Researchers make breakthrough in cleaning up the 'forever chemicals' used in chip manufacturing

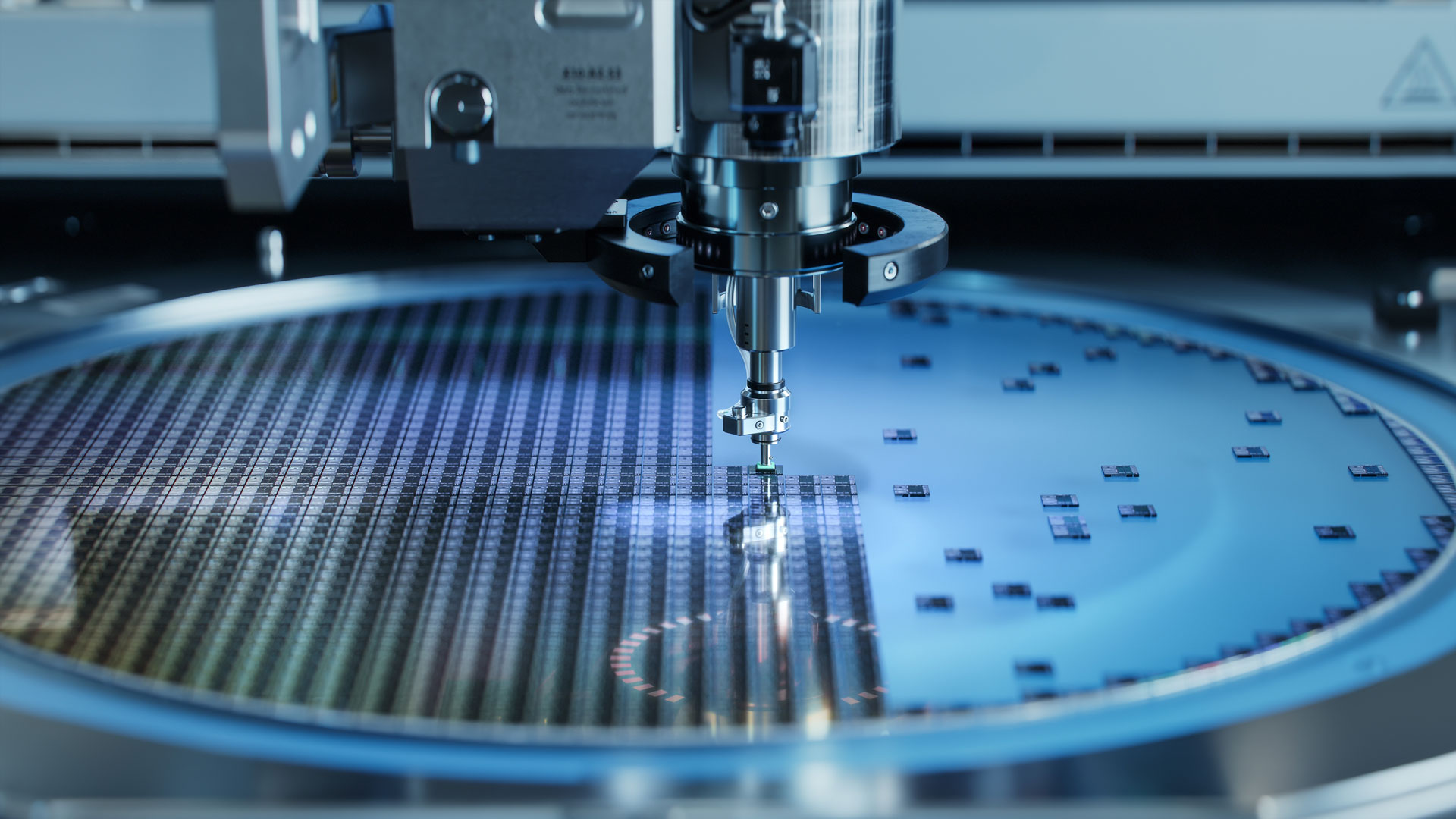

The semiconductor industry is among the worst offenders in PFAS use and pollution.

A team at Australia's Monash University has published its work on a new water filtration membrane that can successfully remove small PFAS molecules from water flow. PFAS, or polyfluoroalkyl substances, are a key piece in multiple facets of semiconductor manufacturing that have earned the name "forever chemicals" for their difficulty to clean up.

Monash's research team is ready to utilize some key partnerships to bring the filters to market at a high scale, keeping PFAS out of the groundwater at plants in all of the various industries that work with forever chemicals. The semiconductor industry, however, has long been opposed to legislation or other initiatives to restrict its use of PFAS in fabrication, forming lobbying groups and other coalitions to conserve the use of forever chemicals in chipmaking.

Monash University's Graphene Membrane

Monash University's team, led by Ph.D. candidate Eubert Mahofa, has designed a modified graphene membrane that selectively stops PFAS chains while allowing water to pass through freely. The membrane stops over 90% of PFAS that pass into it, a major improvement over traditional polyamide membranes, which can only remove around 35% of PFAS.

