Germany for their GDP. Yet the media will report all the AI chips being built here (no such thing yet as no ASIC mass produced AI only s/w, no AI firmware)....sure, IP is created here, like AMD but the MFG of AMD devices once a fab is built here, is sent to the sovereign wealth fund of Dubai.Reply