Intel will keep using TSMC's services even when 18A is ramped up: 'It is a good supplier'

The question is, what percentage of Intel's products will be outsourced?

Although Intel would like to reduce its use of TSMC’s manufacturing services , the company will keep ordering chips from the Taiwan-based foundry for the foreseeable future, a high-ranking executive said at a technology conference yesterday.

Intel’s grand plan is to produce as many products as possible internally at Intel Foundry, but as this may not be the most optimal strategy, it is currently assessing what percentage of its products should be produced at TSMC.

"I think a year ago we were talking about trying to get [usage of TSMC] to zero as quickly as possible, but that is no longer the strategy," said John Pitzer, vice president of corporate planning and investor relations at Intel, at the Morgan Stanley Technology, Media & Telecom Conference. "We think it is always good to have at least some of our wafers with TSMC. They are a great supplier. This creates healthy competition between them and Intel Foundry."

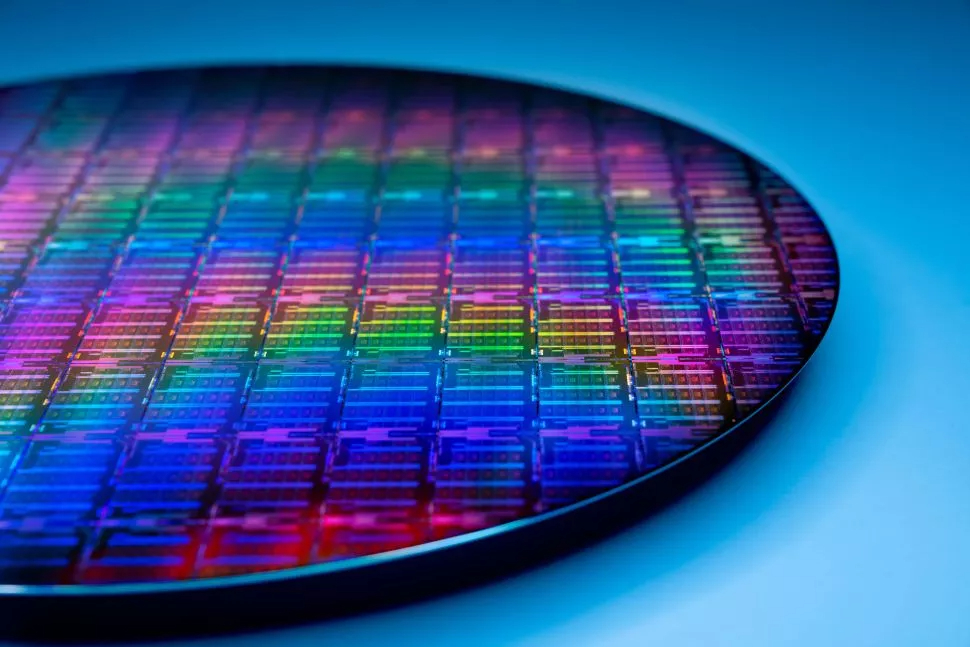

Intel currently produces silicon for its flagship Core 200-series ‘Arrow Lake’ and ‘Lunar Lake’ processors for desktops and laptops at TSMC and then assembles them using its Foveros 3D advanced packaging technology at its packaging facilities in the U.S. As a result, the company has to pay TSMC a premium, which significantly hurts its gross margins.

With its next-generation Core 300-series ‘Panther Lake’ CPUs, Intel expects to use its own manufacturing facilities, including the most advanced Fab 52 and Fab 62 in Arizona, to make the compute chiplet of the processor using the company’s 18A fabrication technology. Since the majority of manufacturing operations will be performed internally, Intel expects to enjoy higher gross margins with its next-generation products.

However, some of Intel’s products will continue to be made at TSMC. Currently, around 30% of Intel’s products are outsourced, but the company expects this share to decrease considerably in the future.

"Not quite sure what the right sort of [outsourced production] level is," said Pitzer. "Is it 20%? Is it 15%? We are working through that. But we will use, I think, external foundry suppliers longer under this new strategy."

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Intel is, of course, interested in producing its most advanced high-margin products, such as Xeon processors that cost thousands of dollars each, internally. In fact, the company has never outsourced these parts. And clearly it would prefer not to outsource premium high-volume CPUs for client PCs.

However, Intel may use TSMC’s services to make niche products for client computers as well as various controllers that add tremendous value to Intel’s platforms but are sold for $10–$15.

Such controllers usually rely on trailing nodes that Intel currently lacks (since Intel’s 14nm and 22nm process technologies were designed for CPUs and use proprietary IPs). So the use of TSMC and other foundries to make them is a good fit.

Anton Shilov is a contributing writer at Tom’s Hardware. Over the past couple of decades, he has covered everything from CPUs and GPUs to supercomputers and from modern process technologies and latest fab tools to high-tech industry trends.