"PFAS are difficult to manage because they dissolve easily in water and can spread far from their original source, making contamination challenging to contain and remediate," shared Mahofa. "Our approach solves this by filtering out and concentrating these harmful chemicals while still allowing water to flow through efficiently, making it a strong candidate to supplement the technologies for PFAS destruction."

PFAS have been known as forever chemicals since their societal reckoning in the 1990's. Defined by carbon-fluorine bonds, which can have half-lives over eight years long, PFAS chains consistently leech into groundwater supplies, remaining there indefinitely. Certain PFAS are highly dangerous to humans if inhaled or ingested, and others will end up "stuck" in humans or animals after death.

The new filtration method utilizes specific chemical relationships to catch even the smallest PFAS bonds, which typically slip past traditional polyamide methods. The new barrier stops these bonds at varying temperatures while still maintaining efficient water flow, making the new tech nothing short of a breakthrough development.

"This breakthrough in PFAS filtration has the potential to revolutionize how PFAS contamination is managed globally, with applications ranging from landfill leachate treatment to industrial wastewater purification," says Professor Mainak Majumder of the Australian Research Council, which contributed to the research, in the press release.

Monash University and the Australian Research Council have close connections with NematiQ, a graphene-focused manufacturer that has pledged to help bring the new filter to market. Commercialization seems like a likely next step for the new technology, made easier by the study's focus on using highly scalable shear alignment printing to produce its filters.

What Makes PFAS Dangerous

PFAS have been used in industrial manufacturing since Teflon's invention in the 1930s. Today, countless industries, including semiconductors, use the chemicals in various facets of manufacturing. PFAS were originally thought to be chemically inert and harmless to humans, an assumption that held for decades. However, once PFAS was found swimming in the bloodstream and organs of longtime industrial workers, more research was done, and more risks were found.

PFAS chemicals are now linked to a variety of toxic effects by governments and health organizations, including developmental issues, infertility, and cancer. PFAS exposure comes from industrial chemicals that soil water tables and rainwater but also from clothes, cosmetic items, and consumption of animals with PFAS exposure. It is estimated that the majority of humans living today have some amount of PFAS already permanently in their bodies.

Certain PFAS, including PFOS and PFOA, have already been banned by the European Union and eventually worldwide as of 2009 for their egregious health risks. The EU is beginning to pursue legislation that would ban the entire PFAS group, but this legislation has been challenged by myriad lobbyist efforts, including serious resistance from the semiconductor industry.

PFAS and the Semiconductor Industry

The semiconductor industry uses PFAS up and down the microchip supply chain, and as such has launched multiple efforts to slow progress on PFAS restrictions. Semi, an industry association representing companies across the electronics supply chain, publishes an explainer guide on the semiconductor industry's use of PFAS in chip fabs. The guide includes all of the following uses for PFAS in chip fabs.

PFAS are present in chemicals necessarily used during chip fabrication, including photoresist liquids used during lithography and etch chamber gases used in wafer production. Chemical purifiers that produce hydrogen for use in EUV lithography also may contain PFAS, along with more tertiary parts of development like lithium batteries or plastic chip packaging. Semi's public page presents an overwhelming amount of possible places where PFAS may be used, tacitly stating that PFAS use is so widespread that to remove it entirely from chipmaking is too uphill a fight.

A collection of industry members also recently established the Semiconductor PFAS Consortium, a group more obviously dedicated to combating efforts to stop PFAS use in chipmaking. While the Consortium claims on its homepage that it is not focused on advocacy, this is not the case. The group's efforts in American politics were widely reported in August, when the Consortium spread its whitepapers against PFAS restrictions across Capitol Hill.

The PFAS Consortium's parent company successfully lobbied lawmakers for a bill removing chip fabrication plants from inclusion in certain environmental restrictions on manufacturing byproducts. The Consortium promised lawmakers that it would voluntarily self-regulate and eventually decrease its use of pollutants if legislation was not enacted forcing them to do so.

The semiconductor industry stands staunchly opposed to any further restrictions on PFAS use, with the PFAS Consortium's 2023 paper containing the quote, "it is going to be extremely difficult, if not impossible in some instances, to find viable alternatives [to PFASs] without stepping back decades in technological advancement."

This stance has been defended even in the face of breakthrough findings that disprove it. The Consortium recently argued against a widespread study proposing safer and effective alternatives to PFAS use in chipmaking. While the study identifies multiple surfactants that are both superior in quality and lower in toxicity than PFASs in etching wafers, surfactants which are now used instead of PFAS by some smaller fabs, the Consortium quickly published its own negative response to the study, only accessible by approved members of certain companies.

How the semiconductor industry responds to the recent breakthrough study on PFAS filtration remains to be seen. Data taken in 2022 from an unnamed chip fab found 78,000 parts per trillion of PFAS in the fab's wastewater, worlds higher than the EPA limit of 4 ppt, proving that Monash University's new water filtration would directly positively impact the local ecosystems around high-PFAS-use chip fabs. It is nice to hope that fabs across the industry will voluntarily use the new filters for the well-being of their communities, but the semiconductor industry's track record shows this will likely not be the case.