-

bit_user Reply"I think a year ago we were talking about trying to get to zero as quickly as possible, but that is no longer the strategy," said John Pitzer, vice president of corporate planning and investor relations at Intel

I didn't expect they'd quit sourcing from TSMC overnight, but this announcement is a worrying sign.

"We think it is always good to have at least some of our wafers with TSMC. They are a great supplier. This creates healthy competition between them and Intel Foundry."

That doesn't make much sense, at a time when IFS is still contributing to their own bottom line. It's not as if IFS doesn't already face enough competition from them.

Intel used to make its chipsets on its own older nodes. They started outsourcing those sometime around 2019, I think, due to a major supply constraint on their 14 nm production.The article said:Such controllers usually rely on trailing nodes that Intel currently lacks (since Intel’s 14nm and 22nm process technologies were designed for CPUs and use proprietary IPs). So the use of TSMC and other foundries to make them is a good fit. -

helper800 Reply

Are they actually bankrupt or are you using a turn of phrase? That would be news to me.Gururu said:How are they going to pay TMSC they are bankrupt. -

phead128 What's stopping potential customers from bypassing the middle-men to source from original TSMC to begin with. Intel has to be more reliable, cheaper, and better yields than TSMC to get customers to switch.Reply -

JamesJones44 Replybit_user said:I didn't expect they'd quit sourcing from TSMC overnight, but this announcement is a worrying sign.

If it is low volume products like their GPUs or tile components like the I/O tile (just using it as an example) it might make sense to use a 3rd party instead of building/expanding capacity which may go under utilized. However, if they start letting TSMC compete with IFS on price, performance, etc., which seems like that may be the angle, then I 100% agree it could be a very bad sign. -

2Be_or_Not2Be Reply

If IFS could produce enough quantity and the client's usage is US-based, then it could be worth a bit more to the client to have local production (shipping, logistics, etc.). IFS really needs to get rolling, and it doesn't need its own PR people to say things that lessen them as first-look contract producers.phead128 said:What's stopping potential customers from bypassing the middle-men to source from original TSMC to begin with. Intel has to be more reliable, cheaper, and better yields than TSMC to get customers to switch. -

thestryker Reply

Intel has never used TSMC for their chipsets as far as I'm aware (maybe mobile, I'm less tapped into that market). They started using older chipsets anywhere they could though and increased usage of older nodes. There were also some chipsets manufactured on Intel 16 (22nm) after they'd stopped using it.bit_user said:Intel used to make its chipsets on its own older nodes. They started outsourcing those sometime around 2019, I think, due to a major supply constraint on their 14 nm production. -

thestryker The biggest problem Intel has is a complete lack of a competitor for N7 (and its derived nodes). While Intel 7 is performance/density competitive enough it's very expensive and can't be used for external customers. That gap is one they don't have any plans to fill as the available nodes will be Intel 12 in ~2027 (the UMC node) and then Intel 3. This is the gap that Intel's GPUs/tiles, SoC and IO tiles have lived in*. I imagine this won't change any time soon as Intel would need available EUV capacity and it's possible using TSMC for these is more cost effective.Reply

Intel also has chips being made at TSMC which were always made there from companies they've acquired. It never made sense in the past for them to port over to their own nodes so that also likely wouldn't change until Intel has EUV capacity. Of course the other problem with EUV capacity is that they've kicked the can down the road on their biggest EUV expansions. Servicing the highest profit margin parts is always going to come first in the fab game so while they may have plenty of capacity for internal and external customers it's believable they wouldn't for low margin parts.

*They did leverage Intel 7 for the GNR IO tiles, but I think that's more about keeping everything in house and the DUV fabs active than being the best move fiscally. -

TerryLaze Reply

It would be more worrying if intel would out of spite build FABs for old nodes just to not buy them from tsmc...maybe they could look into getting them from glofo.bit_user said:I didn't expect they'd quit sourcing from TSMC overnight, but this announcement is a worrying sign.

People aren't tsmc users out of fandom, they don't use them because they love them, so IFS just has to be as reliable, cheap, and yield-y , even just the ballpark and not even just as good.phead128 said:What's stopping potential customers from bypassing the middle-men to source from original TSMC to begin with. Intel has to be more reliable, cheaper, and better yields than TSMC to get customers to switch.

Throw in the tariffs and now many companies are restricted in how much product they can get out of tsmc, even more than before, and tsmc will have the US expenses that will increase their prices even more, again.

TSMC US is booked out into late 2027, what do you think will these companies do that can only get orders in for 2028 and later?!

They are going to wait three years for their products to become obsolete just because they don't want to use intel?! -

Gururu Reply

No they are not, I just wanted to jump in on the bashing.helper800 said:Are they actually bankrupt or are you using a turn of phrase? That would be news to me.