Sunny Grimm is a contributing writer for Tom's Hardware. He has been building and breaking computers since 2017, serving as the resident youngster at Tom's. From APUs to RGB, Sunny has a handle on all the latest tech news.

-

bit_user The article seems comprehensive and well-researched.Reply

: )

One small critique I'd make is that cancer isn't mentioned until the 10th paragraph. I'd probably work it into the first sentence, if not the headline. I'm sure nobody is pro-cancer.

As for regulation, I think taxing pollutants is a more productive approach than outright bans. It has the advantage of maintaining a financial incentive for the industry to support researching and eventually adopt mitigation technologies and alternatives, while not halting immediate progress.

Also, you have to consider that an outright ban is probably just going to result in the same chemicals being used elsewhere, meaning it only solves the "my backyard" aspect of the problem. However, as PFAS tend to leak into the food chain and as our food supply chains are now quite global, we have some direct incentives to care about what's happening on a much larger scale. -

Notton I was under the impression that there was a preexisting method/tech to remove PFAS.Reply

Like this is from 2022: https://www.sciencedirect.com/science/article/abs/pii/S1385894721055984It already achieves 90% removal using high pressure and membrane.

There are promising technologies in development to breakdown PFAS using high-pressure and high-temperature treatment.

https://www.thechemicalengineer.com/features/breaking-down-barriers-innovations-in-pfas-destruction/ -

bit_user Reply

That also mentions "challenges in high-recovery operation due to adsorption of PFAS and subsequent membrane fouling or scaling," and the conclusion mentions "there remains a challenge from generation of the membrane concentrate. Therefore, developing a high recovery membrane system is critical. In addition, continuous research efforts are needed not only to improve the selectivity for the vast number of PFAS molecules in various sizes, ..."Notton said:I was under the impression that there was a preexisting method/tech to remove PFAS.

Like this is from 2022: https://www.sciencedirect.com/science/article/abs/pii/S1385894721055984It already achieves 90% removal using high pressure and membrane.

Perhaps their graphene membrane avoids some of these issues.

This only deals with destruction? They need to be separated, first.Notton said:There are promising technologies in development to breakdown PFAS using high-pressure and high-temperature treatment.

https://www.thechemicalengineer.com/features/breaking-down-barriers-innovations-in-pfas-destruction/ -

Gururu I failed to see any applicability stated towards fab waste treatment (vs. waste water or landfill leachates) or volumes/quantities in the original paper. Newer, shorter chain, less toxic replacements and competing waste compounds seem to be the big reason to include something else in addition to activated carbon and ion exchange substrates. What are fabs even using if anything?Reply -

beyondlogic ReplyAdmin said:Monash University has developed a water filter to catch PFAS used in chip manufacturing and other industries. The chip industry has been lobbying for years against any progress on legislating PFAS-use.

Researchers make breakthrough in cleaning up the 'forever chemicals' used in chip manufacturing : Read more

how about we stop using forever chemicals in non stick food pans etc or better yet not use them at all lol.

while its a great step in right direction they have been used in everything. -

Gururu Reply

Because the chemicals are freaking magic. From refrigerants to the absolute best termiticides, they solve a lot of problems. Though they stay around and accumulate in the body, I don't know that we attribute a lot of identified cancers to PFAS at this time.beyondlogic said:how about we stop using forever chemicals in non stick food pans etc or better yet not use them at all lol.

while its a great step in right direction they have been used in everything. -

beyondlogic ReplyGururu said:Because the chemicals are freaking magic. From refrigerants to the absolute best termiticides, they solve a lot of problems. Though they stay around and accumulate in the body, I don't know that we attribute a lot of identified cancers to PFAS at this time.

they cause alot of issues in the body then just cancers there linked to alot of issues.

PFAS in general are monitored in uk drinking water since its everywhere. -

bit_user Reply

Well, we need to start co-developing chemicals with their disposal schemes. Like, perhaps you can integrate a molecular handle for use by an enzyme you co-design, so it can disassemble the thing. Then, the chemical companies can sell both the chemical and the enzymes.Gururu said:Because the chemicals are freaking magic. From refrigerants to the absolute best termiticides, they solve a lot of problems. Though they stay around and accumulate in the body, I don't know that we attribute a lot of identified cancers to PFAS at this time.

Or, another possibility is capture, purification, and reuse technologies.

No matter what, there needs to be more pressure on industry to reduce environmental leakage of these chemicals. That would provide the incentive for them to seek alternatives and for the chemical industry to develop these mitigations. As I said, I think taxes and financial penalties work better than outright bans, in this regard. -

Gururu Reply

I totally believe it but the evidence is not convincing enough yet from what I have seen. Don't get me wrong, I have a three filter setup on my kitchen sink for drinking and cooking that is supposed to help on PFAS. Been using it for years.beyondlogic said:they cause alot of issues in the body then just cancers there linked to alot of issues.

PFAS in general are monitored in uk drinking water since its everywhere